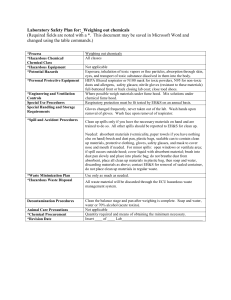

Silver Nitrate - University of South Florida

advertisement

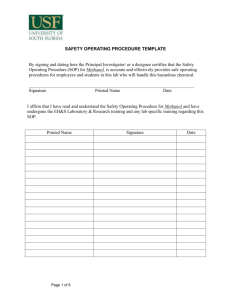

SAFETY OPERATING PROCEDURE TEMPLATE By signing and dating here the Principal Investigator/ or a designee certifies that the Safety Operating Procedure (SOP) for Silver Nitrate is accurate and effectively provides safe operating procedures for employees and students in this lab who will handle this hazardous chemical. _________________________________________________________________________ Signature Printed Name Date I affirm that I have read and understand the Safety Operating Procedure for Silver Nitrate and have undergone the EH&S Laboratory & Research training and any lab specific training regarding this SOP. Printed Name Page 1 of 6 Signature Date CONTACT INFORMATION: Silver Nitrate Chemical Name: Building/Room Number: Date of Creation/Revision 8/2/2012 Principal Investigator: Emergency Phone number: HAZARD SUMMARY Potential physical and health hazards associated with the use of this chemical include: Inhalation: May be harmful if inhaled. Material is extremely destructive to the tissue of the mucous membranes and upper respiratory tract. Skin: Harmful if absorbed through skin. Causes skin burns. Eyes: Causes eye burns Ingestion: Harmful if swallowed Very toxic to aquatic life. SPECIAL HANDLING AND STORAGE REQUIREMENTS Describe special handling and storage requirements for this hazardous chemical in your laboratory, i.e. restricted access to chemical, inclusion of designated areas to limit and minimize possible sources of exposure to these materials. The entire laboratory, a portion of the laboratory, or a laboratory fume hood or bench may be considered a designated area. Special handling and storage requirements for this chemical include: Handling: Avoid contact with skin and eyes. Avoid formation of dust and aerosols. Provide appropriate exhaust ventilation at places where dust is formed. Keep away from sources of ignition – no smoking. Keep away from heat and sources of ignition. Storage: Keep container tightly closed in a dry and well-ventilated place. Light sensitive. ENGINEERING AND VENTILATION CONTROLS Page 2 of 6 Include requirements for specific engineering/ventilation controls for this specific chemical, i.e. fume hood. If the process does not permit the handling of such materials in a fume hood, the lab personnel should contact Environmental Health and Safety at x4-4036 for review the adequacy of ventilation measures. Handling processes should be designed to minimize the potential for splash, splatter, or other likely scenarios for accidental contact. The handling of this chