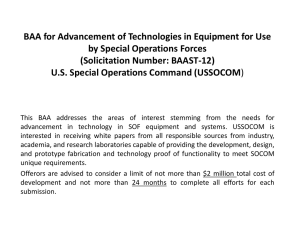

UNDERGROUND RAILWAY JELLY FILLED QUAD CABLES

advertisement

Page 1 of 11 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Revision 0 GOVERNMENT OF INDIA MINISTRY OF RAILWAYS TELECOM DIRECTORATE SCHEDULE OF TECHNICAL REQUIREMENT (STR) FOR COMPOSITE CABLE (OFC + QUAD) Research Designs and Standards Organisation Manak Nagar, Lucknow – 226011 Page 2 of 11 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Revision 0 COMPOSITE (OPTICAL AND QUAD) UNDER GROUND ARMOURED CABLE SPECIFICATION NO. RDSO/SPN/TC/50-2007 (REV.-4) I. SCOPE: The Schedule of Technical Requirement covers machinery & plants, testing equipments and quality assurance plan required for manufacturing of Composite Cable (OFC+QUAD) as per RDSO specification No. RDSO/SPN/50/2007 Revision 4.0 or latest. Vendor shall also comply norms issued by RDSO time to time in this connection and other relevant laws of the country. This STR shall be applicable to all vendors applying for registration. II. ESSENTIAL MACHINERY & PLANT REQUIRED FOR PRODUCTION: S. N. 1.0 Description Qty. Required. Insulation/extrusion line for production of high quality telecommunication core with solid polythene insulation provided with: - Conductor pre heater - Polythene Drying Unit with air blast - On line dia Controller preferably XY axis to ensure uniform thickness of insulation eccentricity in the core & dia over insulated conductor & on line spark Tester (0-15 KV AC) with numeric fault counter to monitor the number of spark over faults occurring during continuous extrusion of cores. - High Precision Temp. Controller Digital Display for Controlling each zone of extruder - Cooling trough of the length 01 Qty. Available Make & Sr. No. Year of Installation Remarks Page 3 of 11 2.0 3.0 4.0 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 of 25 meters (minimum) made up of stainless steel material or any other suitable material to avoid rusting. Rusting may affect the quality of polythene insulation resulting contamination of foreign particles over the surface of insulation - D.C. Drive take up, with proper tension arrangements Quadding machine to make star quad of polythene insulated copper conductor with built in high frequency Spark Tester, tension control Mechanism to maintain uniform tension through out bobbin length, Digital display of quad Lay length. Fully Computer controlled UV curable Fibre Colouring Line with automatic control of UV intensity, Static Charge removal. Machine to be installed and operated in Temperature controlled and dust free environment. Fully Computer controlled Tubing / Secondary coating line comprising of: - 12F Driven Tension Controlled Pay-offs - Jelly Filling System Fully synchronized with Line Speed - Compound De-Humidifier - Cooling Trough (25 Meters long) with hot water section, over length capstan and cold water section. - On-line Dual Axis Diameter Measuring Unit - Lump & Neck-down 01 01 01 Revision 0 Page 4 of 11 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Detector Exit Capstan/ caterpillar Dual Take-up with automatic Changeover. Fully Computer controlled SZ stranding line comprising of: - Strength member Payoff - Double wheel entry capstan - Strength Member tension monitoring and Control - 8 Nos. Loose tube/ Quad Driven pay off with tension Control system (2 nos. of loose tubes & 6 nos. of copper quads) - SZ stranding unit with Lay control and synchronisation with line speed - Dual counter rotating cross binder head - Torsion Blocker - Pressurised Jelly Filling arrangement - Helical Polyester tape Applicator - Dual Wheel Capstan / Caterpillar - Motorised Take up Inner Polyethylene sheathing Line with 65 mm or higher extruder having provision of: - Pay-off - Poly-Al Application system with Pay-offs, Accumulator, tension control, forming bench, glue applicator - Jelly Flooding Arrangement - Compound Pre-heater - Extruder & Crosshead with PID Temperature Controllers - Cooling trough of length of 25 meters (minimum) and made up of stainless steel - 5.0 6.0 01 01 Revision 0 Page 5 of 11 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 body. On line spark tester (0-15 KV AC) with numeric fault counter - Caterpillar with Pneumatic belt tension control - Motorised Take-up Aluminium Wire screening machine comprising of: - Pay-off - Min 30 Pay-offs for Al. wire - Taping Head - Motorised Take up. Steel tape armouring machine consisting of : - Pay-off - Double Tangential Taping Heads - Butt Welding Machine - Caterpillar with Pneumatic belt tension control - Motorised Take up Intermediate/Outer Sheathing Line with 80mm or higher extruder having provision of: - Pay-off - Compound Pre-heater - Extruder & Crosshead with PID Temperature Controllers - Cooling trough of length of 25 feet (minimum) and made up of stainless steel body. - On line spark tester (0-15 KV AC) with numeric fault counter - Caterpillar with Pneumatic belt tension - Motorised Take up Rewinding machine consisting of: - Pay-off - Sequential Meter Marking Unit - 7.0 8.0 9.0 10.0 01 01 01 01 Revision 0 Page 6 of 11 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Spark tester (0-15 KV AC) with numeric fault counter - Motorised Take up Work Shop consisting of following Machines - Lathe - Drilling - Grinding - Welding machines D.G. set (heavy duty) of 100 KVA minimum capacity. Revision 0 - 11.0 12.0 01 Each 01 III. ESSENTIAL TESTING REQUIRED FOR QUALITY ASSURANCE: S. N. 1 2 3 4 5 Description Qty. Required. Tensile testing machines with ranges as given below, (each with 3 sub ranges) to test copper wire, rods, steel tapes, laminates & Al wires etc.:i) Tensile testing machine 0 to 200 N ii) Tensile testing machine 0 to 500 N iii) Tensile testing machine 0 to 10000N Vernier calipers, least count 0.01mm with digital display. Micrometer – least count 0.001 mm with digital display Apparatus for determining melt flow index (extrusion plasto meter with digital temp indication, thermostatic control, accuracy 0.1°C. Analytical monopan balance to weigh to an accuracy of 0.1 mg. 01 01 01 01 01 Qty. Available Make & Sr. No. Year of Installation Remarks Page 7 of 11 6 7 8 9 10 11 12 13 14 15 17 18 19 20 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Apparatus for environmental stress cracking test to ASTM-1693 (Blanking die, Jig, specimen, holders, test tubes, corks, aluminium foil, test tube rack, bending clamps and transfer tools constant temperature, bath range 0 to 1000 C with thermostatic controlled heating system, inbuilt digital temperature. Meter, hour meter and sealing arrangement. Facilities for Dip Test for galvanization; Two nos. of Air circulating ovens with controls to maintain the setting within ±2°C. Temp range 0 to 200 °C with PID control digital display. Hour meter with sealing arrangement to monitor tests timings. 01 Environmental/ cold chamber (Minimum). Apparatus for stability test of filling compound (water bath range, for monitoring temperature, hour meter for recording test duration. Scaling arrangement may also be made for sealing. Flash Point Apparatus Drop Point Apparatus Cone penetrometer Ball point digital micrometers-least count 0.001mm Set up for water penetration test (separate room required for conducting tests). Double Kelvin’s bridge. 01 Test set up for resistance to compression test. Multi meter Analog/Digital Calibration Box for CR,IR and Capacitance etc. 01 01 02 01 01 01 01 01 01 01 01 01 Revision 0 Page 8 of 11 21 22 23 24 25 26 27 28 29 30 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Stamping die (for cutting dumbbell and other type of samples) Digital/Analog Thermometer (duly calibrated) Digital/Analog stop watch. Traveling Microscope/Profile Projector for checking eccentricity / circularity of core. Ageing oven range 0 to 200 deg. C with Digital temperature controller & pressure monitoring facility. Hour meter (with sealing arrangement) Cold Bend test apparatus (cold chamber as mentioned in cold bend test) Hardness Tester (Shore-D) Fully Automatic Computer Controlled Cable Testing Equipment for the following tests: - Conductor Resistance - Resistance Unbalance - Digital capacitance meter range 0.01µF to 1000 µF in three range ± 1 % of the reading. - Capacitance unbalance meter for measurement of capacitance pair to pair & pair to ground with adequate range & digital display. - Attenuation Measurement at 0.8 kHz, 5 kHz & 150 kHz. - ELFEXT and NEXT Measurement at 0.8 kHz, 5 kHz & 150 kHz. - Characteristic impedance test set up (0-20 K Ohm) in three ranges, test frequency 0.8 kHz& 5 KHz. AC High voltage tester 0-10 KV (10 mA capacity) Digital million meg ohm meter range 1 Megohm to 109 Megohm 01 01 01 01 01 01 01 01 01 Revision 0 Page 9 of 11 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 in six ranges, DC test voltage, 100 Volt to 500 Volt ± 2% with one minute timer. Set up for reduction factor test as per VDE spec. Standard to check calibration of Test equipment. DSC Instruments Carbon black content test set up for black Sheathing/Jacketing Compound Carbon black dispersion test set up for black Sheathing/Jacketing Compound Fibre Optic Analyser suitable for measuring spectral attenuation from 1200 nm to 1625 nm, MFD at 1310 & 1550 nm, and Fibre Cut-off Wavelength Fibre Geometry Analyser – Suitable for measuring diameter of core, clad and primary coating, non-circularity and cocentricity error Optical Time Domain Reflectometer (OTDR) – Suitable for measuring Attenuation at 1310, 1550 & 1625 nm wavelength Chromatic Dispersion Test Setup suitable for measuring CD from 1200 nm to 1625 nm, zero dispersion wavelength, zero dispersion slope Fiber Strain Measurement System Fusion Splicer, suitable for splicing SM Fibre Polarisation Mode Test Setup suitable for measuring PMD at 1310, 1550 nm wavelength Crush Test Setup Tensile Test Setup Torsion Test Setup Repeated Bend Test Setup Cable Bend Test Setup 01 01 01 01 01 01 01 02 01 01 01 01 01 01 01 01 01 Revision 0 Page 10 of 11 48 49 Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Abrasion Test Setup Walk-in Type Climatic Chamber (40°c to + 85°c) 01 01 Revision 0 Page 11 of 11 IV. Effective from 01.01.2007 STR for Composite RDSO/SPN/TC/50/2007 Cable (OFC+Quad) Rev. 4.0 Revision 0 PROCESS FLOW CHART - FOR COMPOSITE (OPTICAL & QUAD) UNDER GROUND ARMOURED CABLES ROD BREAK DOWN INTERMEDIATE WIRE DRAWING FIBRE COLOURING SECONDARY LOOSE TUBE INSULATION TUBE QUADDING S-Z STRANDING & JELLY FILLING SHEATHING SCREENING & PROTECTION INTERMEDIATE SHEATH ARMOURING FINAL SHEATH REWINDING & MARKING FINAL TESTING DESPATCH