Chapter 7 Answers

advertisement

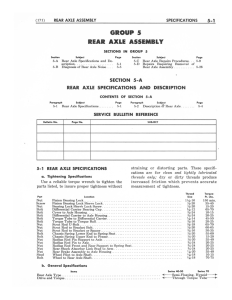

Chapter 7 Differentials and Drive Axles Answers to Review Questions •Classroom Manual, Pages 172–174 Short Answer Essays 1. Final drive is the final gear set of reduction gears in the power train on its way to the drive wheels. 2. A differential is needed between any two drive wheels because the two drive wheels must be at different speeds when the vehicle is turning. If the tires cannot rotate at different speeds, one will scrub on the road. This scrubbing causes abnormal tire wear. 3. Hypoid gears allow the drive shaft to be positioned low in the vehicle because the final drive pinion gear center line is below the ring gear center line. This allows the vehicle, as a whole, to be lower. 4. Three major functions of a differential are: to allow for different speeds between the two drive wheels; to multiply torque, and to change the direction of power flow. 5. The drive shaft drives the pinion gear, which is in mesh with the ring gear. The ring gear is bolted to the differential case. The power flowing from the drive pinion and ring gear causes it to rotate. The differential case normally houses the pinion gears and axle side gears, which are mounted over splines at the end of the axle shafts. 6. The difference between an integral carrier housing and a removable carrier housing is in the integral type housing: the differential carrier housing and the axle housing are the same casting, whereas in the removable type, the carrier housing can be removed from the axle housing. 7. The differences between hunting, non-hunting, and partial nonhunting gears are based on the number of teeth on the ring and pinion gears. A nonhunting gearset is one in which any one pinion gear tooth comes in contact with the same teeth on the ring gear during each revolution of the ring gear. A partial nonhunting gearset is one in which one pinion tooth comes in contact with the same teeth on the ring gear, but more than one revolution is required. The hunting gearset has all pinion gear teeth coming in contact with all of the teeth on the ring gear. 8. The straddle-mounted pinion has two opposing tapered-roller bearings positioned close together and ahead of the pinion gear, using a third bearing behind the pinion to support the rear of the pinion gear. The overhung mounted pinion uses two opposing tapered-roller bearings but does not use a third bearing. The two roller bearings are placed further apart to support the shaft. 9. A limited-slip differential provides more driving force to the wheel with traction when one wheel begins to slip. Limited-slip differentials are similar to conventional units except for a large internal recess around each axle side gear. This recess accepts a clutch assembly. The clutch plates are splined to each axle gear’s hub and the ears of the clutch plates are fitted into the differential case to provide resistance to the movement of the axle side gears in relation to the differential case. 10. There are basically three designs by which axles are supported in a live axle: full-floating, three-quarter floating, and semi-floating. These refer to where the axle bearing is placed in relation to the axle and the housing. The bearing of a full-floating axle is located on the outside of the housing, which places all of the vehicle’s weight on the axle housing with no weight on the axle. Three-quarter and semi-floating axles are supported by bearings located in the housing and therefore carry some of the vehicle’s weight on the axles. Fill-in-the-Blanks 1. Pinion, ring, pinion, side 2. Integral, removable 3. Spiral, bevel gears, hypoid gears 4. Convex, concave, toe, heel 5. Pinion, ring 6. Hunting, non-hunting, partial non-hunting 7. Three, two 8. Helical, planetary, hypoid 9. Clutch pack, cone clutch, and viscous clutch 10. Ball-type, straight roller, tapered-roller Multiple Choice 1. C 2. B 3. C 4. B 5. B 6. D 7. C 8. C 9. D 10. C •Shop Manual, Pages 310–312 ASE-Style Review Questions 1. B 2. C 3. C 4. A 5. B 6. C 7. B 8. C 9. D 10. C ASE Challenge 1. D 2. A 3. D 4. B 5. D