Chemical Treatment of Irrigation Water for SDI

advertisement

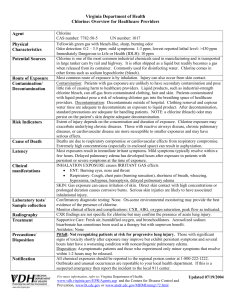

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 Chemical Treatment of Irrigation Water for SDI System Maintenance Dorota Z. Haman Department of Biological and Agricultural Engineering University of Florida P.O. Box 110570 Gainesville, FL 32611 dorota@agen.ufl.edu Gary A. Clark Department of Biological and Agricultural Engineering Kansas State University 147 Seaton Hall Manhattan, KS 66506 gac@ksu.edu Brian J. Boman Biological and Agricultural Engineering Department University of Florida Indian River Research and Education Center 2199 S. Rock Rd Fort Pierce, FL 34945 bjboman@mail.ifas.ufl.edu Michael D. Dukes Department of Agricultural and Biological Engineering University of Florida P.O. Box 110570 Gainesville, FL 32611 mddukes@ufl.edu Chemical treatment of irrigation water is often required to prevent emitter plugging 34 due to microbial growth and/or mineral precipitation. Microbial activity can generally be 35 controlled with chlorine, while acid injection can remove scale deposits, reduce or eliminate 36 mineral precipitation, and create an environment unsuitable for microbial growth. In 37 addition, insecticides may be necessary to control damage due to ants and other insects. 38 1 1 Chlorine Injection 2 3 Chlorine is used in many municipal and industrial water supply systems and home 4 swimming pools to prevent algae and other microorganisms from growing. Chlorine is also 5 used for cleaning and maintaining irrigation systems. Proper injection methods, amounts, 6 and concentrations of chemicals must be used to provide an effective water treatment 7 program without damaging the irrigation system or the irrigated crop. Because chlorine 8 can react with some metals and plastics, the manufacturer of irrigation system components 9 should be consulted to make sure that problems do not occur when chlorine is used in water 10 treatment programs. 11 12 Irrigation systems can become partially or completely clogged from biological 13 growths of bacteria, fungi, or algae, which are often present in surface water and some 14 ground water sources. These microorganisms use chemical elements in the water such as 15 nitrogen, phosphorus, sulfur, or iron as nutrient sources to grow and develop. Generally, 16 filtration alone cannot effectively remove these microorganisms. However, chlorination 17 can be used to minimize or eliminate their growth within the pipes and other components of 18 irrigation systems. 19 20 Chlorine is available in gas, liquid, and solid (granular or tablet) forms. However, 21 only the liquid form (liquid sodium hypochlorite) has an Environmental Protection Agency 22 (EPA) special local need (SLN) label for use as a pesticide in irrigation systems in some 2 1 parts of the United States. Local laws and regulations should be consulted prior to adoption 2 of any chemical treatment practice. 3 4 These three different chlorine forms react differently with the irrigation water, 5 depending on the other chemicals or elements in the water. In addition, chlorine may cause 6 changes in the pH of the water, or precipitate some other element which could result in 7 clogging of the microirrigation components. 8 9 Chlorine gas (Cl2) is commonly used in municipal water treatment systems and is a 10 dangerous source of chlorine. As chlorine gas reacts with water, hypochlorous acid 11 (HOCl), hydrogen (H+), and chloride (Cl-) are formed. This reaction lowers the pH of the 12 irrigation water. The level of the change in pH depends on how much chlorine gas is 13 injected and on the buffering capacity of the water. 14 15 Granular (powered or tablet) forms of chlorine are commonly used to chlorinate 16 swimming pools. Calcium hypochlorite found at local swimming pool supply stores is the 17 form that is typically used. Dissolving calcium hypochlorite in water will result in the 18 formation of hypochlorous acid (HOCl) and hydroxyl ions (OH-), a reaction that raises the 19 pH of the water. Calcium hypochlorite may also react with other elements in irrigation 20 water to form precipitates, which could clog microirrigation emitters and thus defeat the 21 purpose for chlorination. As a result, liquid chlorine (sodium hypochlorite) rather than 22 solid calcium hypochlorite is recommended for use in irrigation systems, especially when 23 the water source is high in other minerals. 