Letters to the Editor / Carbon 41 (2003) 2159 – 2179

2177

Tension–tension fatigue behavior of unidirectional single-walled

carbon nanotube reinforced epoxy composite

Yu Ren a , Feng Li b , Hui-Ming Cheng b , Kin Liao a , *

b

a

School of Mechanical and Production Engineering, Nanyang Technological University, Singapore 639798, Singapore

Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, 72 Wenhua Road,

Shenyang 110016, China

Received 11 April 2003; accepted 3 June 2003

Keywords: A. Carbon nanotubes, Carbon composites; D. Mechanical properties

Owing to the recent rapid development of synthesis

methods for carbon nanotubes (CNTs), high quality, long

and aligned CNT ropes are now available [1–5]. These

advances in synthesis methods enabled the mechanical

properties of CNTs to be more easily assessed, and

applications in macroscopic devices and load-bearing

structures one step closer to reality. To date, some of the

most important mechanical properties of CNTs, such as the

Young’s modulus and tensile strength, have been characterized experimentally [6–10]. At present, however,

studies on the long-term performance of CNTs or CNT

reinforced composites are still absent. An understanding of

their behavior under repeated mechanical loads will enable

the potential of CNTs to be better realized for long-term

structural applications. In this study, the fatigue behavior

of unidirectional, aligned SWNT rope reinforced epoxy

composite was investigated. The SWNT ropes used in this

study were synthesized by the hydrogen / argon electric arc

discharge method, with lengths up to 100 mm [3]. The

density of the SWNT is 1.138 g / cm 3 and a volume

fraction of 65% in the SWNT bundles [7]. The matrix

material used was Epicote 1006 epoxy resin, a room

temperature curing system.

To fabricate the composite sample, a thin layer of

as-prepared epoxy resin was evenly brushed onto a hard

surface pre-pasted with release tape to ensure the composite sample can be easily detached from it after curing.

Twenty millimeter long, weighted SWNT ropes were then

aligned by a slight tension and subsequently laid onto the

epoxy layer. More epoxy was then applied to cover the

SWNT ropes, and the thickness of the small composite

plate was controlled in the range 0.4–0.6 mm using a

roller. The composite (hereafter referred to as SWNT /

epoxy) was cured completely after 72 h at room temperature. Dog-bone SWNT / epoxy specimens with dimensions

*Corresponding author. Tel.: 165-6790-5835; fax: 1656791-1859.

E-mail address: askliao@ntu.edu.sg (K. Liao).

