ENZYMES PART I

advertisement

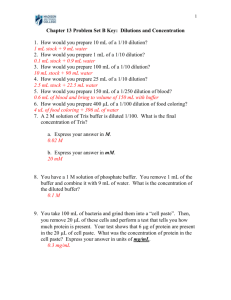

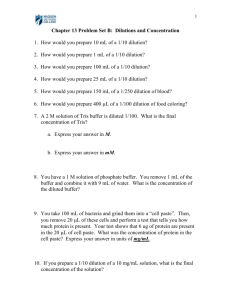

Biology 211 Laboratory Fall 2001 ENZYMES PART I: SWEET POTATO ACID PHOSPHATASE OBJECTIVES Learn a method of extracting enzymes from cells. Obtain experience in using pipets, making dilutions, using a spectrophotometer, normalizing data, and presenting data in graphical form. Understand how enzyme activity depends on enzyme concentration. Understand how temperature affects enzyme activity. Understand how pH affects enzyme activity. PREPARATION FOR LAB Read Campbell et.al. 5/e Chapter 6. Before you come to lab: Search the internet for information on phosphatase, either acid or alkaline. Summarize what you found in the introduction section of your lab report. INTRODUCTION Enzymes, most of which are proteins, have two interrelated roles. One is to act as catalysts and accelerate spontaneous biochemical reactions so they occur with sufficient rates at moderate temperatures. The other is to determine which spontaneous biochemical reactions will be accelerated out of many more possibilities present in the cell. Balance between all the reactions in metabolism is achieved in several ways, by fluctuations in substrate concentrations, by local differences in pH, by changes in enzyme concentration, and by changes in enzyme activation (modulation). Models of enzyme structure and function are well established. This investigation will test aspects of these models, specifically that temperature effects enzyme activity and stability. The null hypothesis is that temperature has no effect on activity or stability. The enzyme chosen is acid phosphatase, a member of the phosphatase group. Enzymes in this group catalyze hydrolysis of phosphoric acid esters of various alcohols, e.g. a hexose phosphate, to yield the alcohol and free inorganic phosphate. This may be a way of recycling phosphate in the cell, and the level of phosphate may be elevated under conditions of phosphate starvation (in algae for example). Acid phosphatases have pH optima below 7, whereas alkaline phosphatases are most active above pH 7. Commercial quantities of acid phosphatase are obtained from plant sources e.g. wheat germ, whereas similar quantities of alkaline phosphatase is obtained from animal intestine and bacteria. Many phosphatases are not fussy about the alcohol so artificial substrates have been developed which facilitate detection and quantitative measurement of enzyme 1 activity. Acid phosphatase will hydrolyze para-nitrophenylphosphate (colorless) to paranitrophenol (yellow at alkaline pH) and free phosphate as shown in Fig. 1. The yellow product can be quantified in a spectrophotometer by measuring absorbance at 410 nm. Figure 1. Enzymatic hydrolysis of para-nitrophenylphosphate yields a colored product. OVERVIEW OF ENZYME LAB Week I: Work in pairs 1. Prepare crude homogenate from sweet potato. To be done by instructor and one representative from each team. 2. While homogenate is being prepared, the other members of each group set up dilution and incubation tubes and prepare reaction mixtures. 3. Activity of acid phosphatase in the homogenate is determined. Week 2: Work in same groups from week 1 1. Instructor will retest enzyme to determine whether it has lost activity. 2. The effect of incubation temperature on the activity of acid phosphatase will be determined. 3. The optimum pH for enzyme activity will be determined. PROCEDURE: WEEK I Prepare Homogenate: Instructor plus one member from each group 1. Obtain a sweet potato and remove the outer layer ("skin") with a paring knife. 