3 1 2 Liquid sodium hypochlorite (laundry bleach) is most commonly used. Mixing 3 liquid sodium hypochlorite in water results in the formation of hypochlorous acid (HOCl) 4 and hydroxyl ions (OH-), a reaction that also raises the pH of the water. Unlike the calcium 5 added in the solid chlorine form, the sodium added in this liquid form does not contribute to 6 clogging problems. Neither the sodium nor the chlorine added to the water would be 7 detrimental to crops or soils at the low concentrations typically used to treat irrigation 8 systems. 9 10 Some problems can occur with water sources that have high iron levels. 11 Hypochlorous acid reacts with iron in solution and oxidizes ferrous iron to the ferric form. 12 The ferric iron then becomes the insoluble ferric hydroxide as a granular precipitate. 13 Chlorine should be injected before (upstream from) the filters so that these precipitates may 14 be trapped in the filters. Chlorine also reacts with hydrogen sulfide and forms elemental 15 sulfur. Because some of the chlorine reacts with the sulfide or ferrous ions, additional 16 chlorine must be provided for these reactions to occur in addition to the chlorine that is 17 needed for the control of microorganisms. 18 19 Most microorganisms are controlled when the free residual chlorine concentration is 20 1 ppm or greater at the most distant end of the irrigation system. However, higher 21 concentrations must be injected due to the inherent chlorine demand of the constituents 22 associated with different water sources. A chemical water test can be used to determine the 23 levels of hydrogen sulfide or ferrous iron present in solution. Based on this test the rate of 4 1 chlorine injection can be calculated. As a start, use 2 ppm of chlorine for each ppm of 2 hydrogen sulfide, plus 0.6 ppm of chlorine for each ppm of ferrous iron. Water from 3 surface sources such as lakes, ponds, or canals should be initially treated with 4 approximately 5 to 10 ppm of chlorine. Higher chlorine levels may be needed to treat water 5 with high amounts of microbial activity that as may occur during the warmer months of the 6 year. 7 8 9 Chlorine injection rates should be checked by testing the treated water at the most distant part of the irrigation system using a test kit designed to measure "free" residual 10 chlorine. Residual chlorine concentrations of 1 to 2 ppm at this location indicate that active 11 chlorine still exists after the water and system parts have been appropriately treated. 12 13 The amount of active chlorine can be tested using a color indicating test kit that 14 measures "free" residual chlorine. A test kit that only measures total chlorine should not be 15 used. While levels of total chlorine may appear to be adequate, the active "free" residual 16 form may not be adequate for a complete treatment of the water. Chlorine test kits/DPD 17 kits can be purchased from either swimming pool or irrigation supply companies. 18 19 After determining the desired chlorine concentration, the proper amount to be 20 injected must be determined. The amount of chlorine to apply to the irrigation system will 21 depend on the desired chlorine concentration in the irrigation water, the concentration or 22 strength of the liquid chlorine source, and the flow rate of water through the irrigation 23 system. 5 1 2 3 The rate of injection of any liquid chemical is directly proportional to the flow rate of water in the irrigation system and can be calculated from the following equation: 4 5 Qchemical = K (u*Qwater/ C) (1) 6 7 Where :Q chemical is the chemical injection rate (L/hr or gph), Qwater is the water flow rate in 8 the irrigation system (L/sor gpm), K is a conversion constant ( K= 3.60 x 10-3 for SI units 9 and K= 5.01 x 10-4 for English units), u is the desired concentration of chlorine in the 10 irrigation water (ppm), and C is the concentration of the component in liquid to be injected 11 (kg/L or lb/gal). 12 13 Liquid sodium hypochlorite is the most convenient and generally safest form of 14 chlorine available to inject into irrigation systems. Stock solutions can be purchased with 15 concentrations of 5.25, 10, or 15 percent available chlorine. Table 1 or Equations 2 – 4 16 may be used to determine the chlorine solution injection rate in gallons per hour (gph) of 17 liquid chlorine for different desired ppm injection levels and irrigation system flow rates. 18 Equations 2 - 4 are specific for liquid chlorine injection and the listed stock solution 19 chlorine concentrations. 