Non solvents - Agence Nationale de la Recherche

advertisement

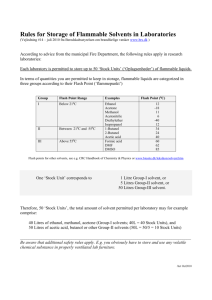

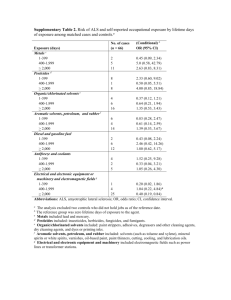

Colloque Chimie durable, ENS Lyon, 18-19 Septembre 2012 NESOREACH: New “eco-compatible” REACH compliant solvents Prof. Bruno ANDRIOLETTI bruno.andrioletti@univ-lyon1.fr Equipe de CAtalyse, SYnthèse, ENvironnement (CASYEN) UMR 5246 CNRS - Université Claude Bernard Lyon1 Domaine scientifique de la Doua - Bât. CPE (Curien 308) - 2ème étage - Aile C 43 boulevard du 11 novembre 1918 69622 Villeurbanne CEDEX 1 Institut de Chimie et de Biochimie Moléculaire et Supramoléculaires Catalyse, Synthèse et Environnement (CASYEN) – Prof. B. ANDRIOLETTI Catalyse Organométallique, Synthèse et Méthodologie de Synthèse (COSMO) – Prof. O. BAUDOIN Chimie Organique 2, Glycochimie (CO2GLYCO) – Prof. JP. PRALY Chimie Organique et Bioorganique (COB) – Dr. Y. QUENEAU Synthèse de Molécules d’Intérêt Thérapeutique (SMITH) – Prof. B. JOSEPH Membranes, Biocatalyse Synthèse, Utilisation, Réactivité des Composés Organiques et Organofluorés (SURCOOF) – Prof. O. PIVA Chimie Supramoléculaire Appliquée (CSAp) – Prof. H. PARROT Génie Enzymatique, Membrane Biomimétiques et Assemblages Supramoléculaires (GEMBAS) – Prof. L. BLUM Organisation et Dynamique des Membranes Biologiques (ODMB) – Prof. R. BUCHET Biomolécules: Synthèse, Propriétés et Assemblages Synthèse, Méthodologie et Catalyse ICBMS Director: Prof. L. BLUM Deputy Director: Dr. Y. QUENEAU 174 people including : • 84 staff 58 CNRS + Univ. Researchers 26 Technicians • 90 non permanent Researchers 63 PhD + post-docs 2 The Current Situation with Solvents Wordwide solvent market: 20 000 kT/year ROW 16% NA 26% • EU: 5000 kT/year • France: 600 kT/year) Current market in France: • Oil-based: 600 kT Asia/Pacific 31% EU 27% • Green solvents 15 kT Forecast for 2015: • Green solvents: 50 kT, • Oil-based: 500 kT 3 NESOREACH Project Develop a fast and reliable method for predicting the toxicological and ecotoxicological properties of the most commonly used solvents: • compile a database containing the main chemical, physical, toxicological and ecotoxicological properties of 250 solvents, • Select the most pertinent parameters for carrying out QSPR and QSAR analyses, • Validate the method on chosen cases. Study case: the substitution of cresol, phenol and NMP in the varnish business • Determine the mechanistic implication of the aforementioned solvents in the synthesis of PolyAmideImides (PAI) and PolyEsterImide (PEI): reactive or non-reactive solvents, • Propose and substitute the toxic solvents in the syntheses of the two thermoset polymers with REACH-compliant alternatives, Le vernis est émaillé dans un four d émaillage qui peut être horizontal ou vertical selon le • Applicative tests, Varnish Control diamètre du fil. Polymerisation oven Wire stretching Application • Up-scaling. winding ANR CPDD “Nesoreach” 2009-2013 Cooling zone (8-20 passes) Oven temp (400-750°C) 4 Study Case NMP (2400 T/year@ IVA-Lyon) : toxic because of the deleterious effects on the development of fetus (Reprotoxic, category 2). Cresol (2600 T/year@ IVA-Lyon) : toxic by skin contact and ingestion (possible irreversible effects) (Mutagenic category 3). Phenol (1100 T/year@ IVA-Lyon) : toxic by inhalation, by skin contact and ingestion (possible irreversible effects) (Mutagenic category). Mechanistic role Resin solubilisation Biosourced or Heat capacity Toxicity