COSHH Assesment Guidance on Hazardous Substances

advertisement

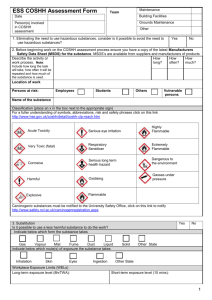

Title: Keywords: COSHH Assessment Guidance on Hazardous Substances Hazardous, Substances, COSHH, Guidance, Health, Safety, Risks, Chemicals, Biological, Fire. COSHH Assessment Guidance on Hazardous Substances 1st June 2013 1st June 2017 Description: Publish Date: Next Review Date: Expiry Date: Policy Owner: Audience: Karen Parker Staff Guidance on Hazardous Substances (‘COSHH’) This guidance has been written to help those who are new to the concept of COSHH Assessments and need some background information as well as Section-by-Section guidance on the use of the University’s COSHH Assessment Form. It will not do the work for you. COSHH Assessments, properly carried out, do take time - the University’s advisers on COSHH have recognised this and so have recommended within the Guide a method of prioritisation so that effort is directed at removing the highest risk first. Contents 1. Introduction 2. What is a COSHH Assessment & what substances are covered? 3. Responsibilities 4. Technical Advice 5. Prioritising Action 6. General Arrangements 7. Guidance for the Completion of COSHH Assessment Form ‘Section by Section’ 8. Useful Links Appendix 1: New Globally Harmonised System (GHS) Pictograms 1 1. Introduction The Control of Substances Hazardous to Health Regulations 2002 (COSHH) aims to protect people against risk to their health, whether immediate or delayed, arising from exposure to hazardous substances. The Health & Safety Commission has issued an ‘Approved Code of Practice’ (ACOP Code: L5) which describes how employers can achieve compliance with the Regulations – the University has undertaken to comply with such ACOP’s where they have been issued. Under the University’s Health & Safety Policy, all Faculties/Professional Services are required by the University to limit exposure to, and where necessary monitor the use or generation of, substances hazardous to health as an on-going priority. Particular care must be taken with the introduction of new substances and new processes/experiments etc. and the risks must be assessed as required. 2. What is a COSHH Assessment & what substances are covered? A COSHH Assessment is a written consideration of the risk created by hazardous substance(s) and the steps that need to be taken to prevent or adequately control any exposure. The term ‘hazardous substances’ should be interpreted in its broadest sense. It may include any substance which is deemed hazardous to health – whether it be solid, liquid, gas etc, whether in isolation or in mixtures, and whether purchased or produced – even as a byproduct - as part of a process. Examples include: hazardous chemicals, biological material, hazardous dusts or fumes etc. European Regulation (EC) No 1272/2008 on classification, labelling and packaging of substances and mixtures came into force on 20 January 2009 in all EU Member States, including the UK. It is known by its abbreviated form, ‘the CLP Regulation’ or just plain ‘CLP’. The CLP Regulation adopts the United Nations’ Globally Harmonised System on the classification and labelling of chemicals (GHS) across all European Union countries, including the UK. Certain substances are classified by Regulation as being hazardous. Not all chemicals are covered by CLP and are covered under separate regulation. It is therefore important to know and understand what is and is not covered. Most industrial chemicals are covered by the CLP Regulation. However some chemicals that have a more specialised job are covered by more specific legislation. The CLP Regulations do not apply to the following chemicals: radioactive substances and mixtures substances and mixtures subject to customs supervision non-isolated intermediaries substances and mixtures for scientific research and development which are not placed on the market and are only used in controlled conditions waste The Health and Safety Executive (HSE) also produce a regularly updated list (called ‘EH40’) of substances that have been assigned ‘Workplace Exposure Levels’ (WELs) which is to be referred to in conjunction with the COSHH Regulations. 2 If you are in any doubt about the degree of hazard of a substance or whether you need to carry out a COSHH Assessment, contact one of the University’s trained COSHH Advisers &/or the Health, Safety & Wellbeing Team. In order to comply with COSHH the University must consider not only the person who may come into immediate contact with a particular material but also anyone else who may be affected by it (e.g. cleaner, maintenance staff, students, and visitors, members of the public or the emergency services). The COSHH Regulations require an assessment of the risks to be carried out before work involving potential exposure to hazards is undertaken. Completed assessments are held by the appropriate Faculties and Professional Services and must be made available for inspection as required. Simplified versions of the relevant full assessment must be issued to all students at the start of each practical session where hazardous substances are involved. 