GROUP 5 REAR AXLE ASSEMBLY - The Old Car Manual Project

advertisement

(171)

REAR AXLE ASSEMBLY

SPECIFICATIONS

5-1

GROUP 5

REAR AXLE ASSEMBLY

SECTIONS IN GROUP 5

Section

5-A

5-B

Page

Subject

Rear .Axle Specifications and Descript.ion .. . .. .. . . . . . . . . . . . . . . .

Diagnosis of Rear Axle Noise . . . .

Section

5-C

5-D

5-1

5-5

Page

Sublect

Rear Axle Repairs Procedures . . . 5-9

Repairs Requiring Removal of

Rear Axle Assembly . ... . . . . ... . 5-26

SECTION 5-A

REAR AXLE SPECIFICATIONS AND DESCRIPTION

CONTENTS OF SECTION 5-A

"aragraph

5-1

Sublect

Rear Axle Specifications . . . . . . . . .

Page

Paragraph

5-1

5-2

Subject

"age

Description 6f Rear Axle .

5-4

SERVICE BULLETIN REFERENCE

Bulletin No.

Page No.

SUBJECT

5-1 REAR AXLE SPECIFICATIONS

a. Tightening Specifications

Use a reliable torque wrench to tighten the

parts listed, to insure proper tightness without

Location

"art

Nut

Screw

Nut

Bolt

Bolt

Bolt

Bolt

Bolt

Nut

Nut

Nut

Bolt

Bolt

Nut

Nut

Nut

Nut

Nut

Stud

Bolt

straining or distorting parts. These specifications are for clean and lightly lubricated

threads only,. dry or dirty threads produce

increased friction which prevents accurate

measurement of tightness.

Pinion Bearing Lock

Pinion Bearing Lock Sleeve Lock . . . . . . .

Bearing Lock Sleeve Lock Screw

Differential Carrier Bearing Cap

Cover to Axle Housing

Differential Carrier to Axle Housing

Torque Tube to Differential Carrier

Torque Tube to Torque Ball

Strut Rod U-Bolt

Strut Rod to Bracket Bolt

Strut Rod to Bracket or Spacer

Chassis Spring Lower End to Spring Seat

'

Chassis Spring Upper End to Frame

Radius .R od Pin Support to Axle . ' ,

Radius Rod Pin t o Axle

Radius Rod Front and Rear Su p por t t o Spr ing Seat

Rear Shock Absorber Link S t u d to Arm

Rear Brake Assembly to Axle Housing

Wheel Pilot to Axle Shaft

,

,

Wheel to Rear Axle Shaft ,

,

,,

' .. ,

,

.

.

.

.

.

.

.

.

.

.

.

.

, . . , . . , ..

,

.

.

.

.

.

,

.

Thread

Size

Torque-

E {6-16

150 min.

35-40

15-20

65-70

10-15

20-25

45-50

20-25

65-70

60-65

30-35

55-60

15-20

35-40

20-25

20-25

20-25

35-40

10-15

70-75

72-20

72-2 0

% -12

%-24

%-24

%-14

%-16

%-18

72-20

%-16

72-20

72- 20

72-20

%-24

%-24

%-24

~6-20

% -18

% -18

Ft. Lb••

b. General Specifications

Item.

Serle. 40-50

Serle. 70

Rear Axle Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. -+--Semi-Floating, Hypoid----+Drive and Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -+--Through Torque Tube----+-

5-2

SPECIFICATIONS

REAR AXLE ASSEMBLY

Ilems

R .A . Gear R atios, with Syncro-Mesh

.

Gea r and Pinion Teeth -Standard

.

Gear Ratio-Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

Gear and Pinion Teeth-Optional.

.

Gear Ratio-Optional

.

R.A. G ea r Ratios, with Dynaflow Drive

.

Gear and Pinion Teeth , 1st. 1948

.

Gear Ratio, 1st . 1948

.

Gea r and Pinion Teeth , Last 1948

Seri es 70 a nd 1949 Series 50-70

.

Gear Ratio, Last 1948 Series 70 and 1949 Series 50-70

.

Ring and Pinion Gear Set-Type

.

How Serviced .. . . . .. ... ...... . .. ... ... . .... ... .... . .. •. .. . . .. . . . . . ..

R ing Gear Atta ched t o Case

.

R.in.g Gear Sidewise Adjustment

.

Pinion T ype

.

Pinion Adjustment-Fore and Aft

.

Differential Side Gears and Pinions-Number

.

Type

.

Rear Axle Oil Capacity

.

Rear Axle Oil Specifications

.

:"u brica n t Drain

.

Pr o peller Shaft-Type

.

Location

.

Number of S plines - F ro n t end . . . . . .. . . .. . . . . ... . . . . . .. . . . . . . . . .. . . .• .

\xle Shaft-No. of Splines

.

( 172)

Ser ies 40-50

Series 70

49- 11

4.45 to 1

41-10

4.1 to 1

41-10

4.1 to 1

51-14

3 .6 to 1

'

51-13

3.9 to 1

49-11

41-10

4.4 5 t o 1

4.1 t o 1

Hypoid

Hypoid

+ - - -M a t ched Sets Only-~

+-- -1 2 C old -H ea de d Rivets--++ - - -2 Threaded Ad just ers------.+S t em

S tem

Sh ims

Shims

+-- - -2 Gea rs- 2 Pinions:----I~~

+Revacycle'- - - - - +

4 pts.

4 pts .

+-- - See Paragraph 1-9 - - --+

+--Housing Cover L ower B olts-+Tubular

Tubular

+--Enclo sed in T orque Tube---+16

16

12

12

c. Dimensi ons of Parts

\xle Housing-O .D. Minimum

O.D . at Gear H ousing

l'orq ue Tube-O.D. at Front End

O .D. at Middle

>ropeller Shaft-O.D . at Cen ter

O .D . at Front S plines

\xle Shafts-O.D. at Splines . .

.

O .D. at Wheel Bearing

~ing Gear Diameter-Pitch

iide Pinion Shaft-Diameter

Ung Gear Rivets-Diameter

.

.

.

.

.

.

.

+-- +-- ~

.

.

.

3 0/16"

11 %"

2"

3% "

11 7,,(6"

2"

3 1 ~"

3 1 ~"

2W

2W

-1.167" to 1. 168" - - --+

-1.295 " to 1.300 "- - --+

1.531 6 " t o 1.5321"- - -+

9. 375 "

9 .375"

W

.

'YI'6"

W

%"

d. Limits for Fitting a nd Adjustment of Parts

NOTE: Limits on fit of parts are for new parts only. "T" means tight and "L" means loose.

vxle Shaft End Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +-- ~acklash ,

Ring Gear-Desired. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

Min. and Max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

~acklash , S ide and Pinion Gears . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

;Iea rance, S ide Gear to Axle Shaft

Jiffer ent.ial Bearing Preload, Notches Tight on Adjuster, from "Free" Position . .

)ifferential Case F la n ge Run-Out, Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

)ifferential Side Bearin g - In C arr ier . . . . . . . .

................

On Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

'inion Bearing Lock S leeve- In Car ri er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

'inion Shaft Front Bearing- In Carrier

On Pinion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

' inion Shaft Rear Bearing-In Carrie r . . . . . . . . . . . . . .

'inion Shaft Rear Bearing C lea rance on P in ion . . . . . . . . . . . . . . . . . . .

Desired, After Assembl y .

..............

Maximum, After Ass embly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

'inion Setting, Mi crometer Reading-with Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . .

Allowable Variation . .. . . . ... . .. .. . . . . . .. . . . . .. . . . .. . . . . ... .. . . ... . . . .

'inion Shaft Spline in Propeller S haft

'ropeller Shaft and Pinion Assembly, Allowable Run-Out

ting Gear Run-Out, Maximum, When Installed on Ca se . . . . . . . . . . . . . . . . . . . . .

Vheel Bearing-In Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vheel Bearing on Axle Shaft, Bearing Pressed Into Housing

-.000 " to .008 "- - - - +

- - .008 " to .010"

-+

- -.008 " to .012"

-+

- -.000 " to .008 "- - - --+

-.0035 "L to .0005"T - - - -+

- - - - 2 Yz to 3

-+

.002"

.002"

+-- - - .0003 "L to .0019 "L--- -+

+-- - -.0012"T to .002 7"T

~

+- - - - .002"L to .01 7"L

~

+ - -- .0006"T to .0005"L- - --+

+-- - - -.000 " to .001"T - - - - -+

+-- - - .000" t o .0011 "T - - --+

+-- - - - Selected F it

~

.0005 "

.00 05 "

.0014 "

.00 14"

+-- -See fig. 5-26 or 5-2 7

~

%.00 1"

%.00 1"

+-- - -.0016 "T t o .0009 "L

~

+-- - - - See Fi g. 5-2 1

~

.003 "

.003"

+-- - - .0008 "T t o .0013 "L-~

+-- - - .000 " to .0031"L

~

+-+-+-+-+--

-

....

