a1. electrical equipment

advertisement

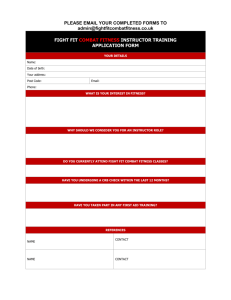

VALERO – KROTZ SPRINGS S.H.G # 55 Page 1 of 27 Issued 09/15/03 POST-FIRE PLANT AND EQUIPMENT CHECKOUT GUIDELINES 1.0 PURPOSE To communicate recommended procedures for checking out equipment and facilities affected by a fire prior to returning the facilities to operation. The guideline provides a checklist to ensure that many potential problem areas that otherwise might not be addressed are adequately considered. 2.0 SCOPE The provisions of this guideline will be applied to equipment and facilities affected by a substantial fire, after the fire has been extinguished, the area appropriately decontaminated, and any required incident investigation inspections have been completed. API RP-579, Fitness-for-Service (especially Section 11, Assessment of Fire Damage), will be utilized in conjunction with the provisions of this guidelines to ensure that equipment and facilities are adequate for their intended and required services before being returned to operation or use after a major fire. 3.0 DEFINITIONS Fitness Team Director: Person designated by management to manage and direct the post-fire fitness-for-service investigation project. Fitness Team I&E Manager: The person designated by management to oversee the instrumentation and electrical system portions of the post-fire fitness-for-service investigation project, reporting to the Fitness Director. Fitness Team Safety Manager: The person designated by management to oversee the fire and safety equipment portions of the post-fire fitness-for-service investigation project, reporting to the Fitness Director. Fitness Team Piping Manager: The person designated by management to oversee the piping, valves, and fittings portion of the post-fire fitness-for-service investigation project, reporting to the Fitness Director. Fitness Team Rotating Equipment Manager: The person designated by management to oversee the pumps, motors, mixers, compressors, and turbines portions of the post-fire fitness-for-service investigation project, reporting to the Fitness Director. Fitness Team Vessel Manager: The person designated by management to oversee the pressure vessel, exchangers, boilers, heaters, incinerators, and tanks portions of the postfire fitness-for-service investigation project, reporting to the Fitness Director. Fitness Team Civil Manager: The person designated by management to oversee the buildings, foundations, structures and stacks, portion of the post-fire fitness-for-service investigation project, reporting to the Fitness Director. VALERO – KROTZ SPRINGS 4.0 S.H.G # 55 Page 2 of 27 Issued 09/15/03 Fitness Team Environmental Manager: The person designated by management to oversee the environmental aspects of the post-fire fitness-for-service investigation project, reporting to the Fitness Director. RESPONSIBILITIES Individual/Group Refinery Manager and Direct Reports Fitness Team Director Assigned Responsibilities Review the description of positions included in this guideline and develop a Fitness Team organization (Director and Managers) similar to that described in the Definitions section. The definitions should serve as rough guidelines: management will combine or subdivide the positions proposed in Definitions, in consideration of the apparent extend and nature of the damage. Continually emphasize Safe Production as the primary goal of the Fitness Team. Staff the Fitness Team organization by appointing a Director and Managers. The Fitness Team Director and Managers need not be Directors or Managers in their normal jobs. Work with the Fitness Director and Managers to determine additional team members required below the Fitness Manager level. Provide resources required (material and personnel, internal and external) to staff and support the Fitness Team’s mission. Develop and maintain a work plan and schedule for the investigations. Work with Fitness Managers to define the resources required for the investigations, and work with management to provide the required resources. Be accountable for the completeness and accuracy of the investigations, ensuring utilization of the checklists (Attachments) and adherence with all applicable codes and standards, including API RP-579 (Fitness-forService, especially Section 11, Assessment of Fire Damage). Continually emphasize Safe Production as the primary goal of the Fitness Team. Accountable for preparation of a final report detailing the findings of the investigations. VALERO – KROTZ SPRINGS S.H.G # 55 Page 3 of 27 Issued 09/15/03 Individual/Group Fitness Team Managers Fitness Team Investigators Health, Safety and Environmental Department Personnel All Departments All Employees and Contractors Assigned Responsibilities Oversee investigations into adequacy of equipment and facilities within their scope of responsibility for intended service, considering all applicable standards and codes, as well as API RP-579, Fitness-for-Service Utilize and document use of and results of appropriate checklists (see Attachments A-F). Provide input to Fitness Team Director on resources required (personnel and material) Provide regular status reports to Fitness Team Director. Continually emphasize Safe Production as the primary goal of the Fitness Team. Ensure that investigations are thorough by using the Checklist provided. Assist in preparation of interim status reports and Final Report as requested by Fitness Team Director. Perform fitness-for-service investigations as directed by Fitness Team Managers and Directors. Provide input to Fitness Team Manager(s) on resources required to complete the investigations. Maintain Safe Production as the primary goal of the Fitness Team investigations. Ensure that all work is performed safely. Participate in JSA's on new jobs. Assist in preparation of interim status reports and Final Report as requested by Fitness Team Director and Managers. Provide environmental and safety technical input to the Fitness Team members. Provide personnel and/or materials to the Fitness Team as required. Advise a Fitness Team member of any observed damage or fire effects. VALERO – KROTZ SPRINGS 5.0 S.H.G # 55 Page 4 of 27 Issued 09/15/03 GUIDELINES Provisions of all other SHG’s shall be observed while performing post fire investigations. The proposed organization noted above should be considered as a starting point. The actual Fitness Team Organization should be determined in consideration of the extent and nature of the fire and the skills and experience of the people available to staff the team, keeping the goal of achieving a thorough investigation in mind. Some of the positions recommended may be combined, or further subdivided. Areas of responsibility should be clearly determined and communicated. It should be clear whether the Fitness team is expected to investigate only, or whether they will be responsible for repairs as well. The checklists provided may be modified to correspond to the organization, but care must be taken not to compromise the thoroughness of the investigation. In any case, the checklists should be carefully reviewed before commencing the fitness evaluation to ensure that roles and responsibilities are understood and that the safety of the evaluators and other personnel in the areas is protected during the evaluation. 