Graphene-Hemin Hybrid Material as Effective Catalyst for

advertisement

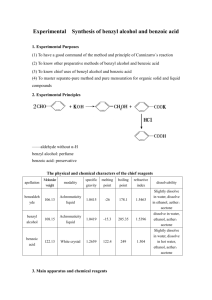

Supplementary Information Graphene-hemin hybrid material as effective catalyst for selective oxidation of primary C-H bond in toluene Yongjia Li1, Xiaoqing Huang1, Yujing Li1, Yuxi Xu2, Yang Wang1, Enbo Zhu1, Xiangfeng Duan2,3, Yu Huang1,3* 1 Department of Materials Science and Engineering, 2Department of Chemistry and Biochemistry, and 3California NanoSystems Institute, University of California, Los Angeles, California 90095, United States * To whom the correspondence should be addressed. E-mail: yhuang@seas.ucla.edu Content S1: Experimental Methods Figure S1: Stability of H-GN and GN Samples in Ethanol Figure S2: XPS Results Figure S3: AFM Results Figure S4 and Table S1: Toluene Conversion Process and Selectivity Using TBHP as Oxidant with Different Catalysts Figure S5: Comparison of Toluene Conversion with Different H-GN Catalyst Dosage Table S2: Comparison of Toluene Conversion and Selectivity by Repeated Addition of Catalyst Table S3: Absolute Production of Benzyl Alcohol, Benzaldehyde and Benzoic Acid Table S4: Comparison of the catalytic activity for oxidation of different substrates catalyzed by H-GN Table S5: Comparison of Toluene Oxidation Catalyst Activity of H-GN with Other Reported Catalysts Reference 1 S1. Experimental Methods S1.1. Construction of H-GN Graphene Oxide (GO) is synthesized by modified Hummer’s method.S1 As-prepared GO aqueous suspension is transferred into ethanol by centrifuge, and diluted to 0.5 mg/ml. 20 ml GO suspension is then mixed in 50 ml round bottom flask with 20 ml 0.5 mg/ml hemin solution in ethanol under vigorous stirring. After 30 min, 0.2 ml ammonia (28%) and 50 μl hydrazine hydrate (35%) are added into solution. After another 30 min vigorous stirring, flask is then placed in oil bath and heated up at 65 oC for 3.5 hours. Hemin-Graphene (H-GN) dispersion in ethanol is washed by centrifuge for 5 circles to eliminate excessive hemin or hydrazine hydrate. The clean H-GN is stored at room temperature in sealed vial. Synthesis of Graphene (GN) is similar to H-GN, except for introduction of hemin as stabilizer. S1.2. Catalytic reactions S1.2.1. Using O2 as oxidant 9 ml toluene is introduced into round bottom flask while vigorously stirring, 0.169 ml t-butyl hydroperoxide (TBHP) in decane (5 mol/l) is then added as initiator. Slow O2 stream is bubbled continuously into solution. After one hour, desired amount of H-GN is diluted to 9 ml in ethanol, and added into flask. After another 30 min stirring, flask is heated up to 60 oC in oil bath. Subsequent catalyst additions (if required) are done after 7 hours ± 1 min, and very 4 hours ± 1 min afterwards. The reaction length varies from 12 hours to 48 hours. S1.2.2. Using TBHP as oxidant 3 ml toluene is added into round bottom flask while vigorous stirring, 5.625 ml TBHP in decane (5 mol/l) is then added as oxidant. After one hour, desired amount of H-GN is diluted to 9 ml in ethanol, and added into flask. After another 30 min stirring, flask is heated up to 80 oC in oil bath. The reaction lasts 12 hours. 