3. Responsibilities Heads of Faculties/Professional Services will assist in the production of the COSHH assessments by nominating the appropriate employee(s) to take charge of this process, liaise with advisers as necessary, and keep them regularly updated on the status of this task. Line Managers &/or Supervisors have the responsibility to ensure that their department holds and update this information where necessary. Where appropriate it is expected that this will also need to be delegated to the relevant level for implementation (e.g. to Lecturers/Tutors/Demonstrators etc.). Employees in general have a responsibility to abide by the assessments made for their area. In some cases they will be required to help in the creation of the initial assessment after liaison with the appropriate technical advisers. All employees have the right to inspect the assessments made on their behalf and to question any assumptions made in those assessments. Employees with responsibility for the supervision of students must ensure that they are given the appropriate level of information and instruction and that they conduct themselves in accordance with any relevant assessment. Students are required under the University Rules to abide by all safety regulations and conduct experiments in the manner set out in the assessed Laboratory/Workshop procedure. Students have a right to see the full assessments on matters which relate to their safety and the basis on which they are made. 4. Technical Advice There are a number of staff within the University who have expertise in dealing with hazardous substances. Initial queries should be directed to the appropriate line manager or to the Faculty/Professional Service’s Health and Safety Coordinator. They in turn may seek advice on the issue from their local technicians, lecturers, and where necessary the Health, Safety & Wellbeing Team. Training courses are made available to those managing this issue within Faculties/Professional Services through the Health, Safety & Wellbeing Team. Individuals 3 with the appropriate level of training may be required to cascade this information down to other staff – normally this will be within their own Faculty/Professional Service. 5. Prioritising Action There are several methods you can use to prioritise your assessments. Firstly, make an inventory of the hazardous substances or processes and then grade them in terms of their relative danger. Below are some of the factors you will need to take into account in doing this: Hazard/Risk Phrases People likely to be exposed Current level of control Current level of knowledge Then plan to carry out COSHH Assessments on the substance(s) or process you feel is most hazardous and let your line manager or supervisor know how you have planned this and whether you need more assistance. 6. General Arrangements The basis of making accurate and meaningful assessments is the initial collection of information on the hazardous material concerned. Where this is a substance that has been supplied to the University, the suppliers or manufacturers are by law obliged to give to the purchaser information relating to the hazards and handling in the form of a ‘Data Sheet’ (safety data sheet (SDS). It is important to users and assessors that these Data Sheets are readily available. However, the safety datasheets are not a substitute for carrying out assessments. Only a full COSHH assessment can determine whether the intended use of the substance(s) presents a risk of exposure to harmful substances – the manufacturer or supplier cannot determine this for you. 7. Guidance for the Completion of the COSHH Assessment Form: Section by Section The University’s COSHH Assessment Form can be accessed via the Health, Safety & Wellbeing pages of the Staff Portal. Much of the information to complete the form should be found in the Safety Data Sheet (‘SDS’) supplied with the product. If you do not have a Safety Data Sheet, you should contact the supplier and request one. Remember, it should be possible for a third party (e.g. HSE Inspectors) to read and understand from the COSHH Assessment what methods are being used to reduce the hazards as far as is reasonably practicable: Please fill in the form with this factor uppermost in your mind. If much of the information required has already been compiled in other documents e.g. laboratory protocols/procedures then it is sufficient to make reference to this and append a copy to the COSHH Assessment form. Section 1 – ‘Assessor’ Enter the full name of the person(s) carrying out the assessment. 