5.1 Inspection And Testing 5.2 Sewers and Drains 5.3 Secure the scene and protect evidence and equipment for investigation. Remove from the fire area, in a timely manner, any special samples needed for the postfire evaluation before the area is cleaned up for repair. The sudden release of propane or butane from a line that has failed in a fire may cause auto refrigeration of such liquid away from the fire area. Embrittlement or cracking of certain metals in this area may result from severe cooling or from water freezing. Check the sewer system for hazardous materials from the fire. (Asbestos, caustic, acid, hydrocarbons, explosive mixtures, etc.) Are sewers in the fire area open? Should they be rerouted? Are there trenches involved? Opening Equipment Make sure all liquids are drained from knockout drums and lines. After a fire, liquids may be found where they don’t normally exist. Be cautious in opening equipment due to hazards from chemicals, chemical residues or ash that can run out or be present. Be alert to the possibility of toxic or other reactive gas release when certain materials or chemical storage equipment have been exposed to or consumed in a fire. For example, certain plastics or similar materials have been known to release hydrogen chloride, phosgene, etc., as a product of combustion or reaction when burned. VALERO – KROTZ SPRINGS S.H.G # 55 Page 5 of 27 Issued 09/15/03 Alert for potential trapped hydrocarbons and/or toxics when cutting piping and/or opening vessels for removal or repairs. Such equipment may be plugged, still pressurized and quite hot. For example, the reactors of a Reformer may be insulated internally and don’t dissipate heat to the outside wall, thus the outside surface may feel quite cool while contents of the vessel may still be extremely warm. Check that all equipment is open and clear of gases, liquids and solids at intermediate upstream and downstream points. VALERO – KROTZ SPRINGS S.H.G # 55 Page 6 of 27 Issued 09/15/03 ATTACHMENT A POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Instrumentation and Electrical A1. ELECTRICAL EQUIPMENT A1.1 Firewater-Related Damage A1.1.1 Check cable trays for water damage to wire/cable insulation. A1.1.2 Check cable trays for hydrocarbon damage to wire/cable insulation. A1.1.3 Check for water damage to motors in the fire and nearby. A1.1.4 Identify and isolate electrical equipment that was sprayed with water during the fire. A1.1.5 Check explosion-proof equipment enclosures for dryness. A1.1.6 Check the electrical conduit and junction box systems for firewater that may have been transmitted to remote areas. Electrical equipment that is moist needs to be dried out. Equipment may not show material damage but can be a future hazard. A1.1.7 In the winter, check for freezing water in conduits near the fire area. A1.2 Heat-Related Damage A1.2.1 Inspect for melted conduit. A1.2.2 Spot check poured electrical seals around the fire area. Such seals may melt well before damage to wire or other insulation becomes apparent. A1.2.3 Spot check wiring outside the intense fire area to see if insulating characteristics have been affected by radiation or conduction. “High pot” “Meggar” any suspect electrical wiring or insulators. A1.2.4 Check for damage to insulating sleeves (made of low melting point material) which isolate bolts from flanges. Such damage can occur at temperatures as low as 180 F and can result in loss of cathodic protection for underground equipment. A1.2.5 Check for damage to insulating flange components made of low melting point material. This damage can occur at low heat levels and not be obvious. Loss of protection from static electricity can result. A1.3 Electrical Motors A1.3.1 Check the following, where appropriate, when exposed to a fire: A1.3.2 Transformers A1.3.3 Switchgear A1.3.4 Breakers and relays A1.3.5 Power supplies at motor A1.3.6 Space heaters A1.3.7 Temperature detectors A1.3.8 Auto shutdown control systems A1.3.9 Variable speed drive control systems A1.3.10 Megger motor for resistance to ground A1.3.11 Bump motors after megging A1.3.12 Tightness of bolts and screws on motor housing and bearing brackets. VALERO – KROTZ SPRINGS S.H.G # 55 Page 7 of 27 Issued 09/15/03 ATTACHMENT A POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Instrumentation and Electrical A1.4 Other items requiring checking when exposed to a fire: A1.4.1 Test back-up power supplies (UPS systems) to confirm proper operation. A1.4.2 Inspect local electrical ground connections for damage. A1.4.3 De-energize battery-supplied power for switchgear control if pressurization of switchgear house is lost during the fire. A1.4.4 Consider replacing coaxial cable or unit cable in a fire area that served sensitive equipment such as vibration monitors, analyzers, etc. A1.4.5 Spot check electrical equipment connected to fire-damaged cables. Some equipment might be damaged because of power supply surges during failure of other equipment. A1.4.6 Refer also to the section on “Turbines and Other Drivers”. A2. INSTRUMENTS A2.1 Equipment with Radioactive Sources A2.1.1 Check the integrity of all radioactive sources, equipment supports, and any attached wiring or instrumentation. A2.2 Instrument Integrity A2.2.1 Prior to startup check that all process controls, instruments, alarms and shutdowns functioned correctly during the fire. A2.2.2 Review requirements for additional instrumentation based on review of the fire. A2.2.3 Check integrity of safety interlock systems to insure correct operation. A2.2.4 Check alarm systems control wiring for a zero-point offset. A2.2.5 Check that conditions on equipment (i.e., pressure, temperature, levels, etc.) are correct as shown on instruments in the control room. Fire damaged instruments circuits will sometimes fail “as