2 S1.2.3. Sampling and analysis Sampling is done per 15 ± 1 min for the first hour and 30 ± 1 min afterwards. All samples are analyzed using Gas Chromatography-Mass Spectroscopy (GC-MS) with chlorobenzene as internal standard. All precursors are pre-screened by GC-MS to filter auto-oxidation products or contaminants. Stability of H-GN and GN Samples in Ethanol Figure S1. Representative images of GO, H-GN freshly prepared and after weeks. a. Freshly made GO (left) and freshly made H-GN (right). b. H-GN in ethanol stored at room temperature over a month (left). GN in ethanol stored at room temperature for less than 3 weeks (right). Stability of H-GN hybrid is tested. After storing H-GN solution for over 3 months, the solution maintains homogenous and no color change is observed. Comparatively, GN from GO solution without any stabilizer forms precipitate within less than 3 weeks. Moreover, the thermal stability is examined by annealing H-GN solution at 80 o C for 48 hours in sealed vial protected by N2 gas. No aggregation or color change is observed. The Soret band absorbance intensity reduces by less than 10%. Hence, it clearly indicates H-GN is stable at room and elevated temperatures. 3 XPS Results Figure S2. XPS survey of GO and H-GN. a. Survey of GO sample. b. Survey of H-GN sample. c. Deconvolution of C1s in GO sample (1. C-C: 284.6 eV. 2. C-O: 286.7 eV. 3. C=O: 287.6 eV. 4. O=C-O: 288.7 eV). d. Deconvolution of C1s in H-GN sample (1. C-C: 284.6 eV. 2. C-N: 285.7 eV. 3. C-O: 286.4 eV. 4. C=O: 287.6 eV. 5. O=C-O: 288.7 eV.). e. Deconvolution of Fe2p in H-GN synthesized in water (1. Fe 2p2/3: 707.1 eV. 2. Fe pre-peak: 705.7 eV. 3. Fe-O: 710.5 eV. 4. Fe 2p1/2: 719.5 eV).S2, S3 4 AFM Results Figure S3. AFM results of GN and H-GN. a. Tapping-mode AFM image of GN. Scale bar = 1 μm. b. Tapping-mode AFM image of H-GN. Scale bar = 1 μm. c. Height profile of GN with selective line scan (taken along the white line in a.) d. Height profile of H-GN with selective line scan (taken along the white line in b.) Different Catalysts 1 µm Figure S4. Toluene conversion using TBHP as oxidant. Reaction temperature is 80 o C. Reaction time is 12 hours. Substrate/oxidant molar ratio is 1. Substrate/catalyst molar ratio is 100,000. 