At the Marriott LAX

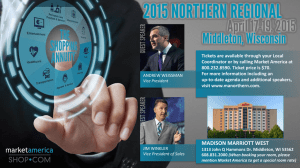

advertisement

At the Marriott LAX Saving Energy, Improving Performance, and Having a Good Time Doing It The Los Angeles Airport Marriott is a 1977 high-rise, full service facility encompassing a nominal 600,000 square feet that include meeting rooms, ball rooms, several restaurants, and 1,000 guest rooms. With annual utility bills in approaching $1.5 million, the facilities engineering group jumped at the opportunity to participate as a pilot project in the Western Region’s Retrocommissioning program ( ). The program is based on a process developed in the commissioning industry. It is targeted at tuning up existing buildings, potentially transforming them from the equivalent of a poorly running family sedan to a high performance Indy racecar. But, unlike the Indy speedster, the improved performance frequently translates to a reduction in energy consumption, typically in the range of 5-25% of the consumption before the effort.1 The process targets low-cost/no-cost performance improvements and paybacks of 2 years or less are common. Frequently, local utility programs have incentives that will help support the process, either by funding the engineering effort, the improvements, or both. Many times, capital improvements are also identified, which while beyond the scope and concept of the retrocommissioning effort, will merit consideration as a part of the facilities long term planning process. The remainder of this article will focus on the results of the effort that was undertaken at the LAX Marriott. Exploring all of the findings in detail is beyond the article’s scope, but a summary of all of the findings has been included and the details behind many of the key findings will be discussed. An Overview of the LAX Project The effort at the Marriott LAX was the outfall of a task force of Marriott Facilities Engineers brought together by Rob Bahl, the Western Region Engineering Director and E.J. Hilts the Western Regional Energy Manager. Other team members included Tracy Tomasek, Doug Rath, Paul Beyer, Steve James, and Jake Cormier. The goal of the task force was to develop a retrocommissioning program that could be 1 For some examples and case studies that illustrate the savings potential, visit www.peci.org and download RetroCommissioning’s Greatest Hit’s, a paper presented at the International Conference for Enhanced Building Operations in 2001 by Tudi Haasl Retrocommissioning the LAX Marriott 1 deployed and implemented in the region’s facilities by 2005. The project is seen as a way to expand Marriott’s ongoing commitment to resource and energy efficiency. Building their own experience and publicly available commissioning resources, the task force developed a process that would allow them to implement retrocommissioning on a system wide basis. The next step was to find a test facility for a pilot project. Task force member Tracy Tomasek volunteered his facility in Los Angeles, and the project was off and running. Portland Energy Conservation Incorporated (PECI), a Portland Oregon based not-for-profit dedicated to energy efficiency and responsible resource use and heavily involved in developing infrastructure for the commissioning industry was retained to assist with the project. The project was initiated by assembling drawings, specifications, balance reports, control diagrams, and utility bills for review by PECI. This information was used to develop a fundamental understanding of the facility and formulate an initial plan of attack. Next, task force members met PECI at the site for a field exercise in which the facility was surveyed to further refine the areas that would be targeted by the process. Based on the initial survey work, trends were set up in the Energy Management System (EMS) to gather data for analysis. Data loggers were deployed on the systems that were not served by the EMS (See Figure 1). Figure 1 - A typical data logger. These electronics packages can be deployed where needed to gather record information, which can later be retrieved for analysis and troubleshooting. Sampling times of less than a second are possible and the battery power packs allow the loggers to operate unattended for weeks at a time. Flexible input options allow virtually any process parameter to be sampled. After the initial visit, the LAX Facilities engineers, led by Rizallion “RC” Cloma retrieved and redeployed the data loggers, accumulating nearly a month of data from numerous systems on the site. This data was forwarded to PECI, who did some preliminary analysis, which resulted in a Findings List (see Figure 2). This information was then used by the task for to focus their efforts on a subsequent site visit during which savings and implementation cost projections were developed. The bottom line is that the project identified improvements in Indoor Air Quality (IAQ) and performance, which could be achieved via low cost/no cost efforts. These measures, when implemented, are anticipated to yield gas and electricity savings in the range of $130,000 to $153,000 annually with a simple pay back 0.5 to 1 year, depending on exactly how the staff goes about implementing them. The complete findings lists as well as the referenced notes are included as part of an Appendix in the manual. Potential capital improvement projects also were identified with a projected annual savings potential of $35,000 and a simple payback range of 3.5 to 5.5 years. 2 Figure 2 - The LAX Findings List (Part 1) Retrocommissioning the LAX Marriott 3 Figure 2 Continued 4 Retrocommissioning the LAX Marriott Getting Ahead of the Game Prior to the initiation of the retrocommissioning effort, the LAX facilities staff had already taken significant steps targeted at improving the performance of their systems and paving the way for the retrocommissioning process. Specifically, the staff worked through the facility performing O&M procedures like calibration and adjustments to eliminate the obvious and allow the systems to be probed in greater depth by the proce process. They also had upgraded their filters in several units to utilize extended surface area technology. In addition to improving IAQ, which is continuously challenged by emissions from traffic at the near-by airport, the filters offered savings on several other fronts. The lower pressure drops offered by the technology directly reduce energy consumption. In addition the extra media surface increases the dust holding capacity by a factor of 2 as compared to conventional filters. As a result, filter life cycles are increased, reducing labor costs, reducing filter costs, and minimizing the waste stream from the facility. A variety of options exist for employing the filters, as is illustrated in Figure 3.2 Standard 30% Prefilters with 65% Standard Final Filters - 24 hr/day, 7 day/week Total Cost, Filters, Labor, and Energy $12,000 $10,000 Standard 30% Prefilters with 75% Extended Surface Area Final Filters - 24 hr/day, 7 day/week $8,000 75% Extended Surface Area Final Filters Only - 24 hr/day, 7 day/week $6,000 $4,000 Standard 30% Prefilters with 65% Standard Final Filters - 12 hr/day, 5 day/week $2,000 $0 0 10 20 30 40 Month 50 60 Standard 30% Prefilters with 75% Extended Surface Area Final Filters - 12 hr/day, 5 day/week 75% Extended Surface Area Final Filters Only - 12 hr/day, 5 day/week Figure 3 - Extended Surface Area Filter Life Cycle Costs: Extended surface area filters offer many options for reducing costs. Success depends on performing filter changes based on pressure drop, not time or visual appearance. Thus, providing pressure drop gauges on all filter bank is key to success. 