is”. Loop check all instruments in the fire area per Valero specifications. A2.2.6 Check and perform dry runs to instrument PLCs (Programmable Logic Controllers) to be sure that such equipment has not been damaged by shorts or power surges. A2.3 Plugging/Fouling A2.3.1 Check orifice taps and fittings for leaks or plugging. A2.3.2 Check electronic equipment to see if performance has been altered by unusually high levels of soot, dust or moist air being drawn into HVAC (heating, ventilating, and air conditioning) systems from the fire area. A2.4 Other A2.4.1 Pneumatic lines A2.4.2 Check aluminum supports for distortion or melting A2.4.3 Check Swagelock tubing fittings for leaks A2.4.4 Pressure test pneumatic tubing per Valero specifications A2.4.5 Look for broken pressure and level gauges in the fire area. A2.4.6 Check valve actuator diaphragms and packing for fire damage due to heat. A3. Insulation & Fireproofing A3.1 Inspect the fireproofing on cable trays above the fire area. VALERO – KROTZ SPRINGS S.H.G # 55 Page 8 of 27 Issued 09/15/03 ATTACHMENT B POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Safety B1. FIRE AND SAFETY EQUIPMENT B1.1 B1.2 B1.3 B1.4 B1.5 B1.6 B1.7 B1.8 B1.9 B2. Check any deluge system over the fire for cracked or plugged nozzles. Operate deluge systems after the fire to insure its proper operation. Check safety showers, eye washes, fresh air equipment, and all fire systems and alarms prior to startup. Check all fire equipment that may need recharging prior to startup. Survey to determine if the fire equipment (e.g., deluge systems, fire monitors, etc.) was in the right place? Did they work properly? Is additional protection needed before startup? After startup? Promptly replace identification labels, tags or signs for lighting or electrical switches, radioactive sources, hazardous chemicals, etc. that have been burned or damaged and not legible. Ensure that adequate supplies of breathing air and respiratory equipment are in the appropriate areas. Ensure gas and/or H2S monitors are reset and working properly. Record any personal monitor readings within 24 hours of exposure. AREA SAFETY B2.1 On units that handle acids, check any standing water for low pH. VALERO – KROTZ SPRINGS S.H.G # 55 Page 9 of 27 Issued 09/15/03 ATTACHMENT C POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Piping C1. CORROSION C1.1 Creep - Check material exposed to temperatures above those listed for sagging or dimension changes—replace if dimension change is greater than about 3%. Temp (oF) 300 500 540 900 1,000 C1.2 Material Lead Aluminum alloys Copper/copper alloys Glass Steels, stainless steels Hardness - Materials exposed to temperatures higher than those listed below should be checked for hardness. Hardness should meet original materials specification. Temp (oF) 400 540 900 1,150 Material Aluminum alloys Copper/copper alloys Low and high alloy steels Precipitation hardened stainless steels C1.3 Stainless Steel C1.3.1 Check equipment normally requiring downtime protection for evidence of polythionic stress corrosion cracking. C1.3.2 Check for sensitization on equipment exposed to temperatures above 800 F. Sensitization may affect corrosion resistance and downtime protection needs. C1.3.3 Check for chloride cracking of equipment exposed to temperatures above 125oF and firewater. C1.3.4 Replace stainless steel castings that in-situ metallography determines have Sigma phase embrittlement. C1.4 Wet Insulation C1.4.1 Consider removing wet insulation to prevent corrosion under weatherproofing on steel equipment and chloride cracking of stainless steel equipment. C1.4.2 Check for chloride cracking under wet insulation covering stainless steel that was operating or exposed to temperatures above 125oF. C1.4.3 Liquid Metal Embrittlement C1.4.4 Check for liquid metal embrittlement of equipment near or below melted aluminum or zinc components or galvanizing. Replace any equipment, which has experienced liquid metal embrittlement. C1.5 Acids C1.5.1 On units that handle acids, check any standing water for low pH. C1.5.2 On alkylation units, replace bolting exposed to the acids because of leaks or spills. VALERO – KROTZ SPRINGS S.H.G # 55 Page 10 of 27 Issued 09/15/03 ATTACHMENT C POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Piping C1.5.3 Inspect any part of a system that might have seen acid carry-over during the fire for corrosion damage. C1.5.4 Caustic/Alkaline C1.5.5 Check carbon steel equipment in caustic service that saw temperatures greater than 120 F during the fire for caustic cracking. C1.6 C2. Miscellaneous C1.6.1 Check for thermal shock cracking of heavy castings, e.g., furnace headers that may been hit (quenched) with a firewater stream. C1.6.2 If ultrasonic inspection reveals pipe or furnace tube walls are significantly different than original, look for internal melting or external oxidation. C1.6.3 Check acid lines subjected to high temperatures for increased corrosion and/or plugging. C1.6.4 Check other chemical lines (ex., caustic and amines) for concentration effects such as precipitation, plugging or residues. C1.6.5 Determine if other additives such as inhibitors, antifoulants, demulsifiers, etc., may become inactive or not perform as effectively if overheated. INSULATION/ FIREPROOFING C2.1 Oil-Soaked Insulation C2.1.1 Replace insulation that has been soaked with oil. C2.1.2 Check for hydrocarbon pick-up in fibrous insulation. Replace, otherwise spontaneous combustion is possible on start-up. C2.2 Wet Insulation C2.2.1 Replace wet insulation on stainless steel equipment to prevent chloride stress corrosion cracking and from steel equipment to prevent corrosion. C2.2.2 Check for water damage to insulation outside the immediate fire area. C2.3 Fireproofing C2.3.1 Test concrete (structural and fireproofing) for mechanical soundness by: C2.3.1.1 Coring and testing C2.3.1.2 Schmidt hammer C2.3.1.3 Velocity meter testing C2.3.2 Replace as required. C2.3.3 Wet Refractory C2.3.3.1 Look for water and/or freezing damage under refractory linings. C2.3.3.2 Modify the unit startup procedures to account for wet refractory. C2.4 Asbestos C2.4.1 Identify areas where materials are made of asbestos. Follow company guidelines for handling, encapsulation, and/or removal as appropriate. VALERO – KROTZ SPRINGS S.H.G # 55 Page 11 of 27 Issued 09/15/03 ATTACHMENT C POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Piping C2.5 C3. MATERIAL FORMING AND FABRICATION C3.1 C3.2 C4. Check for material weldability - hardness, copper, slag, weld area cleanliness, etc., before