Electrochemical Oxidation of Sulfide Copper

advertisement

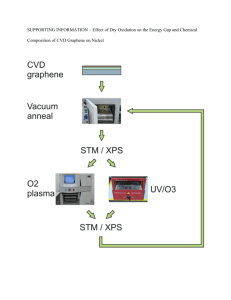

Electrochemical Oxidation of Sulfide Copper-Nickel Alloys: Thermodynamics, Passivating Films and Chemism Selivanov E.N., Nechvoglod O.V., Pankratov A. A. Establishment of the Russian Academy of Sciences Institute of Metallurgy of Ural Division RAS 101 Amundsen St., Ekaterinburg, 620016 Russia e-mail: pcmlab@mail.ru ABSTRACT Thermodynamically stable forms and compounds of copper, nickel, and sulfur ions in water solutions have been determined at preset values of pH and the sulfide electrode potential. Also, probable potentials at the electrodes have been found for the passage of the metals into solution and sulfur to the elemental form. The phase composition of the passivating films formed upon the electrochemical oxidation of copper and nickel sulfides and their alloys in a sulfate solution has been evaluated in experiments. The chemism of the electrochemical oxidation of complex sulfide-metal copper-nickel alloys has been explained. Introduction The electrochemical oxidation of copper and nickel sulfide alloys is accompanied by the formation of intermediate and final sparingly soluble products [14], which affect the dissolution kinetics. Depending on the parameters, the oxidation of copper and nickel sulfides and their alloys has different chemisms. To evaluate the character of passivation and propose a method for intensification of the oxidation of the sulfides, it is necessary to have information about the mechanism of electrochemical processes and data on the phase composition of intermediate and final products of reactions. With the aim of developing a technological scheme for processing of sulfide raw materials by an electrochemical method, it is interesting to study the behavior of the phase components of a sulfide alloy during oxidation under polarization conditions and establish regular features of the electrochemical oxidation of sulfide alloys at the electrode/electrolyte interface. Investigations on specific features of the electrochemical processes, which take place during the electrolysis of copper-nickel sulfide alloys, are significant for advancing the theoretical basis of metallurgical processes in production of nonferrous metals and developing technologies for processing of sulfide materials, which will exclude emission of sulfur dioxide. The aim of this study was to establish specific features of the formation of passivating films and determine the sequence of transformations during the electrochemical oxidation of sulfide-metal alloys. Experimental The regions of stability of the forms of nickel, copper, and sulfur in aqueous solutions were determined by the method of thermodynamic simulation using an HSC 5.1 program package. The thermodynamic simulation was performed on the following assumptions: 1-114 - the calculations were made taking into account the properties of pure stoichiometric substances; - the thermochemical calculations were made disregarding the reaction rate; - although a negative value of pH is devoid of the physical meaning, it still characterized a region with a high acidity of the solutions. The surface of sulfides was oxidized to experimentally evaluate the composition of the products after the electrochemical oxidation of the copper-nickel sulfide alloys. Synthesized nickel and copper sulfides, as well as copper-nickel and nickel converter mattes were taken as the initial samples. The composition of sulfide alloys is shown in Table 1. Table 1 - The chemical composition of samples Sample Содержание, % (Ni+Cu)/S Cu/Ni Ni Cu Fe Co S Nickel sulfide 72,1 - - - 27,5 2,62 - Copper sulfide 71,3 - - - 20,8 3,76 - Copper-nickel matte 22,5 46,7 2,5 0,6 21,6 3,20 2,1 Nickel matte 39,9 31,2 2,6 0,6 20,8 3,42 0,8 A layer of sparingly soluble products was formed in an electrolytic cell for 15 minutes at a current density of 1000 A/m2 in a 100 g/dm3 solution of a sulfuric acid. The surface area of the anode was 1 cm2. During the experiment, 0.025 Ah electricity passed through the test sample. Oxidation products of the anode material appeared on the electrode surface during the experiment. When a passivating layer was