2 See Using Extended Surface Air Filters in Heating Ventilation and Air Conditioning Systems: Reducing Utility and Maintenance Costs while Benefiting the Environment at www.PECI.org for a case study documenting some of the benefits of this technology. A PowerPoint® presentation titled Extended Surface Area Filters, also available at the site provides additional information on the technology. Retrocommissioning the LAX Marriott 5 Double Duct Air Handling Systems Findings The LAX facility incorporates 5 large double duct air handling units to serve its ball rooms, meeting rooms, restaurants and public spaces. A typical unit configuration is illustrated in Figure 4. While this approach was common for handling large areas with multiple zone requirements at the time the LAX facility was designed, it has its drawbacks in terms of efficiency. Specifically: 2 1 3 1 4 5 6 Figure 4 - A Typical Double Duct Air Handling Unit Typically, the units include an economizer section and filters (1), a high pressure supply fan with a diffusion plate in the discharge (2), and a hot and cold deck (3 and 4) to create cold and hot air streams. These airstreams are delivered by as high velocity duct system (5) to constant volume mixing boxes (6), which mix the air streams as necessary to match the requirements of the area served while regulating flow at a constant volume. The systems tended to be designed for large load handling capacities and high flow rates. As a result, the fan energy associated with them can tend to be high relative to the requirements of the load and other approaches. The high velocity duct systems accentuate the friction losses associated with any duct system and further elevate the system’s fan energy requirements. The need to split the supply flow into two separate airstreams forces poor discharge conditions on the supply fan, which further degrades the system efficiency and increases the fan energy. The parallel hot and cold air streams further compromise efficiency by setting the stage for simultaneous heating and cooling. Even the best of mixing boxes will waste some energy due to damper leakage as can be seen from Figure 5. Serving a hot and cold air stream from a common supply stream that is served by an economizer cycle compromises the economizer’s ability to deliver economy. If the economizer is controlled to minimize the cold deck cooling requirements, then the hot deck is burdened with an additional heating load as compared to what would be achieved by recirculating more return air to provide a higher mixed air temperature. But, elevating the mixed air temperature reduces the cooling capacity of the cold deck with out using mechanical cooling. 6 Retrocommissioning the LAX Marriott Lower Level Corridor Mixing Box Performance with a Set Point Change 80 Full Heat Temperature, °F 75 Mixing Box Cold Deck Temperature °F Mixing Box Hot Deck Temperature °F 70 Mixed (Leaving) Temperature °F Return Temperature °F 65 AC5 Imperial Ball Room Hot Deck °F 60 AC5 Imperial Ball Room Cold Deck °F 55 Full Cool 50 3/12/04 12:00 PM 3/12/04 12:28 PM 3/12/04 12:57 PM 3/12/04 1:26 3/12/04 1:55 3/12/04 2:24 3/12/04 2:52 PM PM PM PM Date and Time Figure 5 - Recently Overhauled Mixing Boxes Still Show Evidence of Damper Leakage For these reasons, double duct systems are ideal candidates for some focused retrocommissioning effort. Figure 6 lists the findings associated with the LAX double duct air handlers. The following paragraphs will discuss some of these findings in greater detail. Figure 6 - Double Duct Air Handling Unit Findings Retrocommissioning the LAX Marriott 7 Reducing Air Flow Rates Analysis of the drawings and other contract documents revealed that the LAX double duct units were designed with flow rates that equated to 2.6 to 2.9 cfm/square foot. However, many loads that exist in the areas served by the units can typically be handled by 1.0 to 1.5 cfm/square foot. The conclusion reached from these observations is obvious; in the general case, it should be possible to reduce the airflow rates on the systems. Data loggers and field measurements revealed that: Total flow for the systems was at 100% to 115% of design. Cold deck flow and hot deck flow were nearly identical; i.e. the air handling unit supply flow was evenly split between the hot and cold deck via the actions of the mixing boxes, which in general, were mixing equal volumes of hot and cold air to satisfy the loads they served. Cold deck temperatures were running in the low to mid 50’s°F while hot deck temperatures were running in the 75 to 95°F range. This fact, combined with the previous bullet supported the excessive flow hypothesis. The ability of an air stream to handle a cooling load is a function of the flow rate and the difference in temperature between the air stream and the desired zone temperature. The fact that the mixing boxes were blending hot and cold air to satisfy the load indicated that a supply stream at the cold deck temperature would over cool the space. The mixing process that was occurring in the system represents energy waste due to simultaneous heating and cooling. Reducing the system flow rate would force the mixing boxes to use more cold air and less hot air to handle their loads, reducing the simultaneous heating and cooling in addition to saving energy at the fan due to the reduced flow rate. Further analysis revealed that implementing this measure could save $56,300 by reducing fan energy and simultaneous heating and cooling. Implementing the change can be accomplished in a variety of ways, ranging from a sheave change to installing Variable Speed Drives (VFDs). Purchasing and installing new sheaves and belts is the most straight-forward and cost effective approach and actually delivers the best over-all efficiency since there would be none of the efficiency losses associated with a VFD. However, while more costly, using a VFD to accomplish the speed change has several advantages. Improved Flexibility: Once the drives were installed making the experimental changes necessary to determine the optimum flow rate would be very easy in contrast to multiple sheave changes. It would also allow the operating staff to return to the high flow rates for special situations that might occur such as a function with unusually high cooling loads due to special lighting and equipment or higher than normal occupant densities. Similarly, the staff could depress the flow rates below what was required for functions that might involve filming the proceedings where eliminating background noise may take precedence over comfort. Paving the Way for Future Improvements: Having VFDs in place would be a major step towards making the conversion from constant volume double duct operation to variable volume double duct operation as described in DD02. 8 Retrocommissioning the LAX Marriott Improve AHU Start-up Reliability: The operating staff have experienced startup problems ranging from motor failures to AHU casing damage when the double duct units are started and stopped due to the large flow rates and high static pressures involved and the large motors required to operate the units (see DD03 and DD10). Variable speed drives would minimize the potential for damage by providing a soft start. The facility typically looses one motor a year due to startup problems with a resulting cost of $1,500 to $2,500 depending on the exact motor size and the rigging problems associated with getting a new motor in place. Thus these avoided costs are included as part of the savings potential associated with this finding. The savings calculation was based on the assumption that on the average 0.5 cfm per square foot could be eliminated. On the average, this is probably conservative and the savings achievable might easily be 2 or even 3 times what is projected. However, it will be important to bear several things in mind as implementation proceeds. Even though the average flow rate is high, it is likely that there are zones that need the capacity they are currently served with. Thus, carte-blanche reductions in airflow at the central unit will need to be supplemented with minor rebalancing at selected zones. Determining the exact flow rate reduction can be accomplished in one of several ways. One approach would be to have an engineer do a zone-by-zone load analysis based on the real time loads. Another way would be to deploy data loggers on all or nearly all of the double duct boxes and let them “tell you” what the load