welding. Document all substitute materials and temporary facilities installed with a timetable and method for replacement. GENERAL C4.1 C4.2 C4.3 C5. Other C2.5.1 Check effect of fire on insulation under stainless steel jackets. Mineral wool, foam glass, and glass fiber type-materials could be partially melted. C2.5.2 Check for correct insulation thickness when re-insulating Reformer reactors to prevent reactor shell overheating. Check cast iron equipment for cracking. Are grounding straps/lightning arrestors still intact and functional? Verify that curbing/diking needed to contain spills or leaks is functional, e.g., curbing on alkylation units. PIPING/VALVES C5.1 C5.2 Are up-to-date drawings used to reconstruct the unit? Are they the latest version? Spot check piping, welds (especially chrome welds), valves, bolts and flanges in fringe areas adjacent to the major fire area for hardness, softness, or warpage. C5.3 Check for high stress areas caused by thermal expansion or contraction, especially elbows. C5.4 Check spring hangers involved in the fire for relaxation, cold set, hot set, and galvanized corrosion protection. C5.5 Inspect piping supports to be sure that they are still carrying the load. C5.6 Check for piping strain and misalignment on rotating equipment and at expansion joints. C5.7 Check the operation of valve wheels and chains. Repack affected valves and change gaskets on bonnets and flanges where needed. Replace internal parts made of low melting-point materials. C5.8 Carbon steel gasketing in 5-7 percent chrome valves can be a cause of post-fire failures. Be sure all replacement valves have internal gasketing that meets Valero’s specifications. C5.9 Check that seals or rupture disks, which are often Teflon coated, have not been destroyed from even short exposure to a fire area. C5.10 Shop-test relief valves, replace rupture discs, and inspect the piping going to and from the relief valve for pluggage. C5.11 Check instrument air lines to control valves for leakage. Check orifice taps and fittings for leaks or plugging. C5.12 Check for heat damage to packing or 0-rings made of Teflon or other materials that are not as heat resistant as the equipment in which they are located. VALERO – KROTZ SPRINGS S.H.G # 55 Page 12 of 27 Issued 09/15/03 ATTACHMENT C POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Piping C5.13 In freezing conditions, check steam tracing for proper operation. Check dormant water lines, steam traps, etc. for freeze damage. C5.14 Be alert for plugged valves and piping, upset reactor beds, loose coke and scale, unexpected pockets of hydrocarbons, and catalyst carryover. C5.15 Spot check piping in fringe fire areas for coking or cracking via radiographs, dye tests, or other non-destructive techniques. C5.16 Check bolts in flanges, valve bonnets, etc. for stress relaxation and replace with bolts of the proper material, if needed. Check associated flanges for warpage. C6. PROTECTIVE COATINGS C6.1 C6.2 Nonmetallic C6.1.1 Check to insure integrity of acid resistant coating/mastics on duct work, furnace shells and/or stacks for melting. C6.1.2 Inspect exterior coatings for signs of thermal degradation. C6.1.3 Inspect vessel/pipe internal protective coatings (epoxy, mastic, plastic, etc.) for melting. C6.1.4 Test Teflon coated sleeve plug and gate valves for shut-off capability. C6.1.5 Check the lining and flange surfaces of coated pipe used in acid service for damage (melting, extrusion, etc.). Lead Linings C6.2.1 Inspect lead linings for sagging or melting. VALERO – KROTZ SPRINGS S.H.G # 55 Page 13 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D1. CORROSION D1.1 Creep - Check material exposed to temperatures above those listed for sagging or dimension changes—replace if dimension change is greater than about 3%. Temp (oF) 300 600 540 950 1,000 D1.2 Material Lead Aluminum alloys Copper/copper alloys Glass Steels, stainless steels Hardness - Materials exposed to temperatures higher than those listed below should be checked for hardness. Hardness should meet original materials specification. Temp (oF) 400 540 900 1,150 Material Aluminum alloys Copper/copper alloys Low and high alloy steels Precipitation hardened stainless steels D1.2.1 Pedestal hardness checks and magnetic particle inspection D1.3 Electrical Motors D1.3.1 Bearings and seals D1.3.2 Oil supply systems (or grease) D1.3.3 Coupling and shaft alignment D1.4 Stainless Steel D1.4.1 Check equipment normally requiring downtime protection for evidence of polythionic stress corrosion cracking. D1.4.2 Check for sensitization on equipment exposed to temperatures above 800 F. Sensitization may affect corrosion resistance and downtime protection needs. D1.4.3 Check for chloride cracking of equipment exposed to temperatures above 125 oF and firewater. D1.4.4 Replace stainless steel castings that insitu metallography determines have Sigma phase embrittlement. D1.5 Wet Insulation D1.5.1 Consider removing wet insulation to prevent corrosion under weatherproofing on steel equipment and chloride cracking of stainless steel equipment. D1.5.2 Check for chloride cracking under wet insulation covering stainless steel that was operating or exposed to temperatures above 125 oF. D1.5.3 Liquid Metal Embrittlement D1.5.4 Check for liquid metal embrittlement of equipment near or below melted aluminum or zinc components or galvanizing. Replace any equipment that has experienced liquid metal embrittlement. VALERO – KROTZ SPRINGS S.H.G # 55 Page 14 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D2. D1.6 Acids D1.6.1 On units that handle acids, check any standing water for low pH. D1.6.2 On alkylation units, replace bolting exposed to the acids because of leaks or spills. D1.6.3 Inspect any part of a system that might have seen acid carry-over during the fire for corrosion damage. D1.6.4 Caustic/Alkaline D1.6.5 Check carbon steel equipment in caustic service that saw temperatures greater than 120o F during the fire for caustic cracking. D1.7 Miscellaneous D1.7.1 Check for thermal shock cracking of heavy castings, e.g., furnace headers that may been hit (quenched) with a firewater stream. D1.7.2 If ultrasonic inspection reveals pipe or furnace tube walls are significantly different than original, look for internal melting or external oxidation. D1.7.3 Check acid lines subjected to high temperatures for increased corrosion and/or plugging. D1.7.4 Check other chemical lines (ex.: caustic and amines) for concentration effects such as precipitation, plugging or residues. D1.7.5 