A340-500/600 NAcelle Project

advertisement

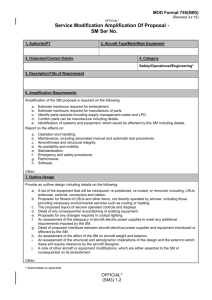

Professional Statement: Airbus A340-500/600 Product Life Cycle and Nacelle Components Final Report (Follow-on to Interim January 2009 Report) Mark Bobbi MB Strategy Consulting March 2, 2009 Mark Bobbi is a leading aerospace/defense strategy and business development consultant and a one of the world’s most experienced aircraft propulsion system specialist. Mr. Bobbi has three decades of aerospace/defense, and energy equipment business development and strategy experience. Mr. Bobbi helped launch new products including the Williams FJ44 and Cessna CitationJet, Pratt & Whitney PW600, ST30/40, and ST5, Kawasaki GPB15X with Catalytic Combustion, Kawasaki M7A, and the Pilatus PC-12. He was previously responsible for Competitive Analysis at Pratt & Whitney and has contributed to numerous other new product and strategy efforts for industry leaders. MB Strategy Consulting “Three Decades of Developing Winning Aerospace, Defense, and Energy Equipment Strategies” Mark A. B obbi Principal Phone: 904-824-1997 Mobile: 203-206-1902 w ww.markbobbistra tegy.com Email: WaldoBob bi@aol.com 104 Hammock Circle, Saint Augus tine, Florida 32084 MB STRATEGY CONSULTING has unparalleled experience in aerospace, defense, and energy equipment finance, operations, engineering/technical, market research, strategic planning and strategic market development, new product development, and aftermarket services. The MB Strategy Consulting track record of success includes direct participation in the development and commercial launch of the following products: Williams FJ44 turbofan engine Kawasaki M7A industrial gas turbine Pilatus PC-12 single engine turboprop Sino Swearingen SJ-30 corporate jet Kawasaki GPB15X industrial gas turbine generator set Kawasaki M7A gas turbine Pratt & Whitney Canada ST30/40 industrial gas turbine Pratt & Whitney Canada ST5 miniturbine Pratt & Whitney Canada PW600 turbofan P&W PW6000 turbofan engine Engine Alliance GP7200 turbofan engine GE/Honda Small Turbofan Mark Bobbi’s consulting history is as follows: Provide strategic market development of a new small low cost turboshaft engine for rotorcraft and industrial applications for the former Allison Division of GM Development of a strategic alliance between two of the world’s largest diesel engine companies, Cummins Engine Co. and Niigata Engineering. Provided advance warning of 1990/1991 airline industry “crash” Assisted a First Bank of New York financial institution in a $700 million aerospace private placement/leveraged buyout Accurate predictions of rapid, high volume growth of regional jets and new generation entry level jets Assisted GE Capital in taking aerospace component unit of ALCOA private Guided Chromalloy’s entry into the RR Trent maintenance market Assisted world leading aircraft company in development of a new super midsized bizjet 2 Developed the aerospace market entry strategy for Honda Motor Company As one of four principal owners, developed small gas turbine (non microturbine) market entry strategy for a new firm, Candent Technologies. The company won US Army SBIR Phase I and II contracts in 2003/2004 for a 770 shp aviation turboshaft engine Provided strategic business planning guidance to operating units of Pratt & Whitney and Pratt & Whitney Canada Developed detailed competitive assessment and financial models of the BIG 3 aircraft engine and Big 6 industrial gas turbine firms including Solar, GE, Alsthom, and Siemens/Westinghouse Developed a comprehensive market and business development strategy for Pratt & Whitney’s industrial turbine operation including recommending launch of FT4000 in 1996/1997. Resulted in launch of the new P&WC ST30/40 in 1998. The engine has won orders from Bombardier and the Swedish Navy for locomotive and fast patrol craft propulsion. Developed a comprehensive market and business development strategy for a Kawasaki Gas Turbine Americas including helping close the first commercial order for the world’s most advanced gas turbine low emission combustion system Helped negotiate a joint marketing agreement between Kawasaki and Cummins for industrial gas turbines As State certified expert witness, helped a CA company win $78 million jury award against GE In 1985, lead market research effort that resulted in formal launch of the Williams FJ44 turbofan engine. Two years later, Cessna selected the engine for its CJ1. The engine was also selected to power the SJ-30 and Premier I jets of Ed Swearingen and Raytheon Aircraft respectively In the mid-1980s, led market research effort that resulted in Kawasaki launch of the 5-7 MW class M7A industrial gas turbine In the mid-1980s, was integral member of market research team that defined the specification for what would become the Pilatus PC-12. Over the past 20+ years, MB Strategy has accurately predicted the long-term competitive landscape in aerospace and defense to include: GE victory in the “Great Engine War”. GE ascendance to the number one position in large commercial jet engines. RR ascendance to the number two position in aircraft jet propulsion behind GE and ahead of P&W Lockheed and P&W victories in the ATF competition (F-22 Raptor) Boeing/Sikorsky victory (and subsequent cancellation of) in the LHX competition (RAH-66 Comanche). Massive growth in regional jets. Record growth in sales and delivery of business jet aircraft including new high-speed aircraft, and new generation entry-level jets. Congressional salvation of the Bell/Boeing V-22 and eventual production. 