Water Quality

advertisement

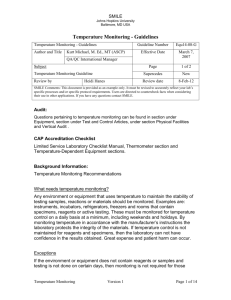

SMILE Johns Hopkins University Baltimore, MD USA Water Quality - Guidelines Water Quality Manual Guideline Number Fac30-02-G Effective Date 12/6/06 Page 1 of 2 Supersedes New Review Date 25 Jan 2012 Subject Water Quality Guidelines Review by Heidi Hanes SMILE Comments: This document is provided as an example only. It must be revised to accurately reflect your lab’s specific processes and/or specific protocol requirements. Users are directed to counter check facts when considering their use in other applications. If you have any questions contact SMILE. Audit: Questions pertaining to water quality can be found in Test and Control Articles Section. CAP Accreditation Checklist: Questions pertaining to water quality can be found in the Quality of Water and Glassware Washing section of the CAP Accreditation Laboratory General Checklist. Background Information: Reagents grades are defined by CLSI Guideline C3-A4 as follows: Clinical Laboratory Reagent Water (CLRW) Special Reagent Water (SRW) Instrument Feed Water Water Supplied by a method manufacturer for use as a diluent or reagent Commercially Bottled, purified water Autoclave and wash water applications CLRW should be pure enough to satisfy the requirements of most routine clinical laboratory testing. This type of water is usually used for the reconstitution of controls and reagents and with instruments using water for analysis. The requirement for microbial content, resistivity, Total Organic Content (TOC) and particulate matter are the same as Type I. SRW is used in testing that requires different purity other than CLRW. This could include different levels of CO2, trace metals, or organic impurities. Instrument Feed Water is intended for internal rinsing, dilution and water bath functions of automated instruments. The specification of this type of water must be confirmed with the manufacturer of a specific instrument. Water supplied by a method manufacturer for use as a diluent or reagent. This type of water must only be used as described by the product labeling for that system. This type of water can not be used for CLRW or SRW unless it meets those specific requirements. Commercially bottled, purified water must meet the required specifications for its intended use. The water should be packaged in a manner that protects it from environmental contamination or degradation during transportation and storage, and from the effects of the container itself. Note that any bottled water, no matter what type, must include a lot number and Fac3.0-02 Water Quality SOP Version#: 1.0 Page 1 of 13 SMILE Johns Hopkins University Baltimore, MD USA expiration date as well as the values for resistivity, microbial count, TOC and information on particulate control in addition to any other applicable parameters. Commercially bottled purified water may have met the specification for CLRW when bottled, but at use, the bottled water should be considered SRW with specifications set by the laboratory based on intended use. The laboratory must validate that the bottled water is fit for its intended purpose in clinical laboratory testing. If a bottle is opened and reused over a period of time, the laboratory must validate the water remaining in the bottle as fit for its purpose throughout the entire period of use. Each new lot of bottled water must be validated for acceptable performance in the test procedures for which it will be used. Validations must include chemical, microbial and particulate quality requirements of purified water. Once validated, the acceptability of purified water should be monitored to ensure it continues to be fit for its intended purpose Autoclave and wash water application water is intended for use as feed water for autoclaves and for automatic laboratory dishwashers with heat drying cycles. It is purified to low level of inorganic, organic and particulate impurities that otherwise could contaminate solutions and media in an autoclave or remain on washed laboratory ware. This was previously referred to as Type III water. There is no consensus to specification of this type of water. Previous definition of water is listed below: Maximum microbial content (CFU/mL) Minimum resistivity (megohm-cm)MΩ-cm Maximum silicate content (mg/L SiO2)*(TOC) Particulate matter Type I ≤10 ≥10 (in-line) ≤0.05 Type II ≤1000 ≥1.0 ≤0.1 n/a ≥0.1 ≤1.0 Type III ≤0.22 um filter n/a n/a CAP minimum monitoring requirement includes periodical testing of resistivity and microbiology cultures. The frequency should be enough and the results trended to detect changes and anticipate maintenance problems. Each laboratory must determine how often to measure the parameters of its purified water and purification system. Silicate content must be done initially to determine if high concentration are present in the source water. Other criteria such as pH, particulate matter, organic contamination is at the discretion of the laboratory. In the new water listing Type I and II are the same as CLRW depending on the content requirement and Type III is similar to autoclave and wash water applications. Resistivity is an indicator of ionic contamination. It is inversely related to ionic content. The higher this value the better the water quality. It is usually reported in megohm-centimeters (MΩcm). Resources 1. Clinical Laboratory Standards Institute (CLSI). Preparation and Testing of Reagent Water in the Clinical Laboratory: Proposed Guideline – Fourth Edition. CLSI Document C3-A4 Vol 26 No 2 (ISBN 1-56238-610-7). Clinical and Laboratory