Converting the Harley Davidson Model 32E generator (6V, 3

advertisement

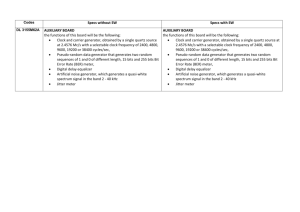

Converting the Harley Davidson Model 32E generator (6V, 3brush) to a 2-brush, 12V. Author : Kim Berts (2004) You need the following things 1) Harley-Davidson Model 32E generator 2) 12 V conversion kit KDR1347A 3) 12 V regulator KDR 2375A 4) possibly other small parts inside the generator which might be in bad condition, also check the driver gear etc. 5) Volt- and ohm-meter Conversion kit The 12v conversion kit, KDR1347A, consists of - armature 12V - generator brushes (2) - field windings (2), connected together - front and rear bearings - gaskets Regulator The +12V regulator has separate mounting instructions, but its connection diagram is also shown in Figure 3 . The Regulator function: When the Armature (Relay) voltage is low, the magnetic field needs to be increased. The Field (Switch) is then grounded by the regulator and the voltage causes a current to flow through the field winding, out through the Field (Switch) terminal to the regulator, causing an increasing magnetic field in the field winding. When the Armature (Relay) output reaches +14V the regulator connects the Field (Switch) winding to +, and the magnetic field is then decreased. Conversion Figure 1. The 32E Generator 1) Disassemble the whole generator, check the condition of the parts, clean well. Obtain the necessary parts. 2) Remove the field windings from the pole shoes, clean the the pole shoes well. Figure 2. Field winding connections 3) Install the new field windings on the pole shoes, so that the wire connecting field winding 1 to 2 is going diagonally across the generator (check Figure 2). Note that the pole shoes need to be quite tight against the generator body, in order for the armature to run freely. You might need to try to flatten the coils a bit, really carefully, in order to get the pole shoes close enough against the body. The field winding ends points to the rear as in the original generator. 4) When you have tightened the pole shoe screws try to install the generator armature, it should turn freely between the field windings. 5) Remove the third brush (regulating brush) from its holder. This brush will not be used any more, but the brush holder will be assembled as the original. 6) Continue assembling the generator. When assembling the ”switch” and ”relay” pole screws, make sure they are well insulated from the gernerator body by the insulating washers. The ”Switch” pole screw will become the new Field (F) and the Relay will become the new Armature (A). 7) Lubricate the bearings, felt washer (if still used, the conversion kit contains a rubber end seal) 8) Make sure the armature turns freely when the generator is fully assembled. Leave the end cover off at the moment 9) The lower field winding’s free wire is routed up to the ”Relay” side (new A), and connected to the small screw on the armature brush holder. Make sure it won’t touch the end cover anywhere causing a shortcut! 10) The upper field winding is connected to ”Switch” terminal (the small screw). This is the new F(ield) terminal. Also here make sure it won’t touch the end cover anywhere causing a shortcut! 11) Install the generator in the bike, do not connect any wires, leave the end cover off. 12) Measure with an ohm meter between ”Relay” and generator body, it should read something like 0.8 ohm or a little less. It should not be a shortcut like 0,0-0,1 ohm reading on the ohm meter! 13) Measure From ”Relay” to generator body, It should read around 5 ohms. 14) Connect the generator to the regulator according to the regulator instructions, or see figure 3. Figure 3. Generator - Regulator connection 15) Also connect the generator light on the dashboard correctly, according to the instructions that comes with the electronic regulator. 16) Make sure your accumulator is fully charged (should read > 12,5 Volts with a volt meter). 17) Start the bike and see if the generator light goes out. 18) If so, your conversion is done ! You could measure the Relay terminal voltage in order to see that it is around 14 Volt. 19) If the generator light does not go out, check that the voltage is ok at the Armature (”Relay”) terminal, measure with the voltage meter. Black meter wire to bike frame, red to ”Relay”. If you have a small negative voltage (-0,5 Volt), then your field should be reversed. This is done by exchanging the field winding wires. Remove the end cover, there you see the field wires attached to the small screws, one on the right brush holder, the other one on the insulated field plate. Remove the screws, switch the wires. Make sure the field plate is insulated from the armature brush holder. Check Figure 4. Figure 4. Generator End - field winding ends 20) Now check again, by starting the bike, now the generator light should go out, and you are all set. Troubleshooting Q: The generator lamp glows after starting (was working ok before) A: It might be sometime that the accumulator has discharged, check the voltage with a voltage meter. If low (11,6-11,7 Volts) then first you should check that you have enough acid ( add distilled water if not), in your accumulator. Then you could either charge it (preferred), or do as below (if for instance out on the road). Start the bike, take an insulated copper wire approx. 1 meter long. Hold one of the ends against the Relay (Armature) and shortly touch the positive pole of the battery. By doing this, you temporarily make a higher magnetizing current flow in the field windings, and this causes the armature to output enough for the charging to start. One thing which might cause discharging is rain or when washing your bike. If you have the terminals under the seat they might get wet, and the accumulator could slowly discharge to bike frame. Another thing is the regulator, which carries +12V continously. If it gets wet (terminals pointing forward) then the battery might discharge there. Always dry these parts thorroughly. The discharging will not occur when the bike is running as the generator continously charges the accumulator, but do check those places after a rainy ride.