1. Introduction

advertisement

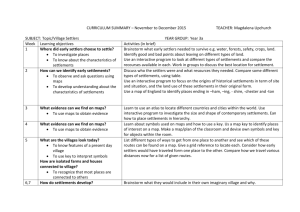

Konstruktionsuppgift 2 G7006B Sofi Isaksson Lea-Friederike Koss Henrik Silfvernagel 1. Introduction The assignment is to calculate the settlements in a road embankment using a computerprogramme called Embankco. The calculations will be performed with and without creep. Also three different ground improvement methods will be suggested and described. One of these suggestions will be recommended if the road will be connected to a bridge. 2. Given conditions The embankment is constructed on a soil profile which consists of a 5 m thick layer of sulphide clay which lies over a 5 m thick layer of sulphide silt. Below the silt is coarse grained moraine. Water table is placed at the ground surface. The silt and clay are slightly over consolidated by 20 kPa. The ground surface and the moraine are assumed to be free-draining. The road embankment will be 3 m high with a width of 6,5 m and inclination of slopes of 1:3. Given parameters for the silt and clay: In task a, b and c the creep is not included and therefore s and s is put =0. For task d the given values for silt and clay are used. The silt and clay are assumed to not be free-draining. 3. Calculations The pore pressure is calculates as: u w g z (1) w 1,0t / m 3 The pore pressure is linear and increasing at greater depth. Effektive stress: 0' g z u is the density for the different soils that was given in the assignment. (2) 4. Results a) What will the settlements be at the centre of the road: Figur 1. Settlement in tbe middle of the road. After 3650 days the settlements don’t increase any more. 3650 days is 10 years and the maximum settlement will be 0,39 m in the middle of the road. According to figure 1 most of the settlements will occur in the clay. b) What will the settlements be at the upper edge of the road (and what will thus the differential settlements be?)? Figur 2. Settlements at the edge of the road. The maximum settlement will occur after 10 years at the edge of the road. The settlement is 0,36 m. The differential settlement will be 0,03 m. As in task a) the clay settles the most. c) How long time will it take until 95% of the settlements is reached at the centre of the road? Figur 3. 95% of the settlements 95% of the settlements is 0,37 m in the middle of the road. 95% of the settlements are reached after 1620 days. That is about 4,4 years. d) What will the settlements be at the centre of the roads if compression caused by creep is included (compare with the results from a)? Figur 4. Settlements when creep is included The settlements over a 10 year period in the middle of the road are 0,795 m when creep is included. When compared to task a) where creep was not included task d) gives 0,405 m higher settlements after 10 years. e) Suggest and describe three suitable ground improvement methods that can be used to significantly reduce the settlements. 1. Pre loading and vertical drainage In fine grained soils that are water-saturated there can be a problem with settlements over a long period of time. Pre loading in combination with vertical drainage is a way to reduce the time of the settlements. This means that a large load is placed on the soil for a period of time, the load is left on the soil either until the settlements have stopped or until they have been reduced to an acceptable level. If the pre loading is combined with vertical drainage the time for the settlements can be reduced even more. The most used type of vertical drainage is pre-fabricated channel systems surrounded by a filter. The drainage system is easily installed by a machine. The distance between the drainages is decided by the properties of the soil and by the timeframe that the settlements should be completed. This method is relativity inexpensive, safe and well tried. It also increases the strength of the soil. 2. Lime-cement piles These piles can be used to reduce settlements and to increase the stability of the soil underneath, for example, rail or road embankments and deep shafts. This method is mainly used when having a clay soil, but can be used with other soils as well. The piles are created by rotation of a blending tool down to the needed depth. There the direction of the rotation changes and while pulling the tool up, the mixture is fed into the hole under strong rotation. The piles can be built down to 25m deep and the diameter is usually 0.6m or 0.8m wide. The piles can either be built alone or with an overlapping massive block, a plate or other similar constructions on top. The distance between the single piles is usually between 0.8m and 1.7m wide. Through the cooperation between the surrounding soil and the piles, a soil is obtained, which has a higher bearing capacity and a higher modulus than the unstrengthened clay. Usually has the bearing capacity of the soil increases 10 to 20 times within one month after strengthening. Different mixtures can be used according to the different soils and the different desired effects, but the most common mixture is lime and cement. 3. Stone piles Stone piles is made from crushed rock, stone, gravel or sand that is packed in vertical holes in the soil that needs strengthening. The method is mostly used for silt and clay rich soils. The piles is usually installed with 1,2 to 3 meters between them. The method is used to minimize settlements and to increase the stability. The piles can be installed in several different ways and the most common way is the dry method. With this method air pressure is used to create a hole at the same time as a pipe is immersed. When the pipe has reached desired depth it is filled with gravel and slowly pulled out. Packing is done by a vibrator rigged in the bottom of the pipe. The material for the piles can often be found near the site. f) What method of ground improvement would you recommend if the road is going to be connected to a bridge? Lime-cement piles can be recommended for this type of construction. This method strengthens the soil more than vertical drainage in clay rich soils. It is well tested and can also be combined with pre loading to reduce the time of the settlements. The Lime-cement piles is environmentally friendly and often cost-effective.