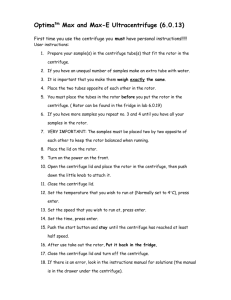

centrifuge care

advertisement

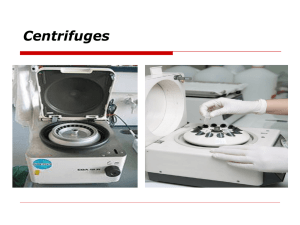

Judelson lab, 2008 SAFE AND CONSIDERATE CENTRIFUGE USE Be considerate 1. If you have a spill of anything in the centrifuge chamber or in the rotor, clean it out. In particular, a build-up of chemicals from spillages may cause (i) a tube to jam in the rotor or (ii) corrosion that could lead to a rotor failure and injury of the operator. 2. For centrifuges with refrigeration, do not leave the door open when the refrigeration is on. Otherwise, condensation forms on the walls which eventually melts into a smelly and corrosive mess. Safety issues 1. Only suitably trained persons may operate a centrifuge. 2. Before use, examine rotors for cleanliness and damage; chemical build-up may cause a tube to jam or cause corrosion that could lead to a deadly and expensive rotor failure. 3. Never exceed the maximum stated speed for any rotor. 4. Balance all tubes, and for swinging bucket rotors always run with a full compliment of buckets. Failure to do so can distort the rotor and cause a traumatic rotor failure. 5. Do not operate the centrifuge without the appropriate rotor cover securely fitted. 6. Use only correctly fitting tubes. If you are using a rubber adapter and your tube breaks, discard the adapter as residual glass bits might cause the next person's tube to fracture. 7. Clean up spills immediately after use. This is very important, especially for spills involving any salts! 8. Do not leave a wet rotor to sit in the centrifuge overnight, as this will cause corrosion and ultimately rotor failure. 9. Never attempt to open the lid of a centrifuge or slow the rotor by hand or open the lid while rotor is in motion as serious injuries may be incurred. 10. When using a refrigerated centrifuge, pre-cool the rotor to the lower temperature before securing the rotor to minimize the chance of it seizing to the spindle. 11. Do not leave the centrifuge until full operating speed is attained and the machine appears to be running safely without vibration. 12. Stop the centrifuge immediately if an unusual condition (noise or vibration) begins and check load balances. Rotor care and cleaning 1. Stress corrosion is initiated by certain combinations of stress and chemical reactions. If the rotor is not kept clean, corrosion will result. Moisture left for an extended time can also initiate corrosion. 2. Do not scratch or otherwise damage the rotor, either when cleaning or removing tubes with a tool (there is an oxide coating on the metal). It follows that rotor cavities and buckets must never be cleaned with an ordinary bottle brush with sharp wire ends. Instead, use plastic coated brushes. 3. Use only mild detergents for cleaning, like a hand soap. DO NOT use alkaline detergents or cleaning solutions which may remove the anodized coating, such as Alconox or most radioactivity cleaners which are highly alkaline. 4. When all parts have been washed, rinse in clean water and allow to dry completely (invert the rotor). 5. Do not leave buckets to soak for any length of time in cleaning or disinfecting products (i.e. overnight) as this may cause corrosion.