5 Table S1. Comparison of selectivity of toluene oxidation using TBHP as oxidant. Substrate/oxidant ratio is 1. Substrate/catalyst molar ratio is 100,000. Reaction temperature is 80 oC and reaction time is 12 hours. Time Catalyst Benzaldehyde % Benzyl Benzoic Alcohol % Acid % 97.4% 2.6% 0.0% 93.8% 3.2% 3.0 12 92.7% 2.7% 4.6% 4 90.8% 5.4% 3.8% 87.1% 5.0% 7.9% 12 85.6% 4.8% 9.6% 4 97.5% 2.5% 0.0% 92.5% 6.2% 1.3% 12 90.6% 6.2% 3.2% 4 76.7% 13.5% 9.8% 72.0% 13.2% 14.8% 54.7% 17.4% 27.9% (hours) 4 8 8 8 8 12 N/A Hemin * GN † H-GN * Substrate/catalyst molar ratio is 100,000. † Dosage of GN is calculated based on GN mass in H-GN for normal catalytic reaction, with substrate/catalyst molar ratio of 100,000. 6 Comparison of Toluene Conversion with Different H-GN Catalyst Dosage Figure S5. Comparison of toluene oxidation conversion with different H-GN catalyst concentrations. O2 is oxidant. O2 pressure is 1 atm. Reaction temperature is 60 oC. Reaction time is 20 hours. Comparison of Toluene Conversion and Selectivity by Repeated Addition of Catalyst Table S2. Comparison of toluene conversion and selectivity with repeated addition of catalyst. Toluene dosage is 9 ml. O2 is used as oxidant. O2 pressure is 1 atm. Reaction temperature is 60 oC. Reaction time is 20 hours for single addition and 2 times addition trials, 30 hours for 5 times and 7 times addition trials. TBHP is used as initiator. Substrate/initiator molar ratio is 100. Substrate/catalyst molar ratio is 100,000. Catalyst dosage is identical for every addition in all trials. Part a: Single addition results Reaction Conversion Benzyl Benzaldehyde Benzoic time (%) Alcohol (%) Acid (%) (hours) TON (%) 0 0.00% 0.00% 0.00% 0.00% 0 1 0.79% 11.6% 88.4% 0.0% 790 2 0.96% 14.3% 82.5% 3.2% 960 3 1.19% 11.5% 79.6% 8.9% 1190 7 4 3.42% 12.5% 78.4% 9.1% 3420 5 4.91% 11.3% 79.7% 9.0% 4910 6 5.57% 12.8% 78.1% 9.1% 5570 7 7.62% 11.4% 78.3% 10.3% 7620 8 8.93% 11.0% 77.6% 11.4% 8930 9 9.12% 10.6% 75.4% 14.0% 9120 10 9.35% 10.4% 76.1% 13.5% 9350 11 9.40% 10.7% 74.9% 14.4% 9400 12 9.42% 10.8% 73.2% 16.0% 9420 13 9.67% 10.1% 69.3% 20.6% 9670 14 9.74% 9.8% 68.5% 21.7% 9740 15 9.82% 9.3% 68.7% 22.0% 9820 16 10.03% 9.7% 64.1% 26.2% 10030 17 10.10% 9.6% 66.2% 24.2% 10100 18 10.14% 8.8% 64.3% 26.9% 10140 19 10.23% 8.6% 60.1% 31.3% 10230 20 10.27% 8.4% 58.7% 32.9% 10270 Part b: 2 times addition results Addition Reaction Conversion Benzyl Benzaldehyde Benzoic time (%) Alcohol (%) Acid (hours) 1st (%) TON (%) 0 0.00% 0.00% 0.00% 0.00% 0 1 0.75% 8.4% 91.2% 0.00% 750 2 0.94% 10.3% 86.4% 3.30% 940 3 1.97% 12.6% 82.4% 5.00% 1970 4 3.65% 12.4% 79.6% 8.00% 3650 5 5.12% 11.4% 79.7% 8.90% 5120 6 6.23% 12.0% 76.5% 11.50% 6230 8 2nd 7 7.28% 12.2% 76.3% 11.50% 7280 8 9.66% 17.4% 65.4% 17.18% 4830 9 11.26% 17.6% 62.3% 20.09% 5630 10 13.42% 16.9% 57.6% 25.50% 6710 11 16.37% 15.8% 52.5% 31.68% 8185 12 16.58% 15.4% 49.4% 35.24% 8290 13 17.38% 14.3% 47.4% 38.28% 8690 14 17.42% 12.7% 45.9% 41.45% 8710 15 17.69% 10.0% 45.3% 44.72% 8845 16 18.23% 9.6% 44.7% 45.69% 9115 17 18.64% 9.4% 44.4% 46.23% 9320 18 18.72% 9.5% 