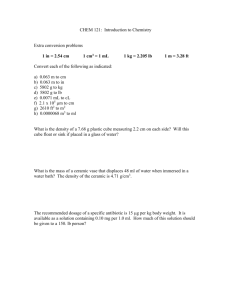

Supportinginfo

advertisement

Advanced piezoresistance of extended metal/insulator core shell nanoparticle assemblies Evagelos K. Athanassiou 1, Frank Krumeich2, R. N. Grass 1 and Wendelin J. Stark *1 Supporting Information 1 Institute for Chemical and Bioengineering, ETH Zürich, Zurich, CH-8093 Switzerland 2 Laboratory of Inorganic Chemistry, ETH Zürich, Zurich, CH-8093, Switzerland Submitted to Physical Review Letters * Correspondence should be addressed to Wendelin J. Stark Email: wendelin.stark@chem.ethz.ch; Fax: +41 44 633 10 83 1 Reducing flame synthesis. Flame spray pyrolysis proceeds by the combustion of a suitable combustable metal containing organic precursor. The precursor is dispersed by an oxygen jet forming a spray, which is subsequently ignited by a premixed flame. In a conventional spray reactor, the precursor combusts to H2O, CO2 and metal oxide nanoparticles. In order to prepare metallic nanoparticles, the flame may be operated in a nitrogen filled glove box under oxygen limitation ([Figure S1], reducing flame synthesis). In order to ensure stable combustion conditions, the flame was encased in a double walled tube. Under oxygen limitation the combustion reaction yielded CO and H2 instead of CO2 and H2O and the metal oxide nanoparticles can be reduced depending on their reduction potential. Experimental set-up for the production of NiMo/Ceramic. A flame spray nozzle was placed in a glovebox [Figure S1] and fed with nitrogen (PanGas, 99.999%). The atmosphere was continuously recycled by a vacuum pump (Busch, Seco SV1040CV) at about 20 m3 h-1 and the resulting combustion gases H2O and CO2 were removed by two adsorption columns (zeolite 4A and 13X), resulting in oxygen levels of below 100 ppm during combustion. For the synthesis of the NiMo/Ceramic nanocomposite (Ni/Mo = 7/3; CeZrO4: 10 vol%, Table S1) an air and humidity stable liquid metal precursor was prepared from corresponding amounts of nickel 2ethylhexanoate (6 wt % Ni), molybdenum 2-ethylhexanoate in mineral spirits (STREM Chemicals, 15 wt % Mo), zirconium 2-ethylhexanoate (13 wt % Zr) and cerium octoate (Shephard, 12.2 wt% Ce). Prior to processing the metal precursors were diluted 2:1 (w/w) with tetrahydrofurane (Fluka, tech.) and then filtered (Satorius, fluted type 288). The 2 liquid metal precursor was delivered to the spray nozzle [1] by a micro annular gear pump (6ml min-1, HNP Mikrosysteme, mzr-2900) and ignited by a premixed pilot flame (CH4 1.2 L min-1; O2 2.2 L min-1, PanGas tech.) surrounding the liquid spray. In order to allow a stable combustion the flame was encased in a porous metal tube. The produced nanocomposite was separated from the off-gas using glass fiber filters (Schleicher&Schuell, GF6, 25.7 cm diameter), mounted on a cylinder above the exit of the reducing flame synthesis reactor. During combustion the atmosphere in the glove box and the concentration of the produced gases (H2, H2O, CO, CO2) was monitored by a mass spectrometer (Balzers, GAM 400). 3 Fig. S1. Experimental apparatus for the preparation of NiMo/Ceramic. Table S1. Metal composition of the liquid metal precursor. Samplesα Ni Mo Ce Zr NiMo/Ceramic 64.75 27.75 3.55 2.30 α Compositions given in wt % Powder Analysis. NiMo/Ceramic was analyzed by X-ray diffraction (XRD; Stoe STADI-P2, G2 monochromator, Cu Ka1, PSD detector) for crystallinity and predominant phase composition, nitrogen adsorption (BET; Tristar Micromeritics Instruments) for specific surface area and mean primary particle size, thermal gravimetric analysis (Linseis TG STA-PT1600, 25-800, 10°C min-1) under air or H2 in argon (7 vol% H2), transmission electron microscopy (TEM; CM30 St-Philips, LaB6 cathode, operated at 300 kV, point resolution ~ 4 Å), energy dispersive X-ray spectroscopy (EDXS), element microanalysis (LECO CHN-900) and scanning electron microscopy (SEM; FEG 1530 Zeiss Gemini). 