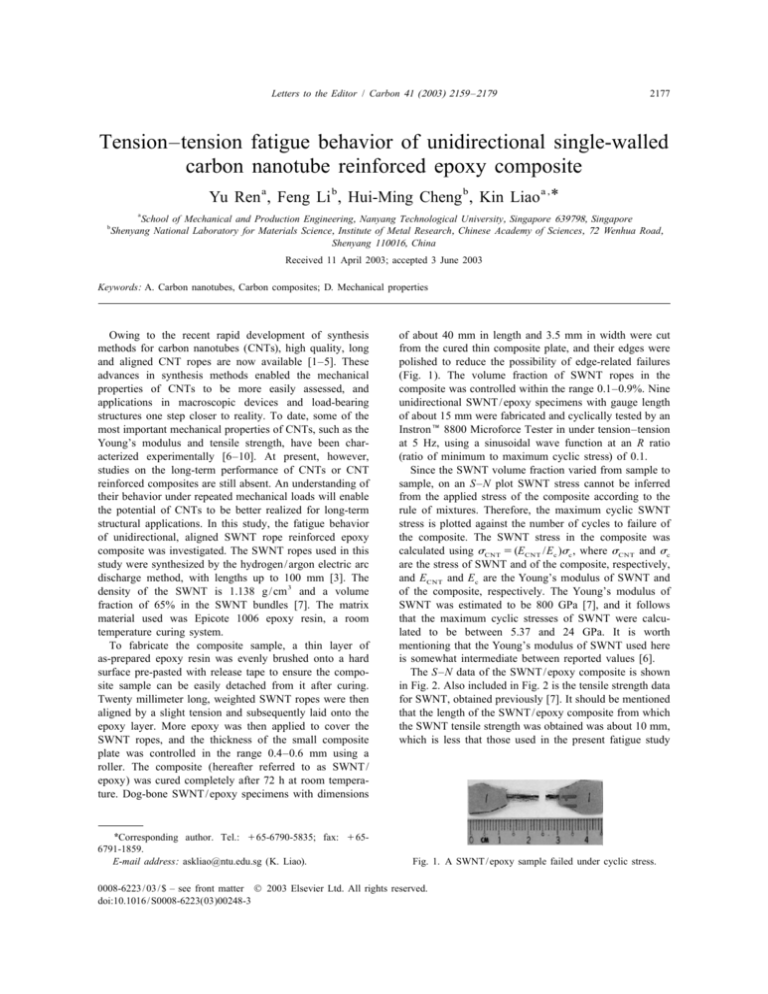

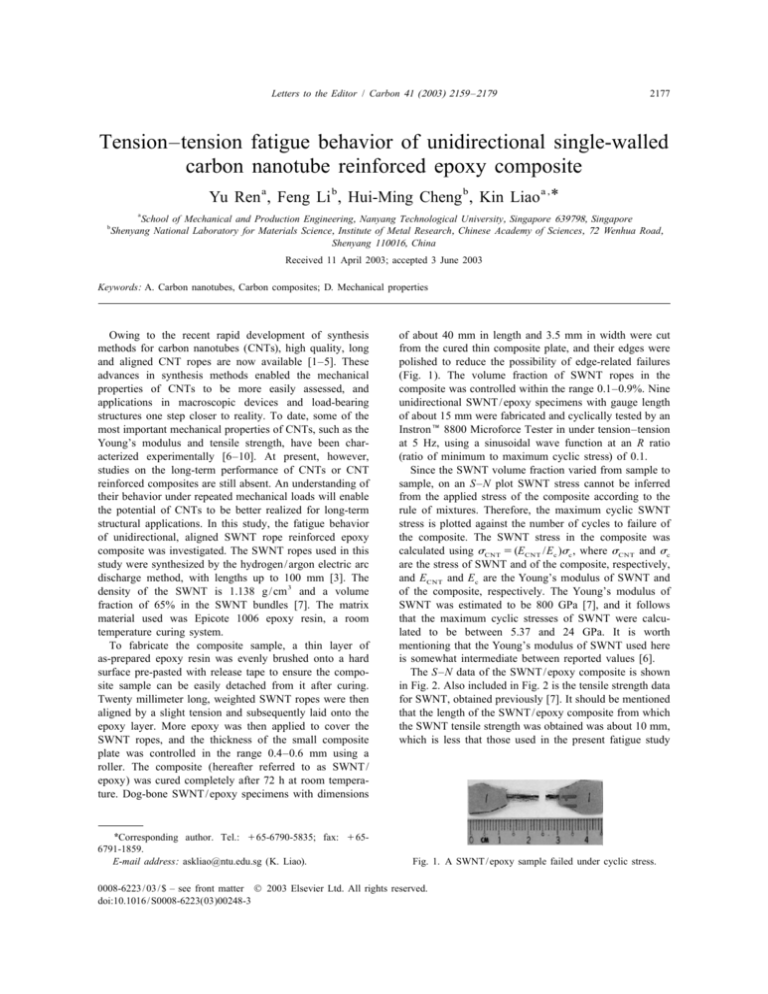

of about 40 mm in length and 3.5 mm in width were cut

from the cured thin composite plate, and their edges were

polished to reduce the possibility of edge-related failures

(Fig. 1). The volume fraction of SWNT ropes in the

composite was controlled within the range 0.1–0.9%. Nine

unidirectional SWNT / epoxy specimens with gauge length

of about 15 mm were fabricated and cyclically tested by an

Instron姠 8800 Microforce Tester in under tension–tension

at 5 Hz, using a sinusoidal wave function at an R ratio

(ratio of minimum to maximum cyclic stress) of 0.1.

Since the SWNT volume fraction varied from sample to

sample, on an S–N plot SWNT stress cannot be inferred

from the applied stress of the composite according to the

rule of mixtures. Therefore, the maximum cyclic SWNT

stress is plotted against the number of cycles to failure of

the composite. The SWNT stress in the composite was

calculated using sCNT 5 (ECNT /Ec )sc , where sCNT and sc

are the stress of SWNT and of the composite, respectively,

and ECNT and Ec are the Young’s modulus of SWNT and

of the composite, respectively. The Young’s modulus of

SWNT was estimated to be 800 GPa [7], and it follows

that the maximum cyclic stresses of SWNT were calculated to be between 5.37 and 24 GPa. It is worth

mentioning that the Young’s modulus of SWNT used here

is somewhat intermediate between reported values [6].