formed, the cell voltage changed during electrooxidation: 1.8 to 2.2 V for nickel sulfide Ni3S; 1.04 to 6.00 for copper sulfide; 1.8 to 2.4 V for the copper-nickel converter matte with Cu/Ni = 2/1; and 1.8 to 2.4 V for the nickel converter matte. The local composition of the passivating layer was evaluated on a JSM-5900LV X-ray spectral microanalyzer. Results Purbe diagrams were constructed for the Ni-S-H2O Cu-S-H2O, and S-H2O systems at pH = 2 to 14 and the range of potentials from 2.0 to 2.0 V. In the Ni-SH2O system (Fig. 1) the region of existence of metallic nickel covered the whole interval of the varying pH values. Therefore, metallic nickel could be obtained in both an acid and an alkaline medium. The precipitation potential of metallic nickel decreased to 1.0 V in an alkaline medium (pH = 14). An increase in the potential caused a consecutive alternation of the regions of existence of the sulfides Ni3S2→NiS→NiS2. At potentials of 0.0 to 0.5 and pH from 2 to 7 NiSO4 was formed. 1-115 Fig. 1. Phase diagram of the Ni-S-H2O system at 25°C. In an alkaline medium the NiS2→NiS transition was possible as the electrode potential increased. The further rise of the potential at the sulfide caused the formation of nickel oxide and hydrates (pH larger than 7). Thus, the Ni3S2→NiS→NiS2→NiSO4+S transitions depend on the electrode potential and pH of the solution. The formation of NiS2 and S in an alkaline medium is thermodynamically impossible. In the Cu-S-H2O system (Fig. 2) metallic copper was stable over the whole interval of pH at potentials lower than 0.2 V. As the potential increased, the formation of the copper sulfide Cu2S was probable in the whole interval of the acidity studied. At a higher potential an adjacent region was the region of existence of the sulfide CuS. In a medium with a considerable acidity the formation of elemental sulfur was possible over a narrow region of the potentials. Fig. 2. Phase diagram of the Cu-S-H2O system at 25°C. 1-116 The Cu2S→CuS→Cu2S→Cu→Cu2O transitions were probable in alkaline solutions, and their occurrence depended on the electrode potential and the pH value. The anodic dissolution of sulfides in an alkaline medium leads to the formation of oxides and hydrates. Considering that the potentials of the anodic dissolution of nickel and copper sulfides in an acid medium are much higher than in an alkaline medium, the sulfides can be more favorably dissolved in energy terms at small pH values. According to the diagram for S-H2O (Fig. 3), elemental sulfur was formed after saturation of the solution with H2S in an acid medium. For sulfur to pass to solution as SO42- or S2O82- requires rising the potential. In the region of positive potentials up to 2.0 V a stable dissolved form was sulfate-ions. At a potential higher than 2.0 V sulfur with the valence +6 oxidized to the state +7 and passed from a sulfate-ion to a thiosulfate-ion. This transformation is purely electrochemical and does not involve hydrogen protons or hydroxyl groups. ---- region of stability of water and its decomposition to hydrogen and oxygen region of stability of SO 24 and S2O 82 Fig. 3. Phase diagram of the S-H2O system at a temperature of 25°C. Thus, from the Purbe diagrams it was possible to determine thermodynamically stable forms and compounds of copper, nickel, and sulfur ions in aqueous solutions at preset values of pH and the electrode potential. They also allowed determining the probable potentials of sulfide electrodes for the passage of the metals to solution and sulfur to its elemental state. The regions occupied by elemental sulfur, sulfide (NiS), and nickel oxysulfate (NiONiSO4) were found on the electrode surface (Fig. 4 and Table 1). According to the literature data [1-8], Ni3S2 can be oxidized either in one stage with the liberation of elemental sulfur and nickel cations or in two stages with the formation of an intermediate compound (NiS): Ni3S2 - 6e¯ = 3Ni2+ + 2S0, (1) Ni3S2 - 2e¯ = 2NiS + Ni2+, (2) 2+ 0 2NiS - 4e¯ = 2Ni +2 S . (3) 1-117 A stepwise mechanism is most probable. The first stage includes the oxidation of nickel in the nonstoichiometric Ni3S2 sulfide, which is accompanied by demetallization and the formation of NiS and nickel