is. Access may be an issue for this option since the majority of the boxes are above high ceilings. A third approach would be via experimentation using incremental reductions in flow during the cooling season until nearly all of the flow on the hot deck is eliminated, which would indicate that all of the cooling capacity was required to offset loads. This approach might be the most viable, especially if the speed reductions are accomplished via VFDs rather than sheave changes. Making changes of this type will ripple out into the other systems in the building and most likely require adjustments in other areas. For example, reducing flow rates will probably change pressure relationships and some rebalancing or verification of exhaust flows and ventilation rates may be necessary to contain cooking odors and ensure good IAQ. Similarly, reducing flows will reduce the potential to simultaneously heat and cool, thus saving energy on other systems. It is important to not take credit for saving energy twice when assessing the benefits of complementary features. For instance, reducing flows in the double duct AHUs will minimize the potential to simultaneously heat and cool. Thus, the benefits of energy recovery to handle the simultaneous heating and cooling will be less than they would be if the flow rates at the double duct units had not been reduced. The calculations used for this evaluation have endeavored to do this to the extent possible given the time constraints and budget. Thus, it would be desirable to implement the major findings first and then re-assess the savings potential of related findings. Retrocommissioning the LAX Marriott 9 Reducing Simultaneous Heating and Cooling Optimizing deck temperatures minimizes simultaneous heating and cooling potential. As a result, both reheat and cooling energy is saved. These savings ripple back to the central plant because the pumping energy pumping energy associated with moving the chilled and hot water to the loads is reduced. This finding proposes automating and optimizing the manual resetting of deck temperatures. The staff currently is accomplishing this manually. While diligent in their efforts, other operational issues often will keep even the most dedicated operator from making the ideal and timely set point changes associated with optimization. Computers, on the other hand, are very good at this. Plus, the points added to allow this to be implemented will provide other advantages in terms of diagnostics and alarm capabilities. These features will add value in terms of improved performance, improved guest satisfaction, and improved persistence of the RCx implementations. Economizer Performance The double duct air handling systems were a good news/bad news situation. The good news was that serving both the hot deck and cold deck in no way compromised the operation of the economizer cycle. The bad new is that this is because there are no economizers. Three of the units simply do not have a connection to outdoor air that would allow operation above minimum outdoor air up to 100% outside air; the fundamental component of economizer theory. Two of the units have a return air connection and an outdoor air connection, but there are no dampers on either connection, thus no ability to modulate the outdoor air flow. The configuration of the units is such that the will operate as essentially 100% outdoor air units, despite the return air connection. Testing during the retrocommissioning process revealed that this was in fact true. Figure 7 - The lack of dampers on the outdoor air intake and its close proximity to the supply fan virtually guarantee that this unit will operate as a 100% outdoor air unit, despite the return air connection (bottom opening). The three units lacking the outdoor air capability to support an economizer cycle offered the greatest opportunity for savings. This is because the lack of economizer capability requires that the central chilled water plant operate on a year round basis. But achieving the savings does not lend itself to the low cost/no cost solutions associated with retrocommissioning and will require some sort of capital expenditure. The conventional approach to the problem would involve extending a large outdoor air duct from the units to the building exterior, a complicated and expensive undertaking in the LAX facility. A more novel but proven approach involves using the cooling towers to generate chilled water directly during cold weather. This still requires the operation of the chilled water pumps and tower fans, but eliminates the need for a very large outdoor air duct and some complex controls. Thus, it additional study may reveal that this is the most viable option for the facility. 10 Retrocommissioning the LAX Marriott Initial estimates indicate that this approach could save $21,400, but could easily require an expenditure of $75,000 to $100,000. The two units that are equipped with outdoor air connections but no control present a much more easily implemented solution; i.e. simply add dampers and controls. However, the characteristics of the climate in Los Angeles (see Figure 8), coupled with the way that the double duct configuration compromises the economizer performance, minimize the savings potential to approximately $4,400. Annual LAX Outdoor Air Temperature Distribution 2500 2000 Hours 1500 1000 500 0 30 40 50 60 70 80 90 100 110 Temperature, °F Average Bin Temperature vs. Hours in the Bin Freezing Space Condition Figure 8 - A view of the Los Angeles Climate: The climate in Los Angeles is relatively cool and dry most of the year. Thus, an economizer-equipped unit would tend to operate on 100% outdoor air much of the time, just as the units do now. The only times that having the ability to modulate the outdoor air flow would provide benefit are when the outdoor temperatures are above the typical space temperature and during when the outdoor air temperatures are below the design cold deck temperatures (typically 50-55°F). Subfreezing weather and the operational issues typically associated with it are simply not an issue in Los Angeles. Preliminary analysis indicates that the most cost effective approach to saving energy with these systems involves removable blank-off plates that are opened and closed seasonally based on outdoor air conditions and alarms generated by the EMS. The plates should be sized to allow enough open louver area to provide the minimum outdoor airflow necessary for maximum occupancy. Determining this will be most easily accomplished via experimentation. Because implementing this measure will increase the recirculation rate, the filters should last longer. Retrocommissioning the LAX Marriott 11 Implementing Schedules Trend analysis revealed thatAC-3, the largest air handling unit on the site, was not being shut down at night when the area it served was unoccupied. This was not news to the operating staff; there was a compelling reason for keeping it on line. Specifically, the operating staff had discovered through painful experience that the unit could be extremely difficult to restart, often resulting in motor failures and damage to the AHU. Each motor failure costs approximately $1,500 dollars for the motor itself and has the potential to cost tens of thousands of dollars in lost revenue due to the inability to condition the ballroom area it serves. On the other hand, solving the problems that prevent scheduled operation has the potential to save $15,100 annually, mostly in the form of fan energy. There are several potential root causes for the problem. 1 Overload Sizing: In theory, the overloads on the motor starter should take the motor off line before the current flow through it is excessive enough to cause damage. Overload sizes should be checked and adjusted to match the motor that is installed. Implementing this recommendation will not solve the start-up problem, but it will help minimize the potential for burning up the motor when it does have to be restarted. 