24600 Apply quality assurance practices in the meat processing

advertisement

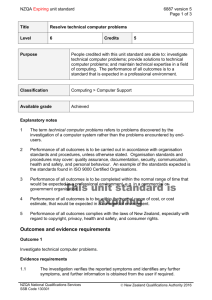

NZQA Expiring unit standard 24600 version 3 Page 1 of 4 Title Apply quality assurance practices in the meat processing industry Level 4 Credits 6 Purpose People credited with this unit standard are able to: describe the principles of a quality assurance system; describe production line quality assurance practices; describe the quality assurance requirements of processed meat products; and apply quality control practices on the production line. Classification Meat Processing > Meat Industry Generic Available grade Achieved Explanatory notes 1 Legislation relevant to this unit standard includes Animal Products Act 1999; Animal Products (Ancillary and Transitional Provisions) Act 1999; Animal Products Regulations 2000. 2 Resource documents include but are not limited to – Industry Standard 8 Quality Assurance (MISC), Industry Agreed Standard 8 Quality Assurance (VISC), available from the New Zealand Food Safety Authority (NZFSA) at http://www.nzfsa.govt.nz/animalproducts/meat/meatman/index.htm. 3 Definition Organisational requirements refer to instructions to staff on policy and procedures which are documented in memo and/or manual format and are available in the workplace. This unit standard is expiring Outcomes and evidence requirements Outcome 1 Describe the principles of a quality assurance system. Evidence requirements 1.1 Quality assurance is described in terms of objectives of a quality assurance system. 1.2 Quality assurance is described in terms of how the system reflects customer requirements. 1.3 Quality assurance is described in terms of how the system reflects company and legislative requirements. New Zealand Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Range 1.4 24600 version 3 Page 2 of 4 requirements may include but are not limited to – specifications, measuring and checking, recording, corrective action, training of employees, internal/external audit. Quality assurance is described in terms of staff responsibilities. Outcome 2 Describe production line quality assurance practices. Evidence requirements 2.1 Quality assurance practices performed on production lines are described in accordance with organisational requirements. Range may include but is not limited to – visual checks, sampling. 2.2 Equipment required for applying quality control practices is identified, and described in accordance with organisational requirements. 2.3 Company documentation applying to quality control practices is described in accordance with organisational requirements. 2.4 Describe company quality indicators for products and the procedures for nonconforming products. Range conditions may include but are not limited to – non-conforming product, contamination, temperature. Outcome 3 This unit standard is Evidence requirements expiring 3.1 Quality assurance is described in terms of meeting customer requirements, and Describe the quality assurance requirements of processed meat products. the relationship between them and the company product specifications. 3.2 The quality requirements for processed meat products are described. 3.3 Corrective actions are described in terms of processed product identified as outside of specification. Outcome 4 Apply quality control practices on the production line. Evidence requirements 4.1 Equipment used in quality control of production line is checked in accordance with organisational requirements. New Zealand Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard may include but is not limited to – set up, operational, free from contamination, calibration. Range 4.2 Quality control practices are applied to production line operation in accordance with organisational requirements. Range 4.3 24600 version 3 Page 3 of 4 optimises productivity and yield, minimises need for rework. Quality status of production line inputs and outputs is identified, and status is indicated on product. Range conforming, non-conforming. 4.4 Quality control results are accurate and complete, and any requirements for retesting are identified in accordance with organisational requirements. 4.5 Quality control factors affecting production line operation are identified, rectified and/or reported in accordance with organisational requirements. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 19 May 2008 31 December 2016 Review 2 27 January 2015 31 December 2016 Rollover 3 17 September 2015 31 December 2018 This unit standard is expiring Consent and Moderation Requirements (CMR) reference 0033 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing New Zealand Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 24600 version 3 Page 4 of 4 to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is expiring New Zealand Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016