Escherichia coli - Salford City Council

advertisement

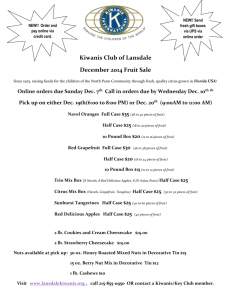

.European Commission Co-ordinated Programme for the Official Control of Foodstuffs for 2002: Microbiological Examination of Pre-cut Fruit, Sprouted Seeds, and Unpasteurised Fruit and Vegetable Juices from Production and Retail Premises in the United Kingdom CL Little and RT Mitchell Health Protection Agency, Environmental Surveillance Unit, CDSC, 61 Colindale Avenue, London NW9 5EQ On behalf of the Food Standards Agency, Local Authorities Co-ordinated Body of Regulatory Services, and the Public Health Laboratory Service. Summary The European Commission Recommendation 2002/66/EC required Member States to carry out a co-ordinated programme in 2002 of sampling and testing ready-toeat pre-cut fruits, vegetables, sprouted seeds, and unpasteurised fruit and vegetable juices from establishments of production and retail for Salmonella spp., Escherichia coli O157, and Listeria monocytogenes, and to verify the application of Hazard Analysis and Critical Control Points (HACCP) procedures by food operators. In the UK examination of ready-to-eat pre-cut fruit, sprouted seeds, and unpasteurised fruit and vegetable juices and comparison with PHLS Microbiological Guidelines revealed that the satisfactory/acceptable quality. vast majority (99%; 2075/2096) were of However, two (0.1%) samples (melon medley; beansprouts) were of unacceptable microbiological quality due to the presence of L. monocytogenes in excess of 102 cfu/g while a further 19 (0.9%) were unsatisfactory due to Escherichia coli levels in the range of 102 to 106 cfu/g. Salmonella spp. and E. coli O157 were not detected in any of the samples examined. A hazard analysis system was in place in most (85%) production and retail premises visited, of which 80% had documented systems, and most managers (83%) had received some form of food hygiene training. The findings from the UK contribution to the EU study concur with previous UK LACORS/PHLS studies on prepared ready-to-eat salad vegetables in that most bacteria of concern with regard to human health are relatively rare in raw ready-to-eat produce indicating that overall conditions during pre- and post-harvest operations were good. 1 Introduction The recognition of the public health benefits of consumption of fresh fruit and vegetables, together with a marked increase in the year-round availability of fresh produce from a global market, has contributed to the substantial increase in consumption of fresh fruits and vegetables in the UK over the last decade1. In addition, ready-to-eat fruit and vegetables requiring minimal or no further processing prior to consumption have seen rapid year-on-year growth since their introduction due no doubt to their convenience to the consumer2. Raw ready-to-eat fruit and vegetables have been implicated as vehicles for transmission of infectious microorganisms particularly in Europe, United States, Canada and Japan, although the frequency of foodborne outbreaks of gastrointestinal illness associated with fruit and vegetables appears to be low compared to products of animal origin3,4. Nonetheless, the EC Scientific Committee on Food (SCF) report on a risk profile on the microbiological contamination of fruits and vegetables eaten raw notes that foodborne illnesses associated with fruit and vegetables in many countries appear to be increasing. The reason for this is not clear but factors include improved reporting, increased consumption, new commodities and changes in production practices3. The large outbreak of Escherichia coli O157 in Japan in 1996 linked to sprouted radish illustrates the potential for serious public health problems arising from the contamination of ready-toeat fruit and vegetables5. Guidance documents have been developed to help producers and retailers minimise microbiological hazards for fresh fruit and vegetables. They incorporate control strategies based on the principles of the Hazard Analysis Critical Control Point system (HACCP), good handling practices, and good hygienic practices6-10. Food businesses must apply the hazard analysis principles in their own premises, which also must be kept clean and maintained in good repair and condition11. Legislation also requires proprietors to ensure that food handlers are appropriately supervised and instructed and/or trained in food hygiene11. Nevertheless, cross-contamination and infected food handlers were the two contributory factors most commonly reported in fruit and vegetable outbreaks of 2 infection in England and Wales4, highlighting the importance of training food handlers in good hygiene practices. A number of ready-to-eat commodities of special concern were identified by the SCF. These include sprouted seeds and fruit juices that have not undergone a treatment to kill or remove pathogenic microorganisms3. Sprouted seeds exhibit a unique hazard potential, since the germination stage breaches the inhibitory barrier of the seed coat, allowing pathogens, which may be present to grow on nutrients from the sprouted plant. No effective decontamination process has been identified that will substantially reduce or eliminate contaminating pathogens. Nevertheless, by washing seeds with chlorinated