The S–N data of the SWNT / epoxy composite is shown

in Fig. 2. Also included in Fig. 2 is the tensile strength data

for SWNT, obtained previously [7]. It should be mentioned

that the length of the SWNT / epoxy composite from which

the SWNT tensile strength was obtained was about 10 mm,

which is less that those used in the present fatigue study

Fig. 1. A SWNT / epoxy sample failed under cyclic stress.

0008-6223 / 03 / $ – see front matter 2003 Elsevier Ltd. All rights reserved.

doi:10.1016 / S0008-6223(03)00248-3

2178

Letters to the Editor / Carbon 41 (2003) 2159 – 2179

(15 mm). The S–N data for unidirectional carbon fiber

reinforced epoxy, shown in the gray rectangular region of

Fig. 2, are adapted from Ref. [11], which encompasses

unidirectional carbon / epoxy data from a variety of

sources. In Fig. 2, the maximum cyclic stress of the carbon

fiber is used instead of that of the composite stress in order

to make a comparison with the data from the present study.

A simple linear relation often used for S–N curves is

sa /sult 5 1 2 m log N, where sa and sult are the applied

and ultimate stress, respectively, N the number of cycles to

failure, and m the slope of the normalized S–N curve. The

S–N curve obtained for the SWNT / epoxy composite is

very flat, similar to the characteristics of the unidirectional

carbon / epoxy composites. Slope m for most unidirectional

carbon / epoxy composites ranges from 0.035 to 0.057 [11].

For SWNT / epoxy composites, m obtained from linear

regression of the quasi-static tensile strength and S–N data

is calculated to be 0.042, which is within the range of the

unidirectional carbon / epoxy composites. However, it

should be mentioned that the estimated maximum cyclic

stress of SWNT is at least twice that of the carbon fiber in

unidirectional composites. In other words, the fatigue

strength of SWNT in epoxy is at least twice that of carbon

fibers.

All fatigue fractures of SWNT / epoxy samples occurred

within the gauge region; a typical one is shown in Fig. 1.

Damage and failure modes of SWNT / epoxy were examined under a scanning electron microscope (SEM).

Selected SEM images of the fatigue fracture surface of

SWNT / epoxy specimens are shown in Figs. 3–5. No

SWNT-bridged transverse matrix cracks were observed on

the specimen surface, which can be attributed to the fact

that the SWNT ropes were all fully embedded in the

matrix material. SWNT-matrix splitting was not observed,

Fig. 2. S–N diagrams. Filled circles are data obtained from this

study. Quasi-static tensile data (filled square with white cross) are

adapted from Ref. [7]; the error bar represents the standard

deviation. The gray rectangular region covers most S–N data for

unidirectional carbon fiber reinforced epoxy composites [11].

Fig. 3. Fatigue fracture surface of a SWNT / epoxy sample. The

lower left corner is a region of the matrix containing no SWNT,

showing a featureless, flat fracture surface, while the failure

modes of the composite portion include SWNT pullout, matrix

cracks bridged by SWNT. Scale bar 10 mm.

as compared to fatigue damage of carbon fiber composites

where fiber-matrix splitting is a common damage mode.

Macroscopically, the SWNT / epoxy composite exhibited

a brittle-type fatigue failure with flat fracture surfaces (Fig.

1), similar to the fracture surface of unidirectional carbon /

epoxy composites. In the lower left-hand corner of Fig. 3

where the epoxy matrix contains no CNT reinforcement, a

flat, featureless fracture surface is seen. However, local

failure modes around the SWNT ropes showed ductile-like

failure with plastic deformation of the epoxy and pullout of

SWNT ropes, as seen from the composite portion of Figs.

Fig. 4. Fatigue fracture surface of a SWNT / epoxy sample.

Bridging of a matrix crack by SWNT ropes is clearly seen. The

small contact angles between the epoxy matrix and the reinforcement suggest good wetting of the SWNT rope by the matrix.

Scale bar 2 mm.

Letters to the Editor / Carbon 41 (2003) 2159 – 2179

2179

although SWNT were loaded at much higher cyclic

stresses. The results show that SWNT ropes have good

potential as reinforcement in fatigue resistant, high fracture

toughness polymer composites.

Acknowledgements

HMC acknowledges financial support from NSFC (grant

No. 50025204).

References

Fig. 5. Fatigue fracture surface of a SWNT / epoxy sample.