43.9% 46.60% 9360 19 18.79% 8.3% 43.3% 48.42% 9395 20 19.20% 8.7% 41.7% 49.59% 9510 TON Part c: 5 times addition results Addition Reaction Conversion Benzyl Benzaldehyde Benzoic time (%) Alcohol (%) Acid (hours) 1st 2nd (%) (%) 0 0.00% 0.00% 0.00% 0.00% 0 1 0.68% 6.60% 90.60% 2.80% 680 2 1.04% 9.00% 83.40% 7.60% 1040 3 2.41% 11.30% 79.30% 9.40% 2410 4 3.51% 12.80% 78.20% 9.00% 3510 5 4.67% 11.70% 78.50% 9.80% 4670 6 6.04% 12.30% 77.10% 10.60% 6040 7 7.43% 12.20% 75.40% 12.40% 7430 8 8.92% 17.00% 68.10% 14.90% 4460 9 10.13% 16.35% 64.40% 19.25% 5065 9 3rd 4th 5th 10 13.18% 18.86% 59.70% 21.44% 6590 11 15.32% 17.53% 57.30% 25.17% 7660 12 17.91% 20.14% 52.80% 27.06% 5970 13 19.45% 17.70% 49.60% 32.70% 6483 14 21.42% 18.63% 45.70% 35.67% 7140 15 23.42% 16.89% 44.20% 38.91% 7807 16 24.78% 13.73% 43.60% 42.67% 6195 17 26.48% 11.73% 37.60% 50.67% 6620 18 27.39% 13.44% 37.50% 49.06% 6848 19 28.67% 13.77% 34.10% 52.13% 7168 20 30.14% 13.76% 30.00% 56.24% 6028 21 31.22% 11.49% 29.80% 58.71% 6244 22 32.65% 10.57% 27.40% 62.03% 6530 23 32.74% 9.23% 25.30% 65.47% 6548 24 33.06% 11.42% 25.40% 63.18% 6612 25 34.26% 10.91% 21.50% 67.59% 6852 26 34.31% 9.47% 21.30% 69.23% 6862 27 34.43% 9.18% 20.60% 70.22% 6886 28 34.57% 7.96% 20.80% 71.24% 6914 29 34.70% 5.28% 20.40% 74.32% 6940 30 34.75% 6.20% 19.60% 74.20% 6946 TON Part d: 7 times addition results Addition Reaction Conversion Benzyl Benzaldehyde Benzoic time (%) Alcohol (%) Acid (hours) 1st (%) (%) 0 0.00% 0.00 0.00 0.00% 0 1 0.69% 6.2% 89.4% 4.4% 690 2 1.25% 10.5% 84.2% 5.3% 1250 10 2nd 3rd 4th 5th 6th 7th 3 1.87% 11.2% 80.6% 8.2% 1870 4 3.25% 13.3% 76.3% 10.4% 3250 5 4.33% 10.2% 78.2% 11.6% 4330 6 5.38% 10.8% 77.5% 11.7% 5380 7 7.02% 12.1% 74.7% 13.2% 7020 8 9.23% 16.0% 68.4% 15.6% 4615 9 10.48% 13.1% 64.6% 22.3% 5240 10 12.23% 15.4% 62.7% 21.9% 6115 11 16.01% 14.3% 57.9% 27.8% 8005 12 18.29% 16.7% 53.6% 29.7% 6097 13 19.80% 16.9% 52.7% 30.4% 6600 14 22.28% 12.8% 48.6% 38.6% 7427 15 24.52% 15.2% 42.1% 42.7% 8173 16 26.01% 12.9% 40.6% 46.5% 6503 17 27.44% 8.2% 42.7% 49.1% 6860 18 28.69% 9.0% 38.6% 52.4% 7173 19 30.34% 8.4% 35.2% 56.4% 7585 20 32.18% 8.1% 33.6% 58.3% 6436 21 34.70% 5.9% 31.7% 62.4% 6940 22 35.68% 5.1% 30.6% 64.3% 7136 23 35.92% 6.5% 26.8% 66.7% 7184 24 36.82% 4.9% 24.7% 70.4% 6137 25 37.34% 7.6% 23.9% 68.5% 6223 26 38.14% 7.3% 20.4% 72.3% 6357 27 38.54% 3.0% 18.6% 78.4% 6423 28 39.23% 2.4% 16.3% 81.3% 5604 29 39.72% 1.1% 15.7% 83.2% 5674 30 40.56% 2.2% 12.1% 85.7% 5794 11 Absolute Production of Benzyl Alcohol, Benzaldehyde and Benzoic Acid Table S3. Absolute production of benzyl alcohol, benzaldehyde and benzoic acid. Reaction temperature is 60 oC. Reaction time varies from 12 hours to 30 hours. Catalysts used include hemin, H-GN and reference without catalyst. O2 is used as oxidant. O2 pressure is 1 atm. TBHP is used as