Separation of zinc(II) from cobalt(II) solutions using supported liquid

advertisement

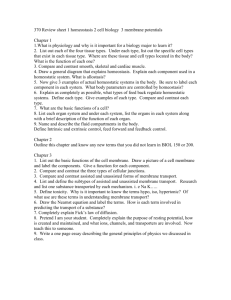

Separation of zinc(II) from cobalt(II) solutions using supported liquid membrane with DP-8R (di(2-ethylhexyl) phosphoric acid) as a carrier Francisco José Alguacil and Manuel Alonso Centro Nacional de Investigaciones Metalúrgicas (CSIC), Avda. Gregorio del Amo 8, Ciudad Universitaria, 28040 Madrid, Spain. E-mail: fjalgua@cenim.csic.es Abstract Selective transport of zinc(II) from cobalt(II) sulphate solutions using a supported liquid membrane impregnated with DP-8R extractant was studied. Several variables were investigated: stirring speed of the feed phase, stirring speed and composition of the receiving phase, diluent of the organic phase, metal concentration and pH of the feed phase, extractant concentration and the lifetime of the membrane. Conditions for the separation of both metals were established: i) aqueous feed: pH 3.0±0.02, [Co]/[Zn] molar concentration ratio near 22; ii) receiving phase: 0.5 M sulphuric acid; iii) membrane phase: DP-8R 10% v/v ib Exxsol D100. Keywords: DP-8R, membrane transport, separation, zinc(II), cobalt(II) 1.INTRODUCTION It is described in the literature [1] that the recovery of cobalt from various leach solutions needs a series of separation/purification steps in order to maintain a lean cobalt solution from which the metal can be finally obtained by an electrolytic procedure. Zinc appeared in the solution, and it is removed by sulphide precipitation but this also leads to significant cobalt losses. Solvent extraction had been considered as an alternative for the purification of the cobalt solution. Besides solvent extraction, supported liquid membrane technology offers the advantage that the extraction, stripping and regeneration operations are combined in a single stage[2,3]. The present works investigates the possibilities of flat-sheet supported liquid membrane technology for the separation of zinc(II) from cobalt(II) sulphate solutions using DP-8R in Exxsol D100 as mobile carrier phase. It should be pointed out that flat membrane geometry is very useful for first laboratory results, but for industrial purposes this geometry is not effective since the ratio of surface area to volume is too low; hollow fiber and spiral wound configurations are then used to provide high surface area to volume ratio. The literature has reported the use of flat-sheet supported liquid membrane configuration in the transport of zinc(II) [4-11], and also of cobalt(II) [12-23], and since relatively few studies concerning the separation of two or more competitive solutes are encountered in 2 the literature, more work is required in this field in order to approach more practical separation problems [24], whereas the transport of a metal through a supported liquid membrane containing an acidic extractant (such as DP-8R) as a mobile carrier is described, in the literature, by a number of steps [2, 25-27] In the present investigation, a flat membrane configuration has been implemented to obtain data on the transport and selective Zn-Co separation using DP-8R (organophosphoric acid) as a carrier. Various experimental conditions which influence the metal transport were studied, and conditions for the zinc-cobalt separation were also established. 