""'

~

w

<:»

;:IIl:I

m

»

;:iCI

THIRD

MEMBER

HOUSING

....m~

»

'"

m

'"

~

PIN

D'

~

BACKING PLATE

I~ LOCK SCREW

STRUT ROD

AND NUT

SLEEVE

4f=2i::=::: BEARING

~

'\

-PINION

....~

< --CARRIER

___ _ _ ......

SHAfT

-

c: -

)

~

SIDE

PINION

SIDE

GEAR

C

m

ADJUSTER

BEARING

LOCK

CASE

RING

LOCK SCREW

SHAFT

LOCK WASHER

n

'"

;:iCI

~

sz

U'I

I

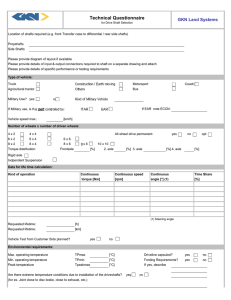

Figur e 5-1 -Rear Axle Assembly

W

5-4

DESCRIPTION

5-2 DESCRIPTION OF REAR AXLE

The rear axle assembly is the semi-floating

type in which the load is carried on the axle

shafts through bearings enclosed in the axle

housing. See figure '5-1. It has a torque tube

drive and a Hypoid type spiral bevel ring gear

and pinion set in which the centerline of the

pinion is below the centerline of the ring gear.

See figure 5-18.

The torque tube is joined to the differential

carrier to form a unit assembly called the third

member housing; the torque tube and carrier

are not serviced separately. This is because a

straightening operation is necessary to line up

the pinion bearing holes with front flange pilot

on torque tube. The third member housing is

bolted to the banjo type rear axle housing. Two

rear axle strut rods form braces between the

front end of the third member housing and the

outer ends of the axle housing to hold third

member square with axle housing. The torque

tube encloses the propeller shaft which is rigidly connected to the pinion through a splined

joint and a pin. See figure 5-1.

The pinion is supported in the differential

carrier by one or two Hyatt roller bearings

(rear) and a New Departure double-row radialthrust ball bearing (front) which is secured to

the shaft by a large lock nut staked in place.

One roller bearing was used during most of the

1948 model production. The last 1948 models

and all 1949 models have two pinion roller

bearings. 1948 model rear axles having two

roller bearings are identified by letters "BB"

REAR AXLE ASSEMBLY

(174)

stamped on bottom center of the rear axle

housing.

The pinion and bearing assembly is held in

position by 'a pinion bearing lock sleeve and

three cone-pointed lock screws which clamp the

double-row ball bearing against a shoulder in

the carrier. Shims placed between the bearing

and the shoulder provide correct relation of the

pinion with ring gear. See figure 5-1.

The ring gear is riveted to the differential

case which is supported in the differential carrier with two differential side bearings.

Threaded adjusters bearing against the outer

races of the side bearings provide means of

adjusting ring gear lash. The differential case

also houses two differential bevel side gears in

mesh with two differential bevel side pinions

mounted on a shaft which is anchored in the

case by a lock screw. See figure 5-1.

The splined inner ends of the axle shafts are

supported by the differential side gears. "Horseshoe" washers retain the axle shafts in the side

gears; washers are held in recesses in side

gears when differential pinion -spacer is installed. The pinion spacer is located between

the inner ends of the shafts and controls end

play of axle shafts. The outer ends of the axle

shafts are supported in the axle housing by

Hyatt roller bearings. Seals are provided on

both sides of each roller bearing to exclude dirt

and to prevent leakage of oil upon the brakes.

Rear axles used with Syncro-Mesh transmissions are equipped with either standard or optional gear ratios. See paragraph 5-1. The rear

axle ratio is indicated by numbers stamped on

the underside of axle housing.

(175)

REAR AXLE ASSEMBLY

NOISE DIAGNOSIS

5-5

SECTION 5-8

DIAGNOSIS

OF REAR AXLE NOISE

CONTENTS OF SECTION 5-B

Paragraph

5-3

5-4

Subiect

Elimination of External Noises . .

Rear Axle Noises . . . . . . . . . . . . . . .

Page

Paragraph

5-5

5-6

5-5

5-6

Sublecr

Checks for Cause of Rear Axle

Noise . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Gear Tooth C on tact . . .

P"ge

5-6

5-7

SERVICE BULLETIN REFERENCE

Bulletin No.

Page No.

5-3 ELIMINATION OF EXTERNAL

NOISES

When a rear axle is suspected of being noisy

it is advisable to make a thorough test to determine whether the noise originates in the tires,

road surface, front wheel bearings, engine,

transmission, or rear axle assembly. Noise

which originates in other places cannot be corrected by adjustment or replacement of parts

in the rear axle assembly.

a. Road Noise

Some road surfaces, such as brick or rough

surfaced concrete, cause noise which may be

mistaken for tire or rear axle noise. Driving on

a different type of road, such as smooth asphalt

or dirt, will quickly show whether the road

surface is the cause of noise.

b. Tire Noise

Tire noise may easily be mistaken for rear

axle noise even though the noisy tires may be

located on the front wheels. Tires worn unevenly or which have the surfaces of the nonskid divisions worn in saw-tooth fashion are

usually noisy, and may produce vibrations

which seem to originate elsewhere in the

vehicle. This is pa rticular ly true wi t h low tire

pressure. Some designs of non-skid treads may

be more noisy than others, even when tires

are new.

c. Test for Tire Noise

Tire noise changes with different road surfaces but rear axle noise does not. Inflating all

SUBJECT

tires to approximately 60 pounds pressure, for

test purposes only, will materially alter noise

caused by tires, but will not affect noise caused

by the rear axle. Rear axle noise usually ceases

when coasting with transmission in neutral at

speeds under 30 miles per hour; however, tire

noise continues but with lower tone as car

speed is reduced. Rear axle noise always

.

"11"

pu

an d" coa st" ,

changes when comparmg

but tire noise remains about the same.

d. Front Wheel Bearing Noise

Loose or rough front wheel bearings will

cause noise which may be confused with rear

axle noise; however, front wheel bearing noise

does not change when comparing "pull" and

"coast". Front wheel bearings may be easily

checked for noise by jacking up the wheels and

spinning them, also by shaking wheels to determine if bearings are loose.

e. Engine and Transmission Noises

Sometimes a noise which seems to originate

in the rear axle is actually caused by the engine

or transmission. To determine which unit is

actually causing noise, observe approximate car

speeds and condit ions under wh ich the noise is

most pr onounced, then stop car in a quiet place

t o avoid inter fe ri ng noises. With transmission

in neutral and clutch engaged, run engine slowly

up and down through engine speeds corresponding to car speeds at which the noise was

most pronounced. If a similar noise is produced

with car standing it is caused by the engine or

transmission, and not the rear axle. With trans-

5-6

NOISE DIAGNOSIS

rmssion still in neutral, run engine through

speeds while slowly disengaging and engaging

clutch. If noise disappears with clutch disengaged, it is caused by transmission. If noise"

continues regardless of clutch position, it is

caused by the engine.

5-4 REAR AXLE N OISES

If a careful test of the car shows that the

noise is not caused by external items as described in paragraph 5-3 above, it is then

reasonable to assume that the noise is caused

by the rear axle assembly.

a. Testing Rear Axle

The rear axle should be tested on smooth

road to avoid road noise. It is never advisable

to test rear axle for noise by running engine

with transmission in high gear with rear

wheels jacked up. Without normal loading to

take up allowable clearances of parts and the

cushioning afforded by the tires, the rear axle

will be quite noisy when operated by power

while resting on car stands.

b. Rear Wheel Bearing Noise

Noises in the rear axle assembly may be

caused by faulty rear wheel bearings, faulty

differential or pinion shaft bearings, differential side gears and pinions worn, or by a mismatched, improperly adjusted or scored ring

and pinion gear set.

A rough rear wheel bearing produces a vibration or growl which continues with car coasting with transmission in neutral. A brinnelled

rear wheel bearing causes a knock or click

approximately every two revolutions of rear

wheel since the bearing rollers do not travel

at the same speed as the rear axle and wheel.

c. Pinion Bearing Noise

Rough or brinnelled pinion bearings p r oduce

a continuous whine starting at a relatively low

speed. The noise is most pronounced on lig ht

load drive between 18 and 25 miles per hour.

d. Different ia l Side Gea r and Pinion Noise

Differential side gears and pinions seldom

cause noise since their movement is relatively

slight on straight ahead driving. Noise produced by these gears will be most pronounced

on turns.

e. Ring a nd Pinion Gear Noise

Noise produced by the ring and pinion gear

REAR AXLE ASSEMBLY

(176)

set generally shows up as drive noise, coast

noise, or float noise.

