labmanual_TFKE54

advertisement

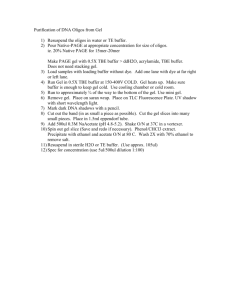

UNIVERSITETET I LINKÖPING Proteinkemi Kemiavdelningen 2012-01-17 Expression, production and purification of Fatty acid binding protein (FABP) from desert ant Cataglyphis fortis Production of FABP in E. coli 1. Introduction In this laboratory experiment, a protein, fatty acid binding protein, FABP, from the desert ant Cataglyphis fortis, is produced by E. coli bacteria. The bacteria used in this lab contain a plasmid, in which the gene for FABP is inserted. This plasmid is also an expression vector, which means that you can turn on transcription of the FABP gene with an inducer. A repressor molecule is initially bound to the operator region of the lac promoter. As an Inducer (IPTG, isopropyl--D-tiogalaktopyranosid) is added it binds to the repressor molecule, thus loosening the operator gene, leading to RNA polymerase can initiate transcription of T7 RNA polymerase. T7 RNA polymerase binds tightly to the T7 promoter, resulting in efficient transcription of the FABP. Plasmid also contains a gene, which codes for antibiotic resistance. This means that one can distinguish between bacteria that have the plasmid from those that lack this, by adding antibiotics to the culture medium. In this way, only the bacteria containing the plasmid are able to grow. The produced FABP will be located in E. coli cytoplasm. This means that you have to destroy bacterial cell walls, to access the FABP. This is done by means of sonication, i.e. breakage of the cell membrane by ultrasound. Then the cell wall is separated from the cytoplasm by centrifugation, to obtain a solution containing only cytoplasm. The cytoplasm is now containing FABP with approximately 2000 other proteins. By using a His-Tag-specific purification method one can separate the FABP from all the other proteins in a single purification step (His-Tag chromatography). Expression of the cloned and mutated protein can be monitored by SDS-PAGE. Therefore, withdraw samples at different stages of production and purification process for analysis at the SDS-PAGE lab. Discuss with the laboratory supervisor how many samples and at what stages of the production samples should be withdrawn. For each sample, save 50 μl solution at 20C. Sample preparation Make following solutions: LB-Medium 20g/l Trypticase (Peptone) 20 g/l NaCl 10 g/l Yeast Extract Kanamycin stock (30 mg/ml) 10 ml Take 300 mg Kanamycin and dissolve in 10 ml dist-H2O. Sterile filtering into autoclaved Eppendorf tubes ~1.5 ml in each tube. Store the stock solution in freezer and thaw it in room temperature before use. IPTG stock (0.5 M ) 10 ml Take 1.19 g IPTG and dissolve in 10 ml dist H2O. Sterile filtering into autoclaved Eppendorf tubes ~1.5 ml in each tube. Store the stock solution in freezer and thaw it in room temperature before use. Autoclaving Autoclave the following materials: 1.95 l LB in 5 l Erlenmeyer flask with magnetic stirring bar 50 ml LB in 250 ml Erlenmeyer flask with magnetic stirring bar Pipette tips LB-medium should be autoclaved and autoclaving time is calculated by using the table in the Autoclaving room. Inoculation of bacteria in overnight culture: After the autoclaving when the solution has cooled to ~37C, add 30 g/ml kanamycin (1000 times dilution) to overnight culture (250 ml flask) containing 50 ml of LB medium. Add approximately five bacteria colonies to the overnight culture. Incubate with stirring at 37 C overnight. Growth of bacteria in big flask Add 30 g/ml Kanamycin (1000 times dilution) to large flasks (5 l ) containing 1,95 l LBmedium. Transfer all solution from O/N culture (50 ml) to the large 1,95-liter LB-solution. Grow at 37 C while stirring. Follow the growth by measuring absorbance at 600 nm, which reflects cell density. This is done by taking out LB medium (~1 ml) with a sterile pipette and then measure in a plastic cuvette, using distilled-H2O as a reference. Induction of protein production When absorbance is approximately 0.8 add 2 ml of the Inducer, IPTG, to induce the production of Fatty acid binding protein (FABP) in E. coli bacteria. After this addition the growth continue at room temperature overnight. Harvest The growth is halted after 12-16 hrs. Bacterial solution is centrifuged at 3000 rpm for 40 min (4 C) in large centrifuge bottles. In this way, one can separate the bacterial cells from the culture medium. The supernatant is poured gently back into the flask and then autoclaved before