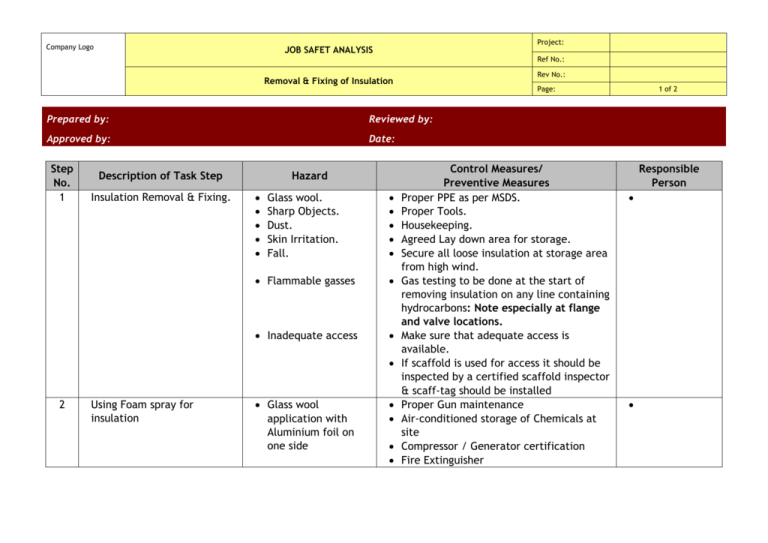

Job Safety Analysis: Insulation Removal & Fixing

advertisement

Company Logo Project: JOB SAFET ANALYSIS Ref No.: Rev No.: Removal & Fixing of Insulation Page: Prepared by: Reviewed by: Approved by: Date: Step No. 1 Description of Task Step Insulation Removal & Fixing. Hazard Glass wool. Sharp Objects. Dust. Skin Irritation. Fall. Flammable gasses Inadequate access 2 Using Foam spray for insulation Glass wool application with Aluminium foil on one side Control Measures/ Preventive Measures Proper PPE as per MSDS. Proper Tools. Housekeeping. Agreed Lay down area for storage. Secure all loose insulation at storage area from high wind. Gas testing to be done at the start of removing insulation on any line containing hydrocarbons: Note especially at flange and valve locations. Make sure that adequate access is available. If scaffold is used for access it should be inspected by a certified scaffold inspector & scaff-tag should be installed Proper Gun maintenance Air-conditioned storage of Chemicals at site Compressor / Generator certification Fire Extinguisher 1 of 2 Responsible Person Company Logo Project: JOB SAFET ANALYSIS Ref No.: Removal & Fixing of Insulation Step No. Description of Task Step Hazard Chemical (Polyol + Iso-cyanide = Polyurethane) Pressurised Injection gun Foaming machine Breathing trouble Rev No.: Page: Control Measures/ Preventive Measures Wear proper PPE as per the MSDS (material Safety Data Sheet) Workers should not play around with the tools Only competent workers are allowed to use the pressurized injection gun Operators must read the manufacturers for using the foaming machine 2 of 2 Responsible Person