2.EXPERIMENTAL 2.1.Materials DP-8R extractant, which is the active substance is di(2-ethylhexyl) phosphoric acid, was supplied by Daiachi (Japan) and was used as received. Its purity was checked to be >97% by potentiometric titration with sodium hydroxide in ethanol media [4]. Exxsol D100 (ExxonMobil Chem. Iberia, Spain) was employed as diluent for the organic phase; other diluents used were: Solvesso 100 and Escaid 100 (ExxonMobil Chem. Iberia), Iberfluid (CS, Spain), and Toluene (Fluka). Stock metal solutions were prepared by dissolving the required amount of ZnSO41H2O and CoSO47H2O (AR grade, Fluka) in distilled water, and metal concentrations were analysed by standard atomic absorption spectrometry (AAS) using a Perkin Elmer 1100B spectrophotometer. All other chemicals used in the present study were of AR grade. In all the experimental work, unless stated otherwise, a [Co(II)]/[Zn(II)] molar concentration ratio of 22 was maintained in the aqueous feed; this represents a typical leach solution [1]. 2.2.Procedure 2.2.1.Liquid-liquid extraction experiments Metal extraction experiments were carried out by mechanical shaking (800 min-1) in separatory funnels of the appropriate organic and aqueous solutions. Experiments were performed at 20C using and organic:aqueous (O:A) phase ratio of 1, whereas previous test indicated that equilibrium was reached within 10 min of contact. The metal distribution coefficients were calculated according to: D= [M ]org [M ]aq (1) 3 where [M]org and [M]aq represents the total metal analytical concentrations in the equilibrated organic and aqueous phases, respectively. Thus, the zinc/cobalt separation factor was calculated as: Zn/Co = DZn DCo (2) 2.2.2.Liquid membrane experiments The organic membrane phase was prepared by dissolving the corresponding volume of DP-8R in the organic diluent to obtain carrier solutions of different concentrations. The polymeric support was impregnated with the carrier solution by immersion for 24 h (previous experiments had shown that longer immersion times do not enhance metal transport, i.e. zinc permeation coefficients of 4.5x10-3 4.7x10-3 and 4.4x10-3 cm s-1 for 24h, 36h and 48h, respectively), then leaving them to drip for ten seconds before being placed in the flat-sheet supported liquid membrane cell. The support used was Millipore Durapore GVHP 4700, which characteristics are given elsewhere [28]. Batch liquid membrane measurements were carried out with a two-compartment permeation cell (Figure 1) which consisted of a feed phase (200 cm3) separated from a receiving phase chamber (200 cm3) by a liquid membrane having an effective membrane area of 11.3 cm2. The feed and receiving phases were stirred mechanically at 1500 and 1000 min-1, respectively (unless stated otherwise) at 20C to avoid concentration polarisation conditions at the membrane interfaces and in the bulk of the solutions. Agitation was performed in both compartments by using cylindrical Teflon impellers having a diameter of 2.4 cm. Membrane permeabilities were determined by monitoring metal concentrations by standard atomic absorption spectrometry (AAS) in the source phase as a function of time. After appropriate dilution of the samples with distilled water, the conditions (concentrations range, wavelength, etc.) for the metal analysis were those established for the spectrophotometer (Perkin Elmer 1100B). The metal concentration in the various phases was found to be reproducible within 98% accuracy. The permeation coefficient (P, within ±3% error) was calculated by equation (3) [25,26]: ln A Ct =- Pt V C0 (3) where Ct and C0 are concentrations of metal ions in the source phase at a given time and time zero, respectively, A is the effective membrane area, V is the volume of the feed phase solution and t the elapsed time. The zinc/cobalt separation factor were defined as the 4 ratio of permeabilities [29]. 