2. Weigh out approximately 100 grams and cut into small chunks. 3. Combine pieces and 100 ml of ice-cold sodium phosphate extraction buffer (0.1 M, pH 7.0) in a blender and homogenize at top speed for about 1 minute. There should be no large chunks remaining. Keep the homogenate on ice from now on. 4. Filter the homogenate by gravity through 4 layers of cheesecloth supported in a funnel, catching the cloudy liquid in a 1-liter flask packed in ice. This removes some cellular 2 debris, but the homogenate will still be cloudy (mostly starch grains and chromoplasts). Since it is important that the homogenate be transparent in a spectrophotometer, more of the particulate matter will have to be removed. 5. Clarify the homogenate by centrifugation in a microcentrifuge for 10 min at top speed and room temperature (this brief warming period will not hurt the enzyme). 6. Decant supernatant fluids and combine in a 50-ml screw-capped tube supported in ice. 7. Each group receives a tube with 1-2 ml of clarified homogenate. Acid phosphatase is quite stable and will not lose activity in a week if kept cold. However, as the homogenate ages it will turn brown. This is the result of oxidases acting on phenolic compounds present in the cells. It does not seem to harm acid phosphatase activity or interfere with determining its activity. Determine Enzyme Activity (a measure of enzyme concentration) The acid phosphatase activity in the homogenate must be known so you can use the appropriate amount of homogenate in subsequent work. Your goal is to find an amount of homogenate (i.e. enzyme) that will catalyze the production of enough nitrophenol in 15 minutes to give an absorbance of about 1.0 (in a 1 cm cuvette). 1. Make a serial dilution of homogenate using cold phosphate dilution buffer (0.05 M pH 7) as given by the plan in Table 1. Make dilutions in microcentrifuge tubes supported in ice. Table 1. Serial Dilutions of Sweet Potato Homogenate Dilution Tube 1:2 1:4 1:8 1:16 1:32 1:64 Homogenate (ml) 0.5 ml of clarified homogenate 0.5 ml of 1:2 dilution 0.5 ml of 1:4 dilution 0.5 ml of 1:8 dilution 0.5 ml of 1:16 dilution 0.5 ml of 1:32 dilution Phosphate Dilution Buffer (ml) 0.5 ml 0.5 ml 0.5 ml 0.5 ml 0.5 ml 0.5 ml Final Volume (ml) 1 ml 1 ml 1 ml 1 ml 1 ml 1 ml 2. Prepare a "Master Reaction Mix" of substrate and pH buffer in a 50-ml screw-capped tube supported in ice. To make the Master Reaction Mix, combine: 9 ml 3X sodium acetate incubation buffer (1 M, pH 5.8) (not phosphate dilution buffer), 18 ml 1.5X paranitrophenylphosphate in water (2.5 mM). This makes 27 ml of which you will need 24 ml for the next step. 3. Set up incubation of homogenate (enzyme) with Master Reaction Mix according to the plan in Table 2. Note that you are not preparing replicates at each dilution. Usually you should but now you are only interested in a rough measure of activity just to see if the enzyme is present and to practice the enzyme activity assay method. 3 Table 2. Directions for Assay of Phosphatase Activity in Clarified Homogenate of Sweet Potato Tube Label A Master Reaction Mix (ml) Preincubate 5 min @ 30 C 3 B 3 C 3 D 3 E 3 F 3 G 3 H 3 (minus homogenate control) (then add) then (then (read) Homogenate incubate add) Absorbance (ul) (min) NaOH at 410 nm Stopping solution (ml) 100 ul of 15 1 clarified homogenate 100 ul of 15 1 1:2 dilution 100 ul of 15 1 1:4 dilution 100 ul of 15 1 1:8 dilution 100 ul of 15 1 1:16 dilution 100 ul of 15 1 1:32 dilution 100 ul of 15 1 1:64 dilution 100 ul of 0.5 15 1 M phosphate buffer (calculate) Net absorbance (subtract tube H absorbance) 0 4. Dispense 3 ml of Master Reaction Mix into each of 7 small glass tubes. 