water a degree of reduction can be achieved12,13. Historically, unpasteurised juice had been considered non-hazardous because of its acidic properties. However, the acid tolerance of E. coli O157 and Salmonella spp. is of particular concern, as it allows them to survive in foods, such as fruit juices, that might seem unlikely. The acidity of fruit juices prevents the multiplication of organisms, but contamination at low levels with pathogens whose infective dose is low, such as E. coli O157, can lead to outbreaks13,14. The SCF recommended that there is a need to carry out further studies on the microbiological status of various pathogens in/on raw fruit and vegetables3. The European Commission (EC) Recommendation 2002/66/EC15, made under Article 14(3) of the Official Control of Foodstuffs Directive 89/397/EEC16, therefore required Member States to carry out a co-ordinated programme of sampling and testing pre-cut fruits, vegetables, sprouted seeds, and unpasteurised fruit and vegetable juices from establishments of production and retail for Salmonella spp., E. coli O157, and Listeria monocytogenes to assess their microbiological safety, and to verify the application of HACCP procedures by food operators. In addition, Enterobacteriaceae, E. coli and other Listeria spp. were enumerated to obtain an indication of hygiene and levels of contamination. In the UK, the programme was guided by the Food Standards Agency, and co-ordinated, on behalf of the Agency, by the Public Health Laboratory Service (PHLS) and the Local Authorities Co-ordinators of Regulatory Services (LACORS), in collaboration with 3 Environmental Health Departments and Official Food Control Laboratories in England, Wales, Scotland, and Northern Ireland. The Food Standards Agency submitted the UK information to the European Commission. Reported here is a more detailed analysis of the UK results from the 2002 EC co-ordinated food sampling programme. Materials and Methods Sample Collection Pre-cut fruit, sprouted seeds, and unpasteurised fruit and vegetable juices collected from production establishments (factories, packing centres) and retail premises were examined in PHLS and non-PHLS laboratories in the UK between 1 July and 31 December 2002 according to a standardised protocol. Single or mixed pre-cut ready-to-eat fruit, prepared sprouted seeds, and unpasteurised fruit and vegetable juices included in the study were those that could be consumed without any cooking or further preparation by the consumer. Pre-cut fruit, sprouted seeds, and unpasteurised juice samples (~100g/ml) were collected by staff from local Environmental Health Departments and were transported to the laboratory in accordance with the Food Safety Act 1990, Code of Practice No 717 and advice provided in the LACORS guidance on microbiological food sampling18. Information on the samples and premises was obtained by observation and enquiry and recorded on a standard proforma. This included information on the premises with regard to documentation of a hazard analysis system, presence of an approved voluntary industry guide to good hygiene practice6,7, the level of food hygiene training received by the manager, and food safety legislation. Food hygiene inspections are carried out in a way that focuses enforcement authority resources on premises presenting most risk to consumers. To do this, food hygiene inspections are carried out in accordance with the Food Safety Act 1990 Code of Practice No 919 which specifies that, amongst other factors, the number of consumers at risk and confidence in management control systems (including the application of HACCP based systems) should be assessed to produce a risk rating of the premises. The risk rating determines the frequency of inspection and ranges from Category A (highest risk, inspected at least every 6 months) to F (lowest risk, 4 inspected at least every 5 years). Consumer at risk scores range from 0 (very few) to 15 (substantial) and confidence in management ranges from 0 (high Confidence) to 30 (no Confidence). Additional information collected on pre-cut fruit, sprouted seeds, and juices included type, country of origin, product packaging, and display temperature. Sample Examination Enterobacteriaceae, E. coli, L. monocytogenes and other Listeria spp., Salmonella spp., and E. coli O157 were enumerated or detected in accordance with PHLS Standard Microbiological Methods20-24. Fruits are typically acidic, therefore to neutralise the antibacterial effect of acid, for pre-cut fruit and unpasteurised fruit juice samples the homogenate and pre-enrichment broths, containing bromocresol purple as a pH indicator, were adjusted to pH 6.8 using 1N NaOH. L. monocytogenes at levels at 102 cfu/g or more were sent to the Food Safety Microbiology Laboratory (FSML), CPHL for further characterisation. Microbiological results were compared to the PHLS Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale (Table 1)25. Satisfactory results indicate good microbiological quality, acceptable results are an index reflecting a borderline limit of microbiological quality, whereas unsatisfactory results indicates that further sampling may be necessary and that environmental health officers may wish to undertake a further inspection of