cations. At the second stage, sulfide sulfur is oxidized to the elemental form, and the nickel cations pass to solution. As follows from the X-ray spectral microanalyses data (Fig. 5 and Table 1), the sulfide film formed on the surface of the sample predominantly consisted of elemental sulfur and NiS in agreement with the thermodynamic simulation data. Fig. 4. Electrode surface formed during electrochemical oxidation of the nickel sulfide Table 1. The X-ray spectral microanalyz data on the local composition of the phases on the surface of the nickel sulfide (according to Fig. 4) No. Phase Concentration, at % S Ni 1 NiSO4-S 23.8-25.8 10.9-11.0 2 S 69.2-70.4 6.2-7.9 3 NiS 45.6-46.4 44.4-47.6 The anodic oxidation of the copper sulfide is effected conditionally via a stepwise mechanism [1, 2]: Cu2S – e = CuS + Cu2+, (4) 2+ 0 CuS - 2 e = Cu + S . (5) The investigators [1, 2, 7-11] think that in conditions of the anodic polarization the copper sulfide (I) decomposes to copper and the copper sulfide (II): Cu2S=Cu+CuS. (6) According to the obtained data (Table 2 and Fig. 5), the copper sulfide (I) is oxidized as a series of intermediate sulfide compounds. 1-118 Table 2. The X-ray spectral microanalyses data on the local composition of the phases on the surface of the copper sulfide (according to Fig. 5) No. Phase Concentration, at % S Cu 1 Cu1.6S 37.6 61.5 2 Cu1.75S 36.8 61.9 3 Cu-CuS 11.7-30.0 69.9-88.1 4 Cu1.6S 38.9 60.4 5 34.2-49.1 33.5-44.2 nCuOmCuSO4 Fig. 5. Electrode surface formed during the electrochemical oxidation of the copper sulfide Cu1.96S The film was formed by an internal sublayer having a dense homogeneous structure and an external layer with dense homogeneous and loose inhomogeneous regions. Inclusions of black color were detected on the film surface. The products of electrooxidation of the synthesized copper sulfide were represented by nonstoichiometric Cu1.8S, Cu1.75S, and CuS and oxide-sulfate inclusions like mCuO·nCuSO4 formed through the interaction of copper cations with a sulfate electrolyte in the presence of oxygen liberated on the anode. In the case of polarization, the first stage includes oxidation of univalent copper, which is accompanied by the formation of copper cations and copper-deficient nonstoichiometric sulfides. Demetallization probably progresses in the following sequence: Cu2.0-1.96S→ Cu1.8S→ Cu1.75S→ Cu1.6S → Cu1.4S → CuS. Sulfide sulfur is oxidized at the second stage. The mechanism of decomposition of sulfide copper (I) by the reaction (6) explains the formation of the regions of metallic copper on the electrode surface. A film of the reaction products had a dense homogeneous structure formed by fine particles of secondary sulfides 4-6 m in size. Elemental sulfur was not detected. Probably, because of a short time of the film formation, the reaction was incomplete due to the formation of intermediate sulfides. 1-119 According to the X-ray spectral microanalyses data (Fig. 6 and Table 3), the passivating layer on the surface of the copper-nickel matte electrode consisted of nonstoichiometric copper sulfides Cu1.8S, Cu1.75S, Cu1.6S, Cu1.4S and Сu1.2S (oxidation products of univalent copper) and, also, nickel oxysulfates. Micrometer-sized particles of the copper sulfide formed dense and loose regions. The loose regions appeared due to a complete dissolution of the nickel sulfides. Dendrites of the copper sulfide Cu1.96S were included in the matrix of the nickel sulfide. The nickel sulfide NiS and elemental sulfur, which are products of the anodic oxidation of Ni3S2, were not detected. The reaction of the electrochemical dissolution of the nickel sulfide Ni3S2 probably was more complete than that of the copper sulfide Cu1.96S. As distinct from Cu1.2-1.75, the electrodissolution of NiS was more vigorous. Table 3. The X-ray spectral microanalyses data on the local composition of the phases on the surface of a copper-nickel converter matte (according to Fig. 6) No. Phase Concentration, at % S Fe Ni Cu 1 Cu1.75S 33.7 0.2 0.4 59.5 2 Cu1.6S 35.7 0.3 0.4 57.2 3 Cu1.4S 33.4 0.3 1.6 47.1 4 Cu1.2S 43.0 0.3 52.1 5 15.2-16.2 1.8 10.8-12.9 1.7-2.6 nNiOmNiSO4 6 Cu1.6S 28.1 0.8 1.2 44.2 7 CuSO4 17.1 0.6 2.6 35.2 Fig. 6. Electrode