Datum Flow Chain Analysis of the Bell Subassembly of the Alarm

advertisement

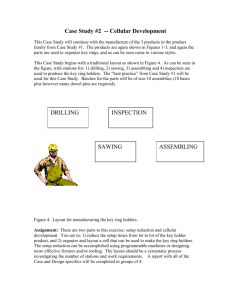

Antoine Guivarch Taesik Lee Carissa Tudryn guivarch@mit.edu tslee@mit.edu tudi@mit.edu 2.875 Mechanical Assembly and its Role in Product Development Dr. Daniel Whitney Project Assignment #2 Quartz Analog Alarm Clock DFC Analysis of the Bell Subassembly PICTURES October 2001 Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 BILL OF MATERIALS 5 subsystems, 32 parts FRONT CASING SUBSYSTEM FC 10 parts BELL SUBSYSTEM BSS 6 parts Front casing Clock paper Battery + contact Battery – contact LED Transparent clock cover Alarm hand Hour hand Minute hand Second hand Support Motor Ring holder Rings (2x, no difference) Bell Capacitor FC1 FC2 FC3 FC4 FC5 FC6 FC7 FC8 FC9 FC10 GEAR BOX GB 4 parts Gear box Gear box switch Printed Circuit Board Flex cable SPRING SLIDE SS 7 parts Base SS1 Slide SS2 Spring SS3 Electric contact holder SS4 Electric contact bumper SS5 Metal contacts SS6 (comes with SS5) & SS7 BSS1 BSS2 BSS3 BSS4 BSS5 BSS6 GB1 GB2 GB3 GB4 BACK CASING SUBSYSTEM BC 5 parts Back casing Battery cover Alarm button On / off switch Knob setter BC1 BC2 BC3 BC4 BC5 Not counted: wires screws Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 CAD Models of Parts Involved in DFC Bell Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 Support Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 Ring Holder Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 Ring Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 Motor Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 Bell Subassembly Exploded Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 Bell Subassembly Assembled Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 LIAISON DIAGRAM FC6 Transparent Front cover FC5 L.E.D. FC10 Second Hand FC8 Hour hand FC7 Alarm Hand FC3 Battery + contact FC9 Minute Hand FC1 Front Casing FC4 Battery contact GB4 Flex Cable FC2 Clock Paper GB1 Gear Box BSS1 Bell Support BSS6 Capacitor GB3 Printed Circuit Board BSS5 Bell BSS2 Motor GB2 Gear Box Switch BSS3 Ring Holder BSS4 Ring BSS4 Ring BC5 Knob SS4 Elec. Contact holder SS1 Spring Slide Base BC4 On/Off Switch SS2 Slide SS6 Metal Contact SS3 Spring SS7 Metal Contact BC3 Alarm Button SS5 Elec. Contact Bumper Guivarch, BC1 Back Casing Lee, Tudryn Mechanical Assembly and its role in Product Development BC2 Battery Cover October 2001 1. Liaison Diagram of the alarm clock: Our goal in this liaison diagram was to describe relationships between parts (not only physical, simply interdependencies). This explains that the liaison diagram involves links that the DFC would not include. For example, the clock paper (FC2) is related to the Gear Box (GB1) on the liaison diagram because it has a hole specially made for the Gear Box for the hands support to reach the front of the clock. But there is no mating or even physical relationship between those two parts. Other similar cases are the GB1 – BC5 – BC1 and BSS1 – BSS2 – BSS3 triangles. For the bell subsystem example, which is the purpose of this report, there is no mating relationship between the Ring Holder BSS3 and the Bell Support BSS1, but the motor shaft (BSS2) goes through the bell support to mate with the ring holder. We added those relationships because the liaison diagram could have been misleading. For example, one can decide on the basis of the liaison diagram to assemble the Bell subassembly first by cutting the BSS1-FC1 link. If we had not included a link between BSS1 and BSS3, one could have thought that it was possible to cut the link between BSS1 and BSS2 and make the BSS2 – BSS3 – BSS4 subassembly independently from BSS1, which is not possible. Datum Flow Chain Analysis of the Bell Subassembly of the Alarm Clock From this point, we did not include the capacitor in the analysis because of its special and accessory role in the subassembly. 2. The bell subassembly is significant in the operation of the alarm clock. Its function is to ring the bell. 3. The motor (BSS2) is driven to spin the ring holder (BSS3). The rings (BSS4) are attached to the ring holder (BSS3) and make contact to the bell. 4. The key characteristics are the clearances between the rings to the bell. The bell ringing is a dynamic process in which rings are pushed away from the ring holder center because of the centrifuge force induced by the rotation of the motor shaft. In order for the ring on the side of the bell to ring it, the clearance between the bell edge and the “outer wall” of the ring has to be negative (see below). After the ring hits the bell, the shock pushes the ring back and contact stops in order for the sound to last. The clearance has then to be positive. There are thus two key characteristics that relate to two different states of the system. This picture shows the negative clearance first because the ring hits the bell before it retracts. The distance from the pin to the center of the bell is labeled d. The ring holder rotates around the motor shaft in respect to the rotating arrow labeled w. Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001 5. The root for the DFC is the support BSS1 because it locates every other part in the subassembly. 6. Datum Flow Chain delivering the key characteristics (see next page) 7. Important Features and Key Characteristics for each Part. Part BSS1 BSS5 BSS2 BSS3 Features square peg x-y plane to prevent z-translation | , | Two clippers (effectors) motor hole Bell center hole Cylinder housing Two small holes on surface for support Shaft Two pins Center hole | | Two clippers (effectors) BSS4 Important KC Center of the motor support to the center of the peg Height: distance from flat bell support to motor support surface Center of motor support surface to end of bell wall Height: bottom of bell to top of bell Cylinder: height of shaft Shaft being perpendicular to motor Radius Center: location of shaft Distance between pin and center-hole Diameter of center-hole Height of clippers Height of pins Diameter of inner and outer of ring 8. There are no over-constraints or any risk of them. Each assembled part is either properly-constrained or purposely under-constrained for assembly or requirement of the mated parts. Assembled Parts BSS1 to BSS5 BSS1 to BSS2 BSS2 to BSS3 BSS3 to BSS4 Guivarch, Lee, Tudryn Constraint Properly constrained Properly constrained Purposely Under constrained Purposely Under constrained Mechanical Assembly and its role in Product Development October 2001 DFC BSS1: support Center hole (Large clearance) Flat surface 1 X, Y, X, Y Flat surface 2 Square peg Cylindrical Wall Pins Z Z, X, Y 5 X, Y, X, Y Top cylinder wall Z Top Surface Cylinder housing Bottom X, Y, X, Y Center Hole Pin hole BSS5: Bell BSS2: motor X, Y, X, Y (Z, Z by friction) KC1: clearance < 0 Edge KC2: clearance > 0 Center hole Post BSS3: Ring holder Floor X, Y range only Inner wall Bottom Surface Z, X, Y Clipper Z (max) Guivarch, Lee, Tudryn Outer wall Top Surface Mechanical Assembly and its role in Product Development BSS4: Ring October 2001 9. Suggestions for redesign of parts that improve constraint or KC delivery We did not find any special improvements for this subassembly, it looks properly designed for the Key Characteristic. Guivarch, Lee, Tudryn Mechanical Assembly and its role in Product Development October 2001