Section 2 – Extent of changes to the Technical File

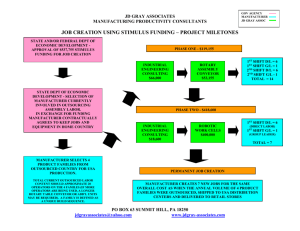

advertisement

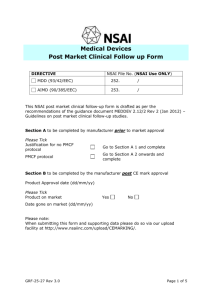

Medical Devices Application Review Form This form is used for: Substantial Change Non-substantial Change Please check all the relevant DIRECTIVE(s) DIRECTIVE NSAI File No. (NSAI Use ONLY) MDD (93/42/EEC) 252. / AIMD (90/385/EEC) 253. / TSE (2003/32/EC) 554. / Human Blood (2000/70/EC) 576. / For products covered by either the MDD or AIMD, is compliance with the additional requirements of 2007/47/EC being claimed : Yes No NOTE : If “No”, please be aware that new certificates (original or renewal) will be issued with an expiry date of 20-Mar-10, until compliance with 2007/47/EC has been confirmed. Please submit an unsigned version of this Application in Word as well as a signed copy - either scanned/secured (pdf) copy. Europe N. America NSAI 1 Swift Square, Northwood, Santry, Dublin 9 Ireland NSAI Inc. 402 Amherst Street Nashua NH 03063 USA Phone : (01) 807 3929 Fax : (01) 807 3996 Medical.Devices@NSAI.ie Phone : (603) 882 4412 Fax : (603) 882 1985 Medical.Devices@NSAIinc.com NOTE : Only completed Applications will be reviewed. RF-25-08 Rev 12 Page 1 of 31 DECLARATION(s) BY APPLICANT Note: this page to be completed by all applicants In signing this form, the manufacturer is verifying that the requirements of the Directive will be applied in full when the change has been implemented. Signed on behalf of the Manufacturer: Date: Name (please print): Position / Title: Contact person (if different to Manufacturer): Phone: Email: -------------------- RF-25-08 Rev 12 Page 2 of 31 Section 1 - Manufacturer and Product Details Manufacturer’s Instructions Please complete all the relevant sections below (excluding the NSAI Review sections). If the data is in supporting documentation, please ensure that there is a clear reference to the exact location of this information. Note the “Manufacturer” as defined by the Directive(s) is “the natural or legal person with responsibility for the design, manufacture, packaging and labelling of a device before it is placed on the market under his own name, regardless of whether these operations are carried out by that person himself or on his behalf by a third party.” Please also supply QMS certificates for any sites listed below NOT registered with NSAI. Please complete Table 1, highlighting any changes as necessary Table 1 (Legal) Manufacturer’s Name (Legal) Manufacturer’s Address Design Site(s): Manufacturing Site(s): (i.e. sites of actual manufacture) Assembly Site(s) if applic.: Sterilisation Site(s) if applic.: Scope of Site(s): (i.e. as shown on the QMS cert) Name and address of EU Authorised Representative (if applicable) Product/Product Family Name: (Ensure product family name is in compliance with NB/MED/2.5.1/REC4) & NBOG’S Best Practice Guide 2006-2 GMDN Reference Number: See www.gmdnagency.com/ MDD Classification: Rule: Conformity Route: Annex AIMD Rationale Conformity Route: Annex Date of this application (i.e. date of Declaration of Applicant) Supply Declaration of Conformity (Please reference location within technical file) Description of the proposed change (compared to the approved design/product range/quality system. Reason for the changes / modifications ( Please give detailed descriptions on the change from existing registered models, if necessary) Please outline if this change arises from a vigilance issue RF-25-08 Rev 12 Page 3 of 31 NSAI Review Check the QMS registration of the various sites listed and that the Declaration of Conformity for this family is present and adequate Check the data supplied against data previously submitted to NSAI – in cases of amendments, review all data fully. Ensure that the product family name is in line with GMDN nomenclature. Check the description of the proposed change; ensure the manufacturer’s description is clear, precise and confirms the extent of the proposed change. Consider the modifications or changes compared to the approved design/product range of the approved quality system, and the validity of the reasons for the change. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 4 of 31 Section 1 – Manufacturer and Product Details (CONTINUED) Manufacturer’s Instructions In cases where the proposed change involves change to the members of a product family or their description, please complete Table 2 with the relevant information relating to only the affected catalogue numbers; otherwise mark as N/A Table 2 Product / Product Family Name: Intended Use: Model/Catalogue Number Description Classification Schedule* *Schedule of Regulations (Irish Statutory Instrument) corresponds to Annex of Directive used for Conformity Assessment NSAI Review The proposed change involves amending the model numbers in the family or their description: No Yes Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 5 of 31 Section 2 – Extent of changes to the Technical File Manufacturer’s Instructions The manufacturer must assess the extent of changes to the Technical File this proposed change will bring- using the guidance below: This is a significant change to the : Quality System Product Range Design Dossier Class In the case of design or product range changes, briefly state the outcome of the review against a) The essential requirements b) The safety and efficacy of the device as demonstrated by the risk analysis. c) The clinical safety of the device In the case of design dossier amendments: a) briefly describe the design dossier amendment here or in an attachment b) briefly state or attach the design or project plan c) attach all relevant verification and validation test data and/or summary reports d) include any update to the solutions to the essential requirements and risk analysis I, as manufacturer, deem that the following sections of the Technical File are affected by the proposed change: YES NO AGREED BY REVIEWER REVIEWER DATE Pre-Clinical Technical Requirements Table 3 – Impact of Change SECTION Intended Use of the Device Correct Classification & Appropriate Annex Labelling & IFU Solutions to Essential Requirements Compliance to Harmonised Standards Performance/complaint Analysis Risk Analysis Sterilisation Stability – Device Stability – Packaging Biocompatibility Medical Electrical Equipment Medical Electrical System Pre-clinical Testing - NonClinical (Bench) Pre-clinical Testing - Clinical (Animal Testing) Clinical Evaluation Design Dossier (MDD Annex 2 Class 3) Other areas: please specify NOTE - If Section is deemed to be not affected by the proposed change please add N/A to the particular sections on the form, i.e. within sections 3 through 14 below - If section is applicable please complete each section (2 through 14 below) in full and supply supporting documentation as required. RF-25-08 Rev 12 Page 6 of 31 NSAI Review Review the manufacturer’s list above and assess its validity against the proposed change(s); from this review, the extent of NSAI’s review will be determined * As noted on page 1, if compliance with 2007/47/EC is not demonstrated, certificate expiry date will be 20-Mar-10. