Fermentation: the (un)converted sugar

advertisement

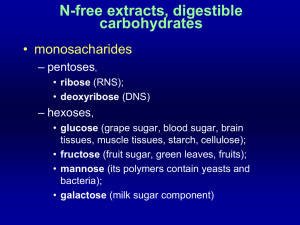

Fermentation: the (un)converted sugar Koomen, L. Pluut, K. Gymnasium Felisenum, The Netherlands Summary Fermentation, as one of the oldest chemical processes, is an important way of winning bio-ethanol out of sugars. So finding the best way to produce bio-ethanol is very useful. The oil sources just cannot bear the amount of oil we use. Bio-ethanol is a possible solution, and therefore a reason to take a closer look at it. What we have been trying , is finding the best possible sugar for fermentation. Does granulated sugar, caster sugar or starch work out best? The fermentation process, which of course is going to be explained in the following paragraph(s), was being measured by the release of carbon dioxide. These measurements resulted in glucose as the best working sugar, which didn’t surprise us. Unfortunately, the amount of carbon dioxide was not realistic. That was no surprise, because, for example, the temperature was not even close to the optimal circumstances and our measurements not as accurate as should. Introduction place: C6H12O6 (s) ---> 2CH3CH2OH In the introduction we will try to explain (l ) + 2CO2 ( g ). C6H12O6 is one of what we expect of our fermentation the sugars that can be formed out of project and explain how fermentation starch. works. Fermentation would not be possible What we expect to be the best without sugars. So the first question is, working sugar is: glucose. The other how do you get sugars? Sugars are sugar we used, sucrose extracted out of starch or for example (C12H22O11), is, also because of potatoes. For our experiment we used hydrolysis, converted into glucose starch and therefore we will explain and fructose. how to get sugars from starch. Starch So basically our sugars are sorted as [(C6H10O5)n] can be converted into followed: sugars, for example glucose because of Glucose: The hydrolysis. In this process, an H2O sugar which is directly available molecule breaks the long carbon chain for fermentation. on some points and thereby forms Sucrose: The sugars. In our experiment we also used sugar that, at first must be unconverted starch, but we do not converted into glucose because expect it to result in a big amount of of hydrolysis. carbon dioxide. Starch: the basic Now we know how to get the sugars, of sugars; a huge molecule that we can use the sugars for the also must be converted into fermentation. In the actual glucose by hydrolysis. fermentation process, the sugars are converted into (bio-)ethanol and So it is logic, that we think glucose CO2. The following reaction takes works out best, because it’s already able to be used for fermentation. The other 2 sugars need time to get converted into sugars and will be used for fermentation later than glucose. For fermentation you also need yeast. We used baker’s yeast for all the 3 sugars. So the baker’s yeast is an control variable. Methods and Materials We firstly weighted 6 empty 0,5L water bottles without the cap. We then filled the bottles with 250,0 ml of regular water. We then weighted the 3 different saccharides: glucose, soft brown sugar and starch. We weighted 2 times 40,0 gram of each saccharides. We then filled the bottles with each one a portion of 40,0 gram of the saccharides, so we got 6 bottles filled with or glucose or soft brown sugar or starch. While doing this we labeled every bottle with the saccharides they had in. We then added 1,0 gram of baker’s yeast, S. cerevisiae, to every bottle. Immediately after that we put a water cup at each bottle. After some careful shaking we put the bottles in a rack. Every 3 days we shaked the bottles carefully. After 1 week we shaked for the last time so that all the compressed C02 could escape. Then we took the water cups off and weight every bottle with their suspension as soon as possible. Because we had 2 bottles for every saccharides we could measure 2 masses differences so that we could make an average. For every saccharides the mass difference was determined and with that also the released CO2 gas. Results: We measured all bottles with their suspension without the water cap after 1 week. The mass difference was the released CO2. We then made an average with their deviations for each type of saccharides. Table 1 presents all those values. Type saccharide Mass CO2(g) Averaged Mass CO2(g) glucose 5,05 5,09 5,07±0,02 starch 3,70 3,06 3,38±0,32 Soft brown sugar 3,62 4,38 4,00±0,38 Table 1: Release of CO2 and averaged release CO2 for each type of saccharides. The average values of each soft brown sugar, starch and dextrose could be put in a graph. Graph 1 shows us the difference more illustrated. Graph 1: Average CO2 release of each type saccharides. Conclusion and discussion As you can see glucose does release the most CO2 of the three saccharides. Soft brown sugar and starch give us respectively 21% and 33% less CO2 than soft brown sugar. As you can see in the introduction, the following chemical reaction that took place is: C6H12O6 (s) 2CH3CH2OH (l ) + 2CO2 ( g ). The amount of moles co2 that is produced is the same amount of moles ethanol. To find out how much ethanol we had produced, we had to know the mol mass of either ethanol and carbon dioxide. CO2 weights 44,01 g/mol and ethanol 46,0688 g/mol. We had 5,07 g CO2. 5,07/44,01=0,115 mol. 0,115 mol . 46,0688 g/mol =5,31 g ethanol. As you can see there was a mass difference after the fermentation what indicates there was a production of CO2. All cultures had a significant amount of CO2 produced with glucose the most producing. As our hypothesis showed, the unconverted sugars, starch and soft brown sugar, are less effective than glucose. Furthermore you can see that against popular belief starch still work out in the fermentation process. The production was indeed less but not much less; only 33% less production. This is a lot if you mind that starch is much easier to obtain. So the efficiency of fermentation is not that high. What starts of as corn or perhaps potatoes, results in a kind of lsmall amount of carbon dioxide and thereby a small amount of bio-ehtanol. Of course our conclusion could have been better. We were not able to check all of the control variables. The temperature, which should have been 37 degrees, wasn’t that high in our experiment. Bibliography 1. www.wikipedia.nl 2. yeast and fermentation: the optimal temperature, by Slaa, J. Gnode, M. and Else, H. 3. Chemie Overal vwo deel 2