Determine if other additives such as inhibitors, antifoulants, demulsifiers, etc., may become inactive or not perform as effectively if overheated. INSPECTION AND TESTING D2.1 D2.2 D3. Remove from the fire area, in a timely manner, any special samples needed for the post-fire evaluation before the area is cleaned for repair. The sudden release of propane or butane from a line that has failed in a fire may cause auto refrigeration of such liquid away from the fire area. Embrittlement or cracking of certain metals in this area may result from severe cooling or from water freezing. INSULATION/ FIREPROOFING D3.1 Oil-Soaked Insulation D3.1.1 Replace insulation that has been soaked with oil. D3.1.2 Check for hydrocarbon pick-up in fibrous insulation. Replace, otherwise spontaneous combustion is possible on start-up. D3.2 Wet Insulation D3.2.1 Replace wet insulation on stainless steel equipment to prevent chloride stress corrosion cracking and from steel equipment to prevent corrosion. D3.2.2 Check for water damage to insulation outside the immediate fire area. D3.3 Fireproofing D3.3.1 Test concrete (structural and fireproofing) for mechanical soundness by: D3.3.2 Coring and testing D3.3.3 Schmidt hammer D3.3.4 Velocity meter testing VALERO – KROTZ SPRINGS S.H.G # 55 Page 15 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D4. D3.4 D3.5 Replace as required. Wet Refractory D3.5.1 Look for water and/or freezing damage under refractory linings. D3.5.2 Modify the unit startup procedures to account for wet refractory. D3.6 Asbestos D3.6.1 Identify areas where materials are made of asbestos. Follow company guidelines for handling, encapsulation, and/or removal as appropriate. D3.7 Other D3.7.1 Check effect of fire on insulation under stainless steel jackets. Mineral wool, foam glass, and glass fiber type-materials could be partially melted. D3.7.2 Check for correct insulation thickness when re-insulating Reformer reactors to prevent reactor shell overheating. MATERIAL FORMING AND FABRICATION D4.1 D4.2 D5. GENERAL D5.1 D5.2 D5.3 D6. Check cast iron equipment for cracking. Are grounding straps/lightning arrestors still intact and functional? Verify that curbing/diking needed to contain spills or leaks is functional, e.g., curbing on alkylation units. PROTECTIVE COATINGS D6.1 D6.2 D7. Check for material weldability before welding (hardness, copper, slag, weld area cleanliness, etc.). Document all substitute materials and temporary facilities installed with a timetable and method for replacement. Nonmetallic D6.1.1 Check to insure integrity of acid resistant coating/mastics on duct work, furnace shells and/or stacks for melting. D6.1.2 Inspect exterior coatings for signs of thermal degradation. D6.1.3 Inspect vessel/pipe internal protective coatings (epoxy, mastic, plastic, etc.) for melting. D6.1.4 Test Teflon coated sleeve plug and gate valves for shut-off capability. D6.1.5 Check the lining and flange surfaces of coated pipe used in acid service for damage (melting, extrusion, etc.). Lead Linings D6.2.1 Inspect lead linings for sagging or melting. PUMPING EQUIPMENT D7.1 Any pump and driver involved in a fire or located very near a fire should be pulled and thoroughly inspected, cleaned and reassembled. VALERO – KROTZ SPRINGS S.H.G # 55 Page 16 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D7.2 Lube and Seal Oil Systems D7.2.1 Thoroughly recondition lube and seal oil systems near a fire. Flush and refill with fresh oil. Check all instrumentation and alarms/shutdowns. D7.2.2 Verify proper operation of the auxiliary pump on loss of oil pressure. D7.2.3 Mechanically clean all seal or lube oil piping going through a fire area. Even if not seriously damaged, low flow rates in this small piping can overheat the oil and form deposits inside. Future problems with plugging and maintaining an adequate supply of oil can result. D7.2.4 Install new oil filters. D7.2.5 Check the cooling water flow through exchangers and flow control systems. D7.2.6 Check for piping distortion and proper slope. D7.3 Piping D7.3.1 Check for piping strain from piping involved in the fire area. D7.3.2 Check for piping strain on equipment nearby but not in the fire area. The expansion of connecting piping may cause stresses and rubbing of rotating parts in pumping equipment. Piping modifications may be necessary. D7.4 Foundations D7.4.1 Inspect foundations of pumping equipment for mechanical soundness. D7.4.2 Check the tightness of all foundation anchor bolts. D7.4.3 See “Foundations and Substructures”. D7.5 Other Items D7.5.1 Pump cases exposed to relatively high temperatures are susceptible to hardening and cracking. Have them dye-checked or mag-particle tested. D7.6 Specific Equipment D7.6.1 Check the following, where appropriate, when exposed to a fire: D7.6.1.1 Centrifugal Pumps D7.6.1.1.1 Mechanical seals D7.6.1.1.2 Seal flush systems D7.6.1.1.3 Vibration monitoring systems D7.6.1.2 Reciprocating Pumps D7.6.1.2.1 Relief valves D7.6.1.2.2 Diaphragms D7.6.1.2.3 Elastomers, seals D7.6.1.3 Blowers D7.6.1.3.1 Temperature detectors D7.6.1.4 Reciprocating Compressors and Gas Engines D7.6.1.4.1 Heads D7.6.1.4.2 Valves D7.6.1.4.3 Temperature detectors VALERO – KROTZ SPRINGS S.H.G # 55 Page 17 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D7.6.1.4.4 D7.6.1.4.5 D7.6.1.4.6 D7.6.1.4.7 D7.6.1.4.8 D7.6.1.4.9 Distance piece studs and nuts, tightness Electrical system Speed control system Auto shutdown devices and controls Piping and bottle supports Turbochargers on gas engines D7.6.1.5 Axial and Centrifugal Compressors D7.6.1.5.1 Case guide keys D7.6.1.5.2 Temperature and pressure detectors D7.6.1.5.3 Gas flow control systems D7.6.1.5.4 Auto shutdown control systems D7.6.1.5.5 Inlet guide vane (IGV) control systems D8. TURBINES AND OTHER DRIVERS D8.1 Any pump and driver involved in a fire or very near should be pulled and thoroughly inspected, cleaned and reassembled. D8.2 Lube and Seal Oil Systems D8.2.1 Thoroughly recondition lube and seal oil systems near a fire. Flush and refill with fresh oil. Check all instrumentation and alarms/shutdowns. D8.2.2 Verify proper operation of the auxiliary pump on loss of oil pressure. D8.2.3 Mechanically clean all seal and/or lube oil piping going through a fire area. Even if not seriously damaged, low flow rates in this small piping can overheat the oil and form deposits inside. Future problems with plugging and maintaining an adequate supply of oil can result. D8.2.4 Install new oil filters. D8.2.5 Check the cooling water flow through exchangers and flow control