the premises concerned to determine whether hygiene practices for food production or handling are adequate or not. An unacceptable microbiological result indicates that urgent attention is needed to locate the source of the problem. There are no guidelines for Enterobacteriaceae in fresh fruit and vegetables as these products often carry high levels of these organisms as part of their normal flora25. Table 1. PHLS guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale: Key to classification for fresh fruit and vegetables25 Criterion Escherichia coli Listeria spp. (Total) Listeria monocytogenes Salmonella spp. Escherichia coli O157 Microbiological quality (cfu per gram/ml unless stated) Satisfactory Acceptable Unsatisfactory <20 <20 <20 Not detected in 25g/ml Not detected in 25g/ml 20 - <102 20 - <102 20 - <102 102 102 N/A Unacceptable/ potentially hazardous N/A* N/A 102 Detected in 25g/ml Detected in 25g/ml *, N/A, Not applicable 5 Results Forty-five Local Authority Food Liaison Groups participated in this study and 248 Local Authorities submitted samples. A total of 2096 pre-cut fruit, sprouted seeds, and unpasteurised fruit and vegetable juice samples were examined by 32 laboratories (24 Public Health Laboratories (PHLS) from all 8 PHLS Groups; 8 non-PHLS) in England, Wales, Scotland and Northern Ireland. A further 11 samples did not fit the criteria described in the study protocol and were not included in the analysis. Microorganisms isolated from open pre-cut ready-to-eat fruit, prepared sprouted seeds, and unpasteurised juices Salmonella spp. and E. coli O157 were not detected in any of the pre-cut fruit, sprouted seeds, or unpasteurised fruit and vegetable juice samples examined (Table 2). Total Listeria spp. (including L. monocytogenes) were detected in 9% (86/997), 8% (66/808), and 0.7% (2/291) of pre-cut fruit, sprouted seeds, and unpasteurised juice samples examined, respectively and were present at 102 cfu/g or more in 0.1% (1) of precut fruit and 0.1% (1) of sprouted seeds samples (Table 2). L. monocytogenes was detected in 8% (78/997), 3% (28/808), and 0.7% (2/291) of precut fruit, sprouted seeds, and unpasteurised juice samples examined, respectively and was present at 102 cfu/g or more in 0.1% (1; 260 cfu/g) of pre-cut fruit and 0.1% (1; 100 cfu/g) of sprouted seeds samples (Table 2). The L. monocytogenes isolates in excess of 102 cfu/g were L. monocytogenes serotype NT (non-typeable). E. coli was present in 0.3% (3/997), 4% (32/808), and 0.3% (1/291) of pre-cut fruit, sprouted seeds, and unpasteurised juice samples examined, respectively and was present at 102 cfu/g or more in 0.3% (3) of pre-cut fruit and 2% (16) of sprouted seeds samples (Table 2). Enterobacteriaceae were present in 60% (594/997), 95% (765/808), and 27% (78/291) of pre-cut fruit, sprouted seeds, and unpasteurised juice samples examined, respectively and 6 were present at 104 cfu/g or more in 11% (111), 84% (676), and 4% (12) of the pre-cut fruit, sprouted seeds, and unpasteurised juice samples, respectively (Table 2). There are however no EU or US guidelines for Enterobacteriaceae in fresh vegetables or fruit as these products often carry high levels of these organisms as part of their normal flora26. Table 2. Microbiological results of 2096 pre-cut fruits, sprouted seeds, and unpasteurised fruit and vegetables juices ND* in 25g Pre-cut fruit (n=997) Enterobacteriaceae Escherichia coli Listeria spp. (total) -L. monocytogenes Salmonella spp. Escherichia coli O157 Sprouted seeds (n=808) Enterobacteriaceae Escherichia coli Listeria spp. (total) -L. monocytogenes Salmonella spp. Escherichia coli O157 Unpasteurised fruit and vegetable juices (n=291) Enterobacteriaceae Escherichia coli Listeria spp. (total) -L. monocytogenes Salmonella spp. Escherichia coli O157 911 997 997 728 808 808 289 291 291 D§ in 25g 86 78 0 0 66 28 0 0 2 2 0 0 cfu/g or ml <10/ <20 10/20 -<102 102 <103 103 <104 104 <105 105 <106 106 <107 107 NE¶ 396a 994b 84b 76 b 191 0 1 1 160 2 1 1 132 0 55 1 40 9 7 7 38a 776b 9 16 17 11 1 1 63 2 146 1 298 2 128 104 5 28 8 27b 213a 289b 2b 2b 30 1 14 6 5 1 2 1 *ND; Not detected; §D, Detected; ¶NE, Not examined (full set of microbiological parameters not performed on sample due to insufficient sample collected) a, lower limit of detection 10 cfu/g; b, lower limit of detection 20 cfu/g Microbiological quality of pre-cut ready-to-eat fruit, prepared sprouted seeds, and unpasteurised juices Based on the PHLS microbiological guidelines for some ready-to-eat foods at the point of sale (Table 1)25, 99.5% (992/997) of pre-cut fruit were satisfactory, 0.1% (1) were acceptable, and 0.3% (3) were of unsatisfactory microbiological quality due to the 7 presence of E. coli in the range of 102 to 105 cfu/g. However, one (0.1%) sample (melon) was of unacceptable microbiological quality due to the presence of L. monocytogenes at 260 cfu/g (Fig. 1). Of the sprouted seeds examined, 96.1% (776/808) were satisfactory, 1.9% (16) were acceptable, and 1.9% (16) were of unsatisfactory microbiological quality due to the presence of E. coli in the range of 102 to 106 cfu/g. However, one (0.1%) sample (beansprouts) was of unacceptable microbiological quality due to the presence of L. monocytogenes at 100 cfu/g (Fig. 