Non-toxic petroleum based solvent Cost constraints Boiling point 5 NESOREACH Project: Consortium C. CREN SCA-USR59 Solaize Prof. LANTERI LSA-UMR 5180 Université Lyon 1 ANR CPDD “Nesoreach” 2009-2013 Prof. ANDRIOLETTI ICBMS-UMR 5246 Université Lyon 1 V. MERCIER Essex IVA Meyzieu 6 Developing a Database: Scientific Approach Solvent database Physico-chemical descriptors Theoretical descriptors Eco-toxicological descriptors Toxicological descriptors Data analyses Data analyses Description : • PCA • Classification methods Modelling • QSAR QSPR relationships Description : • PCA • Classification methods Substitution of solvents within the frame of REACH A. Levet, SCA/LSA 7 Compiling the Solvent Database (1) • 295 solvents grouped ranked in 17 chemical families (IUPAC) • Physico-chemical descriptors • • • • Molecular weight, Boiling and melting point, Hansen solubility parameters, Octanol/water partition coefficient (LogP) (Some values confirmed by counter-current chromatography (CCC)) … • Theoretical quantum descriptors • HOMO and LUMO energy, • Dipole moment, • Electrostatic potential … Calculation hardness (LUMO-HOMO) and reactivity((LUMO+HOMO)/2) A. Levet, SCA/LSA 8 Compiling the Solvent Database (2) • Geometric or topological descriptors calculated by two programs: – Prochemist • Topological indices : Wiener, Kier, Balaban, Randic… – Sybyl • Molecular volume and surface area, • Atom and binding numbers… A. Levet, SCA/LSA 9 Compiling the Solvent Database (3) • Ecotoxicological descriptors (Records in dedicated databases and validated by INERIS) • EC50 Fish • EC50 Invertebrate • EC50 Algaes Fish 161 151 Invertebrate 157 120 122 121 Algae 124 • Using of the database : (in progress) • Development of QSAR models to predict solvent EC50 • Establishment of a solvents classification A. Levet, SCA/LSA 10 Preliminary Results: Predicting an Eco-toxicological Class • Discriminating Factorial Analysis (AFD) % Correct EC50 Fish 78,1 % EC50 Invertebrates 75,8 % EC50 Algaes 72,0 % Observations (F1 and F2 axes: 91%) Less toxic More toxic 4 2 F2 (14%) Most important descriptors : • Water solubility • Log P • δh Hansen parameters 6 1 0 2 3 -2 Limitations : non homogeneous classes 4 -4 -6 -8 A. Levet, SCA/LSA -6 -4 Example : EC50 Fish -2 0 F1 (76%) 2 4 6 8 11 Solubility Tests • Purpose : • Experimental determination of Hansen solubility parameters (δd, δp, δh) of polymers • Determination of solvents for polymers solubilization Soluble Solute Partially soluble Nonsoluble Solvent Non solvent • Process Solubility tests in 52 solvents (visual observation) A. Levet, SCA/LSA 12 Solubility tests • PEI Solvents 12 Partial solvents 15 Non solvents 25 PEI Data use: List of potential solvents with suitable eco-toxicological parameters, solubility tests Identification of the suitable substitution solvent A. Levet, SCA/LSA 13 Solubility tests • PAI Solvents 3 Partial solvents 5 Non solvents 44 PAI Data exploitation : No substitution solvent identified Test of solvent mixtures (In progress) A. Levet, SCA/LSA 14 Polymer Analysis: ATG Purpose : • Quantifying the amount of polymer dissolved in solution evaluation of solvent mixture Polymer analysis by ATG, ATG-TD-GC-MS, IR Temperature ramp 10°C/min 25°C to 1000°C PAI and PEI seem to degrade before the temperature evaporation of the solvents : No quantification possible by ATG A. Levet, SCA/LSA 15 Polymer Analysis: Quantitative MALDI-TOF • Polymer analysis by measuring nitrogen (In progress) Encouraging preliminary tests for the quantification of PEI • Polymer analysis by MALDI-TOF (In progress) 0,01 x10 5 2.5 I Polymer / I Internal standard Intens. [a.u.] Development and validation of the method on a test polymer Use of an internal standard Internal standard 2.0 1.5 Test polymer 1.0 y = 0,0523x - 0,0002 R² = 0,9837 0,009 0,008 0,007 0,006 0,005 0,004 0,003 0,002 0,001 0 0 0,05 0,1 0,15 0,2 Polymer conc (mg/mL) 0.5 0.0 1000 2000 3000 4000 5000 m/z A. Levet, SCA/LSA Problem of reproducibility 16 Solvent Substitution and Mechanistic Investigations HN O O N OCN N O O O OH NH O O N O O O Typical structure of a PAI Mechanistic studies with in situ IR Raw materials (oligomers) 15-40% Additives f ew % - catalysts, - adhesion promoters, - accelerators, - surf actants, - wetting agents. - ... Solvents 60-85% mi x t ure of sol vent s - naphta solvents, - xylene, - NMP, - DMAc, - Cresol C40, - Xylenol, - Phenol - ... Raw materials (oligomers) 15-40% Additives f ew % NON-toxic solvents 60-85% Our goal New "green" class of enamels 17 Our Strategy In situ and ex situ IR analyses • IR spectra of the building-blocks • IR « fingerprint » of a PAI in NMP/PEI in cresol and identification of the characteristic bands = IR reference • IR of PAI/PEI synthesized using the new solvents and comparison with the reference IR. Determine the mechanism of the polymerization • Use phenylisocyanate as model • Determine the need for (non)-reactive solvents 18 The Building Blocks HN O O N OCN N O O O O O H N N O O O NH2 Cl O Et3N + EtOAc 0°C->25°C Benzanilide, N H 91% O O NH2 Benzylphtalimide air, 160°C + OH NH N O 1 hour O O O NH2 + O N O 1) AcOH Et3N, PhNH2 N COOH 2) SOCl2 O O 100% COCl O 93% L. Sandjong Kuigwa, F. Szydlo, ICBMS EtOAc 0°C->25°C O HN O 1,3-dioxo-N,2-diphenyl isoindoline-5-carboxamide 64% 19 IR Signature of the Building Blocks Substrate IR vibration Wavelength (cm-1) Solution ATR 1780 1628 1231 884-921 721 1774 TMA C=O stretch anhydride C=O stretch acide C-O-C stretch C-O et C-C stretch C-H ar def. MDI NCO stretch 2266 2260 Benzanilide C=O stretch 1655 1653 Benzylphtalimide C=O stretch C-N stretch 1716-1735 1377 1703-1734 1382 C=O phtalimide C=O anilide C-N stretch L. Sandjong Kuigwa, F. Szydlo, ICBMS 1226 1724 1654 1376 20 Bruker, MATRIX-MF FT-IR Identification of the Characteristic IR Bands of a PAI C=O amide PAI C=O imide PAI C-N PAI C=O anhydride of TMA C=O carboxylic acid of TMA NCO C-O acid of TMA Conditions: Air, NMP not distilled IR reference t=0min after addition of the starting materials L. Sandjong Kuigwa, F. Szydlo, ICBMS 21 Understanding the Role of the Solvent at 80°C NCO + O 80°C ?? N NCO + O 80°C ?? N CH3 NMP PhNCO aromatic protons 3x(CH2) NMP Conclusion: At 80°C, no interaction between PhNCO and NMP is evidenced L. Sandjong Kuigwa, F. Szydlo, ICBMS 22 Understanding the Role of the Solvent at 150°C NCO + CH3 NMP Complex aromatic region O 140°C ?? N T0 Disappearance of the NCO stretching band 3x(CH2) NMP T200min Conclusion: At 150°C, many new signals appear (and/or disappear in NMR or IR) ⇒ clear reaction between NMP and PhNCO In the industrial conditions, NMP plays a role of non-reactive solvent. L. Sandjong Kuigwa, F. Szydlo, ICBMS 23 Towards the Synthesis of Non-Toxic PAI • Two main solvent suppliers provided new developed solvents under secrecy agreement with IVA and CASYEN: • Three solvents were identified as technically suitable to substitute NMP • Syntheses of PAI: OK (CASYEN) • Enamelling and magnet wires properties: OK (IVA) • Issue 1 = results of toxic evaluation (May 2012): Among the 3 most promising solvents, 2 were shown non toxic (Partial results-90% ) • Issue 2 = accessibility 1 solvent of these 2 solvents is under industrial development (Pilot Scale) New "green" class PAI 24 Towards the Synthesis of Non-Toxic PEI O HO N O O N N O O N O O O O O Ester Imide N O O O O O O O O N O OH O O OH N O n Polyesterimide (PEI) 25 Cresol: A Reactive Solvent NCO OH H N O O 1 eq 1 eq NCO signal Urethane C=O band Urethane C-N-H Band T= 30 min Cresol reacts with phenylisocyanate affording the corresponding urethane. L. Sandjong Kuigwa, ICBMS 26 Is a Reactive Solvent Required? O O O O NCO OCN catalyst/solvent O OH 1 eq O HO 2eq O N N O O O OH Diacid-Diamide See also Patent, Bayer 659018 07/29/1965 imide C=O band o The synthesis of the key intermediate can be controlled in the absence of cresol L. Sandjong Kuigwa, ICBMS A reactive solvent is not absolutely required 27 Synthesis of a PEI in a non-Toxic Solvent C=O imide band C=O Glycol-ester and imide band C=O Ester THEIC band The synthesis of the PEI in a non-toxic solvent is possible L. Sandjong Kuigwa, ICBMS 28 Applicative Properties • One non-toxic commercial solvent was idenfied very promising 19960 MC40 OFA627 Reference in Cresol & phenol In solvent D Bare wire diameter (mm) 0,501 0,501 Insulation increase (mm) 0,044 0,043 Speed (m/mm) (machine = HRE) 130 130 Flexibility (%) (1D) 20% 20% Cut-through (°C) (IEC 100x100) 340 350 Tangent Delta (°C) 197°C 200°C • This solvent is commercial and at a price acceptable for the enamel market. 29 Main Results 5.0 4 4.5 4.0 Solvant partiel 3.5 Non solvant 3.0 PEI Experimental data Solvant 4 4 2.5 2.0 1.5 3 1.0 2 0.0 22 2 2 2 222 2 22 2 2 22 1 1 44 4 4 2 0.5 4 44 4 4 4 4 4 4 4 4 4 44444 4 44 4 4 4 44 4 4 44 44 4 4 44 4 4 4 4 44 4 44 44 44 4 44 4 44 4 4 33 43 33 3 3 333 33 3 3 3 33 3 3333 3 3 3 3 3 3 3 33 3 3 3 3 33 3 33 3 333 3 3 3 3 3 3 3 3 3 33 3 3 3 33 33 22 2 2 2 2 2 2 4 4 4 4 4 2 2 2 2 22 2 1 1 1 1 11 -0.5 2 2 2 2 2 1 1 1 1 -1.0 -1.5 1 1 -2.0 -2.0 -1.5 -1.0 -0.5 0.0 1) Mechanistic investigations on the synthesis of the PAI and the PEI (Spectroscopic) identification of the key intermediates: done Determination of the mechanisms of formation of PAI and PEI: done 0.5 1.0 1.5 2.0 Predicted values 2.5 3.0 3.5 4.0 2) Syntheses of PAI and PEI in new non-toxic solvents PAI: Industrial development of new, suitable solvents compatible with lab-scale syntheses of PAI PEI: A suitable, existing non-toxic solvent has been identified: next step: 100 kg lab scale experiment planned fall 2012. Synthesis of partly bio-sourced solvents (patent in preparation) 3) Solvent prediction A database gathering 17 main physico-chemical and (eco)-toxicological properties of 295 solvents has been compiled; A predictive method displaying promising preliminary results is implemented; Solubility tests using Hansen’s parameters have been carried out 30 4.5 5.0 ACKNOWLEDEMENTS E. Framery, F. Szydlo, L. Sandjong-Kuigwa Equipe de Catalyse, Synthèse et Environnement, CASYEN-ICBMS, Université Lyon 1 P. Lantéri, A. Levet, C. Bordes, A. Berthod, H. Chermette, J.-Y. Gauvrit, P. Mignon Laboratoire des Sciences Analytiques, Université Lyon 1 C. Cren-Olivé Service Central d’Analyse, CNRS Solaize F. Andrioletti, V. Mercier (Essex-IVA) L. Chancerelle, L. Geoffroy INERIS, Verneuil-en-Halatte 31