1. Drive noise is most pronounced on constant acceleration through the speed range of

15 to 45 miles per hour.

2. Coast nois e is most pronounced when car is

allowed to coast through the speed range from

45 to 15 miles per hour, with clutch engaged

and throttle closed.

3. Float noise is most pronounced while holding the car speed constant at intervals between

15 and 45 miles per hour.

4. Drive, coast, and float noises will be very

rough and irregular if the differential or pinion

shaft bearings are rough, worn, or loose.

5 -5 CHECKS FOR CAUSE OF REAR

AXLE N OISE

If there is any doubt about the cause of

noise in the rear axle assembly, the following

progressive checking procedure will assist in

determining the cause. The paragraph numbers given in the checks refer to paragraph in

which repair procedure is given.

1. Place car stands solidly under rear axle

housing so that wheels are clear of floor.

2. Spin rear wheels by hand while listening

at hubs for evidence of rough or brinnelled

wheel bearing. Care must be used to avoid mistaking differential gear noise for bearing noise.

If in doubt, remove rear axle shafts and bearings for examination (par. 5-8, 5-9, 5-12) .

3. If rear wheel bearings are not noisy, or

t hey are not responsible for all rear axle noise,

drain rear axle housing by removing lower

cover bolts, then reinstall bolts. Thoroughly

flush rear axle housing with SAE 10-W or

flushing oil. When flushing, put transmission

in h igh gear and run rear axle slowly for one

or two minutes. CAUTION: Do not suddenly

accelerate or "gun" the engine and do not exceed a speed of 25 MPH. Do not use gasoline,

kerosene, or steam for flushing (see par. 5-12).

Drain h ousing , remove cover and wipe out

housing wi th clea n cloths.

4. Check matching n umber s on ring and pinion gears to make sure that they are matched

set (par. 5-19).

5. Examine ge ar teeth for chips or scores

and for proper gear tooth contact (par. 5-6 &

fig . 5-2). Check ring gear lash with dial indicator (par. 5-23).

6. Check differential side bearings for proper

pr eloa d as follows. Loosen all bearing cap bolts

one f ull turn, tighten to 20 ft. lbs. torque, then

(177)

REAR AXLE ASSEMBLY

NOISE DIAGNOSIS

back off all 4 bolts 14 turn. Remove bearing

adjuster lock on one side and mark adjuster in

line with lock slot in bearing cap. Slowly back

off adjuster until bearing outer race stops turning, noting number of notches required to reach

the breaking point. The number of notches,

or bearing preload should be 2% to 3. If bearing does not turn as adjuster is back off, tighten

adjuster until bearing starts to turn, noting

number of notches required to just start bearing turning. This will indicate the number of

notches that bearing was loose. Bearings should •

be given preload of 2lj2 to 3 notches, using'

procedure given in paragraph 5-23.

7. If gear set is not mismatched, worn, or

scored, and checks made in steps 5 and 6 above

do not show cause for noise, remove differential ring gear and case assembly (par. 5-10).

Inspect differential side bearings (par. 1-13 &

1-14).

5-7

8. Test for pinion shaft bearing wear as

described in paragraph 5-1 step 2, and check

pinion setting (par. 5-21).

9. If pinion shaft bearings are worn or of

doubtful condition or pinion is not properly

set, remove pinion and propeller shaft assembly

(par. 5-11). NOTE: On Dynafiow cars, rear

axle assembly must be removed to install propeller shait spline oil seal. Replace bearings or

reset pinion as required.

5-6 CHECKING GEAR TOOTH CONTACT

The procedure described below may be used

before disassembly to check gear tooth contact

existing between ring and pinion gears, to

determine whether improper adjustment is

cause of noisy gear operation.

The procedure also may be used to check

adjustment following installation of gear set

when the specified tools are not available; how-

A SHOWS CORRECT CONTACT.

GEARS SET UP THIS WAY GIVE BEST RESULTS FOR NOISE AND WEAR.

B SHOWS HEAVY CONTACT ON HEEL OF

TOOTH .

GEARS SET UP THIS WAY WILL EVENTUALLY

BREAK OFF AT THE HEEL. TO CORRECT,

MOVE RING GEAR TOWARD PINION BUT

MAKE SURE THE:~E IS BACK LASH AS GEARS

CAN NOT RUN TIGHT.

C SHOWS HEAVY CONTACT ON TOE OF

TOOTH.

GEARS SET UP THIS WAY WILL EVENTUALLY

BREAK OFF AT THE TOE. TO CORRECT,

MOVE RING GEAR AWAY FROM PINION.

D SHOWS HEAVY CONTACT ON FLANK OF

GEAR TOOTH.

G EARS SET UP THIS WAY A RE NOISY. TO

CO RR ECT, M O VE PINIO N O UT UN TIL CONTACT COMES TO THE FULL W ORKIN G DEPTH

OF GEAR TOOTH WITHOUT LEAVING LOWEST POINT OF CONTACT. SEE A

E SHOWS HEAVY CONTACT ON FACE OF

GEAR TOOTH.

GEARS SET UP THIS WAY ARE ALSO NOISY .

TO CORRECT, MOVE PINION IN UNTIL CONTACT REACHES LOWEST POINT ON GEAR

TOOTH . SEE A

Figure 5-2-Gear Tooth Contact Corrections

THE HEELOF GEAR TOOTH IS THE

LARGE END AND THE TOE IS THE

SMALL END

WO RKING DEPTH

CLEARANCE

5-8

NOISE DIAGNOSIS

ever, it is not recommended as a regular substitute for these tools . The use of the pinion setting gauge and dial indicator as prescribed in

installation instructions will provide a more

accurate adjustment of ring and pinion gears

and will save considerable time.

1. Place car stands solidly under rear axle

housing 'so that wheels are clear of floor.

2. Clean rear end of chassis, bottom of body,

and axle housing, r emoving as much dirt as

possible. DO NOT TAKE CHANCES OF GETTING ABRASIVE SUBSTANCES INTO

AXLE HOUSING OR BEARINGS.

3. Drain rear axle housing by removing

lower cover bolts, then reinstall bolts. Thoroughly flush rear axle housing with SAE 10-W

or flushing oil. When flushing, put transmission

in high gear and run rear axle slowly for one

or two minutes. CAUTION: Do not suddenly

accelerate or "gun" the engine and do not exceed a speed of 25 MPH. Do not us e gasoline,

kero sene, or steam for flushing (see par. 5-12) .

Drain housing, remove cover, and wipe out

housing with clean cloths.

4. Wipe ring and pinion gear teeth dry with

clean cloth. Paint ring gear teeth lightly and

evenly with red lead or white lead of suitable

consistency.

.

5. Lightly apply the brakes so that rear

wheels have a one-hand drag, then run the engin e slowl y with transmission in first gear,

then in r everse, for just a few seconds.

6. Compare marks produced on gear teeth

with marks shown in views A through E in

figure 5-2. Marks should be as shown in view

A. If marks are as shown in views B, C, D, or

REAR AXLE ASSEMBLY

(178)

E, the gears are not correctly adjusted and

may be noisy in operation.

7. Gears marked as shown in views B, C, D,

or E should be adjusted as indicated opposite

these views in figure 5-2. Adjustment will be

satisfactory in most cases where gears are

comparatively new and not improperly worn

or scored. If gears have been run long enough

to wear the teeth appreciably, however, it is

unlikely that adjustment will produce quiet

operation.

8. Procedure for sidewise adjustment of

ring gear is given in paragraph 5-23. If adjustment of pinion is required it will be necessary

to remove pinion and propeller shaft and

change total thickness of pinion bearing shim,

as described in paragraph 5-22.

9. After making the adjustment indicated,

re-paint ring gear teeth and run gears aga in

as described in step 5, above. Final marking

should be as shown-in view A, figure 5-2. Wh en

proper tooth contact is obtained, wipe lead

from gears and ca r r ier with cloth moistened

with clean gasoline or kerosene. Wipe out

housing with clean cloths.

10. Pour a liberal quantity of rear axle lubricant on gears and bearings, and turn rear

wheels to work lubricant into all surfaces.

11. Install housing cover, using a new gasket

and coating bolt threads with white lead to

avoid oil leaks. Align filler plug with first bolt

hole to right of lower center bolt hole in

housing. This change from straight down position increases oil level to 4 pints.

12. Remove car stands so that car is level,

and fill housing to filler plug opening with

approved rear axle lubricant. See paragraph 1-9.