1). Most (99.6%; 290/291) of the unpasteurised juices examined were satisfactory and 0.4% (1) were of acceptable microbiological quality. None of the unpasteurised juice samples were of unsatisfactory or unacceptable microbiological quality (Fig. 1). Fig. 1 Microbiological quality of pre-cut fruit, sprouted seeds, and unpasteurised juices Satisfactory Acceptable Unsatisfactory Unacceptable 0.0% Unpasteurised juices 0.0% 0.4% 99.6% 0.1% Sprouted seeds 1.9% 1.9% 96.1% 0.1% Pre-cut fruit 0.3% 0.1% 99.5% Samples (%) 8 Product and premises information A major feature of the data is that almost all pre-cut fruit, sprouted seeds, and unpasteurised fruit and vegetable juices (99%; 2075/2096) were of satisfactory or acceptable microbiological quality. As there were so few samples of unsatisfactory or unacceptable microbiological quality (1%) an association could not be found between microbiological quality and the product information collected (presented below). Pre-cut ready-to-eat fruit Forty-five percent (449/997) of the samples collected consisted of a single type of fruit, and 55% (548) consisted of mixed fruit types. The breakdown of samples (449) that consisted of a single type of pre-cut fruit was: melon (42%; 189), pineapple (28%; 126), grapes (8%; 36), apple pieces (5%; 25), and watermelon (3%; 15). Other samples (12%; 58) included mango, raspberries, strawberries, and orange pieces. Of the samples (548) that consisted of mixed fruit types, 9% (50) consisted of two different fruit types, 23% (127) of three fruit types, 37% (201) of four fruit types, 22% (119) of five fruit types, and 9% (47) of more than five fruit types. For <1% (4) of samples, this information was not recorded. Of the pre-cut fruit sampled (997), most (82%; 813) were pre-packed and 16% (161) were open. For the remaining 23 (2%) of samples this information was not recorded. Most pre-cut fruit (90%; 893) were stored or displayed at or below 8C, 7% (68) were stored or displayed above 8C, and for the remaining samples (4%; 36) this information was not recorded Prepared sprouted seeds Most (88%; 713/808) of the samples collected consisted of a single sprouted seed type, and 12% (95) consisted of mixed sprouted seed types. The breakdown of samples (713) that consisted of a single sprouted seed type was: beansprouts (55%; 388), salad cress (24%; 171), mustard cress (9%; 65), mung beans (5%; 34), alfalfa sprouts (4%; 28), sunflower sprouts (1%; 8), radish sprouts (1%; 6), aduki beans (<1%; 2), and chick pea sprouts (<1%; 2). For 1% (9) of samples, this information was not recorded. Of the 9 samples (95) that consisted of mixed sprouted seeds, 63% (60) consisted of two different sprouted seed types, 6% (6) of three sprouted seed types, 19% (18) of four sprouted seed types, and 3% (3) of five sprouted seed types. For 9% (8) of samples, this information was not recorded. Of the sprouted seeds sampled (808), approximately two-thirds (64%; 512) were prepacked, 31% (253) were packed and unsealed, and 1% (10) was open. For the remaining 4% (33) of samples, this information was not recorded. Over a third (39%; 295/765) of the packed sprouted seeds had preparation instructions on the label to rinse or wash in water before eating or use, 12% (94) were labelled as washed and ready-to-eat, 6% (45) had no preparation instructions, and for 43% (331) of samples, this information was not recorded. The majority (93%; 13/14) of sprouted seeds samples that were of unsatisfactory or unacceptable microbiological quality had preparation instructions on the label to rinse or wash in water before eating or use. Most sprouted seeds (72%; 581) were stored or displayed at or below 8C, 23% (183) were stored or displayed above 8C, and for the remaining samples (5%; 44) this information was not recorded. Unpasteurised fruit and vegetable juices Most (81%; 236/291) of the samples collected consisted of a single juice type, and 19% (55) consisted of mixed juice types. The breakdown of samples (236) that consisted of a single juice type was: orange (74%; 174), apple (11%; 27), carrot (4%; 9), grapefruit (3%; 8), and tomato (1%; 3). Other samples (6%; 14) included mandarin, pineapple, and cranberry. For <1% (1) of single juice type samples, this information was not recorded. Of the samples (55) that consisted of mixed juice types, 44% (24) consisted of two different juice types, 33% (18) of three juice types, 13% (7) of four juice types, 2% (1) of five juice types, and 4% (2) of more than five juice types. For 4% (3) of samples, this information was not recorded. Of the unpasteurised juices sampled (291), over two-thirds (68%; 198) were bottled or in a carton, 25% (72) were extracted and served at the point of sale, and for the remaining 7% (21) of samples, this information was not recorded. Most unpasteurised juices (68%; 10 198) were stored or displayed at or below 8C, 20% (59) were stored or displayed above 8C, and for the remaining samples (12%; 34) this information was not recorded. Almost three-quarters of unpasteurised juices (73%; 211) were not labelled or advertised as being unpasteurised, 16% (46) were and for 12% of samples, this information was not recorded. Country of Origin Of the 2096 pre-cut fruit, sprouted seeds, and unpasteurised juices