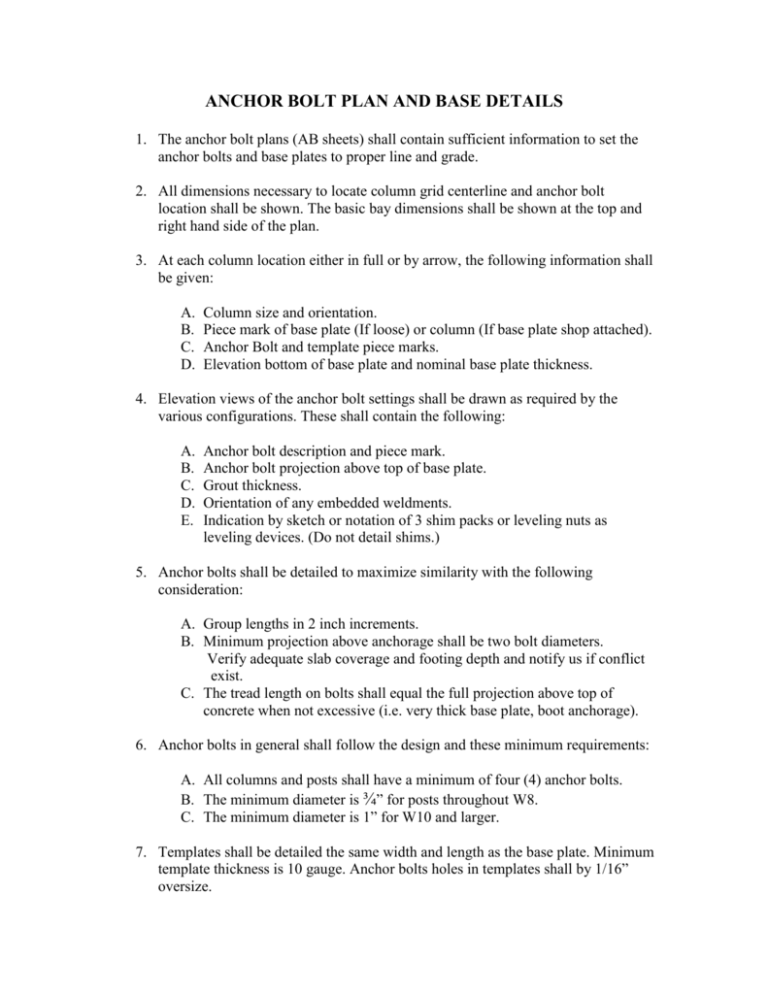

ANCHOR BOLT PLAN AND BASE DETAILS

advertisement

ANCHOR BOLT PLAN AND BASE DETAILS 1. The anchor bolt plans (AB sheets) shall contain sufficient information to set the anchor bolts and base plates to proper line and grade. 2. All dimensions necessary to locate column grid centerline and anchor bolt location shall be shown. The basic bay dimensions shall be shown at the top and right hand side of the plan. 3. At each column location either in full or by arrow, the following information shall be given: A. B. C. D. Column size and orientation. Piece mark of base plate (If loose) or column (If base plate shop attached). Anchor Bolt and template piece marks. Elevation bottom of base plate and nominal base plate thickness. 4. Elevation views of the anchor bolt settings shall be drawn as required by the various configurations. These shall contain the following: A. B. C. D. E. Anchor bolt description and piece mark. Anchor bolt projection above top of base plate. Grout thickness. Orientation of any embedded weldments. Indication by sketch or notation of 3 shim packs or leveling nuts as leveling devices. (Do not detail shims.) 5. Anchor bolts shall be detailed to maximize similarity with the following consideration: A. Group lengths in 2 inch increments. B. Minimum projection above anchorage shall be two bolt diameters. Verify adequate slab coverage and footing depth and notify us if conflict exist. C. The tread length on bolts shall equal the full projection above top of concrete when not excessive (i.e. very thick base plate, boot anchorage). 6. Anchor bolts in general shall follow the design and these minimum requirements: A. All columns and posts shall have a minimum of four (4) anchor bolts. B. The minimum diameter is ¾” for posts throughout W8. C. The minimum diameter is 1” for W10 and larger. 7. Templates shall be detailed the same width and length as the base plate. Minimum template thickness is 10 gauge. Anchor bolts holes in templates shall by 1/16” oversize. 8. Grout holes to be used at the discretion of the field and project manager. Project manager will direct the size and location of any grout holes to be used, on an jobby-job basis. 9. Key plan must be shown on each setting plan if multiple sheets are used. 10. When contract drawings indicate a variety of sizes and lengths for anchor bolts, try to simplify the requirements. If possible, eliminates small quantities of odd sizes by combining with larger or longer bolts that appear in greater quantities. Round lengths to even lengths which are normally stocked. 11. When slotted holes are shown in column base plate, girder bearings, etc. plate washers must be provided. Plate washers are not shown on erection drawings unless they are required to be field welded. Plate washers are the same thickness as the connected material except that washer thickness need not exceed ¼’. Plate washers are billed in the “Field Bolt List” for placement by the field crew. 12. Anchor bolt setting plans must not be combined with framing plans. 13. Grout is required under column base plates whether or not shown to be grouted. Provide minimum 1 ½” grout for ¾” anchor bolts. 14. All anchor bolts with templates are to be shown assembled and called out as anchor bolt assemblies. Furnish an individual template for each column.