surface formed during the electrochemical oxidation of a coppernickel converter matte According to the X-ray spectral microanalyses data (Fig. 7 and Table 4), the surface of the electrochemically oxidized converter matte had homogeneous dense regions with phases in the form of grains and dendrites, as well as loose leached regions. A microanalysis showed that the dense homogeneous layer consisted of nickel sulfides approaching Ni3S2 and NiS as regards the composition. The 1-120 composition of the dendrites corresponded to nNiO·mNiSO4, while fine inclusions of the copper sulfides were similar to CuS. A metallic phase of a nickel-based solid solution including copper, iron, and cobalt was located near the dendrites. In accordance with the conditions of oxidation of the nickel converter matte, the quantity of electricity passed through the electrode was insufficient for a complete oxidation of the metal on the electrode surface (up to 30% of the surface area of the initial sample was covered by nickel crystals 0.1-0.4 mm in size). For this reason, the sulfides were not oxidized and elemental sulfur was not formed. Fig. 7. Electrode surface formed during the electrochemical oxidation of a nickel converter matte Table 4. The X-ray spectral microanalyses data on the local composition of the phases on the surface of a nickel converter matte (according to Fig. 6) No Phase Concentration, at % S Fe Co Ni Cu 1 nNiO·mNi(Cu)SO4 22.8-34.6 0.1 0.1 15.7-19.7 2.1-8.9 2 Ni(Cu)S 31.1 0.1 0.1 27.6 4.7 3 Ni3S2 31.3 0.2 0.1 42.3 1.0 4 Ni-Cu 3.5-7.1 0.9-1.4 0.9-1.1 71.7-83.8 2.9-5.0 5 Cu(Ni)S 21.3-41.4 0.1-0.8 0.1-0.2 8.2-18.4 12.9-27.9 6 CuS 49.7 0.1 0.0 2.9 43.3 Conclusions 1. According to the thermodynamic simulation data, the oxidation of copper and nickel sulfides in an acid medium is followed by the transition of sulfide sulfur to the elemental state and the passage of the metal cations to solution: Cu2.0-1.96S → Cu1.8S → Cu1.75S → Cu1.6S → Cu1.4S → CuS → CuSO4+S and Ni3S2 → NiS → NiS2 → NiSO4+S. 1-121 2. It was confirmed that the electrochemical oxidation of copper and nickel sulfides under polarization occurs in stages; secondary sulfides and sulfur appear on the electrode and form a passivating film. 3. The metallic phase and then the sulfide phase are oxidized during the oxidation of a metallized sulfide-metal Ni-Ni3S2 alloy. References 1. Chizhikov D.M., Gulyanitskaya Z.F., Pliginskaya L.V., Subbotina E.A. Electrometallurgy of Copper-Nickel Sulfide Alloys in Aqueous Solutions. Moscow, Nauka, 1977. 264 p. 2. Chizhikov D.M., Gulyanitskaya Z.F., Gurovich N.A., Kitler I.N. Hydrometallurgy of Sulfide Alloys and Converter Mattes. Moscow, IAN SSSR, 1962. 207 p. 3. Zalazinskii M.G., Khudyakov I.F. Oxidation of low nickel sulfide in sulfate solutions // Journal of Applied Chemistry. 1984. No. 9. P. 2118-2120. 4. Bryukvin V.A., Dyachenko V.T., Tsybin O.I., Leontyev V.G. On the mechanism of the behavior of nickel sulfides in sulfuric acid solutions // Nonferrous Metals. 2007. No. 4. P. 64-67. 5. Ghali E., Maruejouls A, Deroo D. Electrodissolution de la millérite en milieu chlorhydrique// Journal of Applied Electrochemistry. 1980. No. 10. P.709-719. 6. Price D.C., Davenport W.G.. Anodic reactions of Ni3S2, β-NiS and nickel matte // Journal of Applied Electrochemistry. 1982. No. 12. P. 281-290. 7. Selivanov E.N., Nechvoglod O.V., Udoeva L. Yu. Lobanov V.G., Mamyachenkov S. V. Electrochemical Oxidation of Copper-Nickel Metal-Sulfide Alloys // Metallurgy of Nonferrous Metals. № 6. 2009. pp. 577-581. 8. Selivanov E.N., Nechvoglod O.V., Mamyachenkov S. V., Sergeev V. A. Electrochemical Oxidation of Nickel Sulfide Metallic Alloys // Metallurgy of Nonferrous Metals. № 2. 2010. pp. 101-108. 9. Loshkarev A.G., Vozisov A.F. Anodic dissolution of copper sulfide // Journal of Applied Chemistry, XXVI, No. 1. 1953. P. 55-62. 10. Peters E. Direct leaching of sulfides: chemistry and application // Metallurgical Transactions B. V 7B. 1976. P. 505-517. 11. Sabauri G.N., Bryukvin V.A., Blokhina L.I., Levin A.M. Anodic polarization of Cu-Fe-S alloys // Metalls, No. 6. 1993. P. 49-53. The work was supported by the Ministry of Education and Science of Russia, project no. 02.740.11.0821. 1-122