A portfolio of power-trains for Europe: a fact

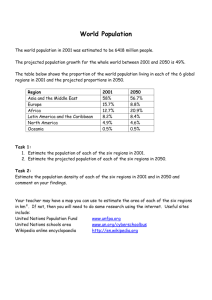

advertisement