MATHEMATICAL MODELLING OF BLAST FURNACE PROCESS AT

advertisement

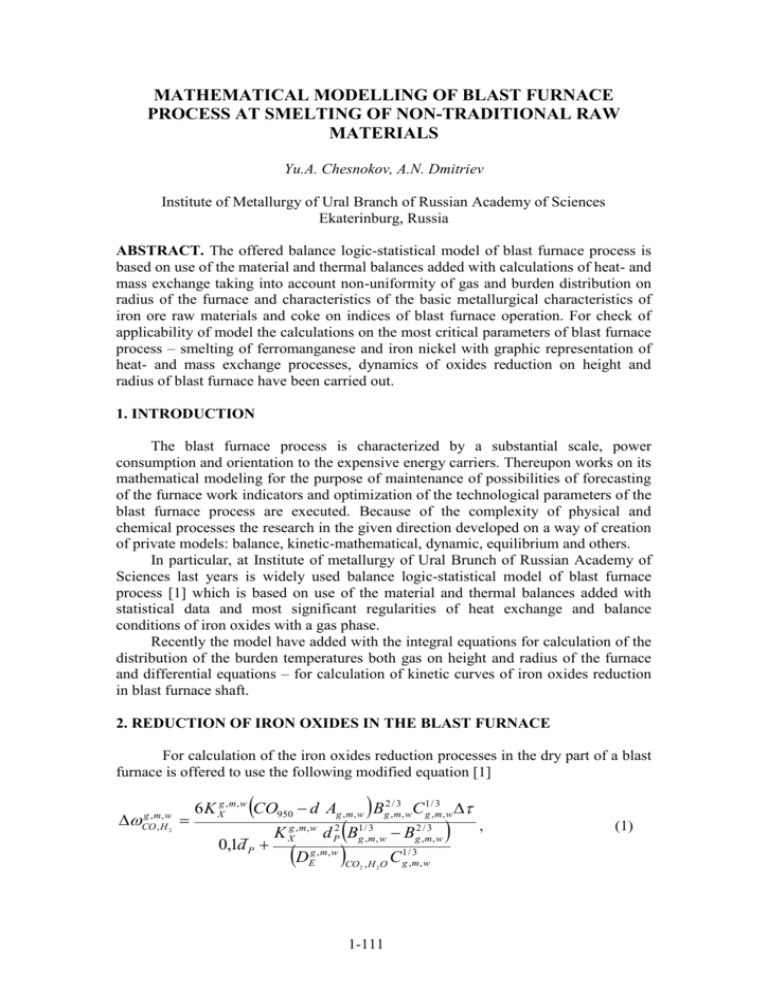

MATHEMATICAL MODELLING OF BLAST FURNACE PROCESS AT SMELTING OF NON-TRADITIONAL RAW MATERIALS Yu.A. Chesnokov, A.N. Dmitriev Institute of Metallurgy of Ural Branch of Russian Academy of Sciences Ekaterinburg, Russia ABSTRACT. The offered balance logic-statistical model of blast furnace process is based on use of the material and thermal balances added with calculations of heat- and mass exchange taking into account non-uniformity of gas and burden distribution on radius of the furnace and characteristics of the basic metallurgical characteristics of iron ore raw materials and coke on indices of blast furnace operation. For check of applicability of model the calculations on the most critical parameters of blast furnace process – smelting of ferromanganese and iron nickel with graphic representation of heat- and mass exchange processes, dynamics of oxides reduction on height and radius of blast furnace have been carried out. 1. INTRODUCTION The blast furnace process is characterized by a substantial scale, power consumption and orientation to the expensive energy carriers. Thereupon works on its mathematical modeling for the purpose of maintenance of possibilities of forecasting of the furnace work indicators and optimization of the technological parameters of the blast furnace process are executed. Because of the complexity of physical and chemical processes the research in the given direction developed on a way of creation of private models: balance, kinetic-mathematical, dynamic, equilibrium and others. In particular, at Institute of metallurgy of Ural Brunch of Russian Academy of Sciences last years is widely used balance logic-statistical model of blast furnace process [1] which is based on use of the material and thermal balances added with statistical data and most significant regularities of heat exchange and balance conditions of iron oxides with a gas phase. Recently the model have added with the integral equations for calculation of the distribution of the burden temperatures both gas on height and radius of the furnace and differential equations – for calculation of kinetic curves of iron oxides reduction in blast furnace shaft. 2. REDUCTION OF IRON OXIDES IN THE BLAST FURNACE For calculation of the iron oxides reduction processes in the dry part of a blast furnace is offered to use the following modified equation [1] g , m, w CO , H 2 6 K Xg , m, w СО950 d Ag , m, w Bg2,/m3, wС 1g/, m3 , w 0,1d P K Xg , m, w d P2 B1g/, m3 , w Вg2,/m3, w D g , m, w E СО2 , H 2 O 1-111 С 1g/, m3 , w , (1) g ,m ,w where CO ,H 2 – increment of degree of reduction of hematite (g), magnetite (m) and wustite (w) at the expense of CO или H 2 agreeably. Other designations are resulted in Section 6. Balance constants (СО2/СО) of reactions 3Fe2O3 CO 2Fe3O4 CO2 , Fe3O4 CO 3FeO CO2 , (2) (3) (4) FeO CO Fe CO2 are described by the equations [2] lg K gCO 2726 / T 2.144 , (5) lg K mCO 1850 / T 2.1 , (6) lg K CO w 688 / T 0.9 . (7) Balance constants of iron oxides reduction reactions by hydrogen ( H 2O / H 2 ) рассчитываются по уравнениям are calculated on the equations K gH, m2 , w K gCO , m, w K wg , (8) where K wg – balance сonstant of reaction of water gas CO2 H 2 CO H2O . (9) Total degrees of reduction of iron oxides are calculated in model according to the equations g , m, w CO H2 g , m, w i 1 CO i 1 H 2 i 1 g , m, w CO Hg ,2m, w , (10) g m w 0.11CO 0.166CO 0.724CO , 0.11Hg 0.166Hm 0.724Hw . 