3.RESULTS AND DISCUSSION 3.1.Liquid-liquid system The extraction/stripping mechanism for both metals can be represented by the general equilibrium: n M aq n (HR ) 2org M(R·HR ) n org nH ac (4) where (HR)2 refers to the dimmer form of the extractant and aq and org to the species in the aqueous and organic phases, respectively. It is evident that metal extraction occurs when the equilibrium is shifted to the right, whereas in excess of acid in the aqueous phase, metal stripping occurs and the equilibrium is shifted to the left. Previous liquid-liquid extraction experiments were performed in order to investigate the extraction of zinc and cobalt using DP-8R dissolved in Exxsol D100. Results obtained are shown in Table 1. The data indicates that extraction at pH near 3.0 gives the best zinc/cobalt separation factor value for the present experimental conditions; thus, this pH value was selected for the membrane permeation studies since transport at pH 3.0 will be a good compromise to obtain a significant zinc removal from the feed solution and keeping the cobalt co-transport as low as possible. 3.2.Liquid membrane system 3.2.1.Influence of the stirring speed in the feed phase Previous experiments were carried out to establish adequate hydrodynamic conditions. The permeability of the membrane was studied as a function of the stirring speed on the feed solution side. The agitation of the receiving phase was kept constant at 1000 min-1. Feed and receiving conditions being maintained as: 7.7x10-5 M Zn(II), 1.7x10-3 M Co(II) at pH 3.0±0.02 and 0.5 M H2SO4, respectively. The DP-8R concentration was 20 % v/v in Exxsol D100 immobilised on the Durapore microporous support. Constant zinc permeability (3.510-3 cm s-1) for stirring speeds higher than 1300 min-1 was obtained. Consequently, the thickness of the aqueous diffusion layer and the aqueous resistance to mass transfer were minimised and the diffusion contribution of the aqueous species to the mass transfer process is assumed to be constant [29,30]. 5 3.2.2.Influence of the stirring speed and composition of the receiving phase The influence of the stirring speed of the receiving phase on zinc transport was studied using the same aqueous and organic phases as described in Section 3.2.1., and using a stirring speed in the feed phase of 1500 min-1. Results obtained shown that the variation of the stirring speed in the 1000-1500 min-1 range does not influence zinc transport. Furthermore, experiments carried out using sulphuric acid solutions in the 0.15-0.5 M range as receiving phases also showed no influence on zinc transport under the present experimental conditions (aqueous feed and organic phases as described above, stirring speed of the feed and receiving phases 1500 and 1000 min-1, respectively). 3.2.3. Organic phase diluent influence The characteristics of the organic phase diluent, chosen as a water-resistant barrier in liquid membrane processes, influence the membrane performance and thus the metal transport [31-34]. In the present work, the use of various diluents for the DP-8R/zinccobalt sulphate system was investigated for permeation studies carried out with feed solutions of 7.7x10-5 M Zn(II), 1.7x10-3 M Co(II) at pH 3.0±0.02 and organic solutions of 10 % v/v DP-8R. The results obtained are shown in Figure 2. For the present system it can be seen that the change of the diluent influences zinc transport, having Exxsol D100 and Solvesso 100 as the diluents giving the best zinc permeabilities values. On the other hand, Table 2 shows the corresponding cobalt concentrations in the receiving phase after 3 hours. It seems that cobalt transport is enhanced using aromatic diluents. From the experimental data, overall best zinc/cobalt separation is, thus, reached using Exxsol D100 as diluent for the membrane phase. 