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 7 of 31 Section 3 - Intended Use of the Device Manufacturer’s Instructions Please enter a full description of the intended use of the device, which supports the product classification: NSAI Review Ensure that the intended use of the device is clearly stated. It is the intended use that is needed to fully verify that the classification is correct. Intended use is always as defined by the manufacturer. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 8 of 31 Section 4 - Correct Classification and Appropriate Annex Manufacturer’s Instructions For MDD - Please enter the Classification of the device, along with the Rule & Rationale for the choice: Class Rule Rationale NSAI Review The classification will be based on the Manufacturer’s intended use for the device. For MDD : Review the Manufacturer’s classification rationale per Annex IX of the MDD 93/42/EEC and the device classification guidelines, MDDEV 2.4/Rev. 8. * Also ensure that any classification changes introduced by 2007/47/EC have been reviewed & implemented. Ensure that the appropriate annex is referenced based on the classification rationale For AIMDs : Ensure device falls under Directive 90/385/EEC & that the correct Annex used * As noted on page 1, if compliance with 2007/47/EC is not demonstrated, certificate expiry date will be 20-Mar-10. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 9 of 31 Section 5 - Labelling and IFU Manufacturer’s Instructions Please provide a sample of the (draft) labelling & IFU in English, and indicate below the location of these items in the File/Submission. – – – – Ensure the language requirements of the countries where the device is to be placed on the market have been fulfilled Ensure the requirements of EN 980 (Symbols for use in the labelling of Medical Devices) are adhered to. Ensure the requirements of EN 60601-1:2006 clause 7 (ME Equipment Identification, Marking and Documents are adhered to. If applicable, ensure the requirements of EN 60601-1-6 (General requirements for basic safety and essential performance - Collateral Standard: Usability) is adhered to. NSAI Review Ensure that the labelling and the IFU comply with the requirements of: Annex I Section 13 of MDD 93/42/EEC or Annex I, Sections 14 and 15 of the AIMD 90/385/EEC and if applicable EN 60601-1:2006 Clause 7 ME Equipment Identification, Marking and Documents EN 60601-1-6 Usability Engineering Process – Results Satisfactory Reviewer & date: Queries? No Yes Number(s) If Applicable: Symbols and Markings on ME Equipment/System are in accordance with Table D1 of EN 60601-1:2006 (Page 631) No Yes EN 60601-1:2006 – Accompanying Documents Satisfactory RF-25-08 Rev 12 No Yes Page 10 of 31 Section 6 - Solutions to Essential Requirements Manufacturer’s Instructions Please indicate how relevant Essential Requirements (Annex I) of the Directive are met with specific reference to the design elements associated with this application and demonstrate how the design outputs meet the design inputs through design verification and validation NSAI Review Ensure that the solutions to the Essential Requirements are completed and reference the location of the supporting documentation. Reference should also be made to the Harmonised Standards used. Ensure the manufacturer adequately demonstrates that the design outputs meet the design inputs through design verification and validation activities In particular, ensure that for products covered by the MDD, any revised requirements introduced by 2007/47/EC are met. * As noted on page 1, if compliance with 2007/47/EC is not demonstrated, certificate expiry date will be 20-Mar-10. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 11 of 31 Section 7 - Compliance with Harmonised Standards Manufacturer’s Instructions Please list the relevant Harmonised Standards and identify where compliance is demonstrated: If standards other than Harmonised Standards are used or where Harmonised Standards are not available, please rationalise their use. For MDD, see http://ec.europa.eu/enterprise/newapproach/standardization/harmstds/reflist/meddevic.html For AIMD, see http://ec.europa.eu/enterprise/newapproach/standardization/harmstds/reflist/implmedd.html Note - The 3 standards below are shown as indication only- please include all other relevant Harmonised Standards from the applicable website(s) above. Table 4 – Applicable Harmonised Standards List – Sample Harmonised Standard EN ISO 13485:2003 EN ISO 14971: 2007 EN 980:2008 Compliant – YES/NO YES YES YES Table 4 – Applicable Harmonised Standards List Harmonised Standard Compliant – YES/NO NSAI Review Verify compliance and check the current Harmonised Standards list to ensure all relevant Harmonised Standards have been included in the Essential Requirements Checklist. Review any justification if a Harmonised Standard is NOT used. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 12 of 31 Section 8 - Performance / Complaint Analysis Manufacturer’s Instructions If the change(s) relate to vigilance issue(s), please provide the Vigilance Report for the vigilance issues that triggered the change(s) and any relevant trending data. NSAI Review Review complaints vs. units placed on the market and the nature of the reportable incidents/associated corrective actions and complaint trends. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 13 of 31 Section 9 - Risk Analysis and Risk Management Manufacturer’s Instructions 1. Please provide a Risk Analysis/ Risk Management report/document/file, including a signed and dated conclusion regarding residual/remaining risks. The analysis and conclusion shall include clear reference to the proposed change(s) 2. Please confirm that the risk analysis has been carried out in compliance with EN ISO 14971:2007 Note – EN ISO 14971:2000 will be superseded by EN ISO 14971:2007 on March 31st 2010 3. If applicable, please indicate which of the multi-functional team provided the clinical input – i.e. risks associated with the clinical use of the device. 4. If applicable please clearly outline how the risks are transposed into the IFU, e.g. numerically between the Risk analysis and the IFU. NOTES – Additional information may be required for devices containing tissue of animal origin, human blood derivatives or medicinal substances: see separate section(s) – If applicable please ensure to include relevant risk analysis for ME Equipment, ME Systems & ME Software NSAI Review Ensure that the Risk Analysis/Management includes the proposed change and complies with EN ISO 14971:2007 completed by a cross-functional team, and that a signed and dated conclusion is made as to whether the remaining risks associated with the proposed change are acceptable, having regard to the intended application of the device. Check that contra-indications in the IFU originate in the risk analysis and that mitigating actions have been incorporated in the IFU if applicable. Also check that the clinical risks (actual risks involved in the use, application of the treatment or deployment of the device) have been identified by a suitably qualified person, if applicable. Determine whether or not the solutions adopted by the manufacturer conform to the safety principles, taking account of the generally accepted state of the art. Verify that the characteristics and performance are not affected during transport and storage and the device lifetime. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 14 of 31 Section 10 - Sterilisation Manufacturer’s Instructions Is the product provided sterile, or intended to be sterilised prior to use? No Yes If “Yes” - Please provide the necessary sterilisation validation protocol & report – If the changes are not subjected to a sterilisation validation, please provide adequate justification for inclusion of the changes in the current validated cycle - Please populate the following table with the necessary information: TABLE 4 – STERILIZATION INFORMATION SUMMARY Device Sub-family Catalogue Number Sterilization Method Sterilization Location Protocol / Report No. For EO Sterilization Only: Please clarify if compliance with EN ISO 10993-7:2008 is being demonstrated - Site Responsible for Release No Yes Please categorize the device according to the duration of contact, per EN ISO 10993-7:2008 / EN ISO 10993-7:1996 A – Limited Exposure B – Prolonged Exposure C – Permanent Contact Please indicate if the following sections apply: - Section 4.3.5 TCLs for surface contacting devices or implants for EN ISO 10993-7:2008 - Special Situations per EN ISO 10993-7:2008 Section 4.3.6, or EN ISO 10993-7:1996 Section 4.3.4 NSAI Review Review the sterilisation validation/revalidation protocol and report(s) to ensure compliance with EN ISO 11135-1:2007 (EtO), EN ISO 11137-1:2006, EN ISO 11137-2:2007 (Irradiation), EN ISO 13824:2004 (Aseptic Processing) or EN ISO 17665-1:2006 (Moist Heat) as appropriate. If applicable, for new model numbers, ensure that they are included in the current validated cycle. Ensure the responsibility for release of sterile product is clearly stated. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 15 of 31 Section 11 – Pre-Clinical Evaluation 11.1 Stability Testing Manufacturer’s Instructions Please define the shelf life/expiry date which is stated for the product / model / catalogue number(s)Years Device Stability For the proposed change(s), please supply the necessary device stability data (protocols & reports for accelerated aging testing, accelerated durability testing, etc) to substantiate the above shelf-life(s). Confirm start date of real time studies: Packaging Stability For the proposed change(s), please supply the necessary data (Protocols & Reports) to substantiate the stability of the product packaging, and hence the product sterility, at the proposed shelf-life(s): NOTE – additional information may be required for devices containing human blood derivatives or medicinal substances: see separate section(s) NSAI Review Review the stability data, including mechanical/device stability, accelerated durability, packaging and sterilisation stability, where appropriate. Ensure compliance to relevant Harmonised Standards, if appropriate; e.g. packaging stability - EN ISO 11607-1/-2:2006. Real time or accelerated data is acceptable; however, real time testing must be planned & should be conducted concurrently with accelerated aging. For new model numbers ensure that the substantive data has been supplied For extension of Shelf life, ensure that the real time data is planned. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 16 of 31 11.2 Biocompatibility Manufacturer’s Instructions Confirm that the devices contact the patient’s body directly or indirectly? Yes If “Yes”, please provide biocompatibility data: If biocompatibility data is required,-please confirm the categorization of the devices with respect to Body Contact: Surface-contacting devices External communicating devices Implant devices Skin Blood path, indirect Tissue/bone Mucosal membranes Tissue/bone/dentin Blood Breached/compromised surfaces Circulating blood Duration of Contact : Limited exposure (< 24hrs) Prolonged exposure (>24hrs <30 days) Permanent contact (>30 days) Has biocompatibility testing been performed on the actual devices in question to demonstrate compliance with EN ISO 10993-1:2003? No Yes If “No”, in accordance with EN ISO 10993-1:2003 clause 6, please document that the material has a demonstrable history of use in a specified role that is equivalent to that of the device in question. Please document the knowledge/experience of the individual responsible for this decision. NSAI Review Review the device biocompatibility, to ensure the device is biocompatible of its intended use. Review the data against the tests suggested by EN ISO 10993-1:2003. If no testing has been completed, ensure that the history of use has been adequately documented & is appropriate for the product family. Has an informed decision been made & documented by knowledgeable/experienced individuals weighing the advantages/disadvantages of the choices made? Confirm that the biocompatibility data supplied substantiates the proposed change(s) Reviewer & date: Queries? RF-25-08 Rev 12 No Yes Number(s) Page 17 of 31 11.3 Medical Electrical Equipment (ME Equipment) & Medical Electrical Systems (ME Systems) Definitions: ME Equipment – electrical equipment having an applied part or transferring energy to or form the PATEINT or detecting such energy transfer to or from the patient and which is: a) b) provided with not more than one connection to a particular supply mains; and intended by its manufacturer to be used: 1) in the diagnosis, treatment, or monitoring of a patient; or 2) for compensation or alleviation of disease, injury or disability ME System – combination, as specified by its manufacturer, of items of equipment, at least one of which is ME Equipment to be inter-connected by functional connection or by us of a multiple socket-outlet Manufacturer’s Instructions Is the MEdicial Device Product (i) ME Equipment (ii) ME System Yes Yes No No Have the applicable requirements of EN 60601-1:2006, including the mandatory risk assessment to EN 14971 been applied to the ME Equipment/ME System for the proposed change(s) Yes No What is the expected Service Life of the ME Equipment/ME System: Years What is the Essential Performance of the ME Equipment/ME System: Does the ME Equipment/ME System incorporate Software Yes No Do the proposed changes affect the ME Equipment/ME System Software Yes No If “Yes” – Have the requirements of EN 62304:2006, including the mandatory Risk Assessment to EN14971, been applied to the Software Development for the proposed change(s) Yes No Please clarify which of the following EN 60601-1-X Collateral Standards have been applied to validate the proposed change(s): TABLE 