2 2 2 (11) (12) For check of adequacy of the accepted scheme of reduction of iron oxides experiments on reduction of agglomerate and pellets by hydrogen in an interval 9001100 оС have been made. In Fig.1 the experimental and settlement kinetic curves constructed with use of the equations (1), (10-12) are resulted. 3. DISTRIBUTION OF TEMPERATURES ON BLAST FURNACE HEIGHT The basic equations for heat exchange calculation in the differential form look like wg dt g wm dt m ( i p i g )d , wg dt g wm dt m , (13) (14) wm dt m ih d V vm (t g t m )d , (15) dt m V vm (t g t m ) ih V vm (t g t m ) , d wm wm (16) 1-112 Fig. 1. The experimental (continuous) and calculating (stroke-dotted) kinetic curves of pellets reduction (а) and agglomerate (b) of Kachkanarsky GOK dt g d V vm (t g t m ) wg , (17) where wm – water equivalent of burden, equals ih wm wm 1 dt m wm d , (18) wg – water equivalent of gas, 1-113 ip wg wg 1 dt g wg d . (19) Solving in common the equations (14) and (16), at an assumption wM = const we receive the equations m wg tm t gк mt mH t gк t mH exp ( ) 1 m , (20) t gк mtmH mtmк tmH exp ( ) tg , 1 m v ( ) V m (1 m) , (21) (22) wm where – t gK and tmH – temperatures of gas and material on top (the final temperature of gas, the reference temperature of material); t gН and t mК – the same in the end of a zone of heat exchange (reference temperature of gas, final temperature of material). For the calculation of dependence of the water equivalent and water number of the burden from temperature we shall be limited to linear functions wm a m в m t m . Integrating (13) and (14) in view of (23) we shall receive t g t gK J аm в t m t mH m t m2 t mH wg 2wg 2 p JK wg , (23) (24) where J p J K – losses of heat and thermal effects of reactions at height of the furnace limited in temperatures t g and t Кg , kJ/t of pig-iron. These equations precisely enough describe processes of heat exchange in the blast furnace at small values of a step on temperature or time. 4. CALCULATION OF NON-UNIFORMITY OF DISTRIBUTION OF GAS ON TOP RADIUS As the primary information allowing to analyze the work of gas in the furnace use usually practical data about distributions CO2 and temperatures of gas on radius of top. Distinguish two basic types of the distribution influencing on parameters of work of the furnace – a peripheral and axial course. In the mathematical model the opportunity of the task of any types of distributions as on practical data, and by expert is stipulated. The curve СО2 f ( r ) will be transformed to non-uniformity of distribution of streams of burden and gas, thus the blast furnace is broken into ten equal rings. Also following assumptions are accepted: ore ( O ) and flux ( F ) are distributed on section of the furnace in regular intervals unlike coke Кr f r and gas. 1-114 Thus these values should be distributed on top radius so that to compensate the accepted assumptions and to reflect such phenomena, as pinching-out of layers of components of burden, an advancing, segregation, etc. As a result by means of calculation heat- and mass exchange on model the set curve is reproduced СО2 f r . For this purpose used the equations with help which the ore loading ( OB ) and the coke consumption (K) are put accordingly in direct and inversely proportional dependence on ( CO2 ) and quantity of gas in dependence on the coke consumption OBr OB CO 2 r CO 2 , (25) Kr O F r , OB r V K K i Ai Vg Ai 1 Bi ln r 1 i V g K Kr g r (26) n , (27) where OB and K – the average ore loading and the average coke consumption; ρi , Ai , Bi , ni – factors which steal up on a condition of maintenance of the greatest possible coincidence set curve and СО2 f r received as a result of calculations of heat- and mass exchange in 10 rings. 