4 Section 2 – ‘Assessment Date’ Enter the full date of the start of carrying out the assessment. Section 3 – ‘Assessment Review’ This section has been put on the front of the form so that it can be seen ‘at a glance’ when the next review is due. You may wish to fill this part in at the end of the assessment process. Put in an early review date if there are uncertainties within the Assessment that you are waiting to clarify. There are no legal minimum times that have been set for reviewing COSHH assessments. Each situation will require this to be considered depending on the degree of risk, the effectiveness of controls over time, and in the light of any significant changes which may indicate that they no longer have relevance (e.g. changes in the process, supplier information etc.). Certainly they should be reviewed/initiated whenever an accident occurs leading to exposure, or potential exposure, of individuals to hazardous substances. For risks that remain fairly constant and controlled over time, an annual review is recommended. Also on a routine basis, monitoring of your controls should be undertaken to check that they are functioning correctly. Section 4 – ‘Summary of process or method’ This section is for you to describe what the process or method involves. Feel free to refer to a separate written protocol if one exists – ideally this should be accurately referenced and dated and a copy kept with the assessment. Section 5 - ‘Key Activity/Task’ The key activity or task where the substance/preparation is being used should be described – concentrating here on any step that may have the potential to expose persons to one of the hazardous substances. Examples of such operations are mixing, filling, spraying, cleaning, emptying, filling, transportation, storage etc. Section 6 – ‘People who could come to harm’ When carrying out a COSHH assessment any person who may be affected must be identified (including employees, visitors, the public etc.). Try to consider all persons, even if they have only occasional access. You can group people in categories if this helps e.g. ‘Students’ or by occupation. Section 7 – ‘Duration of Exposure’ An estimate should be made of the time anyone is exposed to the hazardous substance. The frequency of exposure should also be entered in this section e.g. three or four times a day, three or four times a shift etc. Section 8 – ‘Location and Condition of Use’ The location within the workplace should be described here and the conditions of use should be outlined. Pertinent factors could be: whether it is an enclosed space, whether the area is a designated ‘restricted area’, any adverse conditions to avoid e.g. high temperature etc. Section 9 – ‘Hazardous Ingredients’ The name of the any substances which are hazardous should be entered here. This should be found on the product label or the Safety Data Sheet. If there are more than 5, then either add more rows (i.e. if using an electronic copy of the form – this is preferable) or photocopy the page and change A-E to F-J etc. 5 Section 10 – ‘Quantities Used’ The amount of the substance/preparation used in each operation should be estimated and a tick placed in the appropriate box. The larger option should be chosen if there is any doubt on the exact quantity used. Section 11 – ‘Workplace Exposure Limits’ (WELs) The exposure limits for the hazardous substance/preparation will be outlined in the Safety Data Sheet (SDS) from the manufacturer/supplier. Workplace Exposure Limits (WELs) are published here in EH40/2005 Workplace Exposure Levels. WELs are British occupational exposure limits and are set in order to help protect the health of workers. WELs are concentrations of hazardous substances in the air, averaged over a specified period of time, referred to as a time-weighted average (TWA). Two time periods are used: Long-term (8 hours); and Short-term (15 minutes). Short-term exposure limits (STELs) are set to help prevent effects such as eye irritation, which may occur following exposure for a few minutes. For staff with sufficient training, experience and knowledge (‘competent persons’) this may be a matter of using sound judgement e.g. based on previous monitoring experience and indepth knowledge concerning the adequacy of the control measures. For all other staff, a review of the need to use the substance should be made with the appropriate Line Manager or Supervisor and adequate arrangements put in place to monitor potential or actual exposure levels. Assumptions must never be made about levels of potential exposure in the absence of either: (a) (b) Data from properly conducted scientific monitoring Express opinion from a competent person (who should be able to provide evidence to back up their decisions) Section 12 – ‘Risk/Safety Phrases’ The appropriate risk and safety phrases on the product label and the Safety Data Sheet should be included in this section. Common ‘Risk phrases’ (known as ‘R’ phrases) include ‘Very toxic if swallowed’; ‘Causes burns’. Common ‘Safety phrases’ (known as ‘S Phrases’) include ‘wear eye/face protection’; ‘Keep locked up and out of reach of children’ etc. Section 13 – ‘Actual Potential Route of Exposure’ You decide this by considering the process or method e.g. dust/aerosols may have the potential to be inhaled, other routes may be by ingestion, (absorption) skin contact, injection/puncture etc. Section 14 - ‘Datasheet Attached?’ Enter a Y/N depending on whether you’ve attached the Datasheet(s). 