3 Procurement of a many more than 120 C-17s. Rapid incorporation of aero engine technology in all classes of industrial gas 1`1turbines. Massive growth in sales of base load combined cycle and simple cycle peaking gas turbines and subsequent market “bust” Impending collapse of the Eclipse business jet program 4 Airbus A340-500/600 Product Life Cycle and Nacelle Components 1. Executive Summary – In December 2008, MB Strategy was asked to provide an update of our 2007 report. We fulfilled this requirement with an interim update in January, subsequent to our utilizing industry sources. Six weeks on, we provide our final report concerning A340-500/600 aircraft (Trent 500 nacelle) and in particular the market and “industry” awareness of the Replacement of acoustic exhaust ducts within a specified limited life. This update provides the following in detail: a. Update of market position/ orders and A340-500/600 aircraft production expectations b. Documentation in the aerospace industry regarding life limited components and need for full replacement by spares. c. Any other comments and information based on the document disclosures provided. After exhaustive review of all documents and associated reports and contacts with a variety of sources at or close to A340-500/600 customer airlines, I have come to the following important conclusions: d. Overall Aircraft and Nacelle Forecast Outlook. There has been no change in the production or sales outlook for the A340-500/600 from that August 2007 report. Forecasting firms and investment banking analytical organizations that we know of have the A340-500/600 ending its series production life over the next two years at a total program of 130-135 not including six aircraft for Virgin which will not likely be finished. The year end 2008 Airbus order total is 139 including “white tails.” (Airbus confirmed 1 A340 net orders in 2008.) Among those forecasting 130-135 are Teal Group (Washington, DC-based aerospace/defense consultant), Janes DS Forecast (operating unit of Janes Information Group), Banc America Merrill Lynch Securities, and the Airline Monitor. Only Forecast International has been the outlier, until summer of 2008 forecasting 170 aircraft with production continuing through at least 2018. The number of aircraft on the backlog at the end of 2008 was 24 of which six are for Virgin Atlantic and we know with near certainty that these will not be taken by the customer. In all likelihood, those six orders will be converted to A330; A350 or A380 aircraft as Airbus retain the deposit from the 2004 order from Virgin Atlantic. i. 2008 Orders. Airbus net 1 order for A340-500/600 made up of six new and five cancelled orders; 2 Kingfisher and 3 Air Canada. The comparable Boeing aircraft, the B777 accrued 54 orders. In 2007, Airbus recorded 11 orders for the A340-500/600 while Boeing booked orders for 83 B777s. B777 and A340-500/600 are direct competitors ii. Real Backlog. The real backlog is dropping dramatically even from the Airbus claimed 24 aircraft. Eithad (3 Dash 600s), Iberia (5 Dash 600s), Lufthansa (3 Dash 600s), Arik (1 Dash 500), and Kingfisher (3 whitetails), 3 Unnamed Customers. Jordan’s aircraft has been classified as delivered by Airbus. iii. Available Second Hand Aircraft. Twenty months since our first report, a secondary market for 7/7 Dash 500/600s has appeared; all of these available this year from original customers. iv. Series Production. Production is likely to be completed 2010 as expected 20 months ago. 5 v. Nacelle Forecast - The 2007 Magellan forecast of 721 new nacelles through 2016, when combined with the actual delivered figure (through 2006) of 434 units) is greatly exaggerated as it is based on a Forecast International forecast that is 2 to 3 years old. The total of delivered and forecast new nacelle deliveries is 1,155 which works out to at least 275 aircraft, more than double what all other reliable sources say will be built over the life of the program Among those sources predicting half the number Magellan was were Merrill Lynch, Teal Group, Airline Monitor, and Janes DS Forecast. The FI forecast had to be dated March or April 2004. (Attached you will find Forecast International’s 2005 forecast of commercial jets). The reason we know Magellan was using an old forecast was that its internal nacelle forecast (Also attached), began with 2007 and noted Forecast International’ estimates are provided through 2013 only. As Forecast International forecasts for ten years, the first year of that forecast had to be from March 2004. Forecast International’s 2005 forecast projected 163 from 2007 to 2014 and we believe Magellan’s more than doubling annual production forecast in 2010 and 2011 was a direct result of that out of date forecast. Through 2006, Magellan had delivered 434 assemblies for roughly 100 aircraft. To add 721 as Magellan forecast, another 180 aircraft would have to be ordered bringing the overall total A340-500/600 order book to 275280. e. Component Life and Spares Forecast. With respect to the life of the nacelle component, we can find no technical information that states specifically there is a 40,000 hour life. The original 1999 beta21 test did not project a finite life and only since the March 2007 report did Magellan attempt to estimate a 40,000 life from estimates and the original beta coupon test. i. Sources Report NO ISSUES. In our interim report, we included feedback from at last a half dozen reliable sources with direct contact at A340-500/600 customer airlines and their engineering organizations (Singapore Airlines, P&W Commercial Engines, P&W Composites, and Goodrich Aerostructures). Their contacts reported NO ISSUES with the A340-500/600 exhaust nozzle/duct. For the final report, we took an the extra time to expand our sources to include other A340 operations Virgin, Lufthansa and Emirates. Once again our sources were unanimous in that there were no reported technical issues on the nacelle as a whole or on any nacelle component. Indeed, Virgin and Singapore should be coming upon Magellan’s projected 33,333-37,393 hours within the year. Throughout Magellan documents, the company states they will sell significant numbers of replacement spares due to the “hot life limit.” True enough, if there in fact is a “hard time limit” on this assembly, full replacement would be required. However, there should be manufacturer notices or other technical information available to the customer well in advance of a potential 40,000 hour life issue. Additionally, using Magellan’s own forecast, some 100 nacelle exhaust systems will need to be replaced within 20 months meaning orders would have to be made now due to the very long lead time for Beta21 sheet from the single patented source, Timet1. Had there really been a life issue of such an importance, that issue or problem would have been communicated to the customer airlines and 1 Timet is short for Titanium Metals Corporation. 