initiator. Substrate/catalyst molar ratio is 100,000. Substrate/initiator molar ratio is 100. In repeated addition trials, dosage of H-GN from each addition in all trials is identical. Absolute production is calculated by multiplying selectivity of respective product with overall conversion of toluene. Part a: Without catalyst result Reaction Conversion time (hours) (%) Absolute Production Benzyl Benzaldehyde Benzoic Acid Alcohol (%) (%) (%) 0 0.00% 0.00% 0.00% 0.00% 1 0.00% 0.00% 0.01% 0.00% 2 0.01% 0.00% 0.02% 0.00% 3 0.02% 0.00% 0.05% 0.00% 4 0.05% 0.00% 0.08% 0.00% 5 0.08% 0.00% 0.09% 0.00% 6 0.10% 0.00% 0.11% 0.00% 7 0.12% 0.00% 0.12% 0.00% 8 0.13% 0.00% 0.14% 0.00% 9 0.15% 0.00% 0.16% 0.01% 10 0.17% 0.01% 0.18% 0.01% 11 0.19% 0.01% 0.19% 0.01% 12 0.21% 0.01% 0.20% 0.01% 12 Part b: Hemin result Reaction Conversion time (hours) (%) Absolute Production Benzyl Benzaldehyde Benzoic Acid Alcohol (%) (%) (%) 0 0.00% 0.00% 0.00% 0.00% 1 0.15% 0.01% 0.14% 0.01% 2 0.23% 0.01% 0.21% 0.01% 3 0.34% 0.02% 0.31% 0.01% 4 0.36% 0.02% 0.33% 0.01% 5 0.39% 0.03% 0.35% 0.02% 6 0.41% 0.01% 0.36% 0.04% 7 0.43% 0.02% 0.38% 0.02% 8 0.61% 0.03% 0.53% 0.05% 9 0.73% 0.05% 0.62% 0.06% 10 0.82% 0.05% 0.70% 0.07% 11 0.94% 0.06% 0.79% 0.08% 12 1.02% 0.05% 0.87% 0.10% Part c: H-GN single addition results Reaction Conversion time (hours) (%) Absolute Production Benzyl Benzaldehyde Benzoic Acid Alcohol (%) (%) (%) 0 0.00% 0.00% 0.00% 0.00% 1 0.79% 0.09% 0.70% 0.00% 2 0.96% 0.14% 0.79% 0.03% 3 1.19% 0.14% 0.95% 0.11% 4 3.42% 0.43% 2.68% 0.31% 5 4.91% 0.55% 3.91% 0.44% 6 5.57% 0.71% 4.35% 0.51% 13 7 7.62% 0.87% 5.97% 0.78% 8 8.93% 0.98% 6.93% 1.02% 9 9.12% 0.97% 6.88% 1.28% 10 9.35% 0.97% 7.12% 1.26% 11 9.40% 1.01% 7.04% 1.35% 12 9.42% 1.02% 6.90% 1.51% 13 9.67% 0.98% 6.70% 1.99% 14 9.74% 0.95% 6.67% 2.11% 15 9.82% 0.91% 6.75% 2.16% 16 10.03% 0.97% 6.43% 2.63% 17 10.10% 0.97% 6.69% 2.44% 18 10.14% 0.89% 6.52% 2.73% 19 10.23% 0.88% 6.15% 3.20% 20 10.27% 0.86% 6.03% 3.38% Part d: H-GN 2 times addition results Addition Reaction Conversion time (%) (hours) 1st 2nd Absolute Production Benzyl Benzaldehyde Benzoic Alcohol(%) (%) Acid (%) 0 0.00% 0.00% 0.00% 0.00% 1 0.75% 0.06% 0.68% 0.00% 2 0.94% 0.10% 0.81% 0.03% 3 1.97% 0.25% 1.62% 0.10% 4 3.65% 0.45% 2.91% 0.29% 5 5.12% 0.58% 4.08% 0.46% 6 6.23% 0.75% 4.77% 0.72% 7 7.28% 0.89% 5.55% 0.84% 8 9.66% 1.68% 6.32% 1.66% 9 11.26% 1.98% 7.02% 2.26% 14 10 13.42% 2.27% 7.73% 3.42% 11 16.37% 2.59% 8.60% 5.19% 12 16.58% 2.55% 8.18% 5.84% 13 17.38% 2.49% 8.24% 6.65% 14 17.42% 2.21% 7.99% 7.22% 15 17.69% 1.77% 8.01% 7.91% 16 18.23% 1.75% 8.15% 8.33% 17 18.64% 1.75% 8.27% 8.62% 18 18.72% 1.78% 8.22% 8.72% 19 18.79% 1.56% 8.13% 9.10% 20 19.20% 1.65% 7.93% 9.43% Part e: H-GN 5 times addition results Addition Reaction Conversion time (%) (hours) 1st 2nd 3rd Absolute Production