systems. D8.2.6 Check for piping distortion and proper slope. D8.3 Piping D8.3.1 Check for piping strain from piping involved in the fire area. D8.3.2 Check for piping strain on equipment nearby but not in the fire area. The expansion of connecting piping may cause stresses and rubbing of rotating parts in pumping equipment. Piping modifications may be necessary. D8.4 Foundations D8.4.1 Inspect foundations of driving equipment for mechanical soundness. D8.4.2 Check the tightness of all foundation anchor bolts. D8.4.3 See “Foundations and Substructures”. Alignment and Couplings D8.5.1 Check for equipment misalignment due to any irreversible thermal reaction of the concrete foundations. D8.5 VALERO – KROTZ SPRINGS S.H.G # 55 Page 18 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D8.5.2 Examine all equipment baseplates for possible warpage as a result of bing in or near a fire. A trained rotating equipment specialist may discover warpage that is not always obvious to others. D8.5.3 Inspect all couplings in or near a fire for damage and grease condition. D8.5.4 After checking the piping and foundations, check the shaft alignments of all rotating equipment near the fire area. D8.5.5 Remove driving equipment located in the fire area from their baseplates and check the pedestals with a machinist’s level for alignment and level. D8.6 Other Items D8.6.1 Check for thermally-warped shafts on driving equipment in the fire. D8.6.2 Bearing housings and cases exposed to relatively high temperatures are susceptible to hardening and cracking. Have them dye-checked or magparticle tested. D8.7 Specific Equipment. D8.7.1 Check the following, where appropriate, when exposed to a fire: D8.7.1.1 Electric Motors D8.7.1.2 Transformers D8.7.1.3 Switchgear D8.7.1.4 Breakers and relays D8.7.1.5 Power supplies at motor D8.7.1.6 Space heaters D8.7.1.7 Temperature detectors D8.7.1.8 Bearings and seals D8.7.1.9 Oil supply systems (or grease) D8.7.1.10 Foundation D8.7.1.11 Pedestal hardness checks and magnetic particle inspection D8.7.1.12 Coupling and shaft alignment D8.7.1.13 Auto shutdown control systems D8.7.1.14 Variable speed drive control systems D8.7.1.15 Megger motor for resistance to ground D8.7.1.16 Bump motors after meggering D8.7.1.17 Tightness of bolts and screws on motor housing and bearing brackets D8.8 V-Belt Drives D8.8.1 Inspect and replace belts D8.8.2 Check sheave alignment D8.9 Steam Turbines D8.9.1 Piping distortion and alignment D8.9.2 Piping supports D8.9.3 Speed control systems D8.9.4 Overspeed trip systems D8.9.5 Admission and extraction steam control systems VALERO – KROTZ SPRINGS S.H.G # 55 Page 19 of 27 Issued 09/15/03 ATTACHMENT D POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Rotating Equipment D8.9.6 D8.9.7 D8.9.8 D8.9.9 D8.9.10 D8.9.11 sealing steam control systems Turning gear control system Trip and throttle valve control systems Check for steam leaks Inspect casing guide keys Foundation D8.10 Turboexpanders D8.10.1 Flow control systems D8.10.2 Auto shutdown control systems D8.10.3 Safety shutdown valve D8.10.4 Seal gas systems D8.10.5 Foundation D8.11 Gas Turbines D8.11.1 D8.11.2 D8.11.3 D8.11.4 D8.11.5 Fuel gas control systems Inlet guide vane (IGV) control system Uninterruptible power supply (UPS) system Fire protection systems Air inlet filters VALERO – KROTZ SPRINGS S.H.G # 55 Page 20 of 27 Issued 09/15/03 ATTACHMENT E POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Vessels E1. CORROSION E1.1 Creep - Check material exposed to temperatures above those listed for sagging or dimension changes—replace if dimension change is greater than about 3%. Temp (oF) 300 500 540 950 1,000 E1.2 Material Lead Aluminum alloys Copper/copper alloys Glass Steels, stainless steels Hardness - Materials exposed to temperatures higher than those listed below should be checked for hardness. Hardness should meet original materials specification. Temp (oF) 400 540 900 1,150 Material Aluminum alloys Copper/copper alloys Low and high alloy steels Precipitation hardened stainless steels E1.3 Stainless Steel E1.3.1 Check equipment normally requiring downtime protection for evidence of polythionic stress corrosion cracking. E1.3.2 Check for sensitization on equipment exposed to temperatures above 800 F. Sensitization may affect corrosion resistance and downtime protection needs. E1.3.3 Check for chloride cracking of equipment exposed to temperatures above 125oF and firewater. E1.3.4 Replace stainless steel castings that in-situ metallography determines have Sigma phase embrittlement. E1.4 Wet Insulation E1.4.1 Consider removing wet insulation to prevent corrosion under weatherproofing on steel equipment and chloride cracking of stainless steel equipment. E1.4.2 Check for chloride cracking under wet insulation covering stainless steel that was operating or exposed to temperatures above 125oF. E1.4.3 Liquid Metal Embrittlement E1.4.4 Check for liquid metal embrittlement of equipment near or below melted aluminum or zinc components or galvanizing. Replace any equipment that has experienced liquid metal embrittlement. E1.5 Acids E1.5.1 On units that handle acids, check any standing water for low pH. E1.5.2 On alkylation units, replace bolting exposed to the acids because of leaks or spills. E1.5.3 Inspect any part of a system that might have seen acid carry-over during the fire for corrosion damage. VALERO – KROTZ SPRINGS S.H.G # 55 Page 21 of 27 Issued 09/15/03 ATTACHMENT E POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Vessels E1.5.4 Caustic/Alkaline E1.5.5 Check carbon steel equipment in caustic service that saw temperatures greater than 120o F during the fire for caustic cracking. E1.6 E2. INSPECTION AND TESTING E2.1 E2.2 E3. Miscellaneous E1.6.1 Check for thermal shock cracking of heavy castings, e.g., furnace headers that may been hit (quenched) with a firewater stream. E1.6.2 If ultrasonic inspection reveals pipe or furnace tube walls are significantly different than original, look for internal melting or external oxidation. E1.6.3 Check acid lines subjected to high temperatures for increased corrosion and/or plugging. E1.6.4 Check other chemical lines (ex.: caustic and amines) for concentration effects such as precipitation, plugging or residues. E1.6.5 Determine if other additives such as inhibitors, antifoulants, demulsifiers, etc., may become inactive or not perform as effectively if overheated. Remove from the fire area, in a timely manner, any special samples needed for the post-fire evaluation before the area is cleaned for repair. The sudden release