6 regulatory authorities. Each would have undertaken actions to determine the true nature of the problem, if one existed, and to recommend a solution. Indeed, such a problem may have been considered ‘safety of flight’ by regulatory authorities who would have forced the airline to remove, replace, and/or repair said item. The regulatory agency would have issued an Airworthiness Directive (AD), which is published on the agencies’ web sites and in various airline and aircraft industry publications. No such regulatory action has been taken with respect to the A340-500/600 nacelle and there is no evidence from the operating airlines themselves that any such problem exists, our sources state emphatically. (Singapore, Virgin, Emirates, P&W Commercial Engines, P&W Composites, Goodrich Aerostructures, Barnes Aerospace). Two responses are shown here: Singapore Airlines Source “I contacted my buddy at my previous employer who specializes in this area and he confirms that they are not aware of any major issues with the Trent 500 nozzle or plug assemblies that would result in high maintenance cost issues.” A Major Independent Aircraft Engine Overhaul Center in Singapore “I have not heard anything about this issue, and would keep an eye on this issue. I am also copying this email to our XXXXXX and Marketing XXXXX to check whether they have heard anything from their sources.” ii. THERE IS NO FINITE LIFE. We can find nothing in Magellan documents that states specifically that the ultimate life of the component is 37,000 or 40,000 hours. Those figures are only estimates based on the coupon test and an 2004 independent report2. Even Magellan, in a variety of memorandum, admits that those two figures are ESTIMATES. What Magellan never discusses is that in REAL AIRLINE SERVICE, the component may last far longer than 40,000 hours as both of the references tests do not replicate typical life cycle temperature and stress patters of the installed component. Such real life tests require a significant investment in hardware; for both sea level and altitude testing in a test cell. In some cases, testing is actually done on a complete propulsion system on a representative aircraft or aircraft “test bed.” 3 Small to medium sized companies such as Magellan do not have the resources to conduct such testing. As such, the validity of the Magellan coupon test and prior literature on the same material can not be used to project component life and spares or repair parts consumption. My view is actually the same as that of Mr. Richard Neill that he knows of no “Ductility Exhaustion Mechanisms In Thermally Exposed Thin Sheets of a Near –Beta Titanium Alloy,” F. Sansoz, M. Almesallmy, and H. Ghomen; Metallurgical and Materials Transactions, Volume 35A, October 2004. 3 New engines and their nacelle systems are first tested on engine company aircraft “test beds.” Pratt & Whitney, GE, and RR have used a variety of aircraft to test such large engine propulsion systems including but not limited to the Boeing 747 and first generation A340-200/300. 2 7 ultimate life limit and because of this, there is no valid way to project new replacement spares. More importantly, Mr. Neill goes on to say (and contradict Magellan’s internal forecast) that a more likely scenario is for airlines to conduct repairs of said items; “As far as I know, there are no mandatory FAA or JAA service lifes on the exhaust system to mandate this type of replacement so it will be an Engineering and Maintenance decision made by the Airline and the Overhaul Center that causes this to happen.” Our own forecast for spares/repair sales is in the 100-130 range, well below what Magellan number 190 has predicted, and is predicated on eventual delivery of no more than 135 aircraft (versus 275-280 called for in Magellan’s forecast), and a limited replacement spare and repair market dominated by airline repair shops or authorized nacelle repair firms including the nacelle prime contractor, Aircelle. Any Magellan suggestion that it could capture repair business runs counter to industry practice (airframe structure and nacelle producers such as Aircelle, Goodrich, GKN Aerostructures, and Vought) where forecasts generally excludes repairs unless there is certainty of the company producing the forecast actually winning that repair work. Magellan had no such certainty. In short, for Magellan’s forecast to come true Airbus would have to sell far more aircraft, as many as 180 more and as we now know, those orders are not coming or are unlikely to come in the years ahead. iii. Magellan Spares and Repair “Language”. After having reviewed the documents numerous times, it also became clear to me that Magellan was using the terms Spares and Repairs interchangeably in discussions of future aftermarket sales potential. It should be noted that airlines traditionally repair nacelle/thrust reverser items rather than replace them. There is a very rational economic rationale for such repairs; nacelles, thrust reversers, and exhaust systems are very expensive items to acquire as complete spares. Lufthansa developed a repair on the A340200/300 CFM56-5 nacelle exhaust duct in the late 1990s and reported that out on the Lufthansa Technik website October 10, 2000.4 Most importantly, the Magellan documents, particularly the Rich Neil memo of March 29, 2007 (See Attachment 1) in the first paragraph, states: “This analysis shows that the likely spares requirement was in excess of 800 units over the period 2007 to 2021. So to achieve a volume of only 190 units was an extremely safe number to use in the EAC analysis.” Later, in the same memo Magellan claims; We find it difficult to predict the business that would arise from these repairs and hence we would choose to IGNORE this in any EAC 4 Lufthansa Technik AG, October 10, 2000. “Don't scrap it - A340 nozzle repair”. The developed repair analysis being done. enabled A340 operators to avoid having to scrap the expensive exhaust nozzle (unit price: $375.000). 