Benzyl Benzaldehyde Benzoic Alcohol(%) (%) Acid (%) 0 0.00% 0.00% 0.00% 0.00% 1 0.68% 0.04% 0.62% 0.02% 2 1.04% 0.09% 0.87% 0.08% 3 2.41% 0.27% 1.91% 0.23% 4 3.51% 0.45% 2.74% 0.32% 5 4.67% 0.55% 3.67% 0.46% 6 6.04% 0.74% 4.66% 0.64% 7 7.43% 0.91% 5.60% 0.92% 8 8.92% 1.52% 6.07% 1.33% 9 10.13% 1.66% 6.52% 1.95% 10 13.18% 2.49% 7.87% 2.83% 11 15.32% 2.69% 8.78% 3.86% 12 17.91% 3.61% 9.46% 4.85% 13 19.45% 3.44% 9.65% 6.36% 15 4th 5th 14 21.42% 3.99% 9.79% 7.64% 15 23.42% 3.96% 10.35% 9.11% 16 24.78% 3.40% 10.80% 10.57% 17 26.48% 3.11% 9.96% 13.42% 18 27.39% 3.68% 10.27% 13.44% 19 28.67% 3.95% 9.78% 14.95% 20 30.14% 4.15% 9.04% 16.95% 21 31.22% 3.59% 9.30% 18.33% 22 32.65% 3.45% 8.95% 20.25% 23 32.74% 3.02% 8.28% 21.43% 24 33.06% 3.78% 8.40% 20.89% 25 34.26% 3.74% 7.37% 23.16% 26 34.31% 3.25% 7.31% 23.75% 27 34.43% 3.16% 7.09% 24.18% 28 34.57% 2.75% 7.19% 24.63% 29 34.70% 1.83% 7.08% 25.79% 30 34.75% 2.15% 6.81% 25.77% Part f: H-GN 7 times addition results Addition Reaction Conversion time (%) (hours) 1st Absolute Production Benzyl Benzaldehyde Benzoic Alcohol(%) (%) Acid (%) 0 0.00% 0.00% 0.00% 0.00% 1 0.69% 0.04% 0.62% 0.03% 2 1.25% 0.13% 1.05% 0.07% 3 1.87% 0.21% 1.51% 0.15% 4 3.25% 0.43% 2.48% 0.34% 5 4.33% 0.44% 3.39% 0.50% 6 5.38% 0.58% 4.17% 0.63% 16 2nd 3rd 4th 5th 6th 7th 7 7.02% 0.85% 5.24% 0.93% 8 9.23% 1.48% 6.31% 1.44% 9 10.48% 1.37% 6.77% 2.34% 10 12.23% 1.88% 7.67% 2.68% 11 16.01% 2.29% 9.27% 4.45% 12 18.29% 3.05% 9.80% 5.43% 13 19.80% 3.35% 10.43% 6.02% 14 22.28% 2.85% 10.83% 8.60% 15 24.52% 3.73% 10.32% 10.47% 16 26.01% 3.36% 10.56% 12.09% 17 27.44% 2.25% 11.72% 13.47% 18 28.69% 2.58% 11.07% 15.03% 19 30.34% 2.55% 10.68% 17.11% 20 32.18% 2.61% 10.81% 18.76% 21 34.70% 2.05% 11.00% 21.65% 22 35.68% 1.82% 10.92% 22.94% 23 35.92% 2.33% 9.63% 23.96% 24 36.82% 1.80% 9.09% 25.92% 25 37.34% 2.84% 8.92% 25.58% 26 38.14% 2.78% 7.78% 27.58% 27 38.54% 1.16% 7.17% 30.22% 28 39.23% 0.94% 6.39% 31.89% 29 39.72% 0.44% 6.24% 33.05% 30 40.56% 0.89% 4.91% 34.76% 17 Comparison of the catalytic activity for oxidation of different substrates catalyzed by H-GN Table S4. Comparison of the catalytic activity for oxidation of different substrates catalyzed by H-GN. Reaction temperature is 60 oC. Reaction time is 12 hours. O2 is oxidant and O2 pressure is 1 atm. TBHP is initiator. Substrate/catalyst molar ratio is 100,000. Substrate/initiator molar ratio is 100. Substrate Time Conv. hours % Main Product Selectivity (%) Acetophenone Phenylethanol TON Ethyl6 8.43% 52.17% 43.71% 8430 12 12.62% 54.26% 41.23% 12620 Cyclohexanone Cyclohexanol benzene Cyclo6 6.41% 64.12% 12.08% 6410 12 8.24% 57.28% 14.93% 8240 Benzaldehyde Styrene Oxide hexane Styrene 6 12.38% 76.4% 15.5% 12380 12 23.12% 73.6% 16.1% 23120 18 Comparison of Toluene Oxidation Catalyst Activity of H-GN with Other Reported Catalysts