(179)

REPAIRS

REAR AXLE ASSEMBLY

5-9

SECTION 5-C

REAR AXLE REPAIR PROCEDURES

CONTENTS OF SECTION 5-C

Paragraph

5-7

5-8

5-9

5-10

5-11

5-12

5-13

5-14

5-15

5-16

Sublect

Introduction . . . . . . . . . . . . . . . . . .

Removal of Axle Shafts

Removal of Wheel Bearings and

Oil Seals

Removal of Differential Ring

Gear and Case Assembly

Removal and Disassembly of Propeller Shaft and Pinion Assembly

Cleaning and Inspection of Parts

Replacement of Differential Bearings (If necessary)

Replacement of Ring Gear (If

necessary) . . . . . . . . . . . . . . . . . . ..

Assembly of Pinion, Bearings and

Propeller Shaft

Straightening Pinion and Propeller Shaft Assembly, using Fixture

Page

Paragraph

5-9

5-10

5-17

5-10

5-11

5-11

5-12

5-13

5-14

5-15

5-16

Sublect

Straightening Pinion and Propeller Shaft Assembly, using V-Blocks

5-18 Installation of Pinion and Propeller Shaft Assembly

5-19 Installation Marks on Matched

Ring and Pinion Gear Sets

5-20 Pinion Setting Gauges J-681A and

J-2197

5-21 Checking Pinion Settings with

Gauge

5-22 Adjustment of Pinion Gear . . . . .

5-23 Installation of Differential Ring

Gear and Case Assembly . . . . . . . .

5-24 Installation of Rear Wheel Bearings and Oil Seals . . . . . . . . . . . . . .

5-25 Installation of Axle Shafts

Page

5-16

5-17

5-18

5-19

5-22

5-22

5-23

5-24

5-24

SERVICE BULLETIN REFERENCE

Bullelln No.

Page No.

5-7 INTRODUCTION

a. Arrangement and Use of This Section

This section contains procedures for repair

or replacement of all internal components of

the rear axle assembly except the brakes. The

procedures are arranged inthe progressive order that should be followed for a complete

overhaul of the rear axle.

The procedures should be followed in the

order given, to the extent required to accomplish removal, inspection, installation, and adjustment of only those parts that are to be

repaired or replaced. Individual procedures are

given in separate numbered paragraphs to aid

in selecting the particular procedures required

when less than a complete overhaul is being

performed.

All procedures in this section will be required

for replacement of a ring and pinion gear set.

These parts are furnished in matched sets

only; individual gears are not available. The

matched sets are furnished separately and also

with the ring gear riveted to a differential case.

Sublect

b. When to Remove Rear Axle Assembly

On cars equipped with Syncro-Mesh transmissions, it is not necessary to remove the rear

axle assembly for any of the repairs outlined

in this section; however, these procedures can

be used as outlined if the assembly is removed

from the car.

The rear axle assembly should be removed

from the car before overhaul (par. 5-26) if

there is external indication of damage to rear

axle or third member housings or strut rods,

or if oil is leaking at torque ball or third member flanged joints. These conditions cannot be

corrected with the rear axle assembly under

the car.

On cars equipped with Dynaflow Drive, it is

necessary to remove the rear axle assembly

from car whenever the propeller shaft must be

r emoved. The propeller shaft spline oil seal

located on front end of propeller shaft (fig.

5-33) cannot be properly installed with third

member housing connected to the torque ball.

c. Identification of Removed Parts

When a number of similar parts are removed

5-10

REPAIRS

that are to be re-installed make certain that

they ar e marked, tagged, or kept separated so

that th ey will be installed in their original positions. Th is is particularly im portant in the case

of bearings and rac es, side gears and pinions,

th eir'thrust washer, bearing caps and adjusters.

REAR AXLE ASSEMBLY

(180)

LOCK WASH ER

d. Special Tools

Many rear axle parts returned to the factory

for credit are damaged as the result of improper methods of removal, indicating that the

required special tools were not used. It is

reasonable to assume, therefore, that the required special tools are not being used for

installation and adjustment of new parts in

many cases, with the result that new parts are

damaged during installation and for this reason

fail to give satisfactory service.

The special tools specified in the procedures

covered in this bulletin are absolutely essential

to the proper performance of these procedures.

They are designed to save time and, of even

greater importance, to avoid damage to parts

and to insure proper assembly. These special

tools should be available to all mechanics who

perform rear axle work, and they should be

used by the mechanics as specified in the following procedures.

e. Break- In W it h New Gears

When new gears a re installed in a rear axle

assembly by the dealer, the car owner must be

cautioned to operate the car in the same manner as he would a new car, for a reasonable

length of time until the new gears have r un in

smoothly.

New gears may be scored during break-in

by sustained high speed driving, harsh use of

clutch causing rear wheels to spin, and by

coasting at high speed with clutch disengaged

and engaging clutch suddenly.

Do not exceed 50 MPH for the first 500

miles and do not exceed 70 MP H for th e second

500 miles.

'/"'~-- REMO VER J- 151 5

Figure 5-3-Removing Axle Shaft lock Washer with

Remover J 1515

3. Remove cover and drain rear axle housing.

4. Remove differential side pinion shaft lock

screw, push pinion shaft from differential case,

and remove spacer and pinions.

5. Push each ax le shaft inward and drive the

horseshoe-shaped lock washer from grooved inner end of axle shaft, using Remover J 1515.

See figure 5-3.

6. Support the axle shaft while pulling it

out of axle housing to avoid damaging the

wheel bearing oil seals. CAUTION: Do not pull

an axle shaft part way out of housing and allow

it to rest on oil seals because this will damage

seals; always completely remove shaft f rom

housing.

7. See paragraph 5-25 for installation procedure.

Fig ure 5- 4-Re mo ving Wheel Bearing a nd O il Seal w ith

Re move r J 1436

5-8 REM O V AL OF AXLE SHAFTS

5-9 REMOVAL OF WHEEL BEARINGS

AND OIL SEALS

1. Place car stands solidly under rear axle

housing so that wheels are clear of floor, then

remove rear wheels.

2. Clean the rear end of chassis, bottom of

body, axle housing, wheels and tires, and under

rear fenders, removing as much dirt as possible. DO NOT TAKE CHANCES OF GETTING ABRASIVE SUBSTANCES INTO

AXLE HOUSING OR BEARINGS.

1. After removal of axle shaft (par. 5-8),

disconnect lin k from sh ock absor be r arm.

2. Disconnect brake pipe from wheel cylinder and cover openings in pipe and cylinder

with plugs or tape to exclude dirt.

3. Remove bolts holding brake backing plate

to housing and remove brake assembly. Support

brake assembly to prevent injury to the brake

cable.

(181)

REAR AXLE ASSEMBLY

4. Remove outer oil seal and roller bearing,

then remove inner oil seal, usi ng Remover

J 1436 . See figure 5-4.

5. See paragraphs 5-12 and 5-24 for inspect ion and installation procedures.

REPAIRS

5-11

a number of times while observing indicator

reading. A reading in excess of .0015" indicates

that bearing is worn enough to produce noisy

gear operation.

3. Loosen lock nuts and remove three pinion

bearing sleeve lock screws from housing.

5- 10 REMO V A L OF DIFFERENTIAL RING

GEAR AN D CASE ASSEMBLY

1. After removal of both axle shafts (par.

5-8), remove differential side gears and thrust

washers from case to pr event them falling out

and being damaged.

2. If ring and pinion gear set has been operating quietly and is to be reinstalled, it is advisable to wash lubricant from between gear

teeth and check existing gear lash by means

of a dial indicator, so that t he same lash ca n

be used when parts are reinstalled, to avoid

changing gear tooth contact. See paragraph 523, steps 8 and 9.

CAUTION: Backlash will be reduced w hen

pinion is locked by prying up with a bar if

there is excessive pinion lift due to worn bearings. See paragraph 5-11, step 2.

3. Mark the differential bearing caps so they

can be reinstalled in original positions on the

carrier. Interchanging the caps will cause damaged threads because caps are threaded in production while bolted to carrier.

4. Remove bearing adjuster locks, loosen one

adjuster, support the differential gear and case

assembly while removing bearing caps and

adjusters, then lift differential assembly and

bearing races out of carrier.

5. See paragraphs 5-12 and 5-23 for inspection and installation pr ocedur es.

Fig u re 5-5-Testing Pinion Bearing Wear

5 -1 1 REMOVAL AND DISASSEMBLY OF

PROPELLER SHAFT AND PINION

ASSEMBLY

1. If ring and pini on gear set has been operating quietly and is to be reinstalled, it is

advisable to check the pinion setti ng a fter r emoval of differential case (par. 5-10) so that

the same setting can be used when parts are

reinstalled to avoid changing gear tooth contact. See paragraph 5-21.