being discarded. The pellets consisting of bacteria is resuspended in a small volume (max. 30 ml) resuspension buffer (see below). Sonication (ultrasound treatment): Sonication is often used to break the cell membranes, with ultrasound (typically 20-50 kHz) is generated electronically and the mechanical energy is transferred to the sample via a metal probe that oscillates at high frequency, resulting in limited areas with high pressure. This leads to cavitation and compression in the solution, which ultimately breaks up the cells and the protein content comes out into the solution. Sonication is done at 40 % amplitude and for 6*10 sec with 10 sec intervals on a sample of up to 30 ml. The samples are kept on ice during the process and until the chromatography is done. Affinity chromatography with Qiagen Ni-NTA Solutions: Resuspension buffer 20 mM Tris-HCl, pH 8 150 mM NaCl 5mM Imidazole Washing buffer 20 mM Tris-HCl, pH 8 150 mM NaCl 20 mM Imidazole Elution bufferA 20 mM Tris-HCl pH 8 150 mM NaCl 250 mM Imidazole Elution buffer B 20 mM Tris-HCl pH 8 150 mM NaCl 500 mM Imidazole Dialysis buffer 20 mM Tris-HCl pH 8 250 mM NaCl 5% glycerol Equilibrate the column with 10 ml dist-H2O and 10 ml resuspension buffer Load the sample (1-35 ml). The flow should be approximately 1 ml/min. Collect the run-through in a flask or a beaker. Wash with 4 ml wash buffer. Collect the run-through in a flask or a beaker. Elute with 3 ml elution buffer A. Collect fractions in Eppendorf tubes, 1 ml in each fraction. Load 3 ml elution buffer B. Collect fractions. Pool the fractions containing FABP and dialyze the sample against 3*5 l of dialysis buffer. Determine protein concentration and quick freeze (liquid nitrogen) the sample in suitable aliquots. After use: Wash the column gel with 30 ml 0.5 M NaOH, 10 mls of dist- H2O and store in 30 % etanol. SDS-Polyacrylamidegelelectrophoresis (SDS-PAGE) 1. Introduction The results of the purification process of FABP is studied using SDS-PAGE. It is the most common method to monitor the purity of a protein sample. This method separates proteins according to their size. SDS (sodium dodecylsulfate), which is negatively charged, is added to the sample, and by binding to the protein introduces negative charge, which is directly proportional to protein size. Polyacrylamide gel consisting of a network that proteins have to walk through. The size of the network depends on the ratio of acrylamide and bis-acrylamide. These proportions are chosen so that the proteins wanted to study separate from each other on the gel. The analysis also includes a number of reference proteins of known molecular weight run separately on the same gel. By allocating, the logarithm of molecular weights of reference proteins against migrating distance a straight line is obtained. It is then easy to estimate the molecular weight of the sample using the reference graph. Note! To this lab pre-made polymerized gel plates are used Solutions Electrode buffer 25 mM Tris 0,2 M Glycine 0,1 % SDS Loading buffer 84 mM Tris-HCl 35 % Glycerol 2,8 % SDS 20 µM bromophenol blue Sample Preparation Sample: Appropriate sample quantity to be applied is approximately 10 g of protein, the maximum volume of a sample well is approximately 35 l. First calculate the volume of sample you will need. Then mix with 1/5 of loading buffer. The mixture is heated in boiling water for 2-3 min. Apply the sample in the test wells. Reference: 5 l premixed reference solution. This is then treated as above. Electrophoresis Mount the gel cassette. Use 850 ml electrode buffer and pour it into electrophoresis chamber (in the "inner" and "outer" space). Run the gel at 200 V. Stop the run when the blue band has migrated to the end of the gel. Fixation, staining and destaining: 1. Carefully remove the gel from the glass plates 2. Place the gel in water so that it is well covered 3. Heat in the microwave until it almost boils. It must not boil, which threaten to destroy the gel. Take enough water that it takes ~40 s to heat it. 4. Pour off the water without pouring the gel. 5. Repeat steps 2-4 three more times. 6. Pour Safestain over the gel so that it is just covered. Heat in microwave oven until it almost boils. 7. Stain in 30 min. 8. Bleach in water. For faster bleaching, add some tissue paper. Photography of the gel: Take a picture of the gel at an appropriate occasion. If the gel will be stored for a long time, keep it in 20% (v / v) ethanol before the shooting.