5 EN 60601-1-X EN 60601-1-2:2007 EN 60601-1-3:1994 EN 60601-1-6:2004 EN 60601-1-8:2007 EN 60601-1-10:2008 RF-25-08 Rev 12 Document Title Medical electrical equipment - Part 1-2: General requirements for basic safety and essential performance - Collateral standard: Electromagnetic compatibility - Requirements and tests Medical electrical equipment - Part 1-3: General requirements for basic safety and essential performance - Collateral Standard: Radiation protection in diagnostic X-ray equipment Medical electrical equipment - Part 1-6: General requirements for safety - Collateral standard: Usability Medical electrical equipment - Part 1-8: General requirements for basic safety and essential performance - Collateral Standard: General requirements, tests and guidance for alarm systems in medical electrical equipment and medical electrical systems Medical electrical equipment - Part 1-10: No Yes No Yes No Yes No Yes No Yes Page 18 of 31 General requirements for basic safety and essential performance - Collateral Standard: Requirements for the development of physiologic closed-loop controllers If applicable, please list any EN60601-2-X Particular Standards which have been applied to validate the proposed change(s): TABLE 6: EN 60601-2-X Document Title In respect of the ME Equipment/ME System, please provide each of the following as applicable: Test Report to EN 60601-1:2006 The associated Risk Management File The EN62304 Software Development Process and Validation Report, as well as the software Risk Assessment Test Reports to the applicable EN 60601-1-X Collateral Standards Test Reports to the Applicable EN 60601-2-X Particular Standards Also provide details of Labelling and Marking, as well as “Accompanying Documents”. NSAI Review Review relevant reports and risk management file to ensure compliance has been demonstrated to the harmonized standard EN 60601-1:2006 for the proposed change(s). Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 19 of 31 Section 12 – Pre-Clinical Evaluation (continued) (FOR CLASS 2B IMPLANTABLE AND CLASS 3 REVIEWS ONLY) Section 12.1 – Non-Clinical Testing (Bench Testing) Manufacturer’s Instructions For the proposed change(s): Please supply design input/output document which clearly outlines each device attribute, the design specification, location of data, etc; for example supply the Product Requirements Document (PRD), or Design Description Document (DDD) Please populate Table X with relevant information – Note when utilizing non-harmonized standards (ASTM, AAMI, internal test methods, etc) please justify applicability TABLE 7 – SAMPLE DESIGN DESCRIPTION TABLE 1 Device Attribute (Design Input) Harmonized Std Accelerated Durability – Dynamic atigue Coating Thickness ISO25539 N/A 2 Non-Harmonized Std Doc Ref (Design Input) NSAI N/A Justification: N/A RP-12345 Yes In-house Validated Method Justification: No harmonized standard or ISO/ASTM/AAMI standard available. Hence in-house method was developed and validated per internal procedures; validation reference VR-1234. STM-0234 VR-1234 Yes 3 TABLE 7 - SAMPLE DESIGN DESCRIPTION TABLE Device Attribute (Design Input) 1 2 3 4 5 6 7 8 9 10 11 Harmonized Std Non-Harmonized Std Doc Ref (Design Input) NSAI Justification: Justification: Justification: Justification: Justification: Justification: Justification: Justification: Justification: Justification: Justification: 12 RF-25-08 Rev 12 Page 20 of 31 Justification: Note – please add rows depending on number of attributes for specific device Please supply the following if applicable: o Computer modelling Reports – Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), etc o All relevant bench test Protocols and Reports which should include, but not limited to, justified test parameters per relevant standards, sample size justification, acceptance criteria, justified deviations, etc Note - Depending on type of the device of this submission, physical testing can include, but is not limited to, static and dynamic accelerated durability, bond strength, coating integrity, coating durability, corrosion, simulated use testing etc. NSAI Review Review the physical device test results to assess design inputs versus outputs versus relevant standard requirements. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 21 of 31 Section 12.2 – Clinical Testing (animal model) Manufacturer’s Instructions Please indicate if acute/chronic animal studies have been completed to substantiate the in vivo safety and/or effectiveness of the device design, including the proposed change(s) of this submission? No Yes If “No” please justify Please include all relevant animal reports associated with the device design related to this submission. Section 12.2 (a) Pre-Clinical Performance (In Vivo Acute/Long-term) Manufacturer’s Instructions If applicable to the proposed change(s): Please supply detailed information on all studies in animal models, i.e. study objectives, methodology, results analysis and conclusions including rational for selection of the model(s), which substantiate the stated intended use. NSAI Review Review the pre-clinical study results to assess the adequacy and validity of the documentation supporting the pre-clinical evaluation. Reviewer & date: Queries? No Yes Number(s) Section 12.2 (b) Acute In-Vivo Device Performance Manufacturer’s Instructions If applicable to the proposed change(s): Please provide summary data of acute in vivo device performance against pre-defined requirements, and/or clearly define location of the relevant data within each animal report NSAI Review Review the device pre-clinical study results to assess the adequacy and validity of the documentation supporting the pre-clinical evaluation. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 22 of 31 Section 13 – Clinical Performance (Human Model) Section 13.1 – Clinical Evaluation Manufacturer’s Instructions Please indicate if a clinical evaluation has been completed to substantiate the in vivo safety and/or effectiveness of the device design, including the proposed change(s) of this submission? No Yes If “No” please justify - NOTE – Revisions to the MDD 93/42/EC by 2007/47/EC have implications for the clinical data & the evaluation of the data to be provided by Manufacturers to the Notified Body, to demonstrate the clinical safety & performance of the medical device. Clinical data must always be documented for all medical device classifications. MedDev 2.7.1 (2009) provides guidance on the procedure to be adopted by the Manufacturer to evaluate clinical data. See NSAI Guidance document for further information. Please provide the necessary clinical evaluation report to support the safe use of the device NSAI Clinical Review Evaluation is in accordance with: For MDD: Annex X of MDD 93/42/EEC, ISO 14155-1 & -2, Notified Body Guidance Document NBMED/2.7/Rec 3 (Evaluation of clinical data) and MedDev 2.7.1 (2009). In cases where results have been derived from clinical investigations, the Notified Body shall ensure that the conclusions drawn by the manufacturer are valid in the light of the plan of clinical investigations submitted to the Competent Authority. Review details of the post market clinical follow-up NSAI Clinical Assessment: (Chronology of review) Date: RF-25-08 Rev 12 Page 23 of 31 Review of Clinical Evaluation # 1 Signed & dated clinical evaluation provided 2 Competence of the author justified 3 Scope of the evaluation outlined Yes No Comments Literature Review: : If not Applicable – Clinical Investigation to be reviewed. 