20 21 For a 5.25% available chlorine stock solution: 22 6 1 Injection Rate5.25, gph = (Desired Concentration of Cl in Irrigation Water, ppm) 2 (Irrigation Flow Rate, gpm)/ 971 (2) 3 4 For a 10% available chlorine stock solution: 5 6 Injection Rate10, gph = (Desired Concentration of Cl in Irrigation Water, ppm) 7 (Irrigation Flow Rate, gpm)/ 1850 (3) 8 9 For a 15% available chlorine stock solution: 10 11 Injection Rate15, gph = (Desired Concentration of Cl in Irrigation Water, ppm) 12 (Irrigation Flow Rate, gpm)/2775 (4) 13 14 For example, an irrigation system has a flow rate of 500 gpm and the water is to be 15 treated to 8 ppm of available chlorine using a stock solution with 10% available chlorine. 16 Using Equation 3, the injection rate of the stock solution into the irrigation system should 17 be: 18 19 (8 ppm)(500 gpm)/1850 = 2.2 gph 20 21 Similarly, from Table 1, for a treatment level of 8 ppm and a 10% available chlorine 22 concentration, read an injection rate of 0.4 gph. Note that this is the required injection rate 7 1 for each 100 gpm. Thus, for 500 gpm, the injection rate would be five times as large, or 2.0 2 gph. 3 4 5 If the stock solution concentration was 5.25% available chlorine, then the injection rate should be: 6 7 (8 ppm)(500 gpm)/971 = 4.1 gph 8 9 From Table 1, for a treatment level of 8 ppm and a 5% available chlorine concentration, 10 read an injection rate of 0.9 gph per 100 gpm of irrigation flow rate. Then for 500 gpm, the 11 injection rate would be five times as large, or 4.5 gph. 12 13 If the calculated injection rate is too small for the injection pump, the chlorine stock 14 solution can be diluted with irrigation water. Thus, if the 10% stock solution is diluted with 15 1 part water and 1 part 10% chlorine solution, the new stock solution would be diluted by 16 1/2. It would then have 5% available chlorine, assuming that the water added did not tie up 17 any of the available chlorine. Likewise, if the 10% stock solution is diluted with 4 parts 18 water and 1 part 10% chlorine solution, the new stock solution would be diluted by 1/5, and 19 it would have 2% available chlorine. 20 21 Chlorine is a powerful oxidizing agent and it must be handled carefully. A fresh 22 water source should be available at the field site where liquid sodium hypochlorite is being 23 used so that any contact or spills can immediately be washed off. Protective clothing 8 1 should be worn while handling this chemical and the associated injection equipment. 2 Goggles should be worn to protect eyes against splashes and gloves should be used to 3 protect hands. 4 5 Chlorine gas is a respiratory irritant, which affects the mucous membranes. It can 6 be fatal after a few breaths at 1000 ppm. Therefore, users of chlorine gas must exercise 7 extreme caution to ensure that it is safely injected. Maximum air concentrations should not 8 exceed 1 ppm for prolonged exposure. Chlorine gas should only be used in well-ventilated 9 areas so that any leaking gas cannot concentrate. While this form of chlorine is commonly 10 used in municipal water treatment systems, it should only be used by experienced and/or 11 licensed users. For safety, only vacuum type injectors should be used. 12 13 14 15 16 17 Table 1. Liquid chlorine (sodium hypochlorite) injection rates in gallons per hour (gph) per 100 gallons per minute (gpm) of irrigation water flow rate for different levels of stock solution concentrations of available chlorine (%) and the desired chlorine concentration (ppm). Treatment Level (ppm) Concentration of available chlorine in stock solution* (percent) 1 2 3 4 5 10 15 (gph of injection per 100 gpm of irrigation flow rate) 9 2 1.1 0.6 0.4 0.3 0.2 0.14 0.09 4 2.2 1.1 0.7 0.6 0.4 0.22 0.15 6 3.3 1.7 1.1 0.8 0.7 0.3 0.2 8 4.4 2.2 0.5 1.1 0.9 0.4 0.3 10 5.5 2.8 1.8 1.4 1.1 0.6 0.4 15 8.3 4.1 2.8 2.1 1.6 0.8 0.5 20 11.0 5.5 3.7 2.8 2.2 1.1 0.7 25 13.8 6.9 4.6 3.4 2.8 1.4 0.9 30 16.5 8.3 5.5 4.1 3.3 1.6 1.1 40 22.0 11.0 7.3 5.5 4.4 2.2 1.5 50 27.5 13.8 9.2 6.9 5.5 2.8 1.8 75 20.6 13.8 10.3 8.3 4.1 2.8 100 27.5 18.3 13.8 11.0 5.5 3.7 27.5 20.6 16.5 8.3 5.5 27.5 22.0 11.0 7.3 150 200 * These are commercially available concentrations. Other concentrations are obtained by diluting with water. 1 2 Summary: 3 4 1. Have your irrigation water tested. 5 2. Select the source of chlorine. 6 3. Determine how much chlorine should be injected to obtain the desired concentration 7 (ppm) of chlorine in the irrigation water (Eqs. 2-4 or Table 1). 