4 Crystallinity, particle size distribution, element distribution and material homogeneity Nickel molybdenum alloy nanoparticles (Ni/Mo = 7/3) coated with ceria/zirconia (Ce:Zr ratio = 1:1 at/at; 10 vol % overall) were produced in a single step at a production rate of about 20 g h-1 by simultaneously combusting a spray of the corresponding metal 2ethylhexanoates in a methane/oxygen flame [1] in a closed reactor system. The 20-50 nm as-prepared nanoparticles exhibited high air stability which is in sharp contrast to uncoated metal nanopowder’s often violent reaction with air (pyrophoricity). The absence of undesired carbon soot contamination was confirmed by quantitative carbon microanalysis (Table S2) and X-ray diffraction confirmed the formation of Ni/Mo alloy in the particle core [Fig. S2]. Energy dispersive X-ray spectroscopy followed by scanning transmission electron microscopy [Fig. S3] confirmed the presence of Ce and Zr. The primary particle size distribution [Fig. S4] was evaluated from transmission electron micrographs and confirmed that the ceramic shell did not affected the particle size distribution of the nickel/molybdenum nanoparticles [2]. The core/shell material exhibited a narrow number based particle size distribution. Assuming spherical particles, the results could be fitted to a log-normal distribution with a number based geometric mean particle diameter of 21.2 nm. This agrees well with a calculated particle diameter from specific surface area measurements through N2 adsorption at 70 K (dBET, NiMo: 16.4 nm, Table S2). The about half sized mean metal core crystallite diameter (dXRD: 9.3 nm, Table S2) determined from the peak width using the Scherrer formula confirmed formation of polycrystalline metal particles which stays in line with earlier studies on metal nanoparticles. Transmission electron micrographs displayed nearly spherical particles with a surface coating [Fig. 1(a)] which stays in agreement with the air stability 5 and the previous synthesis of carbon coated copper nanoparticles [Fig. 1(b)]. The preferential reduction of nickel and molybdenum to their metallic form and the simultaneous formation of cerium and zirconium oxide are in agreement with the large difference in the reduction potential of the composite constituents. Reducing flame synthesis results in the formation of metal nanoparticles, when they exhibit a positive or low negative reduction potential such as bismuth, copper [3], cobalt [4], iron, nickel (ERed (Ni2+ +2e- Ni) = -0.25 V) and molybdenum [2] (ERed (Mo3+ +3e- Mo) = -0.20V). On the other hand metals such as cerium (ERed (Ce4+ +4e- Ce) = -1.32 V), zirconium (ERed (Zr4+ +4e- Zr) = -1.45 V), aluminium and chromium have a strongly negative reduction potential and could not be reduced by the other combustion gases (hydrogen, carbon monoxide) in the present flame (O2 below 100 ppm). Fig. S2. X-ray diffraction pattern of NiMo/Ceramic confirmed the presence of the metal nickel/molybdenum nanoparticles. No additional peaks of other metallic or oxide species could be detected. 6 Fig. S3. Energy dispersive X-ray spectroscopy showed that reducing flame synthesis resulted in the preparation of metallic nickel/molybdenum, ceria/zirconia nanoparticles. The presence of carbon and copper on the EDX spectrum is on account of the sample holder (copper grid). Fig. S4. Particle size distribution evaluated from electron micrographs of as-prepared material (350 particles) and fitted to a log-normal distribution. NiMo/Ceramic had an average particle diameter of 21.2 nm. 7 TABLE S2. Particle size and carbon content of NiMo/Ceramic and C/Cu. Samples C (wt%)a ABET (m2g-1) dXRD (nm)b dBET, NiMo (nm)c dBET, ceramic layer (nm)c NiMo/Ceramic 0.44 38.1 9.3 16.4 1.8 a Carbon content as measured by microanalysis. formula. c b Mean crystallite size as detected by XRD using the Scherrer Particle size calculated from the specific surface area [1], error ± 10% (Assumed ρNi/Mo: 8.9 g cm-3, ρCeramic: 6.5 g cm-3). 