4 Literature search protocol provided 5 Rationale for selection/relevance of published literature provided 6 Validity of data with respect to author, study design & state of the art technologies, addressed by the manufacture 7 Copies of actual papers and references provided 8 Clinical data appraisal criteria pre-defined 9 Clinical data analysis & conclusion provided, to address safety & performance of device, compliance with ERs & risk benefit analysis of device 10 Is the pre-clinical with clinical data sufficient to demonstrate compliance with ERs (safety & performance under normal conditions of use) 11 Are gaps identified in demonstration of compliance with ERs 12 Are gaps identified in demonstration of equivalence 13 Are labelling claims substantiated by the clinical data together with the pre-clinical data provided 14 Are the manufacturer’s conclusions valid Conclusion: Internal & External Assessors: Signature: Date: RF-25-08 Rev 12 Page 24 of 31 Section 13.2 – Acute In-Vivo Device Performance Manufacturer’s Instructions If applicable to the proposed change(s): Please provide summary data of acute in vivo device performance against pre-defined endpoints, and/or clearly define location of the relevant data within clinical evaluation report NSAI Review Review the device pre-clinical study results to assess the adequacy and validity of the documentation supporting the pre-clinical evaluation. Reviewer & date: Queries? RF-25-08 Rev 12 No Yes Number(s) Page 25 of 31 Section 14 – Design Dossier – Design Verification & Validation (MDD Annex II Class III or AIMD Annex II only) NSAI Review Briefly state the outcome of the review against: 1. The Essential Requirements 2. The safety and efficacy of the device as demonstrated by the Risk Analysis 3. The clinical safety of the device 4. Design outputs shall meet the input requirements for design and development. Verify that the laboratory results obtained and the conclusions made are applicable to the design specifications and performances claimed. 5. Design validation demonstrates that the product is capable of meeting the requirements for its intended use. Verify that the validation programme and the results obtained are consistent with all the claimed properties and the/or intended uses and conform to the applicable essential requirements. Reviewer & date: Queries? No RF-25-08 Rev 12 Yes Number(s) Page 26 of 31 Additional Information Manufacturer’s Instructions Please use this section to document any additional information not already covered: NSAI Review Review (if applicable). Reviewer & date: Queries? No Yes Number(s) ----------------------------------------------------------------------------- NOTE: Please indicate which, if any, of the following appendices apply to this submission. Please complete the relevant appendix. TABLE 8 – APPLICABLE APPENDICES Appendix Directive Description Devices containing Tissue of Animal Origin A 2003/32/EC B 2000/70/EC Devices containing Human Blood Derivative(s) C 2001/83/EC Devices containing Medicinal Substance Applicable Yes No Yes No Yes No ----------------------------------------------------------------------------- RF-25-08 Rev 12 Page 27 of 31 NSAI Queries Company Query #1 - Company Response: Response Disposition: Company Query #2 - Company Response: Response Disposition: Company Query #3 - Company Response: Response Disposition: Company Query #4 - Company Response: Response Disposition: Company Query #5 - Company Response: Response Disposition: Company Query #6 - Company Response: Response Disposition: RF-25-08 Rev 12 Page 28 of 31 Company Query #7 - Company Response: Response Disposition: Company Query #8 - Company Response: Response Disposition: Company Query #9 - Company Response: Response Disposition: Company Query #10 - Company Response: Response Disposition: Company Query #11 - Company Response: Response Disposition: Company Query #12 - Company Response: RF-25-08 Rev 12 Page 29 of 31 Response Disposition: Company Query #13 - Company Response: Response Disposition: Company Query #14 - Company Response: Response Disposition: Query RF-25-08 Rev 12 Disposition Date Page 30 of 31 Conclusion of Assessment NOTIFIED BODY STATEMENT Conclusion: File Manager: Expert Opinion by: Biomechanical Review by: Electrical Review by: Clinical Review by: TSE Expert Review by: Outcome of Competent Authority Review (where applicable) Date : Date : Date : Date : Date : Date : Approval FOR SUBSTANTIAL CHANGES ONLY – PRESENTED TO THE TECHNICAL REVIEW COMMITTEE ON: Outcome of Meeting : Follow Up required : Approval demonstrated by signed Approval Amendment Record. Competent Authority Notified of Notified Body Decision (Devices incorporating Medicinal Substances/Human Blood Derivatives only) The decision of the NSAI to grant approval / not to grant approval of the file has been communicated to the Competent Authority: Personnel in C.A. Notified of decision: Date of Notification: Notification performed by: If the NSAI decided to grant approval of the file despite the receipt of a negative opinion from the Competent Authority please enter the justification for this decision: RF-25-08 Rev 12 Page 31 of 31 APPENDIX A Medical Devices incorporating tissues of animal origin, covered by the TSE Directive 2003/32/EC only Manufacturer’s Instructions Please complete the table below: Appendix 1 Table 5 Starting tissue used Species Used Geographical sourcing Veterinary controls Feeding restrictions Evidence of compliance with regulation 1774 (where the raw material or intermediates are imported or processed in the EU) GBR rating of tissue Details of collagen, tallow or gelatine used. Details of source establishments Scope of Site(s): EDQM Certificate (Yes / No) #: Expiry Date : (please supply copy) Note – NSAI Certificate will not exceed the expiration date of the EDQM certificate If no valid EDQM Certificate held, please supply: Details of harvesting of the animal tissue Viral inactivation steps Viral clearance validation Source establishments Copy of compliance to Regulations 1744 Details of the source of tissue - geographical location, open/closed herds, feeds, pre and post mortem inspection. NSAI Review Review the information provided, and verify the suitability of the scope of the site(s). Based on the presence/absence & content of the EDQM Certificate, is C.A. Distribution required? No Yes Reviewer & date: Queries? No RF-25-16 Rev. 10 Yes Number(s) Appendix A - TSE ONLY Page 1 of 3 TSE ONLY Rationale