2 Loose Connections: Loose wiring connections can reduce the voltage to the motor, making it difficult for the motor to accelerate up to speed. This prolongs the inrush current, which, in turn, can lead to premature motor failures. There are a variety of techniques that can be used to identify loose connections, ranging from having a licensed electrician physically check them to making a thermographic survey. 3 Fan Wheel Cleanliness: Over time, dirt can accumulate on a fan wheel, adding a surprising amount of weight to the wheel. This added weight changes the moment of inertia of the wheel, which means it will take the wheel longer to accelerate, all other things being equal. If the wheel takes longer to accelerate, the motor in-rush current will last longer and can result in premature motor failure and/or nuisance overload trips that start to occur on a fan that previously has been problem free. This scenario has, in the past, caused un-informed facilities staff to increase the overload size beyond what should be installed for the motor, curing the symptom and not the problem and leading to the issue discussed in 1 above. 4 Motor characteristics: All motors are not created equal; different motors from different manufacturers or different product lines can have radically different starting characteristics and moment of inertia capabilities. If the replacement motors that have been installed did not take the fans starting torque requirements into consideration, its not out of the question that the new motor simply is not capable of starting the existing fan. Initially, this would probably show up as a nuisance overload trip, leading to a solution similar to that described in 3 above and a problem similar to that described in 1 above. It is important to understand that even if the items listed above are not the root cause, implementing other measures may eliminate the problem on this unit. Specifically, a reduction in airflow will result in a significant load reduction on the fan motor since fan power varies as the cube of the air flow. This particular unit has a design brake 12 Retrocommissioning the LAX Marriott horsepower requirement that is very near to the motor horsepower capability, in contrast to the other units. Unloading the motor via an airflow reduction may have a significant impact on the current operating problems. The implementation cost reflected in the findings list provides a VFD to allow the fan to ramp up to speed, minimizing the loads on the power system and motor and the shock to the AHU casing. Installing a VFD on a constant volume system as a balancing device can be undesirable because of the added complexity and efficiency losses represented by the drive (see Figure 9). However, in this situation, it may be a viable way to allow the fan to be scheduled and the savings might outweigh the efficiency losses and complexity issues. The drive also paves the way for the recommendations of DD2. It is also important to understand that implementing the recommendations of DD11 may address the start-up problem because it will significantly unload the motor, and the implementation costs might drop to virtually 0 if the VFD is not required Variable Speed Drive Efficiency 100% 90% Model 40P4, 1 hp 80% Model 43P7, 5 hp Efficiency 70% Model 47P5, 10 hp 60% Model 4015, 25 hp 50% Model 4030, 50 hp Model 4055, 100 hp 40% Model 4075, 150 hp 30% 20% 10% 0% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 110% 120% Percent of full speed Figure 9 - Drive Efficiency Varies with Speed and is never 100%. Notice how the efficiency generally improves as motor size increases and starts to fall off rapidly below 50-6-% speed. Finding Interactions HVAC systems are extremely interactive, both with other systems in the building as well as with the building itself. Thus it is not surprising that many of the findings identified for the for the double duct units are interactive. For example: Reducing air flow reduces over cooling. Reducing over cooling reduces hot deck flow and increases cold deck flow. Retrocommissioning the LAX Marriott 13 Increasing hot deck flow increases the velocity driven energy impact of poor fitting designs. Reduced hot deck flow reduce baseline gas consumption. Reduced hot deck flow reduce parasitic cooling energy consumption (simultaneous heating and cooling). Reduced cooling load reduces central plant flow requirement at part load. A reduced central plant flow requirement increases plant turn down requirement at part load. An increased turn down requirement demands a more robust central plant; problems that were not evident before may become apparent. This interactivity may sound discouraging; some may consider it a reason not to move forward. However, this is not the case. They actually represent opportunities to make improvements in other areas. Successful retrocommissioning leads to continuous commissioning, a process whereby the buildings systems are continuously monitored, adjusted, and optimized, as the operating team continuously adjusts and tunes the systems to meet the constantly varying requirements of the loads they serve and to compensate for wear and aging. Other Air Handling Systems The other air handling systems on the project exhibited similar findings to those described for the double duct units as can be seen from Figure 10. Figure 10 - Other Air Handling Unit Findings Finding AHU08 merits some additional discussion. The project documents and discussions with the operating staff indicate that many of the air handling units on the project are equipped with electric reheat coils which are still active. Time constraints prevented focusing any attention on these units during the project. However, electric heat typically has high operating cost and less than desirable source energy implications associated with using it. In general terms a btu of heat generated by burning fossil fuel to make steam and hot water in the central plant will use 60-70% 14 Retrocommissioning the LAX Marriott less source energy when contrasted with electricity generated with fossil fuels in a conventional power plant. Costs for the steam/hot water approach will typically be 30-50% of the cost associated with using electricity for heat. Most of the efficiency losses associated with using electricity for heat are related to the energy conversion processes used to generate the power and losses associated with transmitting it long distances. Because of these factors, the LAX electric heating coils are worthy of some focused attention as part of on-going O&M and capital planning. More detailed recommendations are included in the notes pages associated with the findings list. Past experience indicates that these efforts will result in energy savings, performance improvements and improved safety. The Marriott LAX Chilled Water Plant The findings associated with the Marriott LAX chiller plant are illustrated in Figure 11. Figure 11 - Findings for the Marriott LAX Chilled Water System The Los Angeles Marriott features a recently upgraded variable flow central chilled water plant. Figure 12 illustrates the plant in the form of a simplified schematic and highlights some of its design features. An attachment to the Findings List Notes included with the manual provides additional details regarding variable flow system operation for those who are interested. This design, often termed a “primary-secondary arrangement” allows constant flow to be maintained through the chillers in one flow circuit while the system load varies with flow in a separated but interconnected flow circuit. Varying the flow with load is the primary energy savings mechanism as contrasted to a constant volume system. To get the flow to vary with the load, the loads served by the system must be equipped with two-way valves instead of three-way valves, which typically would be applied on a constant volume system. Retrocommissioning the LAX Marriott 15 Figure 12 - The Marriott LAX Variable Flow Chilled Water Plant The plant incorporates a constant volume pumping circuit through the chiller evaporators (the yellow highlighting on the drawing to the left) that is coupled with a