2. At this point it may be desirable to t est

pinion shaft bearing wear without removing

pi nion shaft. Install 1 14 " extension on stem of

dia l ind ica tor and mount indicator to bear

down against center drilling in pinion gear,

with indicator stem as near vertical as possible.

See figure 5-5. Pry up on pinion gear with bar

Fig ure 5-6-Re mov ing Pin ion a nd Propeller Sha ft w ith Pull e r

4. P ull pinion and propeller shaft assembly

re arward out of third member housing, using

Pinion Shaft Puller. See figure 5-6.

5. Remove all pinion bearing shims from

propeller shaft and third member housing to

prevent damage or loss.

6. File or cut off one end of propeller shaft

coupling pin and drive out the pin, then pu ll

pr op e ll e r s haft fro m pinion using Press

J 1292-B. See figure 5-7.

7. Drive up staked section of pinion bearing

lock nut with cape chisel and remove nut, grip-

5-12

REAR AXLE ASSEMBLY

REPAIRS

Figure 5-7- Pin ion Press J 1292-B

( 18 2 )

water and when contaminated with even small

quantit ies of water it has a deteriorating effect

on the lubricant. For t his reason steam' or

water should not be used for flushing rear axle

assemblies. If us ed on rear axle parts which

are disassembled, extreme care must be used

to thoroughly dry all parts before installation.

Gasoline, kerosene, or other distillates are

satisfactory for cleaning parts when removed

from r ea r axle housing, if parts are thoroughly

dried before installation. They should not be

used in an assembled rear axle, however, because if all traces of the cleaner are not r emoved the fresh lubr icant will be contaminated .

For this reason, SAE 10-W or flushing oil

only is recommended for flushing and cleaning

an assembled rear axle.

a. Bearings

Thoroughly clean and inspect all bearings as

described under Bearing Service (par. 1-13 &

1-14). Be particularly careful to inspect rear

wheel bearings, including inner race on axle

shafts, for corrosion caused by rust and for flat

spots on roll ers.

b . O t h er Parts

' - - --

BURRLD BY

PIPE WRENCH

Figure 5-8-Mutila ted Bea ring Lock Nut

ping pinion shaft on splined end in vise. Do

not grip pinion teeth in a vise even though

soft jaw liners are used. NOTE: Figure 5-8

shows a bearing lock nut which has been mutilat ed so that it is unfit for use . Th e stake d edge

has been completely cut away in st ead of bein g

raised, and the hexagon section has been badly

burred by us e of a pipe wrench.

8. Press off pinion front bea r ing using blocks

under outer race of rear bearing, t hen remove

all other parts from pinio n shaft. NOT E : T he

doubl e-row f ront bearing is pre loaded and

normally will have a slight drag when installed

on pinion. Do no t condemn bearing until inspected as specified in paragraph 1-14.

9. See paragraphs 5-12 and 5-15 through

5-22 for inspection, assembly, and in stallation

procedures.

Wash all other parts in clean gasoline or

kerosene, and wipe dry with clean cloths.

Thoroughly wash out interior of rear axle and

third member housings and wipe dry with

clean cloths. Blowout all dirt with clean, dry

air stream.

c. Gears

Carefully inspect all gears for scores on face

of teeth, fo r chipped teeth and for excessive

wear. Examine ring gear and pinion for improper tooth contact. See figure 5-2.

5- 1 2 CLEANING AND INSPECTION O F

PARTS

Hypoid lubricant is extremely aller gic to

Fig ure 5- 9-Checking . We ar of Pinion Rea r Bearing

(183)

REPAIRS

REAR AXLE ASSEMBLY

d. Pinion and Rear Bearing

The desir ed clearance between pimon and

the rear (roller) bearing is .0005". The maximum all owable clearance f or qu iet 'gea r operation is .0014". E xcessi ve clea rance at this point

is usua lly ca used by wear of the r oller bearing.

Wear of the r oller bea ri ng ma y be checked

with a micrometer. Befor e chec king, m ak e certain that bearing is ab solutely clean a nd that

micrometer is accurate at zero readin g. Measure across the outer race a nd a roller a t f our or

five points around bearing as shown in figure

5-9, using care to ad j ust micrometer lightly t o

high points of r oller and race to insure an

accurate reading. The m icrometer will read

.6756" to .676" if bearing is satisfactory for

us e. If reading is less than .6756" the bearing

is worn and should be discarded .

5-13

e. Pinion and Propeller Shaft

Chec k for wear of splines on pinion and in

the p r opeller shaft. P in ion m us t be a tight fit

in pr opeller shaft when parts are a ssem bled.

f. Rear :\xle and Third Member Housings

A sprung ho us ing sho uld be r epla ced ;

straight ening is not re com me nded. A housin g

must never be heated with a torch as this may

produce soft spots in the metal in w hich f atigue

and breakage may deve lop in service.

Insp ect third member housing for : oil leak

a t torqu e ball and a t flanged joint between

t orque tube and carr ier ; cracked torque tube ;

strut rod brackets br oken or cracked at w elds ;

pinion shaft bearing bor es galled or worn due

to bearing turning in housing ; str ipped or damaged threads in side bea ring pedestals or caps.

See paragraph 5-28 f or replacem ent of housing.

g. Parts Replacement

\

All parts of rear axle assembly that a re excessively worn, scor ed, ch ipped , or otherwise

damaged should be replaced wit h n ew parts to

insure qu iet operation and satisfact or y se r vice

after assembly.

Figure 5-10-Checking Clearance Betw""n Pinion and

Roller Bearing

An alternate method of checking clearance

between pinion and roller bearing is shown in

figure 5-10. Obtain a piece of tough paper, such

as t yp ewriter "second" sheet which m easures

.0015" thick (use micrometer) and cut a test

strip :%6" w ide . Place bearing on pinion about

lA." above spacer, insert paper test strip between two bearing ro ller s and rotate bearing

until strip is under one roller . If clearance is

sat isfact or y, the bea r ing will hang on the paper

strip a nd the paper strip cannot be pull ed out.

If bearin g drops of its own weight, or paper

strip ca n be ea sily pulled out, the clearance is

excessive and bearing should be discarded.

NOTE: If roller bearing is w orn excessive ly,

it is quite likely tha t the dou ble-row front bearing is worn so that it no longer has any preload. Inspect this bearing very carefully and

discard if loose or doubtful.

Figure 5-11-Removing Diffe rential Bea ring Using Puller J 22 41

5-13 REPLACEMENT O F DIFFERENTIAL

BEARINGS (IF NECESSARY)

1. If a differential bearing is to be r eplaced,

or removed from old differ ent ial case and installed on new ca se, pull bearing from case

using Bearing P ulle r J 2241. See figure 5-11.

The ends of puller j aws fit into notches in differential case so that pressure can be applied

to bearing inner r ace. Do not pull on roll ers .

5-14

REPAIRS

2. Before installing diff erenti al bearing, examine bearing seat on differ ential case for

bur rs or scores. Remove high metal with a mill

file and coat seat with engine oil or white lead.

Figure 5-12-lnstalling Differentia l Bea ring Using Replacer J 2242

3. Install bearing, using Replacer J 2242,

which is designed to pilot in the case and bear

squarely against bearing inner race. See figure

5-12. Bearing must be pressed tight against

shoulder on case.

REAR AXLE ASSEMBLY

(184)

ri v ets ar e drilled and dri ven out from case side,

m etal is sheare d f rom surface of rive ts by

shar p edge of holes in gear. See figure 5-14.

This not only makes removal more difficult but

will distort the case /lang e so tha t a n ew gear

installed. on case wi ll not run true.

Figure 5-14-Gear Imp rop erly Removed

3. After removal of gear, check machined

face of case flange for burrs, particularly

around rivet holes. Clean off all burrs with a

mill file. Place case in Test Fixture U4-B and

check run-out of machined surface of flange

with dial indicator. See figure 5-15. Case may

be located in fixture upon side bearings as illustrated, or upon bearing seats if bearings are

re moved from case. If r un-out exceeds .002",

the flange must be trued up in a lathe to not

over .002" run-out.

4. Check matching numbers on new ring

gear and pinion to make sure the two parts

Figure 5-1 3-Removal of Ring Gear Rivets

5-14 REPLACEMENT OF RING GEAR

(IF NECESSARY )

1. Center punch all ri vet heads on ring gear

side, placing ma rks in center of heads. Dr ill

rivet approxim ately Y2" deep with 1,4" drill.

See figur e 5-13.

2. Whil e supporting flange of differential

case on suitable block , insert punch in drilled

hole and drive each rivet out; rivets will be

easily parted when driven out. NOTE: When

rivets are in stalled, th ey expand more in the

softer case than in th e harder ring gear. I f

Fig ure 5-15 - Checking Run-Ou t of Ca se Flange in Fixture U 4-B

(185)

REAR AXLE ASSEMBLY

have not been mixed with another gear set.