on justification Manufacturer’s Instructions Please provide a detailed rational on the use of the use of the animal tissue in the specific application, comparing the device with materials sourced from other animals, or made with alternative non-animal derived material and the expected clinical benefit. NSAI Review Review the data supplied. Reviewer & date: Queries? No Yes Number(s) Auditing Source Establishments Manufacturer’s Instructions Please information on the auditing of source establishments &/or third party supplier for the animal material used by the medical device manufacturer including details of feeding restrictions: NSAI Review Review the data supplied. Reviewer & date: Queries? No Yes Number(s) Harvesting and viral inactivation of the animal tissue Manufacturer’s Instructions Please provide details on the harvesting of the animal tissue and relevant viral inactivation steps performed on the animal tissue prior to its incorporation into the device. The viral clearance validation study of the animal tissue, protocol and report, should also be supplied – conformity to EN ISO 22442-1, -2, & -3 must be demonstrated: NSAI Review Review the data supplied, and ensure compliance with EN ISO 22442-1, -2 & -3:2007 Reviewer & date: Queries? No RF-25-16 Rev. 10 Yes Number(s) Appendix A - TSE ONLY Page 2 of 3 Description of production steps Manufacturer’s Instructions Please provide details of all production steps in which the animal tissue is present including a description of the key elements adopted to minimise the risk of infection: NSAI Review Review the data supplied. Reviewer & date: Queries? No Yes Number(s) Summary Evaluation Report NSAI Review RF-25-12 completed: . No Yes (Draft Summary Evaluation Report on the Assessment of a Medical Device by the Notified Body for conformity with Council Directive 93/42/EEC and Commission Directive 2003/32/EC) RF-25-13 completed: . No Yes (Final Summary Evaluation Report on the Assessment of a Medical Device by the Notified Body for conformity with Council Directive 93/42/EEC and Commission Directive 2003/32/EC) Comments: Reviewer & date: Queries? No RF-25-16 Rev. 10 Yes Number(s) Appendix A - TSE ONLY Page 3 of 3 Appendix B Medical Devices incorporating Human Blood Derivative only Manufacturer’s Instructions Please compile the technical dossiers in the volumes detailed below: Volume 1: Completed EMEA application form (Doc. Ref. EMEA/CHMP/434094/2005) Volume 2: Product Information and Labelling Volume 3: Appendix II (ref Doc. Ref. EMEA/CHMP/401993/2005) Volume 4: Quality Summary of the ancillary medicinal substance as integrated into the medical device in accordance with MEDDEV 2.1/3 rev 2, section B2, a – q. Volume 5: Quality Summary of the ancillary medicinal substance in accordance with Module 2.3 of Volume 2B, CTD of the Notice to Applicants (Eudralex). Volume 6: Tabular summaries for non-clinical and clinical studies. Volume 7: Quality, non-clinical and clinical documentation in accordance with MEDDEV 2.1/3 rev 2 for the ancillary medicinal substance as integrated into the medical device section B2, a – q. Volume 8: Relevant parts of Module 3 of Volume 2B, CTD of the Notice to Applicants for the ancillary medicinal substance and a copy of the latest PMF annual update. NOTE - Please be advised that following review of the application by the NSAI, amendments may be requested to the technical dossiers prior to their submission to the EMEA. The number of hard and soft copies of the technical dossiers required by the EMEA will vary depending on the appointed Rapporteurs, it is the responsibility of the Medical Device Manufacturer to prepare these as directed by the NSAI. Please complete the table below: Table 6 Derivative(s) Supplier: Supplier Address: Test laboratory used: Laboratory Address: Laboratory Approvals: Contract company used for bioavailability or bioequivalence trails Contact person in the EEA for product recall and defects Approval Certs for above sites: EMEA Scientific Opinion: RF-25-16 Rev.10 Appendix B – Human Blood ONLY Page 1 of 8 NSAI Review Review the information provided, and in particular ensure that the laboratory is an approved facility for the testing and batch release of Blood Derivatives in accordance with Annex III of EC Administrative Procedure for OCABR (EDQM). Based on the presence/absence & content of the EDQM Certificate, is C.A. Distribution required? No Yes Reviewer & date: Queries? No Yes Number(s) Details of human blood derivative(s) used Manufacturer’s Instructions Please provide a detailed description of derivative. The quantities of product derived from human blood should be expressed by mass or international units of biological activity appropriate to the product concerned. Does the Human Blood Derivative has a Ph. Eur. Certificate of Suitability? No Yes If so, please supply a letter of access to the related Drug Master File or a copy of the Ph. Eur. Certificate of Suitability for the component. Please supply PMF Master Files certificates for the human blood derivative (this should include the original certificate and the latest annual up-date) NSAI Review Review the information provided on the qualitative & quantitative composition of the material. Review the Certificate(s) supplied Reviewer & date: Queries? No Yes Number(s) Justification for use of human blood derivatives Manufacturer’s Instructions Please provide an in-dept rational justifying the use of tissue in specific application, including a comparison with materials sourced from non-human derivatives, and expected clinical benefit. RF-25-16 Rev.10 Appendix B – Human Blood ONLY Page 2 of 8 NSAI Review Review the rationale/justification provided. Clinical Review Reviewer & date: Queries? No Yes Number(s) Verification of Usefulness of Device Manufacturer’s Instructions In addition to the justification above, please provide a review of currently available devices & technologies, confirming medical necessity based on an expert clinician recommendation & review: NSAI Review Clinical Review of the information provided. Reviewer & date: Queries? No Yes Number(s) Human Blood Derivative Manufacture Manufacturer’s Instructions Please supply: A copy of the Manufacturing Authorisation for the Ancillary Medicinal Substance containing Human Blood Derivatives. A statement from the Competent Authority which carried out the inspection of the Human Blood Derivative manufacturing sites. Written confirmation from the manufacturer of the ancillary active substance that the applicant will be informed in the case of any modification of the manufacturing process or specifications. Written confirmation from the manufacturer of the human blood derivative to inform the medical device manufacturer in the case of any modifications to the PMF. Written confirmation from the manufacturer of the human blood derivative to complete look back procedures in the event of product recalls. NSAI Review Review the information provided. Reviewer & date: Queries? No RF-25-16 Rev.10 