5. Place tubes, supported in a plastic rack, in a 30oC water bath for 5 minutes. This is a "preincubation" to bring the temperature of the mixtures to 30oC. 6. Note time. While leaving tubes in the water bath add 0.1 ml of clarified homogenate to tube A, cover tube with Parafilm, and mix by inversion and place back into the rack in the water bath. Repeat using each dilution in sequence at 30 second intervals. 7. Allow each tube to incubate for exactly 15 minutes. 8. Again leaving tubes in water bath, add 1 ml of sodium hydroxide stop solution to each tube at 30 second intervals. Mix contents of each tube by inversion immediately after adding base. This stops enzyme activity (pH becomes too alkaline) and develops product color which is pH sensitive. CAUTION: Sodium hydroxide is a strong base (fully ionized) and will harm your skin and clothing. Neutralize spills with dilute acetic acid and rinse with tap water. 4 9. Set the wavelength of a spectrophotometer to 410 nm. Blank with plain water. Measure absorbance of the solutions after transferring the contents to Spec 20 tubes. Remember to periodically blank the spectrophotometer with water. 10. Record absorbance data in Table 2. 11. Calculate absorbance due to enzyme activity by subtracting the absorbance of the minus-homogenate control. 12. Construct a graph showing the relationship between enzyme concentration on the production of para-nitrophenol as measured by the increase in absorbance at 410 nm. 13. Which dilution gives an absorbance of about 1.0 in a 15 min. incubation at 30C? Pour any clarified homogenate you have left over into the community screw-capped tube provided. We will use this preparation again next week. Discard all dilutions. MATERIALS PROVIDED FOR PART I Sweet potatoes Paring knife Cheesecloth and scissors Large plastic funnel Kitchen blender Top-loading balance Foam ice buckets with ice 100-ml graduated cylinder Sodium phosphate extraction buffer, 0.1 M, pH 7.0 Sodium phosphate dilution buffer, 0.05 M, pH 7.0 3X Sodium acetate incubation buffer, 1.0 M, pH 5.8 (42 ml glacial acetic acid per liter, adjust pH with NaOH) 1.5X para-nitrophenylphosphate, 2.5 mM (0.658 g per liter water). Sodium hydroxide stop solution, 0.5 M (20 g NaOH per liter) Water baths set at 30oC Pipets, 1, 5 and 10-ml Pi pumps, green and blue P200 Pipetman and yellow tips Large glass test tubes (16x150 mm) Small glass test tubes (13x100 mm Cuvettes Spectrophotometers 12 ml polypropylene screw-capped tubes Deionized water 50-ml screw-capped tubes 12-ml screw-capped tubes 5 ENZYMES PART II PROCEDURE: WEEK II This week, you will carry out two more procedures with the sweet potato acid phosphatase. In protocol 1, you will determine the effect of temperature on enzyme activity. In protocol 2, you will examine the effect of varying pH on enzyme activity. Preliminary Work (performed by Instructor) 1. Repeat the measurement of acid phosphatase activity in homogenate dilutions (Table 2 in Part I) to determine if the stored crude homogenate has lost activity. 2. Determine a homogenate dilution that fits the following criteria: 0.1 ml of the homogenate dilution, incubated 15 min at 30oC, pH 5.8, and with 1 mM substrate (which is saturating), produces enough product (p-nitrophenol) to give an absorbance of about 1.0 at 410 nanometers. 