Contribution (Oral/Poster/Keynote) Clean and efficient solvothermal

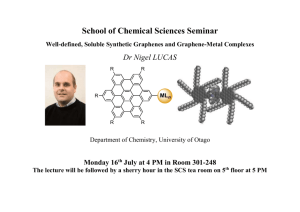

advertisement

Contribution (Oral/Poster/Keynote) Clean and efficient solvothermal deoxidation of alkyl-functionalized graphene sub-oxide dispersions with carbon monoxide in organic solvents Zhi-Li Chenb), Fong-Yu Kama), Jie Songa), Chen Hua), Loke-Yuen Wongb), Geok-Kieng Limb,c) and Lay-Lay Chuaa,b) a Department of Chemistry, National University of Singapore, Lower Kent Ridge Road, S117543, Singapore b Department of Physics, National University of Singapore, Lower Kent Ridge Road, S117542, Singapore c DSO National Laboratories, 20 Science Park Drive, Science Park I, S118230, Singapore a0030326@nus.edu.sg; chmcll@nus.edu.sg We report an efficient solvothermal process to achieve deep deoxidation of octadecylamine functionalized sub-stoichiometric graphene oxides (sub-GOx)[1] in organic solvents. An initial average carbon oxidation state of ca. 0.6 (i.e., 0.6 OH per basal-plane C) could be reduced to ca. 0.15, while retaining a critical density of the alkyl chains for solvent processability, ca. 0.02 chains per basal-plane C. The products can thus be characterized as single-sheet dispersions of alkyl-functionalized disordered “graphenes”. The oxidation state was characterized by X-ray photoelectron spectroscopy, Fourier-transform infrared spectroscopy and Raman spectroscopy. We found a strong solvent effect in the relative rates of alkylchain degrafting and/or chain scission versus deoxidation and regraphenization. The desired deoxidation and regraphenization is promoted at higher temperatures and by the use of aprotic amide solvents. Furthermore we found that carbon monoxide (CO) was a remarkably efficient fugitive deoxidizer. A key advantage of this solvothermal deoxidation process is the resultant dispersion of conductive graphenes can be directly used for printing, coating or formulating into nanocomposites, without further purification or heat treatment. Thin films of the deoxidized sub-GOx give dc conductivities of up to 40 S cm −1, which is the highest, reported to date for solvent-processable graphene derivatives. These films show temperature independent conductivity that suggests its conductivity is largely limited by tunneling between the alkyl-chain spacers. References [1] a) L.-L. Chua, S. Wang, P.-J. Chia, L. Chen, L.-H. Zhao, W. Chen, A. T.-S. Wee and P. K.-H. Ho, J. Chem. Phys. 2008, 129, 114702; b) S. Wang, P.-J. Chia, L.-L. Chua, L.-H. Zhao, R.-Q. Png, S. Sivaramakrishnan, M. Zhou, R. G.-S. Goh, R. H. Friend, A. T.-S. Wee and P. K.-H. Ho, Adv. Mater. 2008, 20, 3440-3446. Contribution (Oral/Poster/Keynote) Figures C1s N1s NMP 150ºC Photoemission intensity Photoemission intensity DMF 150ºC DMAc 150ºC TCB 150ºC DCB 150ºC solid-state 150ºC Ca Cb 282 284 Cg C -alkyl-sub-GOx 18 286 288 290 Binding energy (eV) 396 292 398 400 402 Binding energy (eV) 404 Figure 1. X-ray photoelectron spectroscopy of the deoxidized sub-GOx obtained in various solvents. Left: C1s corelevel spectra. Right: N1s core-level spectra. A pristine film of octadecylamine functionalized sub-GOx before and after heat treatment at 150°C is shown for comparison. (b) 0.7 0.6 0.6 Absorbance @532nm Absorbance @532nm 0.7 Heat treatment @150°C 0.2mg/mL in TCB 0.5 0.4 0.3 0.2 0.2 mg mL−1 sat’d CO in TCB 0.5 0.4 12h 0.3 0.2 start state 0.1 0 2 4 6 8 Reduction time (h) 10 6h 0.0 25 4h 2h TCB normal bp (a) 50 75 100 125 150 200 Heat-treatment temperature (°C) Figure 2a. Effect of CO on deoxidation of sub-GOx in 1,2,4-trichlorobenzene, measured by absorbance of the dispersion at 532-nm wavelength. (a) Time dependence with and without CO bubbled through the solvent at 1 bar. (b) Temperature−time−transformation plot for the deoxidation of sub-GOx in the presence of CO, showing temperature-dependent limiting behavior. Without CO, the absorbance after 12 h is ca. 0.4 at 200°C, 0.3 at 150°C, and 0.23 (unchanged) at room temperature. Cell path length, 2.0 mm. Dispersion concentration, 0.2 mg mL−1. Contribution (Oral/Poster/Keynote) (a) (b) (c) 10mm 7000 5000 3000 100mm (d) (e) 1000 10mm (f) 4cm Figure 3. Excellent processability of alkyl-functionalized sub-GOx and deoxidized graphene materials. (a) Uniform jetting through print head nozzles. Inset: Photograph of 0.3 mg mL−1 C18-alkylamine functionalized subGOx in chlorobenzene used for printing. (b) Printed arrays on hexamethyldisilazane-treated 300-nm-thick SiO2/ Si wafers. Inset: Zoom-in image of a single printed droplet film, showing uniform interference color. (c) MicroRaman of a printed droplet film, showing uniform G band intensity. (d) Printed arrays on source−drain electrode patterns. Inset: Zoom-in image of single droplet film on an electrode pattern. (e) Printed lines on a commercial plastic foil, with increasing graphene density from left to right. (f) Spray-coated film on an A4-size commercial plastic foil, shown here over a light background with “NUS ONDL” wordings to show film uniformity.