8 Considering all of the evidence, I conclude that Magellan is, as even they admit, ignoring that reality of the marketplace for some financial reason; or Magellan is just totally unaware of the reality of the nacelle aftermarket which is that airlines nearly always repair major components. Either way, there is no reasonable prospect of significant spares business to Magellan on the Trent 500 exhaust system. f. Spares. Our original forecast 20 months ago had 100-300 spare/repairs. After further detailed analysis, our forecast has been reduced to 100-130 for a variety of reasons which are detailed in the body of the report. This forecast is lower than the Magellan 190. More importantly, it is highly likely that a significant majority of nacelle components would be repaired by the customer or independent shop5. However, there is no such repair being discussed by those customers coming soon to the 40,000 hours (Virgin, Singapore, Lufthansa). Magellan produces contradictory statements with respect to the sale of spares or repairs, acknowledging that parts can be repaired by customers but Magellan consciously chose to ignore than probability when producing its internal sales forecast for the Trent 500 system; spares OR repairs. Again, this runs counter to industry practice. g. Technical Documentation. None of the documents specifically state there is a 40,000 hour life or that there is a firm life limit. The original 1999 test did not ascertain such a life nor guarantee one. Also, the 2005 report, while suggesting such a life, did not specifically state one. Only in the March 2007 report did Magellan attempt (Dr. Thamburaj) to predict life on the very limited coupon test. And even Dr. Thamburaj wasn’t thinking about replacement when he offered his life assessment and thoughts on future aftermarket sales. He specifically mentioned the likelihood of repairs, again consistent with industry practice. 2. Sales/Production Outlook – The A340-500/600 was introduced in 2001 with great expectations that the four-engined wide body would secure well in excess of 400 orders over its life. However, since introduction, the aircraft has not performed as expected with range, reliability, and speed issues that put it at a distinct disadvantage versus directly completive Boeing 777 products. We will not go into detail on the performance problems of the A340-500/600 but will simply say that its fuel burn and engine maintenance burden are far higher than competing aircraft and these in part have resulted in poor sales. Indeed, in what was a very bad year for commercial aircraft orders in general, Boeing booked 54 B777s while Airbus took just 1 A340 when considering shifting existing A340 customers to other buyers like Nigeria Arik. Merrill Lynch’s August 27, 2007 Commercial Orders report6 had just 8 RR powered A340500/600s remaining and 43 Trent 500 engines (32 on wing plus 11 spares). The backlog was 19 as of Jan. 1, 2009 with 15-18 reportedly delivered in 2008. However, a look at that backlog shows the end is near. 5 Note: Lufthansa Technik and Singapore Airlines technical unit are two of the most capable aircraft and aircraft engine repair firms in the world with skills comparable or exceeding those of the OEMs. 6 Merrill Lynch Securities, Global Aerospace Weekly, Orders and Backlogs; August 27, 2007 9 Region As of Airbus’s last report in January 16, 2009 for all of 2008, 35 A340-500 and 104 A340600 had been ordered (total 139) and 28 A340-500 and 87 A340-600 had been delivered (115).7 That would leave a backlog of 24 at that time.8 Undisclosed Airbus Executive & Private Jets Qatar Airways China Eastern Airlines Thai Airways International South African Airways M A A F M N E E E Ord Del Opr 2 4 5 6 6 2 4 5 6 6 2 4 5 6 9 8 13 16 20 24 104 5 13 11 14 21 87 5 Region Etihad Airways Intl Lease Finance Corp Iberia Virgin Atlantic Airways Lufthansa TOTALS A340-600 Intl Lease Finance Corp Air Canada Arik Air */** Kingfisher Airlines Thai Airways International Etihad Airways N N F A A M Airbus Executive & Private Jets Singapore Airlines Emirates TOTALS A M 12 19 21 86 A340-500 Ord Del Opr 2 2 3 4 4 2 1 1 4 4 4 4 5 5 10 35 2 5 10 28 2 5 10 28 Of the current customers, Virgin has (6) scheduled for 2009 and these are likely to be cancelled or converted to other Airbus wide body aircraft with three white tails and three to be finished aircraft. Virgin has clearly decided to replace its A340s with B787s. Additionally, the environmental performance of the A340-500/600 (fuel burn and carbon emissions), no longer fit the long-term vision of Virgin principal shareholder Richard Branson. As such, the A340-500/600 backlog takes production to 2009 with the Jordanian Government aircraft having been built in 2008 and is currently scheduled for delivery to the customer with custom interior and mission systems in 2010. Kingfisher aircraft are white tails after Airbus sold 2 of the cancelled Kingfisher aircraft to Nigerian carrier Arik Air. Therefore, the “real” backlog as of this writing is 17 aircraft. 3. Operator Utilization – A340-500/600 are used in very long range operations. The total fleet averages 4200-4500 hours per year on 500-550 cycles.9 There are one or two 7 8 Airbus Industrie, October 2008. Airbus Industrie web site, January 16, 2009. 10 carriers who fly very long stage lengths; Singapore for one fly 14 hour stages so some will quote 5,000 hours as the “typical” annual utilization for the A340-500/600. This is just not the case for the fleet as a whole. Engine on wing time is averaging 20,000 hours even with somewhat troubled introduction of the Trent 500. More importantly, the existence of “white tails” and future availability of aircraft from existing customers such as Thai will increase the number of aircraft not generating significant annual flight hours, further diluting the fleet average. Moreover, the worldwide traffic downturn has led many airlines to reduce capacity. Among those are Singapore who in February 2009, announced it was reducing capacity 11% by parking 17 aircraft by April 2009. We believe A340-500/600 may be among those that are “parked” further reducing utilization and the prospects for “spares” sales on nacelle components. 