of propane or butane from a line that has failed in a fire may cause auto refrigeration of such liquid away from the fire area. Embrittlement or cracking of certain metals in this area may result from severe cooling or from water freezing. INSULATION/ FIREPROOFING E3.1 Oil-Soaked Insulation E3.1.1 Replace insulation that has been soaked with oil. E3.1.2 Check for hydrocarbon pick-up in fibrous insulation. Replace, otherwise spontaneous combustion is possible on start-up. E3.2 Wet Insulation E3.2.1 Replace wet insulation on stainless steel equipment to prevent chloride stress corrosion cracking and from steel equipment to prevent corrosion. E3.2.2 Check for water damage to insulation outside the immediate fire area. E3.3 Fireproofing E3.3.1 Test concrete (structural and fireproofing) for mechanical soundness by: E3.3.2 Coring and testing E3.3.3 Schmidt hammer E3.3.4 Velocity meter testing E3.3.2 Replace as required. E3.3.3 Wet Refractory E3.3.3.1 Look for water and/or freezing damage under refractory linings. E3.3.3.2 Modify the unit startup procedures to account for wet refractory. VALERO – KROTZ SPRINGS S.H.G # 55 Page 22 of 27 Issued 09/15/03 ATTACHMENT E POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Vessels E4. E3.4 Asbestos E3.4.1 Identify areas where materials are made of asbestos. Follow company guidelines for handling, encapsulation, and/or removal as appropriate. E3.5 Other E3.5.1 Check effect of fire on insulation under stainless steel jackets. Mineral wool, foam glass, and glass fiber type-materials could be partially melted. E3.5.2 Check for correct insulation thickness when re-insulating Reformer reactors to prevent reactor shell overheating. MATERIAL FORMING AND FABRICATION E4.1 E4.2 E5. GENERAL E5.1 E5.2 E5.3 E6. E7. Check for material weldability - hardness, copper, slag, weld area cleanliness, etc., before welding. Document all substitute materials and temporary facilities installed with a timetable and method for replacement. Check cast iron equipment for cracking. Are grounding straps/lightning arrestors still intact and functional? Verify that curbing/diking needed to contain spills or leaks is functional, e.g., curbing on alkylation units. PROTECTIVE COATINGS E6.1 Nonmetallic E3.5.3 Check to insure integrity of acid resistant coating/mastics on duct work, furnace shells and/or stacks for melting. E3.5.4 Inspect exterior coatings for signs of thermal degradation. E3.5.5 Inspect vessel/pipe internal protective coatings (epoxy, mastic, plastic, etc.) for melting. E3.5.6 Test Teflon coated sleeve plug and gate valves for shut-off capability. E3.5.7 Check the lining and flange surfaces of coated pipe used in acid service for damage (melting, extrusion, etc.). E6.2 E6.3 Lead Linings Inspect lead linings for sagging or melting. VESSELS E7.1 E7.2 E7.3 E7.4 E7.5 Be aware of potential false levels of hydrocarbons in vessels to be opened. Ensure that vessels are truly hydrocarbon free before entering. Check foundation and grouting for damage. Check the skirt for damage. Remove fireproofing as necessary. Check the vessel for out-of-plumb (leaning). Replace site and gauge glasses that were exposed to high temperatures. VALERO – KROTZ SPRINGS S.H.G # 55 Page 23 of 27 Issued 09/15/03 ATTACHMENT E POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Vessels E7.6 E7.7 E7.8 E7.9 E7.10 Check manway and nozzle bolts for stress relaxation. Inspect all nuclear sources on level detectors for damage. Shop-test relief valves. Check for catalyst degradation due to fire. Spot-check tower internals and catalyst beds for possible upset as a result of being shutdown suddenly, even if the equipment was not directly involved in the fire. E7.11 Check the vessel for internal blistering, bulges, disbonding of liners, and cracking. Consider insitu metallography. Vessels containing wet hydrogen sulfide, amine, caustic, and acid are susceptible to cracking. E8. TANKS, STORAGE E8.1 Level Measurement E8.1.1 Replace sight gauge glasses exposed to the fire or high heat. E8.1.2 Verify proper level gauge operation. Make sure the piping is not plugged or located in a sludge layer. E8.2 Sample Points E8.2.1 Check sample points in the fire area for pluggage or coking. E8.3 Miscellaneous E8.3.1 Check that the floating roof is operational. E8.3.2 Inspect tanks in caustic service for stress cracking. E8.3.3 Check tank base ring for any thermal expansion damage. E8.3.4 Determine if acid carryover was possible into the tank. E8.3.5 Check that the nitrogen blanketing system is operational. E8.3.6 Test the firewater deluge system. E8.3.7 Check primary/secondary seals for damage to tanks near the fire area. E8.3.8 Check tank nozzles and adjoining tank shell area. They may have been overstressed due to thermal expansion of the tank and/or connected piping. E8.3.9 Check fiberglass or coated chemical storage tanks for coating loss or damage. Exposure to only modest temperatures may cause loss of external strength or corrosion protection. VALERO – KROTZ SPRINGS S.H.G # 55 Page 24 of 27 Issued 09/15/03 ATTACHMENT F POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Civil F1. BUILDINGS F1.1 F1.2 F1.3 F1.4 F1.5 F1.6 F1.7 F2. FOUNDATIONS AND SUBSTRUCTURES F2.1 Grouting F2.1.1 Check foundations for loss of bond between the grout and concrete. F2.2 Cracks (Major Damage) F2.2.1 Inspect foundations for cracks and other damage due to metal thermal expansion of anchor bolts, baseplates, rebar, etc. Water can enter causing future corrosion of the metal and severe cracking of the concrete. F2.2.2 Inspect structural concrete or similar fireproofing for hairline cracks where water can enter and cause future corrosion of the metal and severe cracking of the concrete or fireproofing. Foundation F2.3 F2.4 F2.5 F3. Any “safe haven” building exposed to the fire should be inspected to insure it still meets the “safe haven” criteria. Check for friable asbestos and/or transite siding, including integrity of panel fasteners. Watch for water and/or ice buildup on flat roofs for firefighting personnel safety and roof loadings. Check buildings for any cracked glass in windows, including elevated windows, which could be a safety hazard. Check the electrical supply to buildings that could pose an electrocution hazard. Check metal roof beams for deformation and heat damage. Check cinder block walls for cracking and embrittlement. Heat Damage F2.4.1 Check concrete in the periphery of a fire area for loss of strength. Such loss is not always obvious. Concrete may spall when subjected to high temperatures. Bolting