Harley-Davidson and Motorcycle Background - EDGE

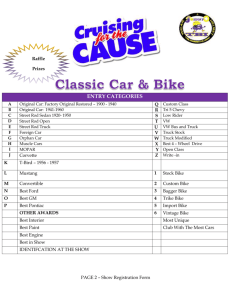

advertisement