4. Aircraft Service Life – We specifically reference the R. Neill memo of 3/29/2007 in which he states that the “history” of the industry points toward Airbus continuing to update the aircraft, implying it would remain in production for some time to come. Mr. Neill states: “The Forecast International Data (March 2007), assumes Airbus will be unable (ed. Author used unavailable) to further improve the A340-500/600 and yet history has seen the opposite and the example I would use is the A300 which first entered service in the early 1970s and production is only now ceasing.” Now, it is true that the A300 was delivered from 1974 through 2007. The original A300 was designed for high capacity, short-to-medium haul routes. Over time, it was gradually evolved to larger capacity, longer range, with many different engine combinations, and in included a very successful production line freighter variant. The A340-500/600 was designed for a very different market; very long range international sectors. There is little prospect for further improvement of the aircraft unless Airbus is willing to spend billions on a new wing and new engines which might close the performance gap with its principal rival, the Boeing 777LR. Airbus is in NO position to invest such sums, considering the near financial disaster of the A380 development, problems with the A400M military transport, and significant spending on the A350XWB. The inability to effect such improvements is borne out in the recent order battle with the B777 which Boeing securing 137 firm orders in 2007/2008 while Airbus booked a total of 10 net over the same two years. AIRLINES DON’T EXPECT ANY FURTHER IMPROVEMENT. Even with a short production run, one might expect the A340-500/600 to operate for more than 20 years after production cessation. The Lockheed L-1011 ended production in 1981 and a few are still in operation worldwide 26 years later. Yet, the economics of the A340-500/600 indicate a much shorter service life than other wide bodies. For one thing, there is no A340-500/600 in freighter operations and future potential for conversion to cargo is limited by its relatively high fuel consumption and maintenance burden, and the near-term availability of the A340’s twin engine “sister” the A330-200F. Generally speaking, wide bodies of all kinds, including first generation types Lockheed L-1011, DC10-10/30, Boeing 747-100/200/300, Airbus A300 and A310 have had their operational lives extended by their shift to the all freight market. Wide body conversions were until very recently, at an all time record. Nearly all MD-11s, just fewer than 200 to be exact, 9 Aircraft Commerce, Issue 38, December 2004/January 2005. The current worldwide economic recession has helped drive airline traffic into negative territory for the first time since October 2001. Even international traffic has declined dramatically and carriers such as Singapore are reducing capacity and grounding aircraft. In February 2009, Singapore announced it was reducing capacity 11% and parking 17 undesignated aircraft by April 2009 to address this downturn. 11 have been converted to cargo service or will soon be so. And while even the MD-11CF and Fs will be replaced by newer twin-engined wide body freighters including but not limited to the B777F and A330F, MD-11s are expected to remain in service for at least another 10-20 years partly because of the unique payload niche the MD-11 occupies (See chart below). However, such is not expected to be the case with the A340-500/600. Firstly, the expected fleet size is far too small on a historical level for conversion consideration. Second, fuel burn and high average maintenance make it woefully inadequate when considering options. An A340-500/600 freighter would have operating costs near that of the 747-400 but a payload capability closer to the MD-11. It is, therefore, not logical to think that the A340-500/600 will migrate to freight service at any time in its life. COST OF OPERATION OF A330-200F versus COMPETITORS on a lease basis 4000 nm sector 80% Payload Factor Block Hours/Mo Cash Purchase Cost 300 A330-200F $70,000,000 300 767F-New $75,000,000 300 767P2F $40,000,000 300 DC10P2F $15,000,000 300 MD11P2F $65,000,000 300 777F $140,000,000 300 747-400F $120,000,000 300 747-400P2F $90,000,000 Payload Block Time Gallons Fuel/BH Fuel Cost/Gallon Maintenance/BH 64.30 9.00 1,900 $2.00 $675 48.40 9.00 1,750 $2.00 $630 48.40 9.00 1,800 $2.00 $925 55.10 8.80 3,100 $2.00 $1,475 70.00 8.70 2,800 $2.00 $1,300 86.10 8.60 2,500 $2.00 $885 97.70 8.50 3,700 $2.00 $1,000 97.70 8.60 3,800 $2.00 $1,550 Operating Cost/BH Cost per tonne/BH Cost per tonne/Stage $4,475 $70 $626 $4,130 $85 $768 $4,525 $93 $841 $7,675 $139 $1,226 $6,900 $99 $858 $5,885 $68 $588 $8,400 $86 $731 $9,150 $94 $805 Operating Cost/mo Lease Cost/MO $1,342,500 $725,000 $1,239,000 $700,000 $1,357,500 $400,000 $2,302,500 $150,000 $2,070,000 $450,000 $1,765,500 $1,400,000 $2,520,000 $1,000,000 $2,745,000 $825,000 TOT OP Cost/MO TOTAL COST PER BH per tonne Estimated NM Flown Cost per Tonne/NM $2,067,500 $6,892 $32,154 120,000 $0.27 $1,939,000 $6,463 $40,062 120,000 $0.33 $1,757,500 $5,858 $36,312 120,000 $0.30 $2,452,500 $8,175 $44,510 120,000 $0.37 $2,520,000 $8,400 $36,000 120,000 $0.30 $3,165,500 $10,552 $36,765 120,000 $0.31 $3,520,000 $11,733 $36,029 120,000 $0.30 $3,570,000 $11,900 $36,540 120,000 $0.30 Source: Bloomberg Investments, November 2006. If the A340-500/600 had better payload and fuel consumption performance, it might have a future along the lines of the MD-11 mentioned above. MD-11 residual value history (AirClaims) is on the next page. 12 MD 11 RESIDUAL VALUES MD-11 Residual Values 100.00% 50.00% %OEC 0.00% 90 19 91 19 92 19 93 19 94 19 95 19 96 19 97 19 98 19 99 00 19 20 1990-2008 01 20 02 20 03 20 04 20 05 20 06 20 07 20 08 20 CEC = Cash equivalent or acquisition cost. With no freighter future in sight and it becoming increasingly clear to owner/operators that the aircraft cannot compete on a seat by seat basis with the B777-200LR and ER, there will likely be a migration to 2nd and 3rd level carriers who generally fly at far lower utilization than their major counterparts. Indeed, the near collapse of the worldwide financial system in late 2008 and the concurrent worldwide economic recession points toward an air cargo market that would have little to do with the A340-500/600. Airline Monitor provided appraised value for a 2008 manufactured A340-500. Data is as follows: 2008 mean list price = $237.1 m 2008 Estimated manufacture realized price = $141.0 m 2008 Apprised value (Avg. three transactions) = $120.1 m This amounts to a value decline of 14%. That is easily the greatest valuation decline of any production wide body aircraft for 2008. However, that decline doesn’t tell the whole story. The realized price of $141m is a 32% discount to list. Such discounts are now typical on narrow body orders but not very long range aircraft such as the 777-300ER/LR whose performance is so superior that the discount level is significantly below that of other aircraft. In order to sell the A340-500/600, Airbus resorted to discount levels not seen in the very long-range sector since introduction of the A330 and B777 in the early 1990s. Finally, we expect many owners to park aircraft in the hopes of selling or leasing out to other customers and the number of “parked” aircraft will greatly impact the future spares market for the aircraft and its major systems including the Trent 500 and nacelle system. 