8 Thermal analysis of NiMo/Ceramic Thermoanalysis allowed quantifying the temperature dependent oxidation (see EPAPS Document No.; [Fig. S5], top curve; under air) of the material and showed that the ceramic coating fails at about 200 °C (sharp increase in sample mass due to oxygen uptake), where Ni/Mo is oxidized to NiMoO4 as shown earlier for pure NiMo particles [14]. Running a thermal analysis under reducing conditions (see EPAPS Document No.; [Fig. S5], bottom curve; under H2/Argon (H2: 7 vol%) atmosphere) detects mass change (oxygen loss as water) from reducible oxide components (NiO + H2 = Ni + H2O; CeO2 + ½ H2 = ½ Ce2O3 + ½ H2O). The theoretical oxygen uptake of CeZrO4 coated Ni/Mo is 31.5 wt% which differs by 3.2 wt% from the here measured value. This difference arises from Ni ions dissolved in the CeZrO4 matrix and agrees with earlier studies on such ceramic catalysts by Srinivas et al. [15]. The here-observed formation of a ceramic shell around a metal is a rare phenomenon and further agrees with the above interpretations since this core/shell geometry is the result of a favorable wetting of the ceramic on the metal core. The wetting arises from an oxide rich interlayer between the Ni/Mo alloy core and the ceramic coating which can dissolve Ni and Mo ions and thus sticks to the nickel oxide coated Ni/Mo core. The strongest argument for this interpretation arises from the comparison of the temperature dependent oxidation profiles of pure Ni/Mo particles [14] (just the core) and the CeZrO4 coated Ni/Mo core/shell particles. Both start being oxidized at 190 °C with a non-significant difference in onset temperature in spite of the ceramic coating. Oxygen transfer through the CeZrO4 coating is not surprising since such ceramics have broad application in fuel cell membranes for their excellent oxygen 9 conductivity [16, 17]. The previous analysis demonstrates why the mixed ceramic CeZrO4 was suitable for the formation of a ceramic layer on metal nanoparticles. Fig. S5. Thermogravimetric analysis (TG) of NiMo/Ceramic under air resulted in a mass gain of totally 28.3 wt % revealing that the particles were covered by a thin ceramic layer. TG under reducing conditions afforded a mass loss of 5 wt% due to oxygen loss as water (MO + H2 ↔ M + H2O). 10 Reversibility of the piezoresistive effect Piezoresistance of NiMo/Ceramic was fully reversible. The deviation of the electrical resistance from cycle to cycle is smaller then the error of the resistivity measurement. Fig. S6. The piezoresistance of NiMo/Ceramic is fully reversible over the application of different pressures (100 and 250 MPa; 30 seconds dwell time). 11 Comparison of experimental data with theoretical model Fig. S7. Comparison of the theoretical model with the experimental data of all samples showed that the electron transport could be based on a tunneling mechanism. Assuming the Ro at p = 103 bar and a compressive modulus of Mceramic = 4.2 GPa, Mgraphene = 2.0 GPa and m = 0.5 me an effective barrier height of V(t)NiMo/Ceramic = 1.46 eV, V(t)2 C∞/Cu = 1.68 eV and V(t)4-6 C∞/Cu = 0.09 eV was calculated. 12 References: [1] [2] [3] [4] L. Madler, H. K. Kammler, R. Mueller, et al., J. Aerosol. Sci. 33, 369 (2002). E. K. Athanassiou, R. N. Grass, N. Osterwalder, et al., Chem. Mater. 19, 4847 (2007). E. K. Athanassiou, R. N. Grass, and W. J. Stark, Nanotechnology 17, 1668 (2006). R. N. Grass and W. J. Stark, J. Mater. Chem. 16, 1825 (2006). 13