Standards Institute, Wayne, PA 2. College of American Pathologists (CAP) 2006. Commission on Laboratory Accreditation, Laboratory Accreditation Program; Laboratory General Checklist Revised 4/6/2006. Fac3.0-02 Water Quality SOP Version#: 1.0 Page 2 of 13 SMILE Johns Hopkins University Baltimore, MD USA Water Quality - Policy Water Quality Policy Approval Signature: Laboratory Director Policy Number Fac30-02-P Effective Date 12/6/06 Review Cycle 1 year Supersedes New Policy The laboratory has processes and procedures to effectively ensure that all water used in the laboratory meets the correct standards for laboratory testing. Purpose This policy provides direction for the processes and procedures to effectively ensure that all water used in the laboratory meets the correct standards. Responsibility The Laboratory Medical Director is responsible for The Laboratory Manager is responsible for The Lead Technologists are responsible for Clinical Laboratory Reagent Water (CLRW) The type of water used for most routine clinical laboratory testing will meet requirements for microbial content, resistivity, Total Organic Content and particulate matter. Instrument Feed Water Water used for internal rinsing, dilution and water bath functions of automated instruments will be according to specification by the manufacturer of the specific instruments. Water Supplied by a The type of water supplied by a method manufacturer for use as a diluent method manufacturer for or reagent will only be used as described by the product labeling for that use as a diluent or system. reagent Commercially Bottled, purified water Each new lot of commercially bottled purified water will be validated for acceptable performance to include chemical, microbial and particulate quality requirements of purified water. Autoclave and wash water applications Water used as feed water for autoclaves and automatic laboratory dishwashers with heat drying cycles is purified to low level of inorganic, organic and particulate impurities to prevent contamination of solutions and media in the autoclave and washed laboratory ware. Supporting Documents The following processes support this policy: Fac3.0-02 Water Quality SOP Water provided in-house Water provided by vendors Version#: 1.0 Page 3 of 13 SMILE Johns Hopkins University Baltimore, MD USA Water Quality – Process Water Quality Process Process Number Fac30-02-Pro Effective Date 12/6/06 Review Cycle 1 year Supersedes New Approval Signature: Laboratory Director Process for water provided in-house Start SOP is reviewed for type of water required Process of Vendor supplied water NO Water provided in-house ? YES Water is checked for quality Who’s Responsible What Happens Type of water is determined Lead Technologist Water is checked for quality QA Technologist Fac3.0-02 Water Quality SOP End Instructions Technical SOPs Water Quality SOP Technicians/Technologists Version#: 1.0 Page 4 of 13 SMILE Johns Hopkins University Baltimore, MD USA Process for water provided by Vendors Start Commercial Water is received in the laboratory Validate acceptability for laboratory use Laboratory information is documented No Used for diluent ? Label and Store Water Yes What Happens Who’s Responsible End Instructions Hospital receiving Dept Laboratory Stock Clerk Label information is documented Laboratory Stock Clerk Logging in water supplied by outside vendors. Specifications for laboratory use are checked QA Technologist Specifications for laboratory grade water in laboratory testing Water is labeled. Laboratory Stock clerk Labeling of Laboratory Reagents Water is stored. Laboratory Stock Clerk Laboratory Technicians/Technolo gists Storage of Laboratory Reagents Commercially supplied water is received in the laboratory Fac3.0-02 Water Quality SOP Version#: 1.0 Receiving Commercially Prepared Water in the Laboratory. Page 5 of 13 SMILE Johns Hopkins University Baltimore, MD USA Water Quality - SOP Author(s), Name & Title Heidi Hanes Document Number Effective Date International QA/QC Coordinator Fac30-02-SOP 14-Dec-06 SMILE Comments: This document is provided as an example only. It must be revised to accurately reflect your lab’s specific processes and/or specific protocol requirements. Users are directed to counter check facts when considering their use in other applications. If you have any questions contact SMILE. Name, Title Signature Date Name, Title Signature Date Approved By SOP Annual Review Version # [0.0] Revision Date [dd/mm/yy] Description (notes) Revision History Name (or location) # of copies Name (or location) # of copies Distributed Copies to Associated Forms: Fac3.0-02 Water Quality SOP Version#: 1.0 Page 6 of 13 SMILE Johns Hopkins University Baltimore, MD USA Name (print) Signature Date I acknowledge that I have read, understand and agree to follow this SOP. Fac3.0-02 Water Quality SOP Version#: 1.0 Page 7 of 13 SMILE Johns Hopkins University Baltimore, MD USA Purpose This procedure is to assure that all water used in the laboratory is of the correct standard for testing. The laboratory must define the type of water necessary for each of its procedures. This is based upon requirements for specific tests, procedures, instrumentations or laboratory. The laboratory should have an adequate supply of needed water. (This statement should be revised to include the type of water necessary. It should state the specifications needed for laboratory use.) Pre-analytic Procedure Refer to the following procedures: Patient Preparation Specimen Collection Safety Specimen Handling Specimen Storage Enter other basic procedures needed