variable flow circuit through the loads (the lavender highlighting on the drawing on the right). Both circuits share a common section of piping typically called the bypass line or decoupling line (the red oval on the drawing on the right). It is this section of pipe that allows one circuit to function independently of the other. The flow rate in the decoupling line will vary and can be from the return to the supply (often termed “forward flow”), from the supply to the return (often termed “reverse flow”) or under some very specific load conditions, zero. Excessive Chilled Water Distribution System Flow A Direct Digital control (DDC) system was included as a part of the plant upgrade project. During the first site visit, the trending capabilities of the system were set up to monitor system performance parameters to allow problems to be identified and diagnosed. Figure 13 illustrates some of the data that was captured. The calculated load was based on chiller temperature and flow measurements taken by the DDC system (also called the EMS). The theoretical flow line illustrates the flow that should exist in the distribution system for the documented load conditions. Unfortunately, the actual flow to the loads was significantly higher than the required flow and showed no tendency to vary with load. This sort of problem is actually quite endemic in variable flow chilled water plants and has operating implications that ripple out to the loads and cause further inefficiencies. For instance: The high distribution flow rate relative to the chiller flow rate means that there is forward flow in the bypass line; i.e. flow bypasses the chillers in the decoupling line. As a result, the temperature to the loads is higher than the temperature leaving the chillers because of the warm, bypassed water blending with the cooler leaving water from the chillers. Most automated plant control strategies target minimizing or preventing this situation. The elevated supply temperatures to the loads cause the control valves at the loads to open more than they would had the design supply temperature been delivered to them. 16 Retrocommissioning the LAX Marriott Chilled Water Base Chart, 03-04-04 11am - 03-05-04 11am 2,000 250 Calculated Load Tons 1,500 200 150 1,000 100 500 50 0 11:36 AM 2:36 PM 5:36 PM 8:36 PM 11:36 PM 2:36 AM 5:36 AM 8:36 AM Flow, gpm Load, tons; Temperature, °F 300 Outdoor Air Temperature Theoritical Flow gpm Total Flow to Loads gpm 0 11:36 AM Date and Time Figure 13 - Marriott LAX Chilled Water Plant Peformance Note the discrepancy between the theoretical flow requirement and the measured flow. Driving the control valves open further aggravates the excessive flow condition in the distribution system, which further aggravates the forward flow in the bypass condition at the central plant. The aggravated forward flow condition drives the process into a viscous circle until things somehow come into balance. On low load days, the higher supply temperatures may actually satisfy the loads, but the plant pays a penalty in terms of efficiency. At some point, some or all of the loads begin to drift above set point due to the elevated supply water temperatures. The retrocommissioning team saw evidence of this in several areas on the project (see findings AHU03 and AHU08). Implementing some of the other findings like the flow reductions at the double duct units will make the plant overflow condition a bigger operational issue since the double duct systems will be less tolerant of high chilled water supply temperatures as the mixing boxes shift more of the flow from the hot deck to the cold deck. The excess flow issues at the Marriott LAX plant can be attributed to three general issues (see Figure 14): Control loops that are out of control: Generally this is caused by the elevated supply temperatures either directly because the valves are driven fully open in an effort to meet a set point that simply can not be achieved with the available supply temperatures. The out of control condition can also be generated by frustrated operators setting the controllers for unachievable set-points (for instance, setting the chilled water valve controller for 45°F which is below the plant design supply temperature and well below the cold deck design temperature). Retrocommissioning the LAX Marriott 17 AHU3, 03-04-04, 4-10 am 100 120 95 90 PCM-2-1 AI 1 AHU3 Cold Deck 100 Temperature, °F 80 75 70 80 Unachievable set point; coil runs wild 60 65 60 40 Valve Command, % 85 AHU-3 Supply Air SP. PCM-2-1 AO 1 AHU3 CHW Valve 55 50 20 45 40 4:00 AM 0 5:00 AM 6:00 AM 7:00 AM 8:00 AM 9:00 AM 10:00 AM Date and Time Figure 14 - The Three General Causes of Excess Flow at the Marriott LAX Chilled Water Plant Set points well below what could be achieved by the current or design operating parameters drive valves fully open (left). Three way valves applied on a system where the flow must vary to achieve design intent maintain nearly constant system flow rates regardless of load condition (bottom right). The lack of a variable speed drive on the distribution pumps means that the pumps must be pushed up their curve to vary flow (top right). Three way valves at the variable flow loads: For a variable flow plant to function, it is essential that the loads be equipped with a valve design that varies flow as the load changes. Sadly, many of the largest loads on the system are still equipped with three way valves. These valves do not contain a balancing valve in the bypass line, which could further aggregate the problem. This is because the bypass connection is relatively short and quite possibly represents much less resistance to flow that the coil it the valve serves. As a result, when the valves modulate to bypass, the flow tends to short circuit around the coil immediately and at a rate in excess of design. This non-linear valve characteristic can also make the valve control loops difficult to tune. Lack of variable speed capability on the distribution pumps: The distribution pumps at the central plant are not equipped with variable speed drives. As a result, flow reductions must be accomplished by forcing the pump up its operating curve rather than reducing its speed. This increases the head in the system, which may over-power the close-off capabilities of the chilled water valves, causing flow through the loads even if it is not required. There was some evidence of this observed at the guest room fan coil units. This problem is compounded by the fact that the pumping head on several of the distribution pumps appears to be excessive for the system. The two larger pumps have nearly twice the head of the smaller pump. Yet, the plant has always been able to serve the loads by operating only the smaller pump. A quick field assessment of the pumping head requirements for the system indicates that it is probably closer to the smaller pumps rating than not. Further support is evidenced by the operating 18 Retrocommissioning the LAX Marriott staff’s reluctance to operate the larger pumps because they know they have problem with over-pressurizing the system and leaks when they do. There is also a subtle but important detail associated with the current control arrangement for the loads that do have two-way valves that prevent the valves from being totally effective. Currently, there is no interlock available to close these valves when the units are off. As a result, the valves tend to drive open when the fan stops. This makes a bad situation worse by contributing to the excess flow condition and by driving the system return temperature down because of the high volumes of supply water that are mixed in with the return. The supply water is still cold since the inactive coils transfer no heat from it. This creates additional operational problems at the central plant, further degrading its efficiency. Many of the issues associated with the chilled water plant actually have there roots in the cancellation of the final phase of the chiller plant upgrade project due to budget problems that were the outfall of the events of 9/11. Completing