SU 10541 - Transport Canada

advertisement

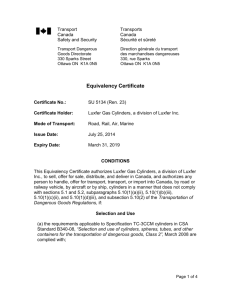

Transport Canada Safety and Security Transports Canada Sécurité et sûreté Transport Dangerous Goods Directorate 330 Sparks Street Ottawa ON K1A 0N5 Direction générale du transport des marchandises dangereuses 330, rue Sparks Ottawa ON K1A 0N5 Equivalency Certificate Certificate No.: SU 10541 Certificate Holder: Worthington Cylinder Corporation Mode of Transport: Road, Rail, Air, Marine Issue Date: March 9, 2012 Expiry Date: March 31, 2017 CONDITIONS This Equivalency Certificate authorizes: 1) Worthington Cylinder Corporation to design and manufacture means of containment used or intended to be used in importing, offering for transport, handling, or transporting dangerous goods in a manner that does not comply with section 5.1 of the Transportation of Dangerous Goods Act, 1992, 2) any person to sell, offer for sale, deliver, distribute, import or use a standardized means of containment, in a manner that does not comply with part 8 of the Transportation of Dangerous Goods Act, 1992, and 3) any person to handle, offer for transport, transport, or import, by road or railway vehicle, by cargo aircraft or by ship on a domestic voyage, dangerous goods included in Class 2, 3, 4, 5, 6.1, 8, or 9 in means of containment in a manner that does not comply with sections 5.1 and 5.2, subparagraphs 5.10(1)(a)(i) and 5.10(1)(b)(i), paragraph 5.10(1)(c), subparagraph 5.10(1)(d)(i), and subsections 5.10(2) and 5.12(1) of the Transportation of Dangerous Goods Regulations, in relation to the manufacture, selection, and use of means of containment only, if: 2012/__/___ Page 1 of 7 Issue Date: March 9, 2012 Equivalency Certificate SU 10541 CONDITIONS Selection and Use (a) subject to condition (b) of this certificate, the requirements applicable to Specification TC-4BWM cylinders in National Standard of Canada CAN/CSA B340-02, “Selection and Use of Cylinders, Spheres, Tubes, and Other Containers for the Transportation of Dangerous Goods, Class 2”, October 2002, as amended in January 2004 and February 2005, published by the Canadian Standards Association (CSA), are complied with; (b) for dangerous goods included in Class 3, 4, 5, 6.1, 8 or 9, the requirements specified in chapter 15 of Transport Canada Standard TP 14850E, “Small Containers for Transport of Dangerous Goods, Classes 3, 4, 5, 6.1, 8, and 9, a Transport Canada Standard”, 2nd Edition, October 2010, published by Transport Canada, except item a. of clause 15.1.2, are complied with; Manufacture and Requalification (c) the cylinders are manufactured at 863 State Route 307 East, Jefferson, Ohio, U.S.A. in accordance with the specific manufacturing process, the inspection, testing, and quality control procedures, and with drawing number W240154M filed by Worthington Cylinder Corporation, with the Director, Regulatory Affairs Branch, Transport Dangerous Goods Directorate, Transport Canada; (d) subject to conditions (e) to (m) of this certificate, the cylinders are in compliance with the requirements applicable to Specification TC-4BWM set out in National Standard of Canada CAN/CSA B339-02, “Cylinders, Spheres and Tubes for the Transportation of Dangerous Goods”, October 2002, as amended in November 2003 and February 2005, published by the Canadian Standards Association (CSA), cited in the rest of this certificate as CAN/CSA B339-02; (e) despite the general requirements of Clause 16.1 of CAN/CSA B339-02, the containers are welded stainless steel cylinders with a longitudinal electric-arcwelded seam; 2012/__/___ Page 2 of 7 Issue Date: March 9, 2012 Equivalency Certificate SU 10541 CONDITIONS (f) subject to conditions (g) and (h) of this certificate and despite the requirements of Clause 16.2.1 of CAN/CSA B339-02, the cylinders are made from solution annealed stainless steel of uniform and weldable quality conforming to the chemical composition of Type 304L or 316L, specified in ASTM Standard A 240 / A240M – 10b, “Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications”; (g) the steel has the following chemical composition: Element Ranges and limits, mass % Carbon (max) Manganese (max) Phosphorus (max) Sulphur (max) Silicon (max) Nickel Chromium Molybdenum Nitrogen (max) Iron Type 304L Type 316L 0.030 2.00 0.045 0.030 0.75 8.0 to 12.0 18.0 to 20.0 ---0.10 Balance 0.030 2.00 0.045 0.030 0.75 10.0 to 14.0 16.0 to 18.0 2.00-3.00 0.10 Balance (h) the tolerances for product analysis are as follows: Element Tolerance over maximum limit or under minimum limit, mass % Carbon Manganese Phosphorus Sulphur Silicon Nickel Chromium Molybdenum 0.005 0.04 0.010 0.005 0.05 0.15 0.20 0.10 2012/__/___ Page 3 of 7 Issue Date: March 9, 2012 Equivalency Certificate SU 10541 CONDITIONS (i) despite the requirements of Clause 16.6 of CAN/CSA B339-02, the cylinders are not heat treated; (j) despite the requirements of Clauses 16.8.1 and 16.8.2 of CAN/CSA B339-02, each cylinder is tested as follows: (i) hydrostatic proof testing at two times the service pressure for a minimum of 30 s and show no defects. Following proof pressure testing, all cylinders must be examined for leaks at a pressure not less than the service pressure. This examination may be conducted manually or by automation, or (ii) pneumatic proof testing at two times the service pressure for a minimum of 10 s and show no defects. The pneumatic proof tests must be performed in accordance with the proof pressure method specified in CGA C-1-2009, “Methods