5. EXAMPLES OF PROBLEMS PRACTICAL SOLUTION OF BLAST FURNACE SMELTING Model possibilities are illustrated by the analysis of blast furnace process at fusion of silikate-nickel and manganous ores. 5.1. Smelt calculation of iron nickel The analysis of development of processes of heat exchange carried out on change of temperatures of gas and burden in horizontal sections and on furnace height (on periphery, on an ore crest and at a furnace wall). As initial data are set - furnace characteristics, composition and properties iron ore raw materials, limestone, coke, blasting parameters, factors of non-uniformity of the gas stream, coordinated with the loading systems profile (a site of an ore crest, its height). As a result of calculation received pig-iron and slag composition, the parametres characterising thermal and reducing work of gas, and also technical and economic indicators of blast furnace smelting. The basic indicators of smelting and the analysis of blast furnace process for conditions of melt of pig-iron about 6 % Ni in a blast furnace in volume 205 м3 are resulted in tab. 1 and in fig. 2. From character of the temperature curves it is visible, that in an ore crest heat exchange is carried out at other relation of water equivalents of and gas, unlike the centre and periphery. Therefore this area promotes formation of low average temperature of top gas – 35 оС. 1-115 Table 1. The basic parameters of smelting of ferronickel in a blast furnace Indices Value Productivity, t/day The sinter consumption, kg/t pig-iron General contents Fe in burden, % Coke consumption, kg/t pig-iron Flux, kg/t pig-iron Blast: natural gas consumption, m3/minute temperature, оС oxygen contents, % Pig-iron, composition, %: [Si] [Ni] [Cr] Slag: quantity, kg/t pig-iron composition, %: (CaO) (MgO) (Al2O3) basic capacity (CaO/SiO2) 53 6430 13,96 1532 82 1558 1100 21,0 1.50 6.39 1.38 5138 28.8 14.9 28.8 0.60 Reduction processes of iron oxides in all cuts are developed actively enough because of tall reductibility of sinter. The greatest activity of reduction processes of iron oxides is observed at furnace centre. At the centre of furnace and on the rim the reduction of iron oxides is terminated completely in the “dry” zone of the board, i.e. to temperatures 950 oС. In the ridge ore the rereduction processes are developed less actively and to the emolliating zone the material is enters in which wustite it is reduced only on 50 %. Therefore early slags in this cut will differ from slags of central and peripheral cuts both on consumption and on properties. 5.2. Smelt calculation of ferromanganese The smelting of manganous ferroalloys in the blast furnace is characterised by the raised coke consumption bundled first of all with high heat consumption of the reduction processes of the manganese oxides in the bottom of a blast furnace. In these conditions for smelting of qualitative ferromanganese are necessary high blast parameters: maximum heat, its deep oxygen enrichment. For the analysis it is offered to use the combined diagramme “ω – t – τ” allowing operatively to estimate the thermal state of furnace together with reduction processes of iron oxides depending on the stay time of materials in the furnace. In fig. 3 the curves of heat interchange and reduction of iron oxides at smelting of 72 % of ferromanganese are presented. The analysis shows, that in comparison with ordinary conditions of smelting the altitude of the reserve zone on a time is much more more stretched (1-1.5 hours against 3.5-4.0 hours, accordingly), that predetermines the conclusion about usage for a ferromanganese smelting of low-shaft furnaces. 