See figure 5-23. .

5. After making sure that su rfaces of case

flange and ring gear are clean and free of

burrs, bolt gear to case using eleven ( 11 ) ~6 " x

1% " bolts with %" SAE nuts placed in rivet

hole counte r bor es to act a s spacers. CAUTION :

It is very importan t to hav e th ese part s bolted

tight tog ether. Do not use washers over rivet

hole counterbores since they will bend and permit parts to separate slig htl y durin g ri veting

operation.

REPAIRS

5-15

as gear may be drawn t o one side and r un

eccent r ic.

9. After all ri vets a re installed, rechec k for

run-out at back of gea r. See figure 5-16. Runout must not exceed .003" .

Figure 5- 17 -Riveting Ring Gear to Case in Riveting J ig J 2196-A

5-15 ASSEMBLY OF PINION, BEARINGS

AND PROPELLER SHAFT

Figure 5-16-Checking Run-Out of Ring Gear in Fixture U 4-B

6. Place bolted assembly in Test Fixture

U4-B and check run-out of back side of gear.

See figure 5-16. If run-out exceeds .003", che ck

for burrs, uneven bolting condition, or distorted

case flange.

7. Place bolted assembly in Ri veting Jig

J 2196-A with cas e flange up. See figure 5-17.

Use only new rivets of corr ect part number,

which allow ~~6 " of shank for heading. Install

rivet in the one open hole from gear side and

securely head it up cold, which requires a pressu r e of eight (8) tons. CAUTION: Excessive

pres sure may cause riv et to squeeze out between gear and case !lan ge, there by distorting

th ese parts. N ever heat riv ets to facilitate

heading because hot ri vets shrink and become

loose in holes during cooling , furth ermore, the

head s may crack off.

8. Remove bolt diametrically opposite new

rivet and inst a ll another rivet in like manner.

Finish riveting by working back and forth

across gear, using even pressure on all rivets;

do not install rivets consecutively around gear

1. Install parts on pinion shaft in the following order : r ear bea r ing spacer, rear bearing

(roller), bearing lock sleeve with thick end

toward spline, front bearing (ball) with shielded

side t oward spline. See figure 5-18. Press f ront

bearing solidly aga inst shoulder on pinion

shaft, using a t ube of proper size to bear

against inner r ace only. NOTE : B earing may

be brinnelled if driven in to place.

2. Install bearing lock nut with thin side

toward spline. While g ripping splined end of

,\~.J,rtl'i. ~\~~~~ER

'"':' (C

~ .

I

-

7 '

-

I

BEA

. RING

DOUBLE ROW BALL BEARIN G

i

\ SHIMS

I\

.. . \ I

I;r

~.I \

I

LOCK NU T

-~l. 1

tt

1• • •_,~.."'7-=~

.r.

i f'

~

.r.

~

•••

CJ I

,~[L.

~w)/JJI'\~

,

"

VJ '

J

.

_

L: LOCK

I~~

SLEEVE

HYPO ID O FFSET

Figure 5-18-Gear Set with Bearings and lock Sleeve-1949 Model

5-16

REPAIRS

REAR AXLE ASSEMBLY

pimo n in vise, tighten nut to a minimum of

150 ft. lbs. torque; nut must hold b ia r ing tight

against shoulder on pinion. Do not grip pinion

teeth in vise even though soft jaw liners are

used. Stake thin edge of nut down into notch

in pinion.

3. Coat splines of pinion and propeller shaft

with white lea d, then press pinion into propeller shaft until coupling pin holes are aligned,

using Press J 1292-B. See figure 5-7. Pinion

m ust not be loose fit in propeller shaft. Install

a new coupling pin and solidly rivet both ends.

I

IMPORTANT: When ever a pinion and propeller shaft are assembled tog ether the complete assembly must be checked for straightness

regardless of whether new or orig inal parts ar e

assembled. S ee para graphs 5-1 6 and 5-1 7 below.

a

( 186)

it to within .015" runout. Recheck for run-out

after each springing operation.

5-17 STRAIGHTENING PINION AND

PR~PELLER SHAFT ASSEMBLY,

USING V-BLOCKS

If the fixture shown in figu re 5-19 is not

available, the pinion and propeller shaft may

be checked and straightened using V-blocks or

rollers and a dial indicator.

1. Support the assembly on V-blocks placed

under the machined section just to rear of

splines at "A" and under the rear (roller)

bearing at " B" . See figu re 5-21.

2. Mount a dial indicator so that readings

for run-out can be taken successively at points

"C" located 3" from ea ch end of shaft tube,

Figu re S-19-Straightening Propeller Shaft in Fixture

5-16 STRAI GHTENING PINION AND

PROP ELLER SHAFT ASSEMBLY,

USIN G FIXTURE

The pinion and propeller shaft assembly may

be quickly and sat isfactorily checked and

straightened by means of the fixt ure shown in

figure 5-19. This fixture sh ould be made locally,

using any 1940 through 1949 model Buick diff erential carrier, as shown in figure 5-20.

1. Mount the pinion and propeller shaft

assembly in the fixture, being sure to tighten

pinion bearing lock screws evenly and securely

to press pinion f r ont bearing solidly against

shoulder.

2. Mount a dia l indicat or on a rod fastened

to a block of sufficient weight to hold the indicator button firmly agai nst t he ground portion

of the propeller shaft, j ust to the rear of t he

splines a s shown in figure 5-19.

3. Turn the sh aft by hand from t he pinion

end a nd note the amount of r unout as shown

by the in dicator. The t otal indicator reading

should not exceed .015" .

4. If the reading exceeds .015", turn shaft

t o high point on indicator and force end of

shaft downward by hand sufficiently to spring

point " E " at m iddle of shaft tube, point " G"

at front (ball ) bearing, and Point " H " at front

end of splines. Whe n checking points "C " and

"E", ca r e must be taken not to permit the

seam or hollow spots on tube to give a "bounce"

to indicator and thus show a wrong indicator

r eading.

3. Check run-out at points "C" first. If t otal

indicator reading is .005" or les s, the shaft is

OK at these points. If run-out exceeds .005",

support the shaft at "A" and "D" (under lock

sleeve) and exer t pressure against high side of

shaft at point "F" located on end of shaft tube

where run-out exists. Use steady pressure and

not shock blows to spring shaf t as requir ed to

bring run-out at points "C" within .002".

4. Check run-out at point " E" after correcting any run-out at point s " C" . If run-out at

" E" exceeds .010" t ot al indicator r eading, support the sh aft at points " F" and exe rt steady

pressure against high side of sh aft a s required

t o bring r un-out w it hin .010" .

5. Check run-out at point "G " after correcting run-out at points "C" and "E". If runout at " G" exceeds .001" total indicator reading, support the shaft at points "A" and "D"

REAR AXLE ASSEMBLY

(187)

REPAIRS

'-#~R

CARRIER

"

I'

-,_.~

5-17

I

I

I

I

~t-+-+-'<i" ~_

I~-+~"'I:-fi

" 2; I

16-~O~~Q~~SHER

&1IT

0

3j6

SUPPORT------

E

i

3Th

9 - 12X 1- HEX HEAD CAP SCREW

16

9 2'

1397249 ASSEMBLY ' y

-!-1. -

,~

~ -14X '.!.HEX

I

-k

HEAD CAP SCREW

LbcK WASHER

I

,J'"

5

"8 DIA .

l

2 HOLES IN EACH LEG

.

7

i6

lk

.

-

f,

44

J

-:.11 ----==

k- ~ ~

'~'~

oJ

1.

2

.!..R

2

.i==

=::r-

8

,,.j,,

I

I

!I

·_ 1 ,

lU

2'R

.

I

I

,

~

t.~R

,

f--

1 - - - - -7 ~

-=---_ooI---+

3 2=_ 15

.::..::

--I

16 -

916

9

'6

1

]

14 LENGTH AS REQ'D

14 NUT

2. 18

k

L.OCK WASHER

~ PLAIN

WASHER OPTIONAL

4- REQ'D .

t

DIA .2'HOLES

Figure 5-20-Fixture for Straightening Propeller Shaft

and exert steady pressure at the rearward

point "F" on high side of shaft.

6. Finally, re- check run-out at points "C",

"E" and "G" to make sure that run-out is

within specified limits at all points. The runout at point "H" should t hen be within .002"

total indicator reading. More than .002" runout at "H" will cause rapid wear of universal

H

I

ALLOWABLE INDICATOR

READING RtNOUT .005"

~q

A

~ 3"

l-F

5-18 INSTALLATION OF PINION AND

PROPELLER SHAFT ASSEMBLY

Before installation of pinion and propeller

shaf t assembly make certain t hat interior of

C

EI

C

I

ALLOWABLE INDICATOR

READING R C :"

joint bushing and possible leakage of oil from

transmission into rear axle.

