Optimal conditions to production of ethanol in yeast fermentation

advertisement

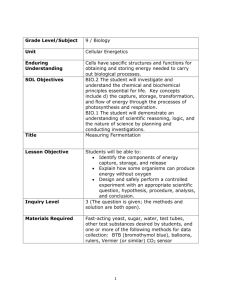

Optimal conditions of ethanol production in yeast fermentation process Joanna Bąk, Joanna Kasprzak II Liceum Ogólnokształcące im. Tadeusza Kościuszki w Kaliszu Introduction Precious yeast, belonging to species Saccharomyces cerevesiae have big economic importance. They are used in food industry, mainly fermentative. Yeast’s ability to sugar fermentation, e.g. glucose and production of ethyl alcohol and carbon dioxide is used in production of wine, beer, other drinks, also bread. Fermentation is a anaerobic chemical process, which consists of enzymatic desintegration of sugars. Microorganisms or produced by them enzymes are necessary to the course of fermentation. In yeast fermentation process glucose by means of yeasts is transformed into ethyl alcohol and carbon dioxide. It is accompanied by emission of thermal energy. Special species of yeasts are able to produce even about 21% alcohol, baker’s yeast, available in food shops, are able to use maximum about 14% alcohol. The progress of yeast fermentation process C6H12O6 ---> 2C2H5OH + 2CO2 + 24 kcal Theoretically from this reaction it is clear that every 180,5g sugar will give 92,1g ethyl alcohol (or 100g sugar 51,1g ethanol). However, in practice yeast use up for other fermentation products, e.g. for breathing process, growth of biomass. A part of ethanol leaks with bubbling CO2. Therefore, it is assumed that practical productivity amounts to about 90% of theoretical productivity, i.e. from 1,7 kg of sugar we obtain 1 litre of ethyl alcohol. . Experimental procedure and approach We added 270g of glukose to 1,5l of destilled water. In that way we received 18% solution. We poured obtained solution to three plastic 0,5l mineral water bottles, filled them ¾ full. Then we added 40g compressed fresh baker's yeast to each bottle. All bottles were shaken for a few minutes. After that each bottle was filled right up to the top with the glucose solution. Then we labelled every bottle and fitted balloons over the necks of bottles. Bottles were placed in different laboratory incubators which were set at temperatures: 20, 35 and 40ºC. Each bottle we left there for two days in constant temperature. After that we took bottles out, carefully stringed and removed balloons from them and weighed the balloons. From obtained masses of balloons we subtracted masses of empty balloons. That is how we calculated masses of obtained CO2. Using filter centrifuge we cleaned content of individual bottles from yeast to measure amount of ethanol in individual bottles. Conclusions Measuring alcohol concentrations in solutions we found out that yeast fermented glucose in yeast fermentation process. One of the products of this reaction si the ethanol. Results Introducing to every filtered solutions device measuring amounts of ethanol, we measured amount of produced ethanol. We have presented results in a table. Temperatura 20C 35C 40C Stężenie etanolu w roztworze (%) 4 9 6 Table 1: The concentrations of ethanol in particular solutions. Weighing individual balloons with CO2, we obtained the following results: Temperatura Masa CO2 (g) 20C 1,6 35C 4,8 40C 1,9 Table 2: mass of produced CO2 in individual temperatures. Most CO2 was produced in temperature 35ºC, least in temperature 20ºC. Explanation Yeasts are live organism, too high temperature causes their death. Maximum temperature which kills these mushrooms is about 40ºC. But content of ethanol causes that yeat become more sensitive. At concentration of 14% alcohol they are extinct in 33C, and at concentration of 20% alcohol in 25C. In 40C and with sensivity for ethanol yeast was weakened, and the most ethanol they produced in 35C – is the closest temperature to optimal 37C, which is the best temperature to growth of yeast as a living organisms. Apart from oxygen and azote, yeast needs other nutrients, like : vitamins from group B, mineral matters (magnesium, potassium, calcium, sodium). These components are called activators of fermentation process, i.e. substances improving the course of this process. The opposite to the activators are inhibitors – substances affecting negative the course offermentation process. Main inhibitors in fermentating setting is ethyl alcohol and sulfur compounds, carbon dioxide, tannins, volatile acids (acetic acid) and some heavy metals (mainly copper). A time of fermentation depend largely on species of yeast and a temperature and may be from 24 hours to several or more days. . As we have already mentioned, the biggest possible to obtain ethanol concetration amounts to about 21%. In order to obtain it, indispensable are however, specially selected yeast with great tolerance for ethyl alcohol. Baker’s yeast can produce up to 14% of alcohol. In our experiment we have obtained maximum 9% of alcohol. There may be a lot of reasons of that. Among others a percent of ethanol which we obtained depended on proportions of used water and sugar. Too big sugar concentration affects negative productivity of yeast’s work. Theorethically, we shouldn’t exceed amount 300g per 1 litre, but in practice it is worth reducing it a bit more and assume that limit amounts to 200-250g per litre, i.e. about 20%. Thus concentration of glucose in our experiment was correct, though it oscillated around upper limit. The only fermentation activators in our experiment were oxygen and azote, which were present only at the beginning. Then, they were pushed out into a balloon by carbon dioxide and they weren’t still supporting the fermentation process. In our experiment ethanol and carbon dioxide were present, too. They were retarding fermentation process, consequently producing ethanol, too. Another reason may be time necessary to produce ethanol. It largely depends on yeast species and the temperature and amounts to from 24 hours to several or more days. At beginning phase there are little yeast cells, but they are in good condition and have great conditions to live. Loss of sugar associated with that is minimal ( about 5g/ litre). When yeast cells achieve population number amounting to about 100 millions in a millimetre, completely capturing environment, as a matter of fact they stop pullulating. Henceforth, until the end of the fermentation process only already existing yeast cells busily convert sugar in alcohol Yeast of the species Saccharomyces cerevisiae, both wild and precious, reveal similar fermentation dynamics. That process stops after six days. Our bottles were left in a thermostat for two days. Another factor is pH of a solution. Optimal pH for the yeast fermentation process is 4,5-4,7. We didn’t estimate which pH reaction our solution had. Summarizing, in our experiment we didn’t obtain the maximal concentration of ethanol, because we hadn’t provided culture medium, optimal pH reaction and maximal time for growth of our yeast. Conentration of sugar and ethanol in our solution were correct (didn’t disturb fermentation process). Temperature differed from optimal by about 2C. Bibliography: 1) E. Solomon, L. Berg, D. Martin „Biologia” 2) G. Kupryszewski „Wstęp do chemii organicznej” 3) www.wikipedia.org 4) www.bryk.pl 5) www.biotechnologia.uni.opole.pl 6) www.ar.krakow.pl 7) "Yeast and fermentation: the optimal temperature" - Slaa, J., M., & Else, H. Vrije Universiteit Amsterdam, The Netherlands (October 2009)