8 4. Inject the calculated amount of chlorine solution. 9 5. Measure the concentration of “free” chlorine at the end of the last lateral. 10 6. If the amount is less than 2 ppm increase the chlorine injection rate. 11 12 10 1 2 3 Acid Injection 4 5 Hypochlorous acid (HOCl) is the effective agent that controls bacterial growths. 6 The amount of HOCl that will be present in solution, and thus active, will be greater at 7 lower pH levels (more acidic conditions). At a water pH of 8, only about 22% of the 8 chlorine injected will be in the active HOCl form, at a pH of 7, about 73% will be in the 9 HOCl form, and at a pH of 6, about 96% will be in the HOCl form (Nakayama and Bucks, 10 1986). Thus, if the irrigation water pH is high, the effectiveness of the injected chlorine 11 may be enhanced by injecting an acid to reduce the pH of the water before injecting 12 chlorine. In addition to increasing the effectiveness of chlorine, acid injection can also 13 prevent the precipitation of minerals, which may plug microirrigation systems. However, it 14 is normally only necessary to reduce the pH one or two units to achieve these desirable 15 benefits. 16 17 At extremely low pH levels (or high acidity) chlorine gas (Cl2) will form. 18 Therefore, for safety, it is very important to store chlorine and acid sources separately. 19 Also, storage and use areas should be well ventilated so that gasses cannot concentrate and 20 become a hazard in a building or other enclosed area. 21 22 23 High pH water may result in increased precipitation of various minerals that can result in microirrigation emitter clogging. In addition to the potential clogging problems, 11 1 water with a high content of bicarbonates can have a negative effect on plant growth. Many 2 sources of irrigation water contain dissolved bicarbonates, which are bases and are thus 3 liming materials. Irrigation with such water can decrease the lime requirement for plant 4 production and can cause adverse plant growth by excessively raising the pH of the soil. 5 The magnitude of the effect depends on the concentration of the bicarbonates in the water, 6 the amount of the water applied, the buffering capacity of the soil, and the sensitivity of the 7 plants being grown. The liming effect of the water can be neutralized by adding acid to the 8 water before it is applied to the crop. 9 10 The problem of high dissolved bicarbonates is likely to occur wherever irrigation 11 water comes from a limestone aquifer or from surface waters (lakes, rivers, or canals) that 12 cut into limestone. A water test should be performed to determine if the problem exists. 13 Interpretation of the test should include an evaluation of the liming potential of the water. 14 This is best determined directly by titration of the water with an acid to the methyl orange 15 end point. An indirect method that uses the calcium (Ca) and magnesium (Mg) analyses 16 may also be used but may result in over-estimation of liming potential. Such an estimate 17 assumes that all of the Ca and Mg are present as bicarbonates, which is not always the case. 18 19 If the pH of the water is below 7.0, it can be safely assumed that it will not be a 20 significant source of liming materials. However, if the pH is above 7.0, the water contains 21 bases, but the amount and sources of those bases are not known. One water source may 22 have a relatively high pH of 8.4 and yet contain a very low level of bicarbonates where 23 another water source, with the same pH, may have a very high bicarbonate level. 12 1 2 Multiplication of parts per million (ppm) of Ca by 0.05 and ppm Mg by 0.083, and 3 summing the two products, will give the milliequivalents of those cations per liter (me/L) of 4 water. In many cases, Ca and Mg will be associated with bicarbonate and carbonate salts. 5 Under those conditions the me/L of Ca plus Mg will be a good estimate of the me/L of 6 associated bases. However, if other non-basic ions such as sulfate are present, the 7 calculation would overestimate the base content of the water. Thus, Ca and Mg analyses 8 may be useful in estimating base content but should be used with caution. 