ALLOWABLE INDICATOR

READING RUNOUT .010"

6~,-

i

I

GI

ALLOWABLE INDICATOR

ALLOWABLE INDICATOR

READING RUNOtT '005'~

' READING RUNOUT .00 1"

Figure 5-2l-Propeller Shaft Run-Out Specifications

3_

"-1----,

F-l

.

D-

B

5-18

REPAIRS

rear axle and third memo er housings are absolutely clean and dry. Also make certain that

parts to be installed are clean and that pinion

bearing shims are not damaged.

1. If the original third member housing and

pinion shaft are being used, place the original

number and thicknesses of pinion bearing

shims over propeller shaft against front bearing, to maintain original setting of pinion.

2. If a new pinion is being installed, change

the total thickness of shims by the difference

between the old pinion and new pinion setting

marks as explained in paragraph 5-19 below.

For example: if old pinion is marked " +3"

(plus 3) and new pinion is marked "-2"

(minus 2), total thickness of shims installed

should be .005" greater than shims removed.

NOTE: Shims furnish ed with new gear sets

are for use as required in adjw,;tment and are

not necessarily of corre ct total thickness.

3. Lubricate both pinion bearings thoroughly

with rear axle lubricant which should also be

used to hold shims against front bearing.

4. As pinion and propeller shaft assembly is

inserted into third member housing, turn pinion front bearing outer race so that the ball

loading groove will be straight up, to prevent

oil running through into torque tube. Also, turn

propeller shaft to engage splined front end in

splines of universal joint.

LSPACER J-l l 92 B- -,

Figure 5-22-Use of Pinion Bearing Spacer J 1192-B

5. As the pinion rear bearing enters third

member housing, place Pinion Bearing Spacer

J 1192-B, (14" thick) between bearing and

pinion gear so that bearing can be pushed into

REAR AXLE ASSEMBLY

(188)

place without binding against spacer on pinion

shaft. See figure 5-22.

6. Lightly tap the pinion forward with a

brass drift until the holes in pinion bearing

lock sleeve align with tapped holes in carrier,

then install the three sleeve lock screws.

Tighten each lock screw a little at a time until

lock sleeve and pinion front bearing are solidly

seated and screws are uniformly tightened to

35-40 ft. lbs. torque. Tighten lock nuts to 15-20

ft. lbs . torque; excessive tightening of nuts

may withdraw lock screws sufficiently to allow

end play of pinion bearing. Remove Spacer

J 1192-B.

7. Regardless of whether original or new

parts affecting pinion setting are installed,

check pinion setting with gauge as described in

the following paragraphs (5-19, 5-20, 5-21).

Figure 5-23-Ring and Pin ion Gear Markings

5-19 INSTALLATION MARKS ON

MATCHED RING AND PINION

GEAR SETS

All Buick ring and pinion gear sets are

selectively matched for quiet operation and

proper tooth contact. After matching, a serial

number is etched on one tooth of pinion and

on rear face of gear to aid in keeping matched

parts together. See figure 5-23. Parts having

different matching serial numbers must n ever

be used together.

Ri ng and pinion gear sets are matched in a

special t est machine which permits adjustment

of pinion depth in ring gear until a point is

reached where quiet operation and proper tooth

contact under load is obtained. At this point,

the setting of pinion with reference to centerline of ring gear is indicated by the machine.

(189)

REAR AXLE ASSEMBLY

This setting may vary a few t housandths of an

inch f r om the desi gn or "nominal" setting due

t o allowable variation in machining the parts.

In order to make it possible to duplicate the

matching setting of the pinion when the gear

set is installed in a third member housing, the

pinion is marked to indicate this setting with

reference to the "nominal" setting. The amount

in thousandths of an inch plus or minus the

"nominal" setting is etched on the small end

of one, pinion tooth. See figure 5-23. When a

pinion is marked "+" (plus) it means that the

pinion must be set at a distance from the centerline of the ring gear equal to the "nominal"

setting plus the amount indicated on pinion

t ooth. When a pinion is marked " -" (minus)

it means that the pinion must be set at a

distance equal to the "nominal" setting minus

the amount indicated on pinion tooth.

Pinion Setting Gauge J 681-A or J 2197 is

required in order to measure the pinion setting

after it is installed in a third member housing.

REPAIRS

5-19

THIMBLE

GAUGE J-2197

Figure S-2S-Micrometer Markings on Pinion Setting Gauges

J 681-A and J 2197

a. Pinion Setting Gauge J 681 A

Has the thimble and slee ve of the micrometer

marked exactly like a standard micrometer.

. See figure 5-25. Wh en the thimble is turned

clockwise t o extend the spindle, the r ead ing becomes less. Consequently, wh en this gauge is

used to measure depth of a pinion marked "+"

(plus) , the amount marked on the pinion tooth

must be subtracted from the " nominal" micrometer reading. Likewise, if pinion is marked

"-" (minus), the amount marked on the pinion

tooth must be add ed to the " nominal" micrometer reading.

E xample:

a

b

Nominal mi crometer r eading

.379

(fig. 5-26)

.

.379

Pinion marking (fig. 5-23)

.

-2

+3

Cor re ct setting (micrometer

re a ding )

.

3.76

.381

Figure S-2 4-Pinion Setting Ga ug e

5-20 PINION SETTING GAUGES J 681 -A

AND J 2 19 7

P ini on Setting Gauges J 681-A and J 2197

are identi cal except for the markings of the

micrometer secti on, as described below. Either

tool consists of a mi cromet er gauge, a checking

gauge, an adapter for use with hypoid gear

sets, and a clamp to hold the adapter in position. The micrometer gauge has sliding stepped

collars so that gauge can be used in all models.

The checking gauge should be used to test the

accuracy at zero of the micrometer gauge

before using the gauge. See figure 5-24.

b. Pinion Setting Gauge J 21 97

Has the thimble a nd sleeve of the micrometer marked the opposite of a standar d micromet er. See figure 5-25. When the thimble is

turned clockwise to extend the spindle, the

reading becomes greater. Consequentl y, when

this ga uge is used t o measure depth of a pinion

marked "+" (plus) the amount marked on

the pinion tooth must be added to the "nominal" micrometer reading. Likewise, if pinion

is marked "-" (minus), the amount marked

on the pinion tooth must be subtracted from

the "nominal" micrometer r eading.

VI

I

h)

o

PINION

:la

m

-a

~

SERIES

NOMINAL

MICROMETER

READING

1940-41-42

80-90

.203

1940-41 -42

40,50,60,70

.379

1946-7 -8-9

40,50,70

.379

YEAR

;;

CA

PINIO NS MARKED "0" USE THE NOMINAL

MICROMETER READING.

ADAPTER TO

BE USED WITH

HYPO ID GEARS ONLY

PINION SETTING TABLE

YEAR

MICROMETER READINGS FOR PINIONS MARKED "PLUS" (+)

SERIES

+1

+2

+3

+4

+5

+6

+7

+8

+9

+10

+11

+12

+13

+ 14

+1 5

1940-41-42

80-90

.20 2

.20 1

.200

.199

.198

.197

.196

.195

.194

.193

.192

.19 1

.190

.189

.1 88

1940-41 -4 2

40 ,50,60,70

.378

.377

.376

.375

.374

.37 3

.372

.371

.370

.369

.368

.367

.366

.365

.364

1946-7-8-9

40,50,70

.37 8

.377

.37 6

.375

.374

.37 3

.372

.37 1

.370

.369

.36 8

.367

.366

.365

.36 4

YEAR

SERIES

,

:la

;

:la

,m~..

~

MICROMETER READINGS FOR PINIONS MARKED "MINUS" (-)

-1

-2

-3

-4

- 5

-6

- 7

-8

-9

-10

-11

-12

-13

-1.4

-15

1940-41-42

80 -90

.204

.205

.20 6

.207

.20 8

.209

.21 0

.2 11

.2 12

.2 13

.2 14

.2 15

.216

.2 17

.21 8

1940-41-4 2

40,50,60, 70

.380

.381

.382

.383

.3 84

.385

.386

.387

.388

.389

.390

.391

.392

.393

.394

1946-7-8-9

40,50,70

.380

.381

.38 2

.383

.384

.385

.386

.387

.388

.389

.390

.391

.392

.393

.394

CA

CA

m

~

D'

~

,-....

....

\0

o

<;»

Figure 5-26-Plnlon Setti ngs wi th Gau ge J 681 -A

.,

""'

....

\0

....