1-116 Centre of furnace Ore crest Periphery of furnace Temperature, оС Reduction degree, share of units Fig. 2. Distribution of temperatures of the burden and gas (at the left) and reduction processes (on the right) in vertical sections (rings 1, 8, 10) of the blast furnace at ferronickel smelting 1-117 Fig. 3. The analysis of reduction processes and heat interchange for ferromanganese smelting conditions As a result of the fulfilled explorations the existing mathematical model of the blast furnace smelting is added by a method of the taking into account kinetic singularities of reduction process of iron oxides until temperatures of 900-950 оС. The measure of the registration of irregularity of allocation of gas on shaft top radius is developed. The calculated analysis of the critical conditions and parameters of the combined blast has shown essential spreading of functionality and a raise of adequacy of the model. 6. SYMBOLS g ,m, w CO , H 2 – gain of the reduction degree of the hematite, magnetite and wustite at the expense of CO or H 2 accordingly; K Хg ,m,w – constants of the reduction velocities for the hematite, magnetite and wustite; CO950 – CO content at 950оС, %; d Р – diameter of the ore piece, mm; ( DEg ,m,w ) CO2 , H 2O – the effective diffusivity defining the diffusive resistance of the reduced layer for hematite, magnetite and wustite accordingly; Ag ,m , w , B g ,m , w , C g ,m, w , D g , m , w – auxiliary coefficients; 1-118 t m , g – temperature of materials or gas, accordingly, оС; V – volume heat-transfer factor; ih – heat effect of the reaction, kJ/(h ∙ t); i p – warmth losses, kJ/(h ∙ t); m – the ration of water equivalents of the burden and gas; (О), (К), (F) – consumption of ore, coke and limestone, accordingly, kg/t pig-iron; OB – ore burden; Vg – top gas amount, kg/t pig-iron; (CO2) – contents of the carbon dioxide in the top gas, %. 7. CONCLUSION Thus, the short description of a balance logic-statistical model of the blastfurnace smelting and results of the solution of practical problems of the blast-furnace smelting are presented. AKNOWLEDGEMENTS This work was executed with support from Council under Grants for Leading Scientific Schools of Russia (School № 4358.2008.3). REFERENCES: 1. Chentsov A.V., Chesnokov Yu.A. and Shavrin S.V.: The Logic-Statistic Balance Model of Blast Furnace Smelting. Ural Branch of Russian Academy of Sciences, Ekaterinburg, 2003. 2. Popel S.I., Sotnikov A.I. and Boronenkov V.N.: The theory of metallurgical processes. Moscow, Metallurgy, 1986. 3. Chentsov A.V., Chesnokov Yu.A. and Shavrin S.V.: 'Controllable parameters of system of loading and elements of modelling of domain process'. Izvestia Vuzov, Chernaya Mettalurgia 2006 7 22-24. 4. Belyaev I.L, Chentsov A.V., Chesnokov Yu.A. and Shavrin S.V.: 'Use of twodimensional model of blast furnace process at pig-iron melt about 6 % Ni'. Izvestia Vuzov, Chernaya Mettalurgia 2006 9 18-20. 5. Kudinov D.Z., Chesnokov Yu.A. and Shavrin S.V.: Features of blast furace process at melt of manganous alloys in the form of diagrams ω – t – τ. Izvestia Vuzov, Chernaya Mettalurgia 2002 3 76-77. 1-119