3. Label this dilution of homogenate Stock Homogenate. Protocol 1: Effect of temperature on enzyme activity 1.Set up incubation tubes (13x100 mm glass tubes) in according to the plan in Table 3. Prepare a "Master Reaction Mix" of substrate and pH buffer in a 50-ml screw-capped tube supported in ice. To make the Master Reaction Mix, combine: 7 ml 3X sodium acetate incubation buffer (1 M, pH 5.8) (not phosphate dilution buffer), 14 ml 1.5X paranitrophenylphosphate in water (2.5 mM). This makes 21 ml of which you will need 18 ml for the next step. Tube Label Master Mix (ml) 10 20 (Room T) 30 50 70 100 3 3 Table 3. Setup for Protocol 1 Homogenate Incubation Incubation (ul) Temperature Time (min) (C) 100 10 15 100 20 (Room T) 15 3 3 3 3 100 100 100 100 30 50 70 100 Absorbance at 410 nm 15 15 15 15 Incubate according to the plan in Table 3. Remember that the incubation is carried out just as in Part I. The Master Mix is preincubated 5 min at the given temperature, enzyme is added, and after the 15 min. incubation 1.0 ml of sodium hydroxide (0.5 M) is added to stop the reaction. 2. All the tubes are cooled by immersion in water at room temperature. 3. Determine the absorbance at 410 nm against a water blank. 6 5. Plot the relationship between temperature (X-axis) and enzyme activity (measured by the increased absorbance at 410 nm, Y-axis). 6. What is the optimum temperature for measuring acid phosphatase activity? Protocol 2: Effect of pH on enzyme activity 1. Set up incubation tubes (13x100 mm glass tubes) according to the plan in Table 4. For this protocol, you will not prepare a master mix, because you need to vary the buffer for each tube. Table 4. Setup for Protocol 2 Tube Label Buffer (ml) Substrate (1.5X para-nitro phenylphosphate) (ml) (preincubate 5 min. @ 30C) Homogenate (100 ul) Incubation Time (min.) pH 3 pH 4 pH 5 pH 6 pH 7 pH 8 1 ml pH 3 1 ml pH 4 1 ml pH 5 1 ml pH 6 1 ml pH 7 1 ml pH 8 2 ml 2 ml 2 ml 2 ml 2 ml 2 ml 100 ul 100 ul 100 ul 100 ul 100 ul 100 ul 15 15 15 15 15 15 Absorbance at 410 nm 2. Preincubate the buffer and substrate for 5 min. at 30C. Then add homogenate and incubate 15 min. at 30C. 3. Stop reaction by adding 1 ml of sodium hydroxide (0.5 M) solution to each tube. Mix contents of each tube by inversion immediately after adding base. 4. Read the absorbance at 410 nm against a water blank. 5. Plot the relationship between pH (X-axis) and enzyme activity (measured by the increased absorbance at 410 nm, Y-axis). 6. What is the optimum pH for measuring the activity of acid phosphatase? MATERIALS PROVIDED FOR PART II Crude homogenate stored from last week. Enzyme activity determined before lab by Instructor. Foam ice buckets with ice Sodium phosphate dilution buffer, 0.05 M, pH 7.0 3X Sodium acetate incubation buffer, 1.0 M, pH 5.8 (42 ml glacial acetic acid per liter, adjust pH with NaOH) 1.5 X para-Nitrophenylphosphate, 2.5 mM (0.658 g per liter water). Sodium hydroxide stop solution, 0.5 M (20 g NaOH per liter) Water baths set at 20, 30 (2 or 3), 40, 50, 60, 70, and 80C Pipets, 1, 5 and 10-ml 7 Pi pumps, green and blue P1000 and P200 Pipetman and yellow (P200) and blue (P1000) tips Large glass test tubes (16x150 mm) Small glass test tubes (13x100 mm Cuvettes Spectrophotometers 50-ml polypropylene screw-capped tubes Deionized water CREDITS Part I of this investigation was developed by Robert C. Hodson, University of Delaware from Uehara K, Fujimoto S, and Taniguchi T, 1974. Studies on violet-colored acid phosphatase of sweet potato. I. Purification and some physical properties. Journal of Biochemistry 75:627-638. Copyright Robert C. Hodson, University of Delaware, 1999. ENZYME LAB REPORT You will receive a second handout outlining the procedure for constructing an outline, analyzing your results and writing a lab report for this lab. The enzyme report will count 40 points. 8