3.2.4.Influence of zinc concentration The influence of the total zinc concentration in the transport of this metal by DP-8R was investigated. This study was carried out using feed phases which contained various zinc concentrations at constant cobalt concentration and a membrane phase of 10 % v/v DP-8R in Exxsol D100. The results are shown in Figure 3 in which the initial flux, J, is plotted against the total zinc concentration in the feed phase. The initial flux was calculated according with [35]: J = P [M ]total (5) where, P is the permeation coefficient and [M]total is the totall metal concentration in the feed phase. It was observed that at low zinc concentrations, the initial flux is a function of 6 the total metal concentration in the feed phase, but, at higher metal concentrations, J value is less dependent of the zinc concentration. This may be attributed to two reason: membrane saturation and lower effective membrane area and maximization due to saturation of the membrane pores with metal-carrier species and in addition, the build-up of a carrier layer on the membrane interface which assists the retention of the separating constituent on the entry side and leads to a nearly constant flux [36]. In the case of cobalt transport, the metal content in the receiving phase after 3 hours seems to increase slightly with the decrease of the cobalt/zinc molar concentrations ratio in the feed phase (Table 3); however, good zinc/cobalt separation is generally achieved using DP-8R as carrier. 3.2.5. Influence of the pH In order to asses the role of the pH of the feed phase solution during the permeation of zinc (and cobalt), pH variation studies in the range 2.0-5.0 were carried out using a feed solution of 7.7x10-5 M Zn(II) and 1.7x10-3 M Co(II), a receiving phase of 0.5 M sulphuric acid and a membrane phase of 20 % v/v DP-8R in Exxsol D100. As seen from Figure 4, the transport of zinc reaches a maximum at a pH value of 3.0. On the other hand, the transport of cobalt is increased as the pH value of the feed phase increases from 2.0 through 5.0 (Table 4), thus, decreasing the separation of both metals. Accordingly transport at pH 3.0±0.02 achieved the best compromise for the separation of both metals, this result is in accordance with previously obtained solvent extraction results. 3.2.6.Influence of extractant concentration The results concerning transport of zinc(II) from the feed phase containing 7.7x0-5 M Zn(II), 1.7x0-3 M Co(II) at pH 3.0±0.02 and the receiving phase 0.5M H2SO4 and varying concentration of the carrier in the range 5-30 % v/v dissolved in Exxsol D100 are shown in Table 5. As it can be expected, the permeability value increased with initial DP-8R concentration, this may be due to an increase in extractability into the liquid membrane. At higher carrier concentrations the decrease of permeability can be explained in terms of the increase in solution viscosity that increases membrane resistance. At near 10 % v/v DP-8R, a limiting permeability value is obtained, this being attributed to a permeation process controlled by the diffusion in the stagnant film of the aqueous feed phase [37,38], thus, Plim= 1/Δaq= 4.510-3 cm s-1 and assuming a value of the average aqueous diffusion coefficient of the zinc-containing species Daq= 10-5 cm2 s-1 [28,39], then the thickness of the aqueous boundary layer (daq) is calculated to be 2.2x10-3 cm. The transport of cobalt is increased with the increase in the carrier concentration of the membrane phase (cobalt concentrations in the receiving phase after 3 h were 2.3x10-5, 7 4.8x10-5, 1.2x10-4 and 2.2x10-4 M for 5, 10, 20 and 30 % v/v DP-8R, respectively). This can also account for the decrease in zinc permeability from a certain extractant concentration range. 