53Martinovs

advertisement

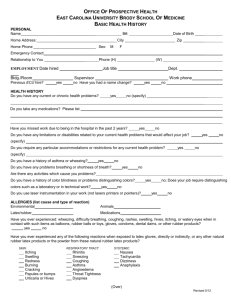

5th International DAAAM Baltic Conference "INDUSTRIAL ENGINEERING – ADDING INNOVATION CAPACITY OF LABOUR FORCE AND ENTREPRENEURS" 20–22 April 2006, Tallinn, Estonia METHOD OF FORECASTING OF MECHANICAL PROPERTIES AND DURATIONS OF SERVICE LIFE OF DETAILS FROM RUBBER Martinovs, A. & Gonca, V. Abstract: Wide application in various areas of techniques of rubber details demands skill to predict service life of these details. Existing methods of forecasting of service life of rubber products are based on measurement of changes of mechanical modules of rubber in current of their operation. Authors have experimentally established stochastic dependence between mechanical and electric/ optical characteristics of rubber materials. The mathematical model of rubber which allows to deduce analytical dependence, between mechanical and electric (dielectric permeability) characteristics of rubber during its ageing is offered. Specifications and the equipment, allowing the express train by a method to define dielectric permeability of rubber directly in a product at any moment of its operation are developed. It has allowed to develop a simple method of definition of service life of a product from the rubber, based on measurement of its dielectric permeability (or specific resistance, or infrared ray transmission capacity), during any period of its operation. Key words: rubber, dielectric permeability, mechanical properties, artificial aging, service life. rubber and forecast how will they change during ageing as well as predict the lifespan of the rubber product. In this work are analysed publications of the last six years from journals „Rubber Chemistry and Technology” and „Caoutchouc and Rubber” (Kautshuk i rezina; in Russian), are investigated articles of K.T.Gillen [ 1 ], M.Celina [ 1 ], W.V.Mars [ 2 ], V.Gubanov [ 3 ], V.Druzinin [ 4 ] and others authors, are studied functioning standards [ 5 ]. Is established, that in forecasting of service life of details from rubber are used only mechanical testings, what are frequently united with artificial ageing. Non- mechanical measurements, which are easy automatizable, were not used in forecasting methods. The objective of the Thesis is to develop expressmethod, which is based on the electric (dielectric permeability, specific resistance) or optical (infrared ray transmission capacity) measurements, for determination and forecasting of mechanical properties and lifespan of elastomers (rubber). 2. MATHEMATICAL MODEL In base of method of forecasting use improved variant of model, given in literature [6 ], in which de-structuring and structuring processes are included. In this model complicated structure of rubber is substituted with platelike structure. Ageing of every platelike element is characterised by cross-link yield γ: 1. INTRODUCTION Rubber products have very wide use in many different economic sectors. In order to solve specific engineering and technical tasks, it is necessary to determine mechanical properties of the 279 N t , (1) N max where N(t)- number of links in time moment t, which carry tension load, Nmax - maximal number of these links (t=0). Changes of cross-link yield dγ in time dt are characterized by equation: 3. OBTAIN INITIAL DATA TO FORECAST t In order to forecast mechanical properties and lifespan of rubber in the beginning it is necessary to obtain initial data. To do this it is proposed to take samples of new rubber and rubber aged 24, 72 and 168 hours at 1000C in air [7]. For these samples with different levels of ageing elongation characteristics are produced [8 ]. For approximation of tensile strain under constant elongation w characteristic use function 0 q d , (5) where σ 0 – mechanical stress on crosssectional area at unstrained conditions; – deformation; q, d – material constants, which are determined with method of the least square. For each sample is measured breaking time in elongation t *, length of the work area of the sample put on tension test in unstrained conditions l 0 , average rate