sampled a third (33%; 689) were produced in the UK (Table 3). Fifteen percent (325) of samples were not of UK origin, i.e. grown in other EU or Third countries. The country of origin was not known for over half (52%; 1082) of the samples, of which eight were labelled as packed in the UK. Table 3. Country of origin of pre-cut fruit, sprouted seeds, and unpasteurised juices collected (n=2096) Country of Origin Pre-cut fruit UK Other EU - Belgium - Denmark - Germany - Greece - Ireland - Italy - Netherlands - Spain More than one country (EU & Third country) Third countries - Brazil - China - Costa Rica - Cuba - Ghana - Israel - Ivory Coast - South Africa - USA - Zimabwe Not Known - Packed in the UK Total 174 (18%) 21 (2%) 1 Number of Samples (%) Sprouted seeds Unpasteurised juices 408 (50%) 107 (37%) 9 (1%) 15 (5%) Total 689 (33%) 45 (2%) 1 3 2 7 1 1 10 253 (25%) 2 4 4 13 (2%) 6 14 (5%) 280 (13%) 2 1 155 (53%) 1082 (52%) 291 2096 28 1 19 1 2 38 6 68 3 549 (55%) 6 997 378 (47%) 2 808 11 Production method Over three-quarters (79%; 1664/2096) of the samples collected were produced using conventional farming methods, 6% (117) of samples were produced using organic farming methods, and for 15% (315) of samples this information was not recorded (Table 4). Table 4. Production method of pre-cut fruit, sprouted seeds, and unpasteurised juices collected (n=2096) Production Method Conventional 841 (84%) Number of Samples (%) Sprouted seeds Unpasteurised juices 612 (76%) 211 (73%) Organic 16 77 (9%) 24 (8%) 117 (6%) Not Known 140 (14%) 119 (15%) 56 (19%) 315 (15%) Total 997 808 Pre-cut fruit (2%) 291 Total 1664 (79%) 2096 Type of premises Most (97%; 2036/2096) samples of pre-cut fruit, sprouted seeds, and unpasteurised juices were collected from retail premises, of which over three-quarters (77%; 1579/2036) were from supermarkets (Fig. 2). A small proportion of samples (3%; 60) were collected from production establishments. Fig. 2 Pre-cut fruit, sprouted seeds, and unpasteurised juices collected from retail premises (n=2036) Supermarket 77% Greengrocer 8% Not Recorded 1% Delicatessen 1% Health Food Shop 3% Market Stall Juice Bar 2% 1% Coffee Bar 2% Other 3% Farm Shop 2% 12 Food Hygiene Inspections Over half (55%; 1162) of the premises visited were categorised as Inspection Rating Category C (inspected at least every 18 months) (Fig. 3). Most of the premises visited were categorised in consumer at risk score 5 (few numbers of customers, 45%; 933) and 10 (intermediate numbers of customers, 41%; 866) (Fig. 4). Most of the premises visited had a confidence in management score 5 (moderate confidence in management/control systems, 44%; 931) and 10 (some confidence in management/control systems 31%; 654) (Fig. 5). Fig.3. Inspection Rating Category of premises (n=2096) C 55% D 13% B 12% A 3% Not Recorded 7% F 2% E 8% Fig.4. Consumers at Risk score of premises (n=2096) 15 (Substantial) Not Recorded 0 (Very few) 5 (Few) 10 (Intermediate) 13 Fig.5. Confidence in management score of premises (n=2096) 30 (No confidence) 1% Not Recorded 9% 0 (High confidence) 12% 20 (Little confidence) 3% 10 (Some confidence) 31% 5 (Little confidence) 44% Hazard Analysis System and Industry Guide to Good Hygiene Practice Over two-thirds (68%; 1430/2096) of premises visited had a documented hazard analysis system in place, and a further 17% (346) had an undocumented system in place (Table 5). Nine percent (190) of premises had no hazard analysis system in place and for 6% (130) of premises, this information was not recorded. Forty-one percent of premises visited had an approved voluntary industry guide to good hygiene practice (Table 5). Food Hygiene Training The majority of premises had managers that had received some form of food hygiene training (83%; 1733/2096), 8% (170) had not and for 9% (193) of premises, this information was not recorded (Table 5). Of those managers with food hygiene training, approximately half (46%; 796) were trained to a basic level, but 27% (465) and 12% (201) were trained to an intermediate or advanced Level, respectively. A further 6% (111) had attended another recognised course (HACCP, in-house training), and in 9% (160) the type of training was not specified (Table 5). Significantly, where managers had received some form of food hygiene training, hazard analysis systems were more likely to be in place and documented (82%) compared to those managers that had not received training (32%) (P<0.00001) (Table 6). 14 Table 5. Hazard analysis systems and management food hygiene training in premises Hazard analysis In place & documented In place & undocumented Not in place Not recorded Retail Premises (%) (n=2036) Production establishments (%) (n=60) Total premises (%) (n=2096) 1395 341 (68%) (17%) 35 5 (58%) (8%) 1430 346 (68%) (17%) 184 116 (9%) (6%) 6 14 (10%) (23%) 190 130 (9%) (6%) 40 (67%) 1733 (83%) 24 10 4 (60%) (25%) (10%) 796 465 201 111 (46%) (27%) (12%) (6%) 2 6 14 (5%) (10%) (23%) 160 170 193 (9%) (8%) (9%) 15 26 19 (25%) (43%) (32%) 852 669 575 (41%) (32%) (27%) Management food hygiene training Received training and 1693 (83%) attended a: basic 6 hour course 772 (46%) intermediate course 456 (27%) advanced course 197 (12%) other recognised 111 (6%) course training not specified 158 (9%) No training 