for your lab. The exceptions to these procedures are listed below: Enter exceptions to the procedures listed above that are needed for this procedure. Or NA Analytic Procedure Specimen Information: NA Reagents/Media: NA Supplies: Resistivity meter pH meter Clean container to hold water Equipment Calibration/Maintenance: I. Daily Checks: Step 1 Fac3.0-02 Water Quality SOP Action Check all indicator lights on the system. (Some systems have lights indicating whether the system is on or off, if the filters are within specific limits, etc.) Version#: 1.0 Page 8 of 13 SMILE Johns Hopkins University Baltimore, MD USA 2 3 II. If Then Lights are not correct Follow steps to correct. (Innumerate steps to take.) Check connections, pipes, hoses, etc. for leaks. If Then Leaks found Follow steps to correct. (Innumerate steps to take.) Check and record pressure level for gauges. (Some systems have pressure gauges that need to be within specific ranges.) If Then Outside acceptable ranges. Follow steps to correct. (Innumerate steps to take.) 4 Record all required information in the log. 5 If there are any issues, report all problems to the supervisor. Monthly Maintenance (Monthly maintenance requirements are defined by the manufacturer. Below are some examples, modify as needed.) A. Change filters. (Some systems contain filters that need periodical changing according to the manufacturer’s requirements.) Step III. Action 1 Describe location of filter. 2 List steps to perform. 3 List steps if problems occurs. Quarterly Maintenance (Maintenance requirements are defined by the manufacturer.) List the procedure for any required maintenance. IV. Preventative Maintenance. (Maintenance requirements are defined by the manufacturer.) List the procedures for preventative maintenance. Quality Control: NA Fac3.0-02 Water Quality SOP Version#: 1.0 Page 9 of 13 SMILE Johns Hopkins University Baltimore, MD USA Test Method Instructions: If your water system does not have a built –in meter to measure resistivity follow steps below. If it does have a built in meter follow steps in Alternate A. A. Follow the steps in the table below to check the resistivity. (The acceptable range depends on water type. The higher the number, the better the water quality.) Step Action 1 Turn the resistivity meter on and allow it to warm up for 5 minutes before use. 2 Obtain at least 50 ml of water to be tested in a clean container. 3 Place resistivity probe in the water up to the testing line. 4 Record the reading in the log and repeat 4 more times. 5 Do not discard water. Use the same aliquot for determining pH (if necessary). 6 If Then Outside acceptable ranges. Follow steps to correct. (Innumerate steps to take.) A. Alternative: Step Action 1 2 Record on log. If Then Outside acceptable ranges. Follow steps to correct. (Innumerate steps to take.) B. Follow the steps in the table below to check the pH, if necessary. (Checking of pH may be necessary if the pH will affect the testing, such as in staining procedures.) Fac3.0-02 Water Quality SOP Version#: 1.0 Page 10 of 13 SMILE Johns Hopkins University Baltimore, MD USA Step Action 1 Use the same 50 ml aliquot of water used to determine resistivity. If used Alternate A draw off 50 ml aliquot. 2 Turn on pH meter and allow it to warm up for 5 minutes before use. 3 Place pH probe in the water up to the testing line. 4 Record the reading in the log and repeat 4 more times. 5 Discard water. 6 If Then Outside acceptable ranges. Follow steps to correct. (Innumerate steps to take.) C. Follow the steps in the table below to check for microorganisms. Step Action 1 List sample collection procedures. 2 List sample submission instructions and contacts. 3 Record on log 4 5 If Then Outside acceptable ranges. Follow steps to correct. (Innumerate steps to take.) Retest water source. Take questionable water source out of use until retesting is completed. If it continues to be outside acceptable range, contact manufacturer. File microbiology reports. Calculations: NA Expected Values: The various water types used in the lab should have the following readings: Glassware cleaning o Resistivity: >1.5 Fac3.0-02 Water Quality SOP Version#: 1.0 Page 11 of 13 SMILE Johns Hopkins University Baltimore, MD USA o pH: 6.5 – 7.5 o Microbial content: NA Chemistry analyzer o Resistivity: >10.5 o pH: 6.7 – 7.3 o Microbial content: <7CFU/ml Interpretation of Results: NA Method Limitations: NA Post-analytic Procedure How are Results Prioritized: NA Result Entry into Lab Reporting System: NA Notification of Result to Appropriate Personnel: NA Archiving Results and Report Documents: NA Specimen Retention: NA References: List sources of information such as instrument manuals that may assist with the procedure. 1. Clinical Laboratory Standards Institute (CLSI). Preparation and Testing of Reagent Water in the Clinical Laboratory: Proposed Guideline – Fourth Edition. CLSI Document C30A4 Vol 26 No 2 (ISBN 1-56238-610-7). Clinical and Laboratory Standards Institute, Wayne, PA 2. Clinical Laboratory Standards Institute (CLSI). Clinical Laboratory Technical Procedure Manuals; Fourth Edition. CLSI Document GP2-A4 (ISBN 1-56238-458-9). Clinical and Laboratory Standards Institute, Wayne, PA Appendices: Attach supporting documents such as package inserts, forms, log sheets or charts. Fac3.0-02 Water Quality SOP Version#: 1.0 Page 12 of 13 SMILE Johns Hopkins University Baltimore, MD USA A. Water Quality Maintenance Log (Attached is a sample log sheet. Adjust form according to laboratory needs and standards.) Fac3.0-02 Water Quality SOP Version#: 1.0 Page 13 of 13