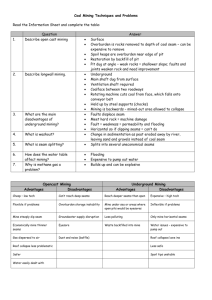

Variable Parameters in Mining

advertisement

Systems of Approach Variable Parameters These are within the power of the mining design engineer. Although he can be severely restricted when designing face and developments, the mining design engineer will ultimately have the power to choose whatever deemed appropriate in all these parameters: i) Number and Sequence of Seams Worked: The inter-relationship between workings in adjacent seams, the future of un-worked seams, the future of exploited seams, possibility of gas emissions and/or water penetration, consideration of two thinly separated seams as one and sequence of working. ii) Width and Length of Panels: Dictated by fixed parameters to a large extent, but the final decision is taken by the design engineer who has a large scope. Seam thickness, depth of workings, type, price and availability of machines, regularity of the seams and many other factors affect the choice. iii) Thickness of Extraction: Although influenced by fixed parameters but numerous alternatives are available to mining design engineer. Seam thickness, competence of roof and floor strata, machinery (especially supports) available and their relative prices, capacity of transport equipment on and outside the face area, together with gas and dust emissions are the main factors. iv) Induced Fractures: Thick seam working considerations especially in steep seams, possibility of gas emissions from adjacent strata, danger of water inundations etc. v) Width and Number of Pillars Between Panels: Mainly for reasons of support, gas transfer, subsidence etc. There could be no pillar in rare cases in longwall mining, one pillar in the case of traditional systems in longwall mining or many which will resemble room and pillar mining. In room and pillar, the main question is whether or not the pillars are to be won later. 1 vi) System of Waste Support: Many choices are available from total filling, termed solid stowing in horizontal mining, to partial stripping and ultimately total caving which is predominant today. vii) Rate of Face Advance: For highest output the maximum speed of face advance is ideal but many constraints limit this. In room and pillar, mainly support considerations are the limiting factor. In longwall, face ends operations and gas and dust emission prohibit the highest speed. Also, only theoretically at present, the speed of pressure arch advance rate may limit the face advance rate causing roof instability on the face. viii) Shape and Dimension of Roads: The mining engineer has a large scope. In room and pillar, rectangular cross sections are normal. In longwall mining, both rectangular and arched roadways can be chosen, depending on support and economic criteria. The main considerations are to preserve the ground stability by means of minimizing the energy release and to observe operational requirements. ix) Direction of Extraction Relative to Dip: Purely a technical, operational and economic parameter. Theoretically anything can be chosen from position 0 to 90 on the horizontal plain. Availability of machinery and their relative costs, together with operational restrictions, are commonly the deciding factors. x) Method of Heading Drivage: In room and pillar method, using the continuous miner is predominant. In longwall mining, drilling and blasting is was conventional but using road heading machines such as the TBM is fast becoming the obvious choice, especially in retreating system. In the advancing system, heading drivage must be designed in a way that it produces minimum interference with the operating face. Keeping these at some 40-50 metres in front of the face is the answer, but at the cost of installing and uninstalling the supports. xi) Ventilation Considerations: This affects the rate of advance and hence output, system of working etc. Generally, ventilation is more expensive in room and pillar due to large amount of leaked air. But 2 this leaked air prevents gas concentrations to occur. In longwall mining, on the other hand, concentration of working is high and therefore the presence of both gas and dust may constrain the face advance rate. Ventilation system must therefore be designed efficiently in all cases for its important impact on the production rate. xii) Details of Working Method: Such as pillar extraction and exact configuration of the rooms in room and pillar and the optimum number and capacity of machines such as shuttle cars and continuous miners to be applied. On a typical longwall face, the number and the type of shearer loaders and the exact sequence of their cutting cycle in relation to the supports have to be decided by the mining design engineer. 3