9 10 Crops that are particularly sensitive to high pH soil are usually the first to show the ill 11 effects of high bicarbonate water. Blueberries, azaleas, and pine seedlings are well known 12 for their sensitivity to pH-induced iron deficiencies. However, just about any crop may be 13 affected given the right conditions. Heavy or frequent irrigations applied to soils or media 14 of low buffering capacity will present the most problems to sensitive crops holding capacity 15 and are sometimes irrigated two or three times each day. 16 17 Where high levels of bicarbonates in the water have caused soil or potting media pH 18 to be too high for proper plant performance, it may be necessary to lower the soil pH. This 19 may be accomplished by addition of extra acid in the irrigation water. Injection of acid 20 into the irrigation water is a direct way of neutralizing the bases present. 21 22 23 It is not necessary to neutralize all of the bases in order to reduce the problem to insignificant levels. If 80% to 90% of the bases were neutralized, water that would have 13 1 caused a problem in six months of irrigation might now take up to five years of irrigation at 2 the same rate in order to cause a crop growth problem. Treating for less than100% 3 neutralization allows some room for error in acid application rates, variability in water, etc. 4 Also, the risk of over-acidifying is not worth the benefit of neutralizing the last 10% to 20 5 % of the bases. 6 7 The amount of acid mixed with the irrigation water will depend on the quantity of 8 bases that the water contains and on the strength of the acid used. The base content of the 9 water is determined in the water test and the strength of the acid is given on the container. 10 Table 2 shows the properties of three common acids. One milliequivalent (me) of acid 11 completely neutralizes one milliequivalent of base. 12 13 The most commonly used acids include sulfuric, hydrochloric, and phosphoric acid. 14 Other acids could be used but cost and availability usually limit the choices to these three . 15 Phosphoric and sulfuric acids may have some nutritional value but this should be a minor 16 consideration in choosing an acid for bicarbonate neutralization. 17 18 Hydrochloric, sulfuric and phosphoric acids are highly toxic materials irritating to 19 the skin, eyes, nose, throat, lungs, and digestive tract. Goggles and chemical resistant 20 (rubber, neoprene, vinyl, etc.) gloves, apron and boots should be worn whenever handling 21 these acids. Acid must be poured into water, never vice versa, and should be done in a 22 well-ventilated area. Should a spill or splash occur, remove all clothing and shower 23 immediately. Immediately rinse eyes with large quantities of water and drink large 14 1 quantities of water if the acid is ingested, but do not induce vomiting. Seek immediate 2 medical attention for all eye, nose, throat, lung, and digestive tract exposures and for skin 3 irritation, which persists after showering. It is generally advisable to dilute concentrated 4 acid in a plastic mixing tank prior to injection into the irrigation system, rather than directly 5 injecting concentrated acid. Most metallic fittings, tanks, and other parts of the irrigation 6 system will be damaged by acid, even dilute acid, so proper precautions must be taken. 7 Flushing the system after acid application is frequently sufficient to avoid substantial 8 damage. 9 10 In addition to the dangers involved with handling strong acids there is also the 11 danger of over-application of acid. Excess acid addition could result in injury to plant parts 12 that come in direct contact with the water, such as plants leaves with overhead sprinkler 13 irrigation systems. Also, an excessive acidification of the soil or potting media could result 14 in plant injury or death. 15 16 The pH of the acid-treated water should be monitored on a daily basis. It can be 17 done with a pH meter or with pH papers (both methods require some experience to give 18 reliable results). A pH between 4.5 and 5.0 should be maintained in the system. Because the 19 neutralization reaction continues slowly over a period of a day or two, it is important to 20 measure the pH of the water immediately after acid addition to avoid over-acidification. 21 The pH will usually be lower than that measured once the reaction is complete. If the pH 22 after treatment is very different from that calculated from the chemical analysis, you may 23 want to have another water sample analyzed before continuing. 15 1 2 Summary: 3 4 1. Have your irrigation water tested. 5 2. Select an acid of known strength. 6 3. Determine how much of your acid is needed to neutralize 80% of the bases in your 7 water. 8 4. Add the calculated amount of acid to your water. 