164 (8%) Not recorded 179 (9%) Industry Guide to good hygiene practice Present 837 (41%) Not present 643 (32%) Not recorded 556 (27%) Table 6. Hazard analysis in place and documented in relation to management food hygiene training Premises details Food hygiene training Yes No Hazard analysis in place and documented 1348/1649 (82%) 16/ 50 (32%) <0.00001 Hazard analysis in place and undocumented 114/1649 (7%) 30/ 50 (60%) <0.00001 Hazard analysis not in place 66/1733 (4%) 119/ 170 (70%) <0.00001 P value Significantly more managers from premises with a consumer at risk score of 0-5 (15%; 141/961) had received no food hygiene training compared to managers in premises scoring 10 or above (2%; 20/952) (P <0.00001). In addition more managers of premises with confidence scores of 20 and above (16%; 16/97) had received no food hygiene training compared with those premises with confidence scores of 10 or less (8%; 142/1820) (P <0.01). 15 Discussion This study has shown that the vast majority (99%) of pre-cut ready-to-eat fruit, sprouted seeds, and unpasteurised fruit and vegetable juices sampled at production and retail premises in the UK were of satisfactory/acceptable microbiological quality. Two (0.1%) of the samples were unacceptable, and 19 (0.9%) were classified as unsatisfactory according to published microbiological guidelines25. Unacceptable results were due to the presence of L. monocytogenes at 102 cfu/g or more while unsatisfactory results were due to E. coli levels in the range of 102 to 106 cfu/g. E. coli is a faecal organism and is an environmental microorganism found in soil and water. Therefore, fruit and vegetables may easily become contaminated with these bacteria. However, the absence of the pathogens Salmonella spp. and E. coli O157 and the low incidence of E. coli (1.7%) and L.monocytogenes (5%) associated with these products indicate that agricultural, harvesting, hygiene and production practices were good overall. The findings from this study concur with that of recent UK LACORS/PHLS microbiological studies on various prepared ready-to-eat salad vegetables27-30 and the US FDA survey of domestic fresh produce (salad vegetables and fruit)31, in that most bacteria of concern with regard to human health are relatively rare in raw ready-to-eat produce. However, the FDA survey of imported fresh produce undertaken in 199932 found that 4% of fresh produce were of unacceptable microbiological quality due to the presence of salmonellas or Shigella spp. and may reflect differences in conditions during pre- and post-harvest operations, and the origin of the produce in question. Vegetables carry a natural non-pathogenic epiphytic microflora, the majority of which consists of Gram-negative bacteria belonging to either the Enterobacteriaceae or the Pseudomonas group. The numbers of bacteria present will vary depending on seasonal and climatic variation and may range from 104 to 108 per gram26. The findings from this and previous studies29,30,33,34 have shown that high levels of Enterobacteriaeae are normal in fruit, salad vegetables and sprouted seeds, therefore levels of faecal indicator organisms such as E. coli are a better indication of contamination and hygienic quality. Levels of E. coli in raw ready-to-eat fruit and vegetables however should be kept to a minimum. 16 The SCF report concludes that Good Agricultural Practice and Good Hygiene Practice are the basis for the safe production of fresh produce, and that the most efficient way to improve the safety of produce is to rely on a proactive system reducing risk factors during production and handling3. A fifth (20%) of pre-cut fruit, sprouted seeds, and unpasteurised juices were stored or displayed at above 8°C. Where prepared ready-to-eat fresh produce and juices are being stored they should be kept at or below 8°C to satisfy the legal requirements of the Food Safety (Temperature Control) Regulations 199511. As a matter of good practice it is recommended that such fresh produce should also be kept at or below 8°C during display for sale. Voluntary industry guides have been produced to help minimise microbial food safety hazards from farm to fork, i.e. from produce suppliers to food handlers. A hazard analysis system was in place in most (85%) production and retail premises visited, of which 80% had documented systems, and most managers (83%) had received some form of food hygiene training. As shown in a metaanalysis of UK food studies35, high confidence in the food business management of food hygiene, as indicated by Local Authority Inspectors' Confidence in Management scores, and food safety procedures, i.e. the presence of a hazard analysis system, was in turn related to management food hygiene training. There is growing acceptance throughout the European Community and in many other countries of the value of the application of HACCP principles in ensuring the microbiological safety of foods. Implementing and maintaining food safety procedures based on HACCP principles is expected to become a European legal requirement for all food businesses regardless of size36. Although the results from this study indicate that overall pre-cut fruit, sprouted seeds and unpasteurised fruit and vegetable juices from production and retail premises were of satisfactory/acceptable quality, occasional outbreaks of salmonellosis, E. coli O157, and L. monocytogenes in Europe, US, Canada, and Japan have been linked to a diversity of fresh fruit and vegetables3,4, including a variety of sprouted seeds (cress, clover, mung bean, alfalfa, radish), melons, and unpasteurised orange and apple juices12-14 and demonstrate that major health problems can arise from consumption of contaminated fresh produce if hygiene practices break down. It follows that the need for a sound approach to food safety management cannot be overemphasised. 