for Pressure Testing Compressed Gas Cylinders”, Tenth Edition, published by the Compressed Gas Association (CGA), cited in the rest of this certificate as CGA C-1-2009. Following proof pressure testing, all cylinders must be examined for leaks. This examination may be conducted manually or by automation. Leak testing must be conducted by submersion under water or any other equally sensitive method to detect a leak at a pressure not less than the cylinder’s marked service pressure. Other leak testing methods that are at least as sensitive as submersion under water at service pressure may be permitted with the agreement of the Director, Regulatory Affairs Branch, Transport Dangerous Goods Directorate, Transport Canada; Cylinders that leak or exhibit injurious defects must be rejected; (k) the representative cylinder that is hydrostatically tested in accordance with Clause 16.8.3 of CAN/CSA B339-02 is held at 4 times its service pressure for at least 60 s without leaking or bursting; (l) despite the requirements of Clause 16.9.2 of CAN/CSA B339-02, the elongation is at least 10% for Type B and C specimens; (m) despite the requirements of items (a) to (c) of Clause 4.17.2 of CAN/CSA B339-02, the Transport Canada mark, the specification designation, and the service pressure marked on each cylinder is: “TC - SU 10541 - 16”; 2012/__/___ Page 4 of 7 Issue Date: March 9, 2012 Equivalency Certificate SU 10541 CONDITIONS (n) each cylinder is requalified at least every five years in accordance with the proof pressure test method specified in CGA C-1-2009 including an internal and external visual inspection conducted in accordance with CGA C-6-2007,”Standards for Visual Inspection of Steel Compressed Gas Cylinders”, Tenth Edition, published by the Compressed Gas Association (CGA); (o) the documents referred to in Clause 4.18 of CAN/CSA B339-02 are retained by the manufacturer and by the Independent Inspector, as defined in that standard, for the service life of the cylinders; (p) the certificate holder reports any incident involving loss of contents or failure of the cylinders to the Director, Regulatory Affairs Branch, Transport Dangerous Goods Directorate, Transport Canada; and (q) prior to applying for renewal of this certificate, the certificate holder reports a summary of the cylinder manufacturing and performance experience to the Director, Regulatory Affairs Branch, Transport Dangerous Goods Directorate, Transport Canada. This Equivalency Certificate serves as the registration of Worthington Cylinder Corporation pursuant to Clause 25.2 of CAN/CSA B339-02, to manufacture cylinders of the designs specified herein. Worthington Cylinder Corporation’s registered mark, pursuant to CAN/CSA B339-02, is: M4543 Note: The issuance of this Equivalency Certificate in no way reduces the certificate holder’s responsibility to comply with any other requirements of the Transportation of Dangerous Goods Regulations not specifically addressed in this certificate. Signature of Issuing Authority Original signed by ___________________________ David Lamarche P. Eng., ing. Chief Permits and Approvals Division 2012/__/___ Page 5 of 7 Issue Date: March 9, 2012 Equivalency Certificate SU 10541 (The following is for information purposes only and is not part of the certificate.) Contact Person: Steven T. Gentry Regulatory Affairs Manager Worthington Cylinders Corporation 1085 Dearborn Drive Columbus, Ohio 43085 U.S.A. Telephone: Facsimile: E-mail: 614-438-3057 614-840-4830 stgentry@worthingtonindustries.com Explanatory Note This Equivalency Certificate authorizes the design and manufacture of welded steel cylinders based on the requirements for Specification TC-4BWM cylinders set out in CAN/CSA B339-02 using stainless steel as an alternative to carbon steel. The certificate holder has demonstrated that when manufactured under the conditions stipulated herein, the cylinder could be used with equivalent safety. This Equivalency Certificate also authorizes the use of the cylinders manufactured in accordance with the conditions of this certificate for the handling, offering for transport or transport of dangerous goods included in Class 2, 3, 4, 5, 6.1, 8 or 9. Legend for Certificate Number SH - Road, SR - Rail, SA - Air, SM - Marine SU - More than one Mode of Transport Ren. – Renewal 2012/__/___ Page 6 of 7 Issue Date: March 9, 2012 Equivalency Certificate SU 10541 NOTE Under Canadian Law, a foreign manufacturer of non-specification cylinders cannot be charged with an offence under the Transportation of Dangerous Goods Act, 1992 for failure to comply with the conditions of an Equivalency Certificate. However, certain remedies under the Act are available to Transport Canada in this eventuality. These include: 1. detention of dangerous goods and consequently the means of containment containing them (subsection 17(1)); 2. detention of the means of containment whether full or empty (subsection 17(1)); 3. directions not to import the means of containment or to return them to origin (subsection 17(3)); 4. inspectors’ directions (section 19); 5. directions to importers of the means of containment to issue notices of defective construction or recall (subsection 9(2)); and 6. revocation of the certificate, thereby making any use of the means of containment an offence (subsection 31(6)). If none of the foregoing are adequate, Protective Directions may be issued to prohibit or to control the use of the means of containment (section 32). 2012/__/___ Page 7 of 7