9 5. Measure the pH of the water as it comes out of the irrigation line. 10 6. If the pH is not between 4.5 and 5.0, increase or decrease the amount of acid. 11 7. If the amount of adjustment in Step 6 is more than 15 to 20% of the calculated 12 13 14 value, consult a specialist before extended use of the system. 8. Retest the well water and irrigated soil about once a year and keep a record of the test results. 15 16 17 Should you add an acid example? 18 19 20 21 22 Table 2. Some properties of acids used in irrigation systems. 16 Acid name and chemical formula Sulfuric H2SO4 Hydrochloric HCI (also called muriatic acid) Phosphoric H3PO4 Commonly found concentrations Approximat e normality Common container sizes (gallons) Approximate cost* of acid Approximate cost* of treating 1000 gallons of water containing 4 me base/L 93% H2SO4 (also sometimes expressed as 66 Baume) 34.7 N 15 55 $75/drum ($8.50/CWT) $0.13 1.265 sp. gr. (battery acid) 9.19 N 1 15 $3/gal $1.04 20 Baume (has a specific gravity of 1.16 and is 32% HCI) 10.2 N 1 14 $2.80/gal $27/drum $0.88 $0.61 15 55 $50/drum ($9.00/CWT) $0.29 15 55 $320/drum ($40.50/CWT) $0.42 85% H3PO4 44.1 N *The costs will vary - they only reflect relative costs of the three acids and differences in sources. After Kidder and Hanlon, 1985 1 2 3 Other Maintenance Considerations 4 5 Research and experience have shown that insects can substantially increase the costs 6 of operating and maintaining microirrigation systems. Rats and mice have been reported to 7 chew holes in drip tubing (Stansly and Pitts, 1990). Childers et al. (1992) reported that 8 larvae of Tortricidae (Lepidoptera) and pupae of Chrysoperla externa (Hagan) had caused 9 emitter clogging. Emitter clogging from spiders and ants is a problem throughout the 10 industry. One of the biggest challenges is caused by ants that enter the system when it is not 11 in use, and then end up clogging emitters when the system is pressurized. In addition, ants 12 and other insects can damage tubing and emitter components and make them non- 13 functional. 14 17 1 The diaphragms of pressure compensating emitters can be significantly damaged by 2 ants. Emitters with portions of diaphragm missing or holes that destroyed the pressure and 3 flow reducing abilities of the emitters have been observed. Magnification showed scratch 4 marks typical of ant damage on other plastic components. The bodies of the used emitters 5 showed a significant decrease in weight due to the missing plastic. 6 7 Durability of components and ease of maintenance are important considerations 8 with regard to long-term operation and maintenance of SDI systems. Insects can plug 9 emitters and impair components to an extent that they render the system unusable. 10 Therefore, during the design phase of an SDI system, consideration should be give to 11 maintenance aspects. When possible, larger orifice diameters should be used since they are 12 less prone to clogging than smaller orifices. Emission devices without wafers or 13 diaphragms should be considered, since they are not as affected by ant damage. Once the 14 system is installed, weed and insect control need to be part of the overall maintenance 15 program for microirrigation systems. Injection of “insecticide” into the irrigation water 16 may be considered. 17 18 19 REFERENCES 20 21 22 Boman, B. J. and R. C. Bullock. 1994. Damage to microsprinkler riser assemblies from Selenisa sueroides caterpillars. Applied Engr. Agr. 10(2):221-223. 18 1 2 Boman, B. J. 1995. Effects of orifice size on microsprinkler clogging rates. Applied Engr. Agr. 11(6):839-843. 3 Childers, C. C., S. H. Futch, and L. A. Stange. 1992. Insect (Neuroptera: Lepidoptera) 4 clogging of a microsprinkler irrigation system in Florida citrus. Fla. Entomol. 5 75(4): 601-604. 6 7 8 9 10 Kidder, G. and E.A. Hanlon. 1985. Neutralizing excess bicarbonates from irrigation water. Notes in Soil Science No. 18. Soil & Water Science Dept., Univ. Fla., Gainesville. Nakayama, F.S. and D.A. Bucks. 1986. Trickle Irrigation for Crop Production: Design, Operation, and Management. Elsevier. Amsterdam. 383 p. Pitts, D.J., D.Z. Haman and A.G. Smajstrla. 1990. Causes and Prevention of Emitter 11 Plugging in Micro Irrigation Systems. Bulletin 258. Fla. Coop. Ext. Ser., Univ. 12 Fla., Gainesville. 13 14 Stansly, P. A., and D. J. Pitts. 1990. Pest damage to micro-irrigation tubing: Causes and prevention. Proc. Fla. State Hort. Soc. 103:137-139. 15 16 17 18 19