17 Acknowledgements The authors would like to thank all the staff in the Environmental Health Departments throughout the UK who collected samples for this study, and all the staff in both PHLS and non-PHLS laboratories who performed microbiological examination. Thanks are extended to John Barnes at the Food Standards Agency for guidance on carrying out the microbiological component of the EC Recommendation 2002/66/EC, David Lock at LACORS for coordinating the participation of Environmental Health Officers and advice from the LACORS Food Examination Focus Group, FSML (CPHL) for typing isolates, the PHLS Group FWE Coordinators Forum, in particular Melody Greenwood, for their advice in preparing the sampling protocol, and to Lilian Hucklesby for entering the data References 1. Department for Environment, Food & Rural Affairs. National Food Survey 2000. London: The Stationary Office, 2001. 2. Campden & Chorley Food Research Association Group (CCFRA). Marketplace Report. Focus on Prepared Vegetable, Salad and Fruit Products in the UK, 1999. CCFRA, Chipping Campden. 3. European Commission Scientific Committee on Food. Report on the risk profile on the microbiological contamination of fruits and vegetables eaten raw. SCF/CS/FMH/SURF/Final 29 April 2002. < http://europa.eu.int/comm/food/fs/sc/scf/out125_en.pdf> 4. Long SM, Adak GK, O’Brien SJ, Gillespie IA. General outbreaks of infectious intestinal disease linked with salad vegetables and fruit, England and Wales, 1992-2000. Comm Dis Pub Health 2002; 5: 101-5. 5. Ministry of Health and Welfare of Japan, National Institute of Infectious Diseases and Infectious Disease Control Division. Verocytotoxin producing Escherichia coli (enterohaemorrhagic E. coli) infection, Japan, 1996-June 1997. Infectious Agents Surveillance Report 1997; 18: 153-4. 6. Food Safety and Hygiene Working Group. Industry Guide to Good Hygiene Practice: Retail Guide, 1997. Chadwick House Group Ltd, Chartered Institute of Environmental Health, London. 7. Fresh Produce Consortium. Industry Guide to Good Hygiene Practice: Fresh Produce, 1999. Chadwick House Group Ltd, Chartered Institute of Environmental Health, London. 8. Knight C, Stanley R. Assured Crop Production: HACCP in Agriculture and Horticulture, 2nd ed., CCFRA Guideline No.10., 2000. Campden & Chorleywood Food Research Association Group, Chipping Campden, UK. 9. Chilled Food Association. Microbiological Guidance for Produce Suppliers to Chilled Food Manufacturers, 1st ed., 2002. Chilled Food Association Ltd., London. 10. Brown KL, Oscroft CA. Guidelines for the hygienic manufacture, distribution and retail sale of sprouted seeds with particular reference to mung beans, CCFRA Technical Manual No.25, 1989. Campden & Chorleywood Food Research Association Group, Chipping Campden, UK. 11. The Food Safety (General Food Hygiene) Regulations 1995. London: HMSO. 18 12. Tauxe R, Kruse H, Hedberg C, Potter M, Madden J, Wachsmuth K. Microbial hazards and emerging issues associated with produce. A preliminary report to the National Advisory Committee on Microbiologic Criteria for Foods. J Food Prot 1997; 60: 1400-8. 13. Parish ME. Public health and nonpasteurised fruit juices. Crit Rev Microbiol 1997; 23: 10919. 14. Taormina PJ, Beuchat LR, Slutsker L. Infections associated with eating seed sprouts: An international concern. Emerg Inf Dis 1999; 5: 626-34. 15. Commission Recommendation 2002/66/EC of 25 January 2002 concerning a coordinated programme for the official control of foodstuffs for 2002. Official Journal of the European Communities 2002; L26: 8-16. 16. Council Directive 89/397/EEC of 14 June 1989 on the official control of foodstuffs. Official Journal of the European Communities 1989; L186: 23-6. 17. Food Safety Act 1990, Code of Practice No 7: - Sampling for Analysis and Examination (Revised October 2000). London: FSA, 2000. 18. LACORS. LACOTS Guidance on Food Sampling for Microbiological Examination. Available at www.lacors.com. January 2002. 19. Food Standards Agency. Food Safety Act 1990, Code of Practice No 9:- Food Hygiene Inspections (Revised October 2000). London: FSA, 2000. 20. PHLS. Standard Methods for Food Products. Enumeration of Enterobacteriaceae by Colony Count Technique. Standard Method: F23. London: PHLS, 1998. 21. PHLS. Standard Methods for Food Products. Direct Enumeration of Escherichia coli. Standard Method: F20. London: PHLS, 1998. 22. PHLS. Standard Methods for Food Products. Detection of Salmonella spp. Standard Method: F13. London: PHLS, 1998. 23. Public Health Laboratory Service (PHLS). Standard Methods for Food Products. Detection and Enumeration of Listeria monocytogenes and other Listeria spp. Standard Method: F19. London: PHLS, 2000. 