13 In short, the future of the A340-500/600 is poor at best. Among those expected to park aircraft (or sell), are Thai with four A340-500s, Qatar with 4 Dash 600s, and ILFC (operated by Cathay) with 3 Dash 600s as well. For suppliers including Aircelle and its component “partners”, they share a similar fate. 5. Propulsion Maintenance Outlook – The Trent 500 was developed solely for the A340500/600. It uses the fan of the Trent 700, a scaled down core, and a five stage LP turbine versus the 4 stage turbine of the Trent 700. Therefore, commonality with other members of the Trent family is very low, on the order of 30-40%. The nacelle, including the engine “plug”, or hot components of the nacelle and engine nozzle, were also specifically designed for the Trent 500 and Airbus A340-500/600. In other words, there is NO commonality of Trent 500 nacelle components with any other Trent engine. The Trent 700 uses a Common Nozzle Assembly or CNA. Trent 500 uses a primary nozzle, forward plug and aft plug. As anyone in the engine business knows, commonality is one of the key’s to long-term financial viability of an engine/nacelle program and assurance that parts will stay in service far beyond the end of the life of their initial host aircraft. Those parts will eventually need to be replaced or repaired. A large installed base of engines provides significant long-term spares and services revenue with high commonality within engine families providing support for higher engine residual values. CF6-80C2, one example, is used on the B747-400, A300-600, A310-200/300, B767 and MD-11. In some cases, modules are interchangeable. In most cases, parts from one engine can be used on another. The Trent 500 is a “one off” utilized ONLY on the Airbus A340-500/600 aircraft. That means that it can’t be used on any other aircraft and while RR will see Trent 500 parts common to other Trents used on other Trents in the future aftermarket, the nacelle maker will not see such use as, again, there is NO commonality with any other Trent nacelle. The MB Strategy turbine industry forecast model is used to forecast spares material consumption/demand for nearly all the world’s aircraft and industrial engines. The model is based on known engine installed bases, utilization and material maintenance cost per hour, adjusted for percent of parked fleet, and availability of used parts. The model’s forecasts are in then year (escalated) dollars. The specific Trent 500 model is as follows in two forms, the Blue bars projecting spares sales on a per hour basis under Long Term Maintenance Agreements (assumes 100% on LTMA), and shop visits. The red bars show our forecast based on total annual hours divided by shop visit rate. The first 3-5 years of service are generally provided free under warranty or in the case of this particular aircraft, as part of the initial sale “discounting” procedure. As you can see, RR benefits from “hour one” while its suppliers generally have to wait for a specific shop visit to take place before receiving revenue from RR or RR partner/JV service ventures. Most importantly however, is the curve of both forecasts. We expect utilization, LTMA and spare revenue to peak in about seven years with a steady decline thereafter. In addition to lower annual utilization affecting these curves are parking aircraft for extended periods of time, and occasional scrapping leading to cannibalization of engines which reduces new parts sales. (Next Page) 14 Trent 500 Spares Sales: PBH vs Shop Visit Models $350,000,000 $300,000,000 Annual Then Year Sales $250,000,000 $200,000,000 TRENT 500 Spares Sales (PBH) $150,000,000 Trent 500 Spares Sales (Shop Visit) $100,000,000 $50,000,000 $0 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 CY 6. Nacelle Maintenance/Spares – A nacelle requires substantially less maintenance than the engine it encloses. As mentioned earlier, the Trent 500 is seeing around 20,000 hours “on wing” before major service. The nacelle in this application will see 40,000 hours, says Magellan. Comparatively, short haul wide body and narrow body engines see 6,000-15,000 hours while nacelles and thrust reversers see 12,000-25,000 hours. The reason for the difference is quite obvious. Very long range aircraft generate far fewer cycles. High hour/to cycle ratios generate higher on wing life as the engines are operating at cruise power and lower temperatures and stresses for far longer periods than their short/medium haul counterparts. The following chart shows the MB Strategy nacelle spares model for the Trent 500/A340500/600 application. (Next Page) 15 Nacelle Spares Sales: PBH vs Shop Visit Models $16,000,000 $14,000,000 $12,000,000 Sales/Year $10,000,000 Nacelle Sales (5% of PBH) $8,000,000 Nacelle Sales (5% relative to engine shop visit cost) $6,000,000 $4,000,000 $2,000,000 $- 01 20 03 20 05 20 07 20 09 20 11 20 CY 13 20 15 20 17 20 19 20 As a general rule of thumb, nacelle maintenance cost is around 5% of the total engine maintenance cost. Nacelles also can carry a higher percentage of repaired components since there are few if any life limited parts. Major nacelle produces Goodrich and SAFRAN (Aircelle) will confirm a very small percentage of nacelle sales being in spares or repair services. In short, a nacelle is very much like the airframe itself; it generates far less service and parts sales revenue than aircraft equipment (electric power, hydraulics/controls, avionics, environmental controls) and engines. And, the components