of elongation w, with which work area border marks separate. Temperature T, at which tension tests are performed, ageing temperature T n and ageing time t n are taken. It is experimentally established that the biggest relative measurement errors are related to determination of breaking time t * and parameter q of elastic properties. This is why measurement error of these characteristics Δq and Δt * further are used in forecasting method. Parameter d is absolutely accurate because error of this parameter is included in measurement error of parameter q. Relative measurement error for other characteristics – l 0 , w, T, T n , t n , is much smaller compared to measurement errors of t * un q, therefore average values of these characteristics are used in forecasting method, leaving errors of measurement out. In experiments is used rubber 2H-1-MБC-C 2 ГOCT 733890. It is characterised by initial data to forecast: tn0=0; tn1=(1·24·3600)600s; tn3=(3·24·3600)600s; Qd t 3 Q t x W t k T t s t k T t d t t e a 1 t e Z dt (2) where Qd – de-structuring energy (energy needed to tear link), J; Q s – structuring energy (energy needed to have a new link); W – elastic potential (energy of deformation received by one volume unit) of given platelike element, J/m 3 ; T – absolute temperature, K; x – distance between centres of contiguous atoms in unstrained conditions, m; k – Boltzmann constant; a – structuring constant; Z=6 – number of the closest contiguous atoms in cubic structure; =110 13 Hz – frequency of thermal oscillations of atoms; t – time, s; x 3 W/- energy mechanically delivered to one link. Given differential equation is characterized by conditions at the beginning, at the moment of mechanical loading and at the end: if t=0, then γ=1; if t=t 0 , then γ=γ 0 ; (3) if t=t*, then γ=0. If during ageing anisotropic state within rubber are not developed (ageing in not deformed state), then it is possible to include in model the differential equation with cross-link yield , time t and relative dielectric permeability : d t dt . (4) 2 Coefficient is material constant, which characterizes electrical properties of rubber and is linked to electrical field frequency ratio, which is used in dielectric permeability measurements. If during ageing relative dielectric permeability of rubber increases, then >0, if decreases, then <0. 280 If functional correlations between mechanical parameters q, d, t * and electrical or optical are known, then electrical or optical measures can be used for determination of mechanical parameters of given type of rubber. Authors have experimentally established stochastic dependence between mechanical and electric/ optical characteristics of rubber materials. Examples for rubber with basic content: natural caoutchouc – 55.46%, filler K354- 27.73% (produced in “Baltijas gumijas fabrika” in Riga) see in Figure 1- 3. Methodology and results of investigations are given in literature [9]. Infrared ray transmission capacity is measured with Perkin Elmer FT-IR Spectrometer Spectrum 1000. tn7=(7·24·3600)600s; q0=3.530.45MPa; q1=4.170.30MPa; q3=4.740.50MPa; q7=5.430.50MPa; d0=0.70; d1=0.69; d3=0.64; d7=0.64; t0*=28.42.8s; t1*=23.53.2s; t3*=21.63.5s; t7*=19.53.5s; l0=20.00.3mm; w=2.1560.055mm/s; T=(20+273)1K; Tn=(100+273)1K. 4. DETERMINATION OF STRUCTURING ENERGY, DESTRUCTURING ENERGY AND MATERIAL CONSTANTS Fig. 1. Correlation between parameter q of elastic properties and relative dielectric permeability Forecasting method requires knowing values of de-structuring energy Qd, structuring energy Qs, atomic structure constant x and structuring constant a. Assuming, that during ageing the values of these parameters are constant. To determine their values will use correlation (2), where 4 cases of elongation under constant rate and 3 cases of artificial ageing without mechanical load can be written down as equation system: Fig. 2. Correlation between parameter q and specific resistance Qd 3 x W t Q k T s t k T 0 i t e a 1 t e Z dt 0 ti* (6) Q Q d s j j 1 t e kTn a 1 t e kTn Z dt tn j 1 tn j (7) where i=0, 1, 2, 3; j=1, 2, 3. Equations (6) describe processes of elongation at constant speed to failure for: 1) new rubber (i=0, 0 =1); 2) rubber, which has been aged for 24 hours at elevated temperature (i=1); 3) rubber, which has been aged for 72 hours at elevated temperature (i=2); Fig. 3. Correlation between parameter d of elastic properties and infrared transmission capacity at 2915cm -1 281 4) rubber, which has been aged for 168 hours at elevated temperature (i=3); In this processes cross-link yield changes from i (before elongation test) to =0 (time of failure). t i * designates time in which sample is destroyed. Equations (7) describe process of rubber ageing at elevated temperature Tn without mechanical load in period of time from: 5) t n0 =0 to t n1 =24 hours. During this process cross-link yield changes 0 =1 to 1 (j=1); 6) t n1 =24 to t n2 =72 hours. Cross-link yield changes from 1 to 2 ; (j=2); 7) t n2 =72 to t n3 =168 hours. Cross-link yield changes from 2 to 3 (j=3); Set 1. 2. 3. 4. 5. 6. 7. 8. 9. q, t* q t* q+Δq t*+Δt* q-Δq t*-Δt* q+Δq t*-Δt* q-Δq t*+Δt* q t*+Δt* q t*-Δt* q+Δq t* q-Δq t* Qd 10-19J 2.28 Qs 10-19J 2.33 10-10m 5.638 9.7 2.05 2.06 4.633 6.4 2.29 2.35 6.322 7.2 2.25 2.30 5.692 5.2 x and using equations (5), (8), (9) can get d 1 q wt W t (10) . d 1 l0 System of equations (6) – (7) has 7 independent equations with 7 unknown quantities Qd, Qs, x, a, 1, 2, 3. The solution of such equation system is found with numerical methods. Results for different initial data sets are given in Table 1. Average values from parameters q and t* (see 1 row from Table 1) establish highest probability of service life. Two another sets of parameters Qd, Qs, x and a set minimal and maximal values of forecasting service life. 5. FORECASTING OF LIFESPAN AND MAXIMUM DEFORMATION IN CREEP UNDER CONSTANT TENSILE LOAD a Creep (under constant tensile load P) process can be described by equation (2), which in this case looks like following: 0 0 t e 0 tm 2.34 2.35 5.712 9.8 2.28 2.29 5.340 8.3 2.27 2.30 5.968 3.7 2.25 2.30 5.355 8.7 2.31 2.35 5.970 9.1 a 1 t e Qs k T Z dt (11) where 0 – cross-link yield before loading; t m – maximum lifespan of sample in creep. Process of creep is divided into two parts: 1) sample is loaded until assigned P value under constant elongation speed w, time t=[0...t0]; 2) creep as a result of constant tensile load P, time tt0. For approximation of deformation from moment t 0 , when sample takes full load P, is recommended to use function: c (12) 0 1 b t t0 , where 0 – deformation relevant to the moment in time t0; c, d – constants characterizing samples under creep test, which are determined with method of the least square. Example of creep characteristic for rubber 2H-1-MБC-C 2 ГOCT 7338-90 is given in Figure 4. Table 1. The solutions of equation system (6) – (7) in dependence on values of parameters q and t * Elastic potential W for rubber in equations (6) in general case is found as follows: W 0 d , Qd x3 W ( t ) k T t (8) 0 where d- deformation change in time dt. If the speed of elongation w is constant, then wt (9) l0 282 maximum deformation of rubber 2H-1MБC-C 2 ГOCT 7338-90 are shown in Figure 5 and 6. Rhombus show the values of highest probability of lifespan and maximum deformation, small lines– range of forecasted error interval; uninterrupted line characterizes experimental values, ideal congruence between forecasted and experimental results. As shown, all values of lifespan and maximum deformation are within forecasted error interval. Given method fits for any size solid. Creep test is not sustained for sample studied. Creep test is not obligatory to be realized until the destruction of sample. By improvement of tensile tests quality and determination precision of cross-sectional area, is possible to scale down forecasting quantity inaccuracy interval. Fig. 4. Creep characteristic until sample destruction Maximum lifespan in creep t m is calculated from equation (11); maximal deformation m – from equation (12), by replacing t with t m . Mechanical stress 0 in creep under constant tensile load P is constant (in time tt0). It is