6 Section 15 – ‘Control Measures’ Outline the existing or proposed measures that will reduce the risk of anyone being exposed to the hazardous substance or mixture of substances. Check that they meet legal requirements, industry standards and represent good practice. If they do, detail this here. COSHH requires that exposure should be controlled by measures other than personal protective equipment so far as is reasonably practicable. The following control measures should be considered to reduce the risk (a combination of control measures may be required). It would be a good idea for you to put down in writing if any of these methods have been considered and rejected as unsuitable. 1. 2. 3. 4. Eliminate the need for the process or the use of the substance/preparation; Substitute the substance/preparation with a less harmful alternative; Total enclosure of the process; Use plant, processes and systems of work, including training, that minimise the generation of, suppress or contain spills, leaks, dust, fumes and vapours; 5. Limit the quantities of the substance/preparation stored or used; 6. Local exhaust ventilation; 7. The reduction in the number of persons exposed; 8. Reduction in the period of exposure; 9. Regular cleaning of contamination from walls, surfaces etc; 10. Provision of safe means of storage and disposal; 11. Provision of adequate facilities for washing, changing and storage of clothing, including arrangements for laundering contaminated clothing. 12. Personal protective equipment (Gloves, eyewear, shoes, overalls, respirators etc.). Section 16 - ‘Indication of Danger’ This should be found on the product label and Safety Data Sheet. There will also be an associated symbol on the label; these symbols are transitionally changing from orange and black (as per the CHIP Regulations) to a Globally Harmonised System (GHS) which are red and white labels. The CHIP Regulations will be replaced by the Chemical Labelling and Packaging Regulations (CLP) in June 2015. 7 Put a tick in the appropriate box under indication of danger, or you can be more specific by putting in the letter of the hazardous ingredient i.e. A-F etc. For sensitiser, carcinogen, mutagenic and toxic for reproduction categories, you will have to refer to the Safety Data Sheet and ‘Risk Phrases’ on the label e.g. ‘may cause cancer’ or ‘may cause birth defects’. Again put a tick in the appropriate box. Risk & Safety Phrases are transitionally being replace by ‘Hazard Statements’, these include physical hazards and health hazards, further information can be found here. NB*Carcinogen If complete prevention of exposure to a carcinogen is not reasonably practicable, all the control measures listed under ‘Additional control measures’ must be taken. Also, the areas and installations that may be contaminated by carcinogens should be designated and warning signs used. NB*Biological Agent This means any micro-organism, cell culture, or human endoparasite which may cause infection, allergy, toxicity or otherwise create a hazard to human health. For biological agents, there is published HSE guidance on ‘Biological Agents Managing the risk in laboratories and healthcare premises’. Section 17 – ‘Route of Exposure’ The route of entry or contact should be recorded here by putting a tick in the appropriate box. This information will be found in the risk phrases on the product label and in the Safety Data Sheet, for example ‘irritating to eyes’, ‘may cause sensitisation by skin contact’, ‘may cause sensitisation by inhalation’ etc. Section 18 – ‘Chemical State’ A tick should be entered in the appropriate box. Section 19 – ‘Flammability’ The appropriate information should be provided on the product label. The Safety Data Sheet should provide information on the flash point (f.p.) of the substance/preparation. Substances/preparations are classed as: ‘Flammable’ if flash point is less than or equal to 210C; ‘Highly Flammable’ if flash point is below 210C; ‘Extremely Flammable’ if flash point is below 00C. Oxidising substances/preparations may cause fire or explosion in contact with combustible materials. Substances that are classified under these headings should be subject to separate detailed risk assessments with regard to their flammable properties, in addition to the health aspects considered in your COSHH assessment. Section 20 – ‘Volatility’ This information should be provided in the Safety Data Sheet. The relevant information is the boiling point (b.p.): ‘Low volatility’ if boiling point is above 1500C; ‘Medium volatility’ if boiling point is between 500C and 1500C; ‘High volatility’ if boiling point is below 500C. A tick should be placed in the appropriate box. 8 Section 21 – ‘Dust Rating’ This information should be provided for solids. A tick should be entered in the appropriate box. ‘Low’ is applicable to pellet-like solids that do not break up and little dust is seen during use. ‘Medium’ is applicable to crystalline, granular solids where dust is seen during use but this settles out quickly. ‘High’ is applicable to fine light powders where dust clouds can be seen during use and these remain in the air for several minutes e.g. cement, chalk dust etc. Section 22 – ‘First Aid Procedures’ The Safety Data Sheet should describe first aid measures for