that generate the highest maintenance burden of all are the inlet cowl, thrust reverser and thrust reverser actuation, and exhaust plug. The plug is the second highest cost component of these four but is also subject to airline repair schemes. a. Magellan Beta21 Testing – In order to determine suitability of Beta21 titanium (Proprietary Timet material) for the Magellan Aeronca nozzle and plug assembly, and to support future spares sales estimates for the Trent 500, Magellan (Orenda), in 1999, performed a coupon furnace test of Beta21 Titanium sheet samples and individual components used in that assembly. The test was conducted for 300 hours at 1300F10. The test ultimately resulted in recommendations as follows: a) Change braze alloy to allow for lower brazing temperature. This would require full qualification of the new braze. This will avoid excessive beta grain growth. b) Evaluate new custom designed braze alloy compatible to Beta21S and new heat cycle which would reduce the amount of time over the beta transus temperature. c) Reduce oxygen diffusion to bulk of the foil by utilizing oxygen diffusion barriers as protective coatings. “Investigation of Oxidation Effects of Furnace Exposed Titanium Alloy (Beta21) Honeycomb Structure,” Magellan Orenda Aerospace Corporation, February, 1999. 10 16 d) Increase foil thickness from 0.003” to an optimum thickness (0.011”??). This is expected to considerably extend the service life of the honeycomb foil but there will be a weight penalty associated with this. We know that Magellan made those changes as we have seen the published overweight condition of delivered assemblies. At that time, Magellan Aeronca would have assumed 100,000 hours of ultimate life. Therefore, we have reviewed all other testing information including various emails and reports dating from October 2005. We can find no specific reference to a known 40,000 hour life but only a projection. Now, the resultant data was used by Magellan to also forecast spares but later the company reduced life expectancy from 100,000 hours to 40,000 hours. They used their “assumption” derived from the test. There is no statement in the test report concerning a specific life in hours. A prediction of 1/3 of the original 100,000 hour life came in a note from Raj Thamburaj to Richard Neill, dated March 12, 2007. The 40,000 hour life prediction came later, March 14, 2007 in a note from Richard Neill to Stephen Moore of Pratt & Whitney Canada of a forwarded note from the Thamburaj note of March 12, 2007. The 40,000 hour prediction was used for “conservatism” in forecasting spares and was attributed to a former Director of Engineering at Aeronca, Dave Tack. In conjunction with the new 40,000 hour life, Magellan used Forecast International forecasts for additional aircraft and the very high annual utilization (5,000 hours annually) to project spares/repair sales. We believe both the FI forecast and utilization data are suspect. This is based on the FI data provided to Magellan (through 2007), and MB Strategy acquisition of an FI A340 report from April 2007 which had 213 A340-500/600 combined history and forecast through 2016.11 We now know Forecast international now projects less than 170 aircraft in the A340-500/600 program. Teal Group, Bank of America - Merrill Lynch, and others do not project totals of more than 135. On the issue of utilization, fleet data has the A340-500/600 at between 4200 and 4800 hours depending upon customer with one lone operator, Singapore, seeing 5000 hours annually on its Singapore/LA route (This figure may decline as Singapore cuts capacity through April 2009). Using 5,000 hours across the fleet inflates the spares requirements, as does the forecast for upwards of 170-213 total aircraft from Magellan’s forecast provider. More importantly, if, as Magellan claims, the nacelle plug/nozzle is good for just 40,000 hours, then we would expect them to have informed any customer who is getting close to that figure. One that we know of is Virgin which we are told are in excess of 30,000 hours on 3 airframes this year. THERE IS NOTHING ON ORDER. Based on the aircraft in service from 2002-2004 according to Magellan assumptions, there would be as many as 100 NACELLES COMING UP ON REPLACEMENT over the next 24 months. If this is true and Magellan expected replacement spares work on those components, they would have had to order Beta21 material from Timet due to the long lead time associated with this proprietary material. More over, normal industry practice would have Magellan informing the airlines well in advance, at last two years, prior to any recommended inspection. If Magellan were aware before March 2007, I have no doubt that the company would have informed Aircelle, Airbus, and the airline customers. Even if Magellan had good forecast and utilization data in 2007 when it conducted the Beta21 test, the test itself was not representative of what that component actually sees in service. It is most unusual for a financial forecast of such importance to be based on such limited testing involving the replacement spares value of several hundred aircraft. Life of a component cannot be easily projected based on data derived from this one test. 11 Forecast International Aircraft Forecast, April, 2007. 17 There must be far more empirical data (from other similar Beta21 applications), and there must be more representative tests which replicate an A340-500/600 flight cycle of takeoff, climb, cruise, descent, and landing at typical weight and cruise speed. Each of the components of a flight cycle has far different temperature and stress characteristics that simply cannot be replicated in a 300 hour coupon test. Such a test could be accomplished only on the aircraft itself or complete engine in a high altitude test cell. Magellan was not in a position to do this due to the enormous cost. As such, the company’s analysis of component life cannot be relied upon as a factor in forecasting spares sales. Additionally and very importantly, Magellan constantly references “repairs” in its documentation including the Guarantee Letter which is covered later. This implies strongly that there would be many more repairs then new spares. Finally, the Rich Neil memo of March 29, 2007 states that Magellan choose to “ignore” the probability of airlines repairing these components in forecasting aftermarket sales. b. Guarantees. MB Strategy reviewed Magellan “guarantees” Appendix X of documents provided to see if there was any reference to 40,000 hours. (Magellan is more than likely “warranteeing” the component for 40,000 hours and not providing a firm guarantee on that same figure.) This document details repair costs per flight hour (2000 base) based on annual utilization of 5,000 hours and average flight duration of 7 hours. There is no ultimate life metric in this document and only discussed repair hours required to effect repair and test of the repaired assembly. If we use the Magellan quoted $/hour for each of the nozzle and plug, we get a total repair cost or guaranteed not to exceed cost of $4400 for the nozzle and $6,400 for the plug. Repairs are generally 35-65% of unit cost on airframe and engine items but in t his case, the cost represents just 5% of the $222k revenue per unit shown in Aeronca documents.12 No reasonable customer would buy a spare at list (less some discount) when they can get a repair for a fraction of the cost. This fact also places the Magellan spares/repair forecast in serious question. In point of fact, most if not all customers will choose to REPAIR and not replace which I standard procedure in the nacelle marketplace. c. 12 Future Spares. The future new spares market for Trent 500 nacelles is therefore extremely limited. We expect the fleet of less than 130 operational aircraft to decline post 2010 as more efficient and environmentally acceptable long-range twins including B777LR, B787, and A350XWB replace them in front line service, and some carriers park the aircraft due to their relatively high costs and the extended worldwide airline traffic downturn. As these aircraft are replaced, they will be “parked” and as a significant percentage of the A340500/600 fleet could be parked or generating very low annual utilization by the year 2010. As we mentioned earlier, Thai, Qatar and ILFC/Cathay could sell or park 7 Dash 500s and 5 Dash 600s. The former represents 20% of the Dash 500 fleet. Early serial numbers will likely be permanently retired under 20 years of life; and parted out. This will also depress new spares and repairs demand as engines and nacelles will be among the first items to be acquired and put back into the world operating inventory. Exhibit 8.3, Aeronca Inc. A340 nacelle program, December 31, 2006. 18 Airbus A330/340 Parked Aircraft History13 A330/340 Parked Aircraft History Post 9-11 35 30 25 Units 20 15 Post US Financial Market "Collapse" 10 5 08 5/ 14 /1 20 07 4/ 12 /1 20 06 4/ 12 /1 20 05 4/ 12 /1 20 04 4/ 12 /1 20 03 4/ 12 /1 20 02 4/ 12 /1 20 01 4/ 12 /1 20 00 4/ 12 /1 12 /1 4/ 19 99 0 Reporting Period d. Historical Comparables. Finally, there are two major historical parallels to the spares future ahead of Trent 500 suppliers; the P&W JT8D Standard and JT9D. JT8D STD new spares sales peaked in the very early 1990s then plummeted to zero in 2000. JT9D spares sales peaked in 1997, then slumped dramatically as first generation 747-100/200/300s were parked and parted out. In short, the available inventory of usable engines ended the spares booms for each of those power plants. Additionally, a huge independent engine component repair industry developed that further eroded the demand for new engine spares from the OEM. The same will happen to the Trent 500 but on a much earlier schedule. e. MB Strategy Analysis of Nozzle/Plug Spares/Repairs. Based on this scenario, we believe that Trent 500 new spare/repair nacelle sales will be in the range of 100-130. This range at the low end of what we forecast more than a year ago (100-300). Our current forecast is based on far more detail. This range does not cover the 2007 Magellan forecast of 190. However, that forecast assumes production of a total of 721 which is equivalent to around 180 aircraft. Assuming we, Teal Group, and others are closer to total aircraft build reality, the total on wing number of nacelles is 540 or 135 aircraft shipsets. That number would result in far fewer forecast spare/repair sales than Magellan projects, around 25% less or around 130. Additionally, we expect third part repair parts activity in this sector, not withstanding the small fleet size. If the new component price is extraordinarily high as it might be in this unusual case as Magellan would attempt to recover its NRC, then a customer will be forced to develop a component repair and this would further depress spares sales of the Magellan component. Additionally, if Magellan is correct in forecasting 200 spare/repair nacelles by 2010, they would have to be ordering Beta21 from Timet. Finally, Merrill Lynch, December 15, 2008. Merrill Lynch and Airclaims, Merrill’s supplier, do not break out A330 from A340. We suspect that most of the parked family are A340-200 and 600s. 13 19 MB Strategy believes average fleet utilization will decline gradually to close to 4,000 hours as aircraft are sold into secondary markets and parked in substantial numbers. Therefore, we would have to reduce the forecast 130 spares/repairs by another 20% to 104. This projection assumes 40,000 hour nozzle/plug life even though MB Strategy believes the actual in service life will be higher due to typical cycle parameters and the difference between that cycle and the Magellan engineering analysis. 7. Conclusion – The outlook for nacelle spares sales on Trent 500 is worse than that overall for the Trent 500 engine itself and the aircraft. RR can look forward to that steady stream of engine Long Term Maintenance Agreement revenues on the engine, and potentially the ability to leverage any Trent 500s that are removed from parted out A340-500/600s. Nacelle component suppliers will not have such flexibility as their products cannot be used on any other aircraft/engine combination. Finally, any aftermarket sales on the Trent 500 nacelle is more likely to accrue to companies and airlines that develop their own nacelle repairs in order to avoid the significant replacement cost for such a component ($700K per aircraft). * * 20 * Attachment 1 Neill Memo March 29, 2007 21 Attachment 2 Aeronca Forecast 22 Forecast International Large Commercial Jet Forecast June 2005 23