calculated: P 0 , (13) F0 where F0 - cross-sectional area of the work area of the sample at unstrained conditions (perpendicular to direction of elongation). Using equations (5), (8) (9), (10), (12), get the expression to calculate elastic potential in random moment in time tt0 for creep: q 0 W t d 1 q d 1 d 0 0 q 1 d b t 0 q 1 c d l0 w . (14) To calculate cross-link yield 0 before loading, use equation (6) and tension test [8] data for given ageing levels rubber. If functional correlations between mechanical parameters 0, q, d, t * and electrical or optical are known, then yield test is not necessary, mechanical parameters of given type of rubber can be determined with electrical or optical measures. 6. COMPARISON AND ANALYSIS OF NUMERICAL AND EXPERIMENTAL RESULTS Fig. 5. Comparison of forecasted and experimentally determined lifespan of rubber sample in creep Fig. 6. Comparison of forecasted and experimentally determined values of maximum deformation of rubber sample in creep under constant tensile load The comparison of numerical and experimental results of lifespan and 283 7. CONCLUSION Method for forecasting mechanical properties and lifespan of elastomers in creep under constant one-way tensile load is developed and experimentally tested. All experimental values of lifespan and maximum deformation are within forecasted error interval. Electrical and optical measurements can be used to obtain initial mechanical parameters necessary for forecasting method. At the same time use of electrical/ optical parameters helps increase accuracy of determination of mechanical parameters and consequently improve the quality of forecast. 5. 6. This work has been partly supported by the European Social Fund within the National Programme “Support for the carrying out doctoral study programm’s and postdoctoral researches” project “Support for the development of doctoral studies at Riga Technical University”. 7. 8. 8. REFERENCES 1. Gillen K.T., Celina M. New Methods for Predicting Lifetimes, Part 2: The Wear-out Approach for Predicting the Remaining Lifetime of Materials. Sandia National Laboratories, Albuquerque, New-Mexico 87185 and Livermore, California 94550 Sandia Report, SAND2000-0715, 2000, p.45. 2. W. V. Mars. Cracking Energy Density as a Predictor of Fatigue Life Under Multiaxial Conditions. Rubber Chemistry and Technology, 2002, 75. 3. Gubanov V.V. About calculation of lifetime of rubber. In: Questions of dynamic and durability, Riga, Zinatne, 1985, 46, 33- 36. (Губанов В.В. О расчете долговечности резины// В кн.: Вопросы динамики и прочности, вып. 46. - Рига: Зинатне, 1985. - с. 33 – 36). 4. Druzinin V.A. Estimate of long-term durability of rubber details at large 9. deformations. In: Questions of dynamic and durability, Riga, Zinatne, 1984, 44, 44-53. (Дружинин В.А. Оценка длительной прочности резиновых изделий при больших деформациях// В кн.: Вопросы динамики и прочности, вып. 44. Рига: Зинатне, 1984. - с. 44 - 53.) ISO 11346:2004. Rubber, vulcanized or thermoplastic. Estimation of life-time and maximum temperature of use. Martinovs A., Gonca V. A rubber fall model for yield deformation. In International Conference on bionics and prosthetics, biomechanics and mechanics, mechatronics and robotics, Varna, 2004, 4, 47- 50. DIN 53508 Prüfung von Kautschuk und Elastomeren. Künstliche Alterung, Oktober 1993. DIN 53504 Prüfung von Kautschuk und Elastomeren. Bestimmung von Reißfestigkeit, Zugfestigkeit, Reißdehnung und Spannungswerten im Zugversuch, Mai 1994. Martinovs A., Timmerberg J., Gonca V. Research of relevances between mechanical and electrical parameters of rubber. For publishing in Riga TU Scientific Proceedings accepted work, Riga, RTU, 2005, p.8. Andris Martinovs, lecturer, doctoral studies Riga Technical University, Institute of Mechanics; Rezekne Higher Education Institution Adress: Atbrivosanas aleja 76, LV 4600, Rezekne, Latvia e-mail: andris@ru.lv Vladimir Gonca, professor, Dr.sc.ing. Riga Technical University, Institute of Mechanics Adress: Ezermalas Str. 6 - 305, LV-1014, Riga, Latvia e-mail: Vladimirs.Gonca@rtu.lv 284