'-'

::a

m

J>

SERIES

YEAR

1940-41-42

1940-41-42

::a

NOMINAL

MICROMETER

READING

80-90

,~..

m

J>

.977

40,50,60,70

CI'

CI'

m

~

.802

l:D

!:(

1946 -7-8-9

40,50,70

.802

PINIONS MARKED "0" USE THE NOMINAL

MICROMETER READING.

ADAPTER TO

BE USED WITH

I

HYPOID GEARS ONLY

PINION SETTING TABLE

YEAR

MICROMETER READINGS FOR PINIONS MARKED "PLUS" (+)

SERIES

+1

+2

+3

+ 4

+5

+6

+7

+8

+ 9

+10

+11

+12

+13

+ 14

+15

1940-41-42

80-90

.978

.979

.980

.981

.98 2

.983

.984

.9 85

.986

.987

.988

.9 89

.990

.991

.992

1940-41-42

40,50,60,70

.803

.804

.805

.806

.807

.808

.80 9

.810

.811

.812

.813

.814

.815

.816

.817

1946-7-8-9

40,50,70

.803

.804

.805

.806

.807

.80 8

.809

.810

.811

.812

.813

.814

.815

.816

.817

YEAR

SERIES

1940-41-4 2

80· 90

MICROMETER READINGS FOR PINIONS MARKED " MINUS" ( -)

- 1

-2

-3

- 4

-5

- 6

- 7

-8

- 9

-10

- 11

- 12

-13

- 14

-15

.976

.975

.974

.973

.97 2

.971

.97 0

.969

.968

.967

.966

.965

.964

.963

.962

1940-41-42

40 ,50,60,70

.801

.800

.799

.798

.797

.796

.795

.7 94

.793

.792

.791

.790

.789

.788

.787

1946-7-8-9

40 ,50,70

.801

.800

.799

.798

.797

.796

.795

.794

.793

.792

.791

.790

.789

.7 88

.7 87

::a

m

~

ii

CI'

VI

I

Figure $·27-Plnlon S.ttlngl with Gaug. J 2197

~

REPAIRS

REAR AXLE ASSEMBLY

Example:

Nominal micrometer reading

(Fig. 5-27)

.

Pinion marking (fig. 5-23)

.

Correct setting (micrometer

reading)

.

a

b

.977

+3

.977

-2

.980

.975

c. Nominal Micrometer Readings

Are different on Gauges J 681-A and J 2197

because of the differences in micrometer markings. The nominal micrometer readings for all

1940 through 1948 models when using Gauge

J 681-A are given in figure 5-26. The nominal

micrometer readings when using Gauge J 2197

are given in figure 5-27.

d. A Pinion SeHing Table

Is given in figure 5-26 to simplify use of

Gauge J 681-A, and a similar table is given in

figure 5-27 for use with Gauge J 2197. To use

either table, simply note the marking on the

pinion tooth and look in the column of table

headed by the same marking; the correct micrometer reading for proper pinion setting will

be found in the column opposite the particular

car year and series down at left end of table.

5-21 CHECKING PINION SETTINGS

WITH GAUGE

1. Before Pinion Setting Gauge is installed,

check the ends of pinion teeth and stone off

any burrs; also rub stone over etched markings

to remove high spots. The gauge adapter must

seat flatly and firmly against ends of pinion

teeth in order to secure an accurate micrometer

reading.

Figu re 5-28-Pinion Sett ing Gauge Installed

(192)

2. Install adapter with clamp, and the micrometer gauge as shown in figure 5-28. The

adapter must be firmly held against the pinion

by the clamp. The micrometer gauge must be

firmly seated in the differential bearing seats

in carrier, with micrometer spindle at 90 degrees to surface of adapter.

3. The pinion setting is obtained by adjusting

micrometer until the spindle just touches the

adapter, then reading the micrometer. NOTE:

Swing the micrometer spindle up and down

slightly while adjusting, to feel the exact 'point

at which it contacts the adapter.

4. When the actual pinion setting is obtained,

compare it with the proper micrometer reading

for the pinion marking as shown in figure 5-26

if using Gauge J 681-A, or shown in figure 5-27

if using Gauge J 2197. If the old ring and

pinion gear set is being reinstalled, however,

the original setting of the gears must be maintained, to avoid changing tooth contact.

5. If the pinion setting is not within .001",

plus or minus, of the specified micrometer reading, adjust pinion as described in next paragraph (5-22).

5-22 ADJUSTMENT OF PINION GEAR

The pinion gear setting is adjusted by

changing the total thickness of the pinion

bearing shims which are located between the

pinion front bearing and the shoulder in third

member housing.

1. Remove pinion and propeller shaft assembly as previously described in paragraph

5-11, steps 3 and 4.

2. Remove all pinion bearing shims from

shaft or in third member housing, wipe shims

dry, and measure their total thickness with a

micrometer, or with a dial indicator set to bear

against a flat surface.

3. Increase or decrease total thickness of

shi ms as required to obtain proper pinion setting, by using a different combination of shims.

These shims are furnished in thickn esses

ranging from .010" to .019" in increments of

.001", so that any total thickness may be

obtained by using a combination of different

shims.

4. Install pinion and propeller shaft assembly

with new combination of shims and be sure to

tighten the three bearing sleeve locks uniformly to 35-40 ft. lbs. torque, and lock nuts to

15-20 ft. lbs. torque.

5. Check pinion setting with gauge. Setting

(193)

REAR AXLE ASSEMBLY

should be within .001" plus or minus, of required micrometer reading.

5-23 INSTALLATION OF DIFFERENTIAL

RING GEAR AND CASE ASSEMBLY

1. Before installation of ring gear and case

assembly make sure that differential bearing

seats in carrier pedestals and caps are clean

and free of burrs. Remove any burrs which

might prevent bearings or bearing caps from

seating properly.

2. Place outer races on differential bearings

but do not oil bearings as this would interfere

with bearing adjustment. Install gear and case

assembly incarrier and slide bearing adjusters

into position so that threads are engaged in

threads in carrier pedestal.

3. Install bearing caps with bolts and lock

washers. Make sure that caps are installed in

original positions as marked betore removal.

Turn bearing adjusters to engage threads in

caps. Tighten cap bolts to 20 ft. lbs. torque then

loosen all four bolts 1,4 turn.

REPAIRS

5-23

while observing bearing rollers and outer race,

until rollers and race just stop turning, then

tighten adjuster 4 to 5 notches to properly seat

bearings and adj usters.

6. Slowly back off adjuster until bearing

outer race just stops turning. Recheck for this

Figure 5-30-Adjuster Mutilated by Wrong Tool

"free position" at least once to make sure of

proper position.

7. From the "free Position" tighten the

adjuster 2% to 3 notches to pre-load the bearings, then tighten all 4 bearing cap bolts to

65-70 ft. lbs. torque.

8. Mount dial indicator as shown in figure

5-31. Use a small button on indicator stem so

that contact can be made off the edge of tooth.

Set dial indicator so that indicator stem is as

nearly in line with gear rotation as possible.

If stem bears against edge of tooth, or stem is

at considerable angle to the line of gear rotation, a false indication of backlash will be

obtained.

Figure 5-29-Adjusting Differential Bearings with Wrench J 1365

4. Using Adjuster Wrench J 1365 (fig. 5-29)

turn adjusters as required to set ring gear lash

at approximately .008" t o .012" , with both adjusters in firm contact with bearings. CAUTION: Do not use punch and hammer to turn

adjusters as adjusters will be distorted (see

fig. 5-30) and proper bearing adjustment cannot be obtained.

5. Back off one adjuster (preferably left)

Figure 5-31-Checking Backlash with Dial Indicator

REAR AXLE ASSEMBLY

REPAIRS

5-24

9. Lock the pinion with hammer handle or

small bar and move ring gear through backlash

range while observing movement of indicator

hand. Check backlash in this manner at three

or four points around ring gear to determine.

points of minimum backlash.

10. Th e desir ed backla sh is .008" to .010" ;

how ev er, backlash at minimum point should

not be less than .008" and at maximum

point should not exceed .012" . If original ring

and pinion gear set is being reinstalled, the

original lash of gears should be maintained

to avoid changing tooth contact.

11. If backlash is not within limits specified

ab ove, move ring gear to right or left as r equired to secure proper backlash. To mo ve ring

gear, loosen all bearing cap bolts %. turn ;

loosen one notch on bearing adjuster on side

toward which gear is to be moved and tighten

one notch on opposite adjuster. When one adjust er is loosened always tighten opposite adjus ter the same amount in order to maintain

th e bearing preload adjustment made in step 7

above . One notch change of both adjusters in

the same direction will change backlash .004"

to .005". The offset ends of bearing adjuster

locks used in 1948 are designed to permit halfnotch adjustments.

12. Always tighten all bearing cap bolts to

65-70 ft. lbs. torque after adjusters have been

moved and recheck backlash with dial indicator