Yes Number(s) Appendix B – Human Blood ONLY Page 3 of 8 Human Blood Derivative Supplier(s), Collection and Controls Manufacturer’s Instructions Please complete the table below: Table 7 Details on the control of suppliers Source of blood/donor control Nature of donation – pooled or single donation Details on the collection of source materials NSAI Review Review the information provided. Reviewer & date: Queries? No Yes Number(s) Derivative Manufacturing steps Manufacturer’s Instructions Please outline the derivative manufacturing steps: NSAI Review Does the information provided demonstrate the ability to guarantee batch-to-batch consistency & absence of viral contamination, to the extent that the state of technology permits? Reviewer & date: Queries? No Yes Number(s) Inactivation steps Manufacturer’s Instructions Please document the production steps used to minimise risk of infection and provide the necessary viral clearance validation studies: RF-25-16 Rev.10 Appendix B – Human Blood ONLY Page 4 of 8 NSAI Review Have the production steps used to minimise the risk of infection been adequately validated? Does the data demonstrate the suitability of the inactivation steps taken to minimise the risk of infection? Reviewer & date: Queries? No Yes Number(s) Laboratory Test Details - derivative Manufacturer’s Instructions Please provide details of the laboratory tests and also provide the necessary validation(s): NSAI Review Review the adequacy of the tests & technology used. Have tests been adequately validated? Does the technology represent ‘State of the Art’? Reviewer & date: Queries? No Yes Number(s) Quality Control of derivative Manufacturer’s Instructions Please provide details of the in-process & final test procedures: NSAI Review Review the adequacy of the test procedures Reviewer & date: Queries? No Yes Number(s) Procedures for batch release of derivative Manufacturer’s Instructions Please provide details of the batch release procedures for derivative(s): RF-25-16 Rev.10 Appendix B – Human Blood ONLY Page 5 of 8 NSAI Review Review the adequacy of the procedures Reviewer & date: Queries? No Yes Number(s) Derivative Storage & Stability (in addition to the Device stability covered previously) Manufacturer’s Instructions Please confirm the shelf life of the derivative: Please provide details of the storage & transport requirements along with stability studies and validation for the derivative: NSAI Review Review the adequacy of the data Reviewer & date: Queries? No Yes Number(s) Device Manufacturing Steps Manufacturer’s Instructions Please provide details of the manufacturing steps & any relevant procedures for the device using derivativeIs) along with the relevant validation of the effect on quality & viral safety on the finished device: NSAI Review Review the adequacy of the data & validation(s) provided. Reviewer & date: Queries? No Yes Number(s) Device Testing & Quality Control Manufacturer’s Instructions Please provide details of the device in-process and final test(s) & any relevant procedures: RF-25-16 Rev.10 Appendix B – Human Blood ONLY Page 6 of 8 NSAI Review Review the adequacy of the tests, in particular regarding the safety of the device. Reviewer & date: Queries? No Yes Number(s) Device Batch Release Manufacturer’s Instructions Please provide copies of the batch release procedures for finished devices: NSAI Review Review the procedures to ensure that responsibilities & authorities are adequately defined, and that the system requires batch release notification to be sent to NSAI. Reviewer & date: Queries? No Yes Number(s) Packaging components Manufacturer’s Instructions Please provide details of the packaging components including a description from which the material is constructed using current standard terms – European Pharmacopeia where applicable: NSAI Review Review the data supplied to ensure that the description includes the following details – package size, proposed shelf life (unopened and in use), & proposed storage conditions. Reviewer & date: Queries? No Yes Number(s) Previous Existing Legislation - additional Manufacturer’s Instructions Please provide details of the applications for the same derivative both in and out of the EEA including those which are authorised, pending and refused. If the device does have other applications for the same derivative please provide details of the country, the trade name, date of submission/suspension and the reason for suspension where appropriate: RF-25-16 Rev.10 Appendix B – Human Blood ONLY Page 7 of 8 NSAI Review Review the Marketing Authorisations or Device approval in the EEA. Ensure that the following details are included; the authorisation/approval number, the date of authorisation/approval Reviewer & date: Queries? No Yes Number(s) Risk analysis - additional NSAI Review Ensure that the risk analysis includes a statement of acceptability of residual risks in view of the clinical use and benefits of the device in comparison to other existing devices with similar intended use. It should comprise of a qualitative or quantitative estimate of the risk arising from the use of the product, taking into account the likelihood of contamination of the product, the nature & duration of patient exposure, and the route of administration. Reviewer & date: Queries? No Yes Number(s) Labelling and IFU - additional NSAI Review Ensure that the labelling & IFU include a statement indicating that the device incorporates human blood derivative, as per E.R. 13.3(n) & 13.6(a) of 93/42/EEC Reviewer & date: Queries? No RF-25-16 Rev.10 Yes Number(s) Appendix B – Human Blood ONLY Page 8 of 8 Appendix C Medical Devices incorporating Medicinal Substance only Manufacturer’s Instructions Please provide a dossier detailing the medicinal substance prepared in compliance with MEDDEV 2.1.3 section B3 (A-Q). Please complete the table below: Table 7 Name of Medicinal Substance Medicinal substance supplier Function of Medicinal Substance within medical device EDQM Certificate for Medicinal Substance (Yes / No) Note – NSAI Certificate will not exceed the expiration date of the EDQM certificate If no EDQM certificate is available, please supply the drug master file for the medicinal substance NSAI Review Is the dossier provided complete, as required by MEDDEV 2.1.3 Section B3 (A-Q)? If an EDQM cert. is supplied, is it valid for the medicinal substance? Reviewer & date: Queries? No Yes Number(s) Qualitative and quantitative particulars of the constituents Manufacturer’s Instructions Please provide a description of the substance and the amount (giving a range where appropriate) of the medicinal substance incorporated into each medical device. If the substance is modified during its incorporation into the device, please provide relevant information: NSAI Review Is the data provided sufficient? Reviewer & date: Queries? No RF-25-16 Rev.10 Yes Number(s) Appendix C – Medicinal Substances ONLY Page 1 of 6 Description of method of manufacture Manufacturer’s Instructions