the following steps associated with the final phase of the central plant project will go a long way towards improving the performance of the central plant. Convert all loads to 2-way valves: It may be possible to perform this work inhouse on the smaller valves by adding a balance valve to the bypass connection associated with three-way valves and then throttling it nearly closed. The result will be a valve that operates almost as if it were a three way valves. Outside contractors will probably be required to modify the larger valves due to the need to work with big pipe. Install a variable speed drive on at least the lead pump in the central plant: Adding a drive to one of the larger pumps would also be desirable in terms of operating flexibility and redundancy. Another option to consider would be to sell the existing oversized pumps and use the proceeds of the sale to help fund replacement with variable speed pumps selected for the actual requirements of the system. This approach will provide the best efficiency since the replacement pumps could be optimized for the system’s requirements. Tune control loops: Tuning the control loops to operate at the correct set point and be stable under all load conditions will be a critical final step in the improvement process. Otherwise, the benefits gained from the other steps will not be realized. All of these changes will undoubtedly raise other operational issues with the chilled water system. This is because they will force the system to operate as a variable flow system per its design intent, an operating contingency it has not had to face in the past. This should not be viewed as a problem, but as an opportunity to further improve the efficiency of the plant and maximize the benefits of the potential that the recent upgrade investment represents. Based on past experience, there are two issues that are likely to come to the forefront as the plant is forced to work in the variable flow mode. 1 The loads served by the system need to be tailored to the differential temperature capability of the plant both at design and as the load drops off. In other words, the temperature rise across the loads should match the temperature drop produced Retrocommissioning the LAX Marriott 19 by the chillers. Typically, this is a matter of coil circuiting and flow rates at the loads and evaporator circuiting and flow rates at the chillers. Temperature rises at the loads of 12 - 16°F are both achievable and common. But shallow coils (less than 6 rows) such as those typically found with fan coil units often simply cannot generate a temperature rise greater than 6 to 8°F. Thus, when a system with a design temperature differential in excess of this value must serve a significant quantity of fan coil units, particular attention needs to be paid to ensure that the design differential is realized at the plant. One technique involves selecting some loads for a temperature rise that is excess of the plant requirement to balance out the lower temperature rise loads and deliver a mixed temperature that matches the chillers. Design temperature differentials of 10 - 14°F are typical; the LAX plant appears to be targeted at 12°F. If this contingency is not addressed, the relatively cool return water from the low temperature rise loads like fan coil units tends to drive the system temperature differential down and the flow rate up relative to what might be expected on a non-fan coil equipped system serving the same load. This, in turn creates significant operating problems at the central plant that can cause it to be quite inefficient due to excessive, unnecessary pumping rates and unnecessary auxiliary energy. At the Marriott LAX, the potentially low temperature rise associated with the fan coil units, when coupled with their quantity (approximately 1,000) could mean that the temperature difference of the fan coil unit circuit relative to the plant design is an issue. There is some evidence to suggest that this had been considered at one time in the LAX plant. Specifically, there is an abandon pumping circuit that used to serve a compressor in the laundry area. The configuration of the piping serving this load (now abandon in place) suggests that the pump could be configured to elevate either the supply temperature to or return temperature from some or all of the loads, thus helping to alleviate the low temperature rise associated with the fan coil units. Since the laundry has been decommissioned, this function is no longer provided and there is no indication that the central plant upgrade addressed it directly via some other mechanism. Budget for further analysis of this issue should be included in the engineering support associated with the implementation effort. 2 The bypass configuration in the central plant will tend to make starting the 2nd chiller difficult under some operating scenarios. Specifically, when a chiller closer to the plant return connection than the operating machine is started, the flow changes that occur place a nearly instantaneous load change on the operating machine. Frequently, the capacity control system of the operating machine cannot react quickly enough and the machine trips off line on a nuisance safety trip. There are operating techniques that can be used to deal with this issue, but since the staff’s experience has been that they only need to operate one machine, they probably have not had to develop an operating strategy to deal with it. When the loads on the system reach the point where it becomes necessary to bring a second chiller on line, the operating staff may begin to experience this system nuance. Its important to understand that this does not mean the system is 20 Retrocommissioning the LAX Marriott unworkable; it just means that it needs to be operated with sensitivity to the issue.3 Excessive Evaporator Pump Head In a variable flow chiller plant, the evaporator pumps function to move water from the return side of the bypass connection, through the chillers, to the supply side of the bypass connection. As a result, their head requirements are typically modest since the piping circuits they serve tend to be short relative to the distribution system. Fredrick/Weinman Engineered Products 2-1/2 KH, 2-1/2 x 3 x 12 Serial Number 110188-1-96, 1 inch pattern 4586 impeller, 20 hp, 1750 rpm, Curve number 2-1/2KH-182 160.00 12 inch 140.00 11 inch Head, ft. w.c. 120.00 10 inch 100.00 9 inch 80.00 15 bhp 60.00 10 bhp 7.5 bhp 40.00 Impeller Lines Brake Horse Power Lines Pump Efficiency Lines System Curve 5 bhp 20.00 0.00 0 100 200 300 400 500 600 Flow, gallons per minute The inf or mation on this pump cur ve was r epr oduced f r om the manuf actur er s cer tif ied per f or mance cur ves f or the pur pos es of analys is and illus tr ation. To ver if y cer tif ied per f or mance f or this pump, r ef er to the manuf actur er s cer tif ied per f or mance cur ve Figure 15 - A Typical Centrifugal Pump Performance Curve The pump will operate at the point where the system curve (the dashed red line) intersects the pump impeller curve ( the solid blue, green, yellow and red lines). Most pumps can utilize a range of impeller sizes and the actual impeller installed can be trimmed on a lathe to any size between the maximum and minimum impeller size to match the performance to the system curve. Constant horsepower lines are also depicted on the curves to allow power requirements to be assessed (the gray dash-dot lines). In this example, the system curve intersects the 12” impeller curve at about 378 gpm requiring a little over 15 hp. (inside the red circle). If the desired flow rate is 300 gpm, one way to achieve it would be to throttle the pump to 300 gpm. This would “push” the operating point up the pump curve to the blue circle, reducing the horsepower slightly but not much since the horsepower lines and pump curve are nearly parallel in that area. A more energy efficient option would be to reduce the impeller size to approximately 9-3/4” (the green circle). This would reduce the power requirement to approximately 8 