3.2.7.Lifetime of the supported liquid membrane The lifetime of the membrane was evaluated by using the same support in several runs of 3 h duration. Table 6 summarizes the results obtained where percentage extraction of Zn(II), E(%), was defined as: E(%) = [Zn ]0 - [Zn ]t 100 [Zn ]0 (6) at an elapsed time of 3 h. After three consecutive experiments, the zinc extraction only suffers a slight variation, but the membrane efficiency fell after overnight storage, in the same experimental set-up, in contact with the air. Regeneration of the membrane is achieved by re-impregnating the support. 4.CONCLUSIONS On the basis of the flat-sheet supported liquid membrane studies performed, DP-8R shows a good efficiency for zinc transport and thus its separation from cobalt(II) sulphate solutions; however, the efficiency of the separation process can be improved by using more effective membrane unit, i.e. hollow fiber modules. Conditions for best zinc/cobalt separation are resummed as: i) aqueous feed: pH 3.0±0.02, [Co]/[Zn] molar concentration ratio near 22; ii) receiving phase: 0.5 M sulphuric acid; iii) organic membrane phase: DP8R 10 % v/v in Exxsol D100. The membrane lifetime was evaluated and stable zinc transport was observed after continuous use of the same membrane. Once the zinc transport was suppressed, by re-impregnation of the support, zinc transport ability was recovered. Under the present experimental conditions, zinc mass transfer coefficient in the aqueous phase was found to be 4.5x10-3 cm s-1. ACKNOWLEDGEMENTS To Mr. Bascones and Mr. López for technical assistance and to the CSIC (Spain) for support. REFERENCES [1] K.Kongolo, D.M.Mwema, P.M.Kyony and K.Mfumu, in P.Massacci (Ed.), Proceedings of the XXI International Mineral Processing Congress, Vol.A, Rome, July 8 2000, p.A6-14. [2] P.R.Danesi, Sep. Sci. Technol., 19 (1984) 857. [3] L.L.Tavlarides. J.H.Bae and C.K.Lee, Sep. Sci. Technol., 22 (1987) 581. [4] L.Fernandez, J.Aparicio, M.Muhammed, J. Membr. Sci., 27 (1986) 77. [5] T.-C.Huang and R.-S.Juang, J. Membr. Sci., 31 (1987) 209. [6] T.-C.Huang and R.-S.Juang, J. Chem. Technol. Biotechnol., 42 (1988) 3. [7] R.-S.Juang, Ind. Eng. Chem. Res., 32 (1993) 911. [8] K.Scott, Handbook of Industrial Membranes, Elsevier, Amsterdam, 1997. [9] J.Marchese, M.E.Campderros, A.Acosta and F.Valenzuela, in I.Gaballah, J.Hager and R.Solozabal (Eds.), Global Symposium on Recycling Waste Treatment and Clean Technology (REWAS´99), TMS and INASMET, Warrendale, 1999, p.2183. [10] M.Oleinikova, C.Gonzalez, M.Valiente and M.Muñoz, Polyhedron 18 (1999) 3353. [11] F.J.Alguacil and S.Martinez, J. Chem. Technol. Biotechnol., 76 (2001) 298. [12] M.A.Chaudry, M.T.Malik and A.Ali, Sep. Sci. Technol., 25 (1990) 1161. [13] T.Huang and T.Tsai, J. Chem. Eng. Japan, 24 (1991) 126. [14] A.A.Kalachev, L.M.Kardivarenko, N.A.Plate and V.V.Bagreev, J. Membr. Sci., 75 (1992) 1. [15] D.Y.Takigawa, Sep. Sci. Technol., 27 (1992) 325. [16] R.Mohapatra, S.B.Kanungo and P.V.R.B.Sarma, Sep. Sci. Technol., 27 (1992) 765. [17] J.Marchese, M.E.Campderros and A.Acosta, J. Chem. Technol. Biotechnol., 57 (1993) 37. [18] R.Juang, J. Membr. Sci., 85 (1993) 157. [19] R.Juang and J.Liang, Chem. Eng. Commun., 126 (1993) 13. [20] I.J.Youn, Y.Lee and W.H.Lee, J. Membr. Sci., 100 (1995) 69. [21] J.Marchese, M.Campderros and A.Acosta, J. Chem. Technol. Biotechnol., 64 (1995) 293. [22] I.J.Youn, Y.Lee, J.Jeong and W.H.Lee, J.Membr.Sci., 125 (1997) 231. [23] A.M.Sastre, A.Kumar, J.P.Shukla and R.K.Singh, Sep. and Purif. Methods, 27 (1998) 213. [24] J.de Gyves and E.Rodriguez de San Miguel, Ind. Eng. Chem. Res., 38 (1999) 2182. [25] C.Cianetti and P.R.Danesi, Solvent Extr. Ion Exch., 1 (1983) 565. [26] P.R.Danesi, E.P.Horwitz and P.G.Rickert, J. Phys. Chem., 87 (1983) 4708. [27] N.Parthasarathy, M.Pelletier and J.Buffle, Anal. Chim. Acta, 350 (1997) 183. [28] F.J.Alguacil, A.G.Coedo and M.T.Dorado, Hydrometallurgy 57 (2000) 51. [29] A.Sastre, A.Madi, J.L.Cortina and N.Miralles, J. Membr. Sci., 139 (1998) 57. [30] E.Castillo, M.Granados and J.L.Cortina, Anal. Chim. Acta, 464 (2002) 197. 9 [31] C.Hill, J.F.Dozol, H.Rouquette, S.Eymard and B.Tournois, J. Membr. Sci., 114 (1996) 73. [32] F.Z.El Aamrani, A.Kumar, L.Beyer, A.Florido and A.M.Sastre, J. Membr. Sci. 152 (1999) 263. [33] F.J.Alguacil and M.Alonso, Hydrometallurgy 58 (2000) 81. [34] C.Fontas, V.Salvado and M.Hidalgo, J. Membr. Sci., 223 (2003) 39. [35] F.J.Alguacil and M.Alonso, Environ. Sci. Technol., 37 (2003) 1043. [36] J.P.Shukla, J.V.Sonawane, A.Kumar and R.K.Singh, Ind. J. Chem. Technol., 3 (1996) 145. [37] P.R.Danesi, E.P.Horwitz, G.F.Vandergrift and R.Chiarizia, Sep. Sci. Technol., 16 (1981) 201. [38] F.Z.El Aamrani, A.Kumar and A.M.Sastre, New J. Chem., 23 (1999) 517. [39] M.Rovira and A.M.Sastre, J. Membr. Sci., 149 (1998) 241. 10 Table 1. Values of the zinc/cobalt separation factors (β) at various pH pHeq βZn/Co pHeq βZn/Co 0.80 1.52 1.67 2.01 2.19 2.55 4.7 7.0 9.6 38.3 53.3 154 2.94 3.03 3.29 3.50 4.00 2800 5700 5000 3700 2000 Organic phase: 20 % v/v DP-8R in Exssol D100. Aqueous phase: 7.7x10-3 M Zn(II) and 1.7x10-1 M Co(II). Equilibration time: 15 min. 11 Table 2. Cobalt contents in the receiving phase Diluent Density (kg m-3) Aromatics (%) Viscosity (cP) Co (M) Solvesso100 Toluene Escaid 100 Exxsol D100 Iberfluid 877 866 805 824 782 >99 >99 24 0.2 2 0.8 0.6 1.6 2.6 2.3 3.9x10-4 3.1x10-4 8.1x10-5 4.8x10-5 2.7x10-5 12 Table 3. Cobalt concentration in the receiving phase at various [Co]/[Zn] ratios after 3 hours a [Co]/[Zn]a Co (M) 44.5 22.2 11.1 5.6 2.8 4.3x10-5 4.8x10-5 5.3x10-5 5.7x10-5 6.3x10-5 1.9 1.4 1.1 7.1x10-5 7.9x10-5 8.9x10-5 The various ratios were established by variations of zinc concentrations at constant cobalt concentration (see Figure 3). Other experimental conditions as in Figure 3. 13 Table 4. Cobalt contents in the receiving phase at various pH of the feed phase after 3 hours pH Co (M) 2.0 3.0 4.0 5.0 5.1x10-6 1.2x10-4 4.1x10-4 4.2x10-4 14 Table 5. Zinc permeation at various DP-8R concentrations [DP-8R] (% v/v) PZnx103 (cm s-1) 5 10 20 30 2.8 4.5 3.5 2.8 15 Table 6. Lifetime of the membrane Run Membrane usagea (h) % EZn 1 2 3 4 5 0 3 6 9 Re-impregantion 93.2 92.6 92.7 56.2 93.0 Feed phase: 7.7x10-5 M Zn(II), 1.7x10-3 M Co(II) at pH 3.0±0.02. Membrane phase: 10 % v/v DP-8R in Exxsol D100. Receiving phase: 0.5 M H2SO4. a Before the run. 16 Figure 1. Permeation cell. F: feed phase, M: membrane phase, R: receiving phase. I: impellers. Figure 2. Influence of the diluent of the membrane phase on zinc transport. Receiving phase: 0.5 M H2SO4. The chemical nature of the diluent is given in Table 2. Figure 3. The influence of total concentration of Zn(II) on initial permeability flux (J). Feed phase: Zn(II) and 1.7x10-3 M Co(II) at pH 3.0±0.02. Receiving phase: 0.5 M H2SO4. Figure 4. Influence of initial pH on permeability of Zn(II) as a function of ln [Zn]t/[Zn]0.