In addition to the overall description supplied, please provide details of the incorporation of the medicinal substance into each medical device. If the medicinal substance is altered in any way prior to its inclusion into the device, please provide relevant information: NSAI Review Is the data provided sufficient? Reviewer & date: Queries? No Yes Number(s) Control of starting materials Manufacturer’s Instructions Please provide the specification for the medicinal substance. Where applicable, reference shall be to the European Pharmacopoeia or in the absence of an EP monograph to a national pharmacopoeia of one of the Member States. If no monograph is available from the Member States reference may be to other national monographs or to the manufacturer's specification and methods of analysis. For new active substances and certain known substances additional information will be required which may be provided in the form of a Drug Master File. The guideline "Requirements in relation to active substances"(1) may be of assistance in providing circumstances where reference to a Pharmacopoeia monograph may need to be supplemented by further information: NSAI Review Does the specification for the medicinal substance reference the EP? If not, is a National Pharmacopeia from one of the EU Member States used? If not, what is used? Is a Drug Master File required and supplied? Reviewer & date: Queries? No Yes Number(s) Control of tests carried out at intermediate stages of the manufacturing process of the medical device Manufacturer’s Instructions If necessary, please supply information regarding the control of tests carried out at intermediate stages of the manufacturing process. RF-25-16 Rev.10 Appendix C – Medicinal Substances ONLY Page 2 of 6 NSAI Review This information is only necessary if it is directly relevant to the quality of the substance as incorporated in the medical device Reviewer & date: Queries? No Yes Number(s) Control tests on finished product Manufacturer’s Instructions Please supply details of the qualitative and quantitative tests carried out to control the medicinal substance in the device. NSAI Review Are adequate controls in place? Reviewer & date: Queries? No Yes Number(s) Toxicity Manufacturer’s Instructions Please provide reference to the known toxicological profile of the medicinal substance. In the case of new active substances, the results of the toxicity tests should be supplied NSAI Review Review the toxicological profile provided. This may include information on toxicity and biocompatibility of the medical device which may be available from evaluation in accordance with the EN ISO 10993 series of standards. Reviewer & date: Queries? No Yes Number(s) Reproductive Function Manufacturer’s Instructions Please provide reference to the known profile in relation to reproductive function, of the medicinal substance. In the case of new active substances, the results of the appropriate tests should be supplied RF-25-16 Rev.10 Appendix C – Medicinal Substances ONLY Page 3 of 6 NSAI Review Review the profile provided, similar conditions to Toxicity apply. Reviewer & date: Queries? No Yes Number(s) Embryo/foetal and perinatal Toxicity Manufacturer’s Instructions Please provide reference to the known embryo/foetal & perinatal toxicological profile of the medicinal substance. In the case of new active substances, the results of the toxicity tests should be supplied NSAI Review Review the profile provided, similar conditions to Toxicity apply. Reviewer & date: Queries? No Yes Number(s) Mutagenic Potential Manufacturer’s Instructions Please provide reference to the known mutagenic potential of the medicinal substance. In the case of new active substances, the results of the relevant tests should be supplied NSAI Review Review the profile provided, similar conditions to Toxicity apply. Reviewer & date: Queries? No Yes Number(s) Carcinogenicity Potential Manufacturer’s Instructions Please provide data on the carcinogenicity potential of the medicinal substance. RF-25-16 Rev.10 Appendix C – Medicinal Substances ONLY Page 4 of 6 NSAI Review The need for data on carcinogenicity should be addressed taking account of available information on the medicinal substance, the results of genotoxicity testing, the chemical structure of the medicinal substance, and the duration of potential exposure to the substance. Reviewer & date: Queries? No Yes Number(s) Pharmacodynamics Manufacturer’s Instructions Please provide information on the intended action of the medicinal substance in the context of its incorporation into a medical device. NSAI Review Review the data provided to ensure that this addresses the intended action of the medicinal substance in the context of its incorporation into a medical device. Reviewer & date: Queries? No Yes Number(s) Pharmacokinetics Manufacturer’s Instructions Please provide details on the pharmacokinetics – addressing some or all of the points below as appropriate: description of the pattern of local and systemic exposure to the medicinal substance, where the level of exposure fluctuates, the maximum level and duration of exposure should be considered, where it is considered possible that potential levels of systemic exposure may present a safety concern, maximum peak plasma concentration should be established, taking due consideration of individual variability, new active substances will require information on the release from the device, and, if relevant, its subsequent distribution and elimination. NSAI Review It is anticipated that pharmacokinetic studies will not be required in the majority of cases. Have the areas above been addressed as appropriate? Reviewer & date: Queries? No RF-25-16 Rev.10 Yes Number(s) Appendix C – Medicinal Substances ONLY Page 5 of 6 Local tolerance Manufacturer’s Instructions Please provide details on the local tolerance of the medicinal substance. NSAI Review This is of particular relevance since the route of exposure to the medicinal substance may be different from its conventional application. The relevant results of device testing according to EN ISO 10993 should be provided, or, where appropriate, information from the scientific literature. Reviewer & date: Queries? No Yes Number(s) Risk Analysis - additional NSAI Review Review the risk analysis supplied to ensure that it includes a critical appraisal of the safety of the drug/device combination. Reviewer & date: Queries? No Yes Number(s) Stability – additional NSAI Review Review the stability data supplied to ensure it shows that the medicinal substance maintains its desired function throughout the defined shelf-life of the device, taking account of the manufacturer’s recommended storage conditions. Reviewer & date: Queries? No Yes Number(s) Competent Authority Review NSAI Review Details of Consulting Competent Authority: Date consultation sought: Summary of Competent Authority Opinion: RF-25-16 Rev.10 Date opinion received: Appendix C – Medicinal Substances ONLY Page 6 of 6