Table S5. Results obtained from previous studies on toluene oxidation catalysts Catalyst Support Temp Pressure (oC) (atm) Selectivity Oxidant Conv % Benzyl Benzalde Benzoic Benzyl Alcohol % -hyde % Acid % Benzoate % TON Ref. Hemin Graphene 60 1 O2 50.14 2.59 3.13 94.28 - 4170 S4 Cu-Mn - 190 10 O2 21.6 1.6 9.2 73.7 13.6 8 S5 Cu-Fe Al2O3 190 10 O2 25.4 1.0 27.4 71.6 - 74 S6 MnCO3 - 190 10 O2 25.0 5.3 9.7 80.8 - 50 S7 CoSBA-15 - 80 1 TBHP 8.0 - 64.0 - - 103 S8 Cr Silicalite 80 1 TBHP 18.4 5.2 23.3 25.7 - - S9 Au-Pd Carbon 160 10 O2 50.8 0.1 1.1 4.5 94.3 3300 S10 Au-Pd TiO2 160 10 O2 24.1 0.5 1.2 2.8 95.5 1570 S10 Mn(TF5PP)Cl - 20 1 H2O2 26.0 3.0 - 55.0 - - S11 (FeIIITPP)Cl Chitosan 190 6 Air 5.5 50.3 40.4 9.3 - 6130000 S12 Fe(TPFPP)Cl - 120 1 O2 0.4 33.3 66.7 - - 1200 S13 19 References S1. Hummer, W., Hoffeman, R. J. Preparation of graphitic oxide. J. Am. Chem. Soc. 80, 1339 (1958). S2. Luo, Z., Lu, Y., Somers, L. A. & Johnson, A. T. C. High yield preparation of macroscopic graphene oxide membranes. J. Am. Chem. Soc. 131, 898-899 (2009). S3. Stankovich, S. et. al. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon, 45, 1558-1565 (2007). S4. This study. S5. Li, X. et. al. Liquid-phase oxidation of toluene by molecular oxygen over copper manganese oxides. Catal. Lett.110, 149-154 (2006). S6. Wang, F. et. al. Liquid phase oxidation of toluene to benzaldehyde with molecular oxygen over copper-based heterogeneous catalysts. Adv. Synth. Catal., 347, 1987-1992 (2005). S7. Gao, J., Tong, X., Li, X., Miao, H. & Xu, J. The efficient liquid-phase oxidation of aromatic hydrocarbons by molecular oxygen in the presence of MnCO 3. J. Chem. Tech. Biotech. 82, 620-625 (2007). S8. Brutchey, R. L., Drake, J. J., Bell, A. T. & Tilley, T. Liquid-phase oxidation of alkyl aromatics by a H-atom transfer mechanism with a new heterogeneous CoSBA-15 catalyst. Chem. Commun. 3736-3738 (2005). S9. Singh, A. P., Selvam, T. J. Liquid phase oxidation reactions over chromium silicalite-1 (CrS-1) molecular sieves. Mol. Catal. A: Chem. 113, 489-497 (1996). S10. Kesavan, L. et. al. Solvent-free oxidation of primary carbon-hydrogen bonds in toluene using Au-Pd alloy nanoparticles. Science 331, 195-199 (2011). 20 S11. Rebelo, S., Simoes, M., Neves, G. & Cavaleiro, J. J. Oxidation of alkylaromatics with hydrogen peroxide catalysed by manganese(III) porphyrins in the presence of ammonium acetate. Mol. Catal. A: Chem. 201, 9-22 (2003). S12. Huang, G.. et. al. Highly selective oxidation of toluene using air over [Fe(III)TPP]Cl supported on chitosan. Can. J. Chem. 86, 199-204 (2008). S13. Evans, S., Lindsay Smith, R. The oxidation of ethylbenzene and other alkylaromatics by dioxygen catalysed by iron(III) tetrakis(pentafluorophenyl) porphyrin and related iron porphyrins J. Chem. Soc. Perkin Trans. 2 1541-1551 (2000). 21