F2.5.1 Check the tightness of baseplate and foundation anchor bolts that may have loosened up during the fire. INSULATION/ FIREPROOFING F3.1 Oil-Soaked Insulation F3.1.1 Replace insulation that has been soaked with oil. F3.1.2 Check for hydrocarbon pick-up in fibrous insulation. Replace, otherwise spontaneous combustion is possible on start-up. F3.2 Wet Insulation F3.2.1 Replace wet insulation on stainless steel equipment to prevent chloride stress corrosion cracking and from steel equipment to prevent corrosion. F3.2.2 Check for water damage to insulation outside the immediate fire area. VALERO – KROTZ SPRINGS S.H.G # 55 Page 25 of 27 Issued 09/15/03 ATTACHMENT F POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Civil F3.3 Fireproofing F3.3.1 Test concrete (structural and fireproofing) for mechanical soundness by: F3.3.1.1 Coring and testing F3.3.1.2 Schmidt hammer F3.3.1.3 Velocity meter testing F3.3.2 Replace as required. F3.3.3 Wet Refractory F3.3.3.1 Look for water and/or freezing damage under refractory linings. F3.3.3.2 Modify the unit startup procedures to account for wet refractory. F3.4 Asbestos F3.4.1.1 Identify areas where materials are made of asbestos. Follow company guidelines for handling, encapsulation, and/or removal as appropriate. F3.5 Other F3.5.1.1 Check effect of fire on insulation under stainless steel jackets. Mineral wool, foam glass, and glass fiber type-materials could be partially melted. F3.5.1.2 Check for correct insulation thickness when re-insulating Reformer reactors to prevent reactor shell overheating. F4. GENERAL F4.1 F4.2 F4.3 F5. F6. Check cast iron equipment for cracking. Are grounding straps/lightning arrestors still intact and functional? Verify that curbing/diking/area paving needed to contain spills or leaks is functional, e.g., curbing on alkylation units. PROTECTIVE COATINGS F5.1 Nonmetallic F5.1.1 Check to insure integrity of acid resistant coating/mastics on duct work, furnace shells and/or stacks for melting. F5.1.2 Inspect exterior coatings for signs of thermal degradation. F5.1.3 Inspect vessel/pipe internal protective coatings (epoxy, mastic, plastic, etc.) for melting. F5.1.4 Test Teflon coated sleeve plug and gate valves for shut-off capability. F5.1.5 Check the lining and flange surfaces of coated pipe used in acid service for damage (melting, extrusion, etc.). F5.2 Lead Linings F5.2.1 Inspect lead linings for sagging or melting. STACKS F6.1 Check integrity of stack liners. VALERO – KROTZ SPRINGS S.H.G # 55 Page 26 of 27 Issued 09/15/03 ATTACHMENT F POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Civil F6.2 F6.3 F6.4 F6.5 F7. STRUCTURES F7.1 F7.2 F7.3 F7.4 F7.5 F8. Check to insure integrity of acid resistant coating/mastics on duct work/furnace/stack shells exposed during a fire. Verify operations of all mechanical damper linkages and operability of stack dampers. Perform a thorough refractory inspection. Look for water damage to refractory linings. Warm up slowly to prevent spalling during startup. Inspect all guy wires for damage and overstress. Visually check structures adjacent to the fire area for damage. Pay particular attention to structural members and connections (bolts, gusset plates, end plates and welded joints) for distortion due to thermal or pressure shock. Check integrity of ladders and walkways to handle design loads. Look for ice damage and overloading of decks or other structures due to ice. If structural pieces such as handrails, cross-beams, etc., are made out of pipe, be sure that weep holes are drilled to prevent the possibility of bursting the pipe in a subsequent fire from overheating of trapped air. Inspect piping anchor points and guides for damage and/or failure. WAREHOUSE AND STORAGE AREAS F8.1 F8.2 F8.3 F8.4 F8.5 F8.6 Inspect building for safe access, structural integrity, and electrical service. Inspect critical components (motors, instrumentation, gaskets, and all spares) stored in warehouse areas for fire or water damage. Check nameplates, identification plates, and tags for proper identification. Inspect catalyst and containers. Inspect chemicals and chemical containers. Inspect all bottles, cans, and containers for damage and future reliability. Move all suspect materials to a designated holding area for further inspection and/or disposal. VALERO – KROTZ SPRINGS S.H.G # 55 Page 27 of 27 Issued 09/15/03 ATTACHMENT G POST-FIRE FITNESS-FOR-SERVICE INVESTIGATION CHECKLIST Environmental G1. G2. WASTE AND DRAINAGE G1.1 Curbs and Firewalls G1.1.1 Repair damaged unit curbs to prevent future oil spills from reaching and accumulating oil in surrounding area. G1.1.2 Be sure to close firewall or curb drains opened during or after a fire to facilitate draining of firewater. G1.1.3 Be alert for ponds or accumulation of oil that may have surfaced in new or unexpected locations as a result of poor firewater runoff or temporarily higher ground water levels. G1.2 Sewers and Drains G1.2.1 Make sure hydrocarbons are drained off. Also check for debris. G1.2.2 Check the pumpout system for proper operation prior to startup. Make sure it is not coked-up or plugged. G1.2.3 Check the sewer system for hazardous materials from the fire. (Asbestos, caustic, acid, NMP, hydrocarbons, explosive mixtures, etc.) G1.2.4 Are sewers in the fire area open? Have they been damaged or broken? Should they be rerouted? Are there trenches involved? G1.3 Opening Equipment G1.3.1 Make sure all liquids are drained from knockout drums and lines. G1.3.2 Be cautious in opening equipment due to hazards from chemicals, chemical residues or ash that can run out or be present. G1.3.3 Be alert to the possibility of toxic or other reactive gas release when certain materials or chemical storage equipment has been exposed to or consumed in a fire. For example, certain plastics or similar materials have been known to release hydrogen chloride, phosgene, etc. as a product of combustion or reaction when burned. G1.3.4 Be alert for potential trapped hydrocarbons and/or toxics when cutting piping and/or opening vessels for removal or repairs. Such equipment may be plugged, still pressurized and quite hot. For example, the reactors of a Reformer may be insulated internally and don’t dissipate heat to the outside wall, thus the outside surface may feel quite cool while contents of the vessel may still be extremely warm. Check that all equipment is open and clear of gases, liquids and solids at intermediate upstream and downstream points. AREA SAFETY G2.1 On units that handle acids, check any standing water for low pH.