Pullout of SWNT ropes from the epoxy matrix can be clearly

seen. The pullout length of the SWNT ropes could be as long as

40 mm. Scale bar 5 mm.

3 and 4. Bridging of matrix cracks by SWNT ropes is also

clear from Figs. 3 and 4.

One of the major issues concerning the use of CNT as

reinforcement in polymer composites is its adhesion to the

polymer matrix, because the interfacial characteristics are

critical in controlling the performance of the composite.

Studies have shown that CNT–polymer interfacial adhesion can be very strong [12,13]. From the morphology of

the fracture surface, shown in Figs. 4 and 5, wetting of

SWNT ropes by epoxy seems very good: thin sheets of

epoxy containing SWNT ropes showed small contact

angles between the two. Polymer debris is also seen

sticking onto the SWNT bundles, not detached from them,

unlike the rather clean carbon fiber pullouts seen in micro

fiber reinforced composites. From a molecular dynamics

simulation of CNT pullout from epoxy [12], the interfacial

shear stress between CNT and epoxy was estimated to be

138 MPa, about an order of magnitude higher than that

between carbon fiber and epoxy. Pullout of a SWNT

bundle can be seen on the fatigue fracture surface. The

pullout length of SWNT ropes from the epoxy matrix,

obtained from SEM images, is about 30 mm, and some can

even reach 40 mm or longer, as illustrated in Fig. 5. The

long pullout length of CNT ropes from the epoxy matrix

and the strong interfacial shear stress suggest that CNT

may be an ideal reinforcement for composites with high

fracture toughness.

In summary, we have studied the tension–tension

fatigue behavior of unidirectional, aligned SWNT rope

reinforced epoxy composite. The flat S–N diagram of

SWNT / epoxy is very similar to that of carbon / epoxy,

[1] Terrones M, Grobert N, Olivares J, Zhang JP, Terrones H,

Kordatos K et al. Controlled production of aligned-nanotube

bundles. Nature 1997;388:52–5.

[2] Cheng HM, Li F, Su G, Pan HY, He LL, Sun X et al.

Large-scale and low-cost synthesis of single-walled carbon

nanotubes by the catalytic pyrolysis of hydrocarbons. Appl

Phys Lett 1998;72:3282–4.

[3] Liu C, Cheng HM, Cong HT, Li F, Su G, Zhou BL et al.

Synthesis of macroscopically long ropes of well-aligned

single-walled carbon nanotubes. Adv Mater 2000;12:1190.

[4] Zhu HW, Xu CL, Wu DH, Wei BQ, Vajtai R, Ajayan PM.

Direct synthesis of long single-walled carbon nanotube

strands. Science 2002;296:884–6.

[5] Jiang K, Li Q, Fan S. Spinning continuous carbon nanotube

yarns. Nature 2002;419:801.

[6] Pan ZW, Xie SS, Lu L, Chang BH, Sun LF, Zhou WY et al.

Tensile tests of ropes of very long aligned multiwall carbon

nanotubes. Appl Phys Lett 1999;74(21):3152–4.

[7] Li F, Cheng HM, Bai S, Su G, Dresselhaus MS. Tensile

strength of single-walled carbon nanotubes directly measured

from their macroscopic ropes. Appl Phys Lett

2000;77:3161–3.

[8] Yu MF, Files BS, Arepalli S, Ruoff RS. Tensile loading of

ropes of single wall carbon nanotubes and their mechanical

properties. Phys Rev Lett 2000;84:5552–5.

[9] Yu MF, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS.

Strength and breaking mechanism of multiwalled carbon

nanotubes under tensile load. Science 2000;287:637–40.

[10] Falvo MR, Clary GJ, Taylor RM, Chi V, Brooks Jr. FP,

Washburn S et al. Bending and buckling of carbon nanotubes

under large strain. Nature 1997;389:582–4.

[11] Harris B, Reiter H, Adam T, Dickson RF, Fernando G.

Fatigue behavior of carbon fiber reinforced plastics. Composites 1990;21(1):232–43.

[12] Xu XJ, Thwe MM, Shearwood C, Liao K. Mechanical

properties and interfacial characteristics of carbon-nanotubereinforced

epoxy

thin

film.

Appl

Phys

Lett

2002;81(15):2833–5.

[13] Cooper CA, Cohen SR, Barber AH, Wagner HD. Detachment

of nanotubes from a polymer matrix. Appl Phys Lett

2002;81(20):3873–5.