24. PHLS. Standard Methods for Food Products. Detection of Escherichia coli O157 by Immunomagnetic Bead Separation. Standard Method: F17. London: PHLS, 2001. 25. PHLS. Guidelines for the Microbiological Quality of Some Ready-To-Eat foods sampled at the Point of Sale. Comm Dis Pub Health 2000; 3: 163-7. 26. Lund, B.M. 1992. Ecosystems in vegetable foods. J. Appl. Bacteriol. 73 (Suppl.21): 115S135S. 27. Little, CL, Monsey, HA, Nichols, GL, de Louvois J. The microbiological quality of refrigerated salads and crudités. PHLS Microbiol Dig 1997; 14: 142-6. 28. Sagoo, SK, Little, CL, Mitchell, RT. The microbiological examination of ready-to-eat organic vegetables from retail establishments. Lett Appl Microbiol 2001; 33: 434-9. 29. Sagoo, SK, Little, CL, Ward, L, Gillespie, IA, Mitchell, RT. Microbiological study of readyto-eat salad vegetables from retail establishments uncovers a national outbreak of Salmonellosis. J Food Prot, 2003; 66 (3): 403-9. 30. Sagoo, SK, Little, CL, Mitchell, RT. Microbiological quality of open ready-to-eat salad vegetables: effectiveness of food hygiene training of management. J Food Prot, 2003; In Press. 31. Food and Drug Administration (FDA). January 2003. FDA survey of domestic fresh produce, FY 2000/2001 Field Assignment. Available at: http://www.cfsan.fda.gov/~dms/prodsu10.html. 32. Food and Drug Administration (FDA). 30 January 2001. FDA survey of imported fresh produce, FY 1999 Field Assignment. Available at: http://www.cfsan.fda.gov/~dms/prodsur6.html. 19 33. Robertson, LJ, Johannessen GS, Gjerde BK, Lnocarevic S. Microbiological analysis of seed sprouts in Norway. Int J Food Microbiol 2003; 75: 119-126. 34. Johannessen, GS, Loncarevic, S, Kruse, H. Bacteriological analysis of fresh produce in Norway. Int. J. Food Microbiol. 2002; 77: 199-204. 35. Little CL, Lock D, Barnes J, Mitchell RT. The microbiological quality of food in relation to hazard analysis systems and food hygiene training in UK catering and retail premises. Comm Dis Pub Health 2003: In press. 36. European Commission. 2002. Proposal for a Regulation of the European Parliament and of the Council on the hygiene of foodstuffs. COM (2000) 438 final. 20 Annex 1: Participating PHLS Groups, Laboratories and Local Authority Food Liaison Groups Table 1a. Participating PHLS Groups, Public Health Laboratories and number of samples PHLS Group Public Health Laboratory East Chelmsford Norwich Ashford Brighton London FWEML1 WEMS2 Birmingham Coventry Shrewsbury Stoke Chester Preston Hull Leeds Middlesborough Newcastle Bristol Exeter Gloucester Hereford Plymouth Lincoln Sheffield Cardiff London & South east Midlands North west North South West Trent Wales Total Number of samples* 129 131 89 213 23 93 37 144 24 61 163 158 78 52 50 82 54 33 17 48 21 164 65 11 1940 1, London Food, Water & Environmental Microbiology Laboratory, FSML CPHL 2, Wessex Environmental Microbiological Service Table 1b. Participating Non-PHLS Laboratories and number of samples Non-Public Health Laboratory Belfast City Hospital City of Edinburgh Dundee Scientific Services Dumfries Galloway Glasgow Scientific Services Kings Lynn & West Norfolk Public Analyst Aberdeen Royal Alexandra, Paisley Total Number of Samples* 95 14 8 2 33 7 5 3 167 *Includes the 11 samples not included in the analysis. 21 Table 1c. Local Authority Food Liaison Groups and number of samples Local Authority Food Liaison Group Berkshire Food Co-ordinating Group Cambridge Food Liaison Group Cheshire Food Liaison Group Cumbria IEHO Food Safety Group Derbyshire Food Liaison Group Devon Food Safety Group Dorset Food Group Durham Food Liaison Group East Sussex Food Liaison Group Essex Food Group Gloucester Food Safety Group Greater Manchester Food Liaison Group Hampshire & Isle Of Wight Food Advisory Group Hereford & Worcester CEHOS Food Working Group Humberside Food Liaison Group Kent Food Technical Group Lancashire Assn Of CEHOS, Food Officer Group LFCG1 North East Sector LFCG South West Sector Lincolnshire Co-ordinating Group Merseyside Food Sub-Group North Yorkshire CEHOS Group Northamptonshire Food Liaison Committee Northern Ireland Food Group2 Northumberland Food Safety Group Norfolk Food Liaison Group Nottingham District Food Group Scottish Food Enforcement Liaison Committee3 Shropshire Food Liaison Group Somerset Food Liaison Group South Yorkshire Food Forum Staffordshire Food Safety Group Suffolk Food Liaison Group Surrey Food Liaison Group Tees Valley Food Safety Group Tyne & Wear Food Control Group Wales South West Group Wales North Group Wales South East Group Warwickshire Food Liaison Group West Midlands Food Liaison Group (inc. Black Country) West of England Food Liaison Group West Sussex Food Liaison Group West Yorkshire Principal Food Officers Group Wiltshire Food Group Total Number of Samples* 2 67 87 16 31 48 20 17 73 55 17 77 51 48 77 89 65 10 13 81 73 34 79 95 12 93 88 65 4 6 29 65 34 80 34 57 1 13 6 64 67 30 70 30 34 2107 1, London Food Co-ordinating Group 2, Northern Ireland Food Group comprises of the Eastern, Northern, Southern and Western Groups 3, SFELG comprises of Central Scotland, Fife & Tayside, Lothian & Scottish Borders, North Scotland, and West of Scotland * Includes the 9 samples not included in the analysis. 22