persons exposed to the substance/preparation. This information should be used for the preparation of your own first aid procedures to deal with an accident involving the substance/preparation. The information should be brief and easy to understand. These procedures should be described or referred to under the relevant headings in this section. If necessary, summarise first aid on a separate sheet and make reference to this here. Remember, when someone has been exposed to a harmful substance it’s too late to try and find the first aid details from a collection of datasheets. Section 23 – ‘Spillage Procedures’ The procedures for dealing with spillage should be described here. Precautions for dealing with spillage may vary depending on the size of the spillage and the nature of the hazards associated with handling the substance/preparation. The more dangerous the substance(s), the more planning and detail is required here. Section 24 – ‘Disposal Arrangements’ Tick if any of these apply, otherwise describe the appropriate method, referring to the datasheets. Section 25 - ‘Are the risks adequately controlled?’ Note: The definition of a RISK is: - the likelihood that harm will result from a particular hazard. Take time now to assess the risks arising from the ‘indications of danger’ and ‘routes of exposure’ identified. When carrying this out consideration must be given to what is reasonably foreseeable in relation to the identified hazards and with recognition of the existing control measures that reduce the risk. Your assessment should be based on the information recorded in the previous Sections. If you decide the controls in Section 15 are sufficient, write ‘Yes’. There is no need for an elaborate scoring system: by writing ‘Yes’ you are committing to the fact that, in your view, the risks are well controlled i.e. ‘Low’. Skip onto Section 27. If you’re not happy to do this, then write ‘No’ e.g. it may be the case that certain parts of the process need tight control to ensure safety. Fill in Section 26, consulting with colleagues as necessary first. Section 26 – ‘Special instructions to control the risk’ Only you will know how to specify these. An example would be that you consider a high level of supervision is necessary for a specific part of the process i.e. you might prohibit further progress unless a supervisor is present. 9 Section 27 – ‘Ensure those affected are informed of the risks and controls’ It may be that nothing further needs to be done, but this is a good time to check that the persons who may be affected by the hazardous substance(s) know what the risks are, and what controls have been decided on in order to reduce the risk, including any special instructions. There is no set way of giving this communication: you could consider giving them a copy of the assessment (e.g. for staff) or posting signs/warning notices (e.g. for students or the public). Of course, if you have indicated that monitoring of control measures is required (e.g. making sure that personal protective equipment is used) then you will still have to do this to ensure that you know that this control remains an adequate measure to reduce the risk to an acceptable level. What next? Completing the COSHH assessment form is NOT the end of the matter. All assessments should be brought to the attention of those who are affected by the activities and should be readily available for viewing by interested parties (including Heads of Departments, H&S Coordinators, the University’s Health, Safety & Wellbeing Team, HSE etc.). Following the assessment, the controls need to be put in place, communicated to all, monitored for their effectiveness and reviewed. Monitoring exposure: Monitoring of exposure is required if: a) b) c) Failure/deterioration of the control measures could result in a serious health effect; Measurement is necessary to ensure a WEL is not exceeded; Additional checks are required on the effectiveness of any control measure. Health surveillance: This term is used to describe medical surveillance under the supervision of an employment medical adviser or appointed doctor. It is appropriate for workers liable to be exposed to substances and engaged in the processes listed in Schedule 6 of the COSHH Regulations. Contact the Health, Safety & Wellbeing Team for advice if you think health surveillance is indicated. Where should forms be stored? The completed forms should be kept within the Faculty/Department. Whilst keeping a computer record is sufficient, you are recommended to print off, and file, the assessments as a back-up. 8. Useful links: COSHH Regulations About the CLP Regulations The future of the CHIP Regulations Guidance on labelling and packaging COSHH Frequently asked questions 10 Appendix 1: GHS Hazard Pictograms ‘Hazard statements’ form part of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). They are intended to form a set of standardized phrases about the hazards of chemical substances and mixtures that can be translated into different languages. As such, they serve the same purpose as the well-known R-phrases, which they are intended to replace. 11