hp while still delivering 300 gpm of flow because the pump would not have to move water against a throttled discharge valve. If the pump selections end up having more head than is necessary, the pumps will run out their curves until the flow they produce comes into balance with the pressure requirements of the system they serve at a higher flow rate. The balancing contractor 3 Explaining the details of this issue and what happens when the second chiller is started is complicated and beyond the scope of this case study, but there is a document attached to the Findings List notes that PECI prepared for another similar project which explains the issue in detail. Retrocommissioning the LAX Marriott 21 typically will throttle the pumps back to the design flow, which often (but not always) will save energy as compared to not throttling the pumps. Since the performance of the chillers and chiller plant is related to running at the design flow conditions, the pumps need to be throttled to design even if energy will not be saved. In any case, the throttled pumps will use more energy than necessary because the pressure drop taken by the water as it flows through the throttled discharge valve is dissipating energy that was put into the system by the motor only seconds prior. Trimming the pump impeller to match the pump performance to the system offers a way to achieve design flow with out wasting energy at a throttled valve (see Figure 15). This can be a relatively inexpensive undertaking compared to the savings potential. Typical costs for a 1,000 to 2,000 gpm pump are as follows: $50 to $150 to turn down an existing impeller. $500 to $1,000 for a new impeller if you don’t want to risk your existing impeller, require a quick turn-around, or want to be able to go back to the original operating point at some time in the future. Note that this may not be an option with older pumps if the impellers are no longer stocked. 4 to 8 man-hours plus a gasket set to remove and replace the impeller. Paybacks in the range of 6 months to 2 years are very common. This is a very common finding that can be assessed by a very simple tests and yield significant savings. In addition, there are usually some very obvious indicators of the condition. Either the discharge valve will be wide open and the pump will be rated for much more head that a quick assessment of the system would indicate is necessary4 or the discharge valve will be very heavily throttled. The latter was the case with the evaporator pumps at the LAX Marriott; actually the throttled valves were on the discharge of the evaporators rather than the evaporator pumps, but the Figure 16 - A Throttled effect was the same since the valves are in series with Valve at the Evaporator the pump discharge. Trimming the pump impeller to Discharge at the LAX eliminate the need to throttle the valve has the potential Marriott The position to save $6,500. Since there are actually three indicator is inside the red circle. Full open is straight up. evaporator pumps piped in parallel and the plant typically only needs one chiller, a variety of options exist. Trimming only one impeller provides the fastest payback but introduces some fairly minor operating issues that need to be contended with. Trimming all of the impellers eliminates most of the operating issues, but increases the payback., although it still is projected to be a year or less. 4 For an example of a technique that can be used to quickly assess pump head requirements in the field, go to the Energy Design Resources web site at www.energydesignresources.com and download the design brief titled Design Review, which is free of charge. 22 Retrocommissioning the LAX Marriott The Marriott LAX Condenser Water System Portland Energy Conservation Inc. 1400 SW 5th Avenue, Suite 700, Portland Oregon 97201, 503-248-4636, FAX - 503-295-0820, www.peci.org Cooling Tower Cooling Tower Cooling Tower Cooling Tower Cooling Tower Cooling Tower The condenser water system associated with Chiller 1 Chiller 3 Chiller 2 the LAX Marriott chilled Refrig. Comp. water plant is illustrated as a simple schematic in Pump Pump Figure 17. The condenser Pump Pump Pump PP1 PP3 PP2 pumps exhibit a potential for energy savings via impeller trims that is similar in concept and magnitude to that Figure 17 - The LAX Marriott Condenser Water System described in the preceding section for the evaporator pumps. In addition, there are several attributes of the system that can be exploited to advantage to deliver additional energy savings for a relatively low level of effort. 1 The installed tower Condenser System Performance 3/4/04; 12:30 pm to 1:00 pm capacity is quite generous relative to the installed chiller capacity and is provided as two banks of three cells each. Currently, the staff operates off of one bank while performing maintenance on the other bank. If both banks are utilized Time concurrently, the evaporative surface Figure 18 - Marriott LAX Condenser Water System area is doubled. This Performance will allow the towers to dissipate more heat before fan operation is required, thereby reducing fan energy requirements. 110 200 100 180 Condenser Water from Tower 2 Condenser Water to Tower 2 90 160 70 120 60 100 50 80 40 VFD 2 Speed Command Outdoor Air Temperature VFD 1 Speed Command VFD 3 Speed Command 60 30 40 20 20 10 0 12:30 PM Condenser Water System Set Point 140 VFD Command, % Temperature, °F 80 0 12:35 PM 12:40 PM 12:45 PM 12:50 PM 12:55 PM 1:00 PM Implementing this operating strategy has the additional advantage of further reducing pumping energy since it will split the condenser water flow between two generously sized mains. 2 From an air handling standpoint, each tower cell is an independent air handling system in parallel with the identical air handling systems represented by the other Retrocommissioning the LAX Marriott 23 cells. The fan affinity laws state that the fan power varies as the cube of the flow. Applying this to the tower cells reveals that running two cells at half speed will consume 1/8 (1/2 cubed or 1/2 times 1/2 times 1/2) of the energy that one cell would consume running at full speed. Currently, the system is programmed to run one cell up to full speed before starting a second cell (see Figure 18). Energy savings will be realized by reprogramming the system to start bring all fans on at minimum speed and them ramp them up together rather than one at a time. 3 Chiller efficiency is improved by lowering condenser water temperatures. But, lowering condenser water temperatures will generally require additional fan energy, all other things being equal. In most plants, there is some potential to optimize the condenser set points by experimenting to discover the optimum balance between reduced chiller kW and increased tower fan energy. The kW information available from the tower fan VFDs and the chiller control panels make this a fairly simple undertaking. By adjusting the condenser water supply set point gradually and observing the results in terms of a net kW increase or decrease when the tower energy and chiller energy are added up, the operating staff can optimize over-all efficiency. It may be necessary to determine the optimum setpoint under a variety of conditions and then use the programming power of the DDC system to implement a reset schedule that varies the set point as a function of some parameter like outdoor air temperature to ensure optimization under all conditions. While the savings to be realized by this implementation are modest relative to some of the others ($2,600) they are easily achieved and have the good potential to persist. Since the LAX climate rarely if ever sees subfreezing weather, the limitations to these approaches that would arise in that situation do not need to be considered, further simplifying the implementation. The Marriott LAX Heating Hot Water and Steam Systems Figure 19 - Findings for the LAX Marriott Heating Hot Water and Steam Systems A central hot water system serves the major heating loads at the Marriott LAX. The guest room fan coil units are not served by this system and incorporate electric heat. 24 Retrocommissioning the LAX Marriott A central steam system provides heat for the hot water system along with the pools and Jacuzzi and the domestic water systems. The findings associated with the hot water and steam systems are illustrated in Figure 20. The heating water system is illustrated as a simplified schematic in Figure 20. The plant is a relatively simple constant volume system with heat provided via a steam heat exchanger served by the boilers. Several conservation opportunities exist in the system. One was implemented during the course of the retrocommissioning process. Portland Energy Conservation Inc. 1400 SW 5th Avenue, Suite 700, Portland Oregon 97201, 503-248-4636, FAX - 503-295-0820, www.peci.org Heat Exchanger Pumps 1 and 2 Heat Exchanger Pump HWP1 Pump HWP3 TDV Pump HWP 2 Past experience indicated Figure 20 - The LAX Marriott Central Hot Water Plant The that it might be possible plant has undergone several modifications since it was first built. to operate only one of the The most recent added the secondary pumping circuits to the heat parallel pumps serving exchanger. Notice how the return from the heat exchanger (red circle) connects to the main ahead of the supply connection (blue the heat exchanger rather circle), the reverse of what would normally be designed. While the than both pumps as was flow and temperature conditions that occur as the water flows the practice. Rather than through the series of tees that make up the secondary connections do a lot of calculations to are complex and theoretically interesting, the net effect on plant assess the impacts of such efficiency and operations is negligible. a change, the team took advantage of the forgiving nature of heating water systems, installed a data logger to monitor temperatures and pump energy, and turned off one of the pumps. The result was no detectable change in plant performance accompanied by a reduction in pumping energy that equated to an annual savings of $500. While modest in the context of the other opportunities, the savings was easily achieved with a nearly instantaneous simple payback. The steam system also has the potential for some quick, easily achieved, low risk efficiency improvements. Many of the valves and specialties currently are uninsulated, probably because the insulation was removed for maintenance purposes. Since the steam system operates at a relatively high temperature (approximately 240 260°F) the losses from the uninsulated fittings can be quite significant.5 Installing removable insulation blankets has the potential to make a very significant reduction in the losses from these fittings. The blankets can be quickly removed and reinstalled by the maintenance staff as necessary to service the equipment. At the LAX Marriott, 5 A DOE funded study developed a handy tech sheet for quickly estimating losses from uninsulated fittings in steam systems. It can be downloaded at no cost from http://www.oit.doe.gov/bestpractices/technical_publications.shtml#technical. Retrocommissioning the LAX Marriott 25 the estimated annual savings associated with installing the blankets is approximately $12,500 with a payback of approximately 9 months. Figure 21 - Uninsulated Valves and Specialties at the Marriott LAX Plant (left) and Removable Insulation Blankets Installed on Another Project (Right) Figure 22 - Other Marriott LAX Findings in Miscellaneous Categories 26 Retrocommissioning the LAX Marriott Other Miscellaneous Findings Guest Room Fan Coil Unit Performance 110 Temperature, °F; Relative Humidity, % Figure 22 illustrates other findings identified by the study in a variety of categories. Time constraints precluded analysis of many of these issues, but the evidence suggests they are worthy of additional investigation by the staff. 100 Possible simultaneous heating and cooling when strip heaters run Temperature difference may90 indicate valve leakby (sensors not in wells) Return Air Temp., °F 80 Return Air RH CHW Supply Temp., °F 70 CHW Return Temp., °F 60 50 One item worthy of Tendency towards a high relative attention in particular is humidity may indicate inadequate the guest room fan coil make up air conditioning Date and Time units. While the savings potential for any given Figure 23 - Potential Guest Room Fan Coil Units unit is small, the sheer number of units makes the net savings potential significant for any issue that is repeated from unit to unit to unit. It is not at all uncommon to have a design error, operational error or failure propagate through multiple similar units with significant implications in terms of energy and performance. 40 Wed 3/24/04 3:00 PM Wed 3/24/04 6:00 PM Figure 23 Illustrates some potential issues that showed up in several data sets retrieved from the guest room units. While the sample size was to small to state that the potential deficiencies apply to all units, the fact that these issues showed up more than once means they merit additional consideration. At a minimum, add ional data logging and analysis of a significant (5-10%) sample of the guest rooms would be desirable. Additional actions to be taken can be based on the results of this effort. Wed 3/24/04 9:00 PM Thu 3/25/04 12:00 AM Thu 3/25/04 3:00 AM Thu 3/25/04 6:00 AM Thu 3/25/04 9:00 AM Thu 3/25/04 12:00 PM Thu 3/25/04 3:00 PM Figure 24 - Possible Indications of Errosion Note how the pipe wall has been thinned in this area down stream of reduced port ball valves. Cavitation and erosion could be responsible for this. Both phenomenon might be associated with flow rates in excess of what is required. The Marriott staff has suspected for some time that the flows and pressures in the domestic water system might be excessive, based on the piping failures they have experienced, which appear to be related to erosion. (see Figure 24). While some energy savings potential might exist if the flows and pressures are reduced to eliminate the problem, the far more significant benefit will be realized as reduced failures in the system. Related to the preceding, the Marriott staff has also spent some time exploring the possibility that the domestic water booster pumps could be shut down. The data set illustrated in Figure 25 indicates that while this may not be viable all of the time, it Retrocommissioning the LAX Marriott 27 may be possible some of the time, especially if low pressure shower heads are installed in the upper floors and a high volume bypass with a check valve is installed around the pump set. Shutting down the pump part of the time has the potential to eliminates an 8kW load, saving $3,000 per year. Domestic Water Booster Pump Performance 120 100 Incoming water pressure at pump suction with the pump running Pressure, psig 80 Building height in psi 60 Difference between incoming water pressure and building height psi 40 20 0 3/23/04 3/23/04 3/24/04 3/24/04 3/24/04 3/24/04 3/25/04 3/25/04 3/25/04 12:00 PM 6:00 PM 12:00 AM 6:00 AM 12:00 PM 6:00 PM 12:00 AM 6:00 AM 12:00 PM Date and Time Figure 25 - Marriott LAX City Water Pressure Note how the available city water pressure may exceed the requirement to serve the upper floor of the facility some of the time. Conclusion The preceding paragraphs represent just a few of the details behind the results of the Marriott LAX effort. And that’s only the beginning. Time constraints prevented analysis of a significant amount of the data collected over the course of the project. As the staff and their consultants spend additional time with the trends that have been collected but have yet to be explored, they will more than likely discover additional savings and performance improvements. In fact, the biggest problem most experienced commissioning practitioners have with the data collected in this type of project is making themselves stop playing with it before they blow their budgets. In other words, they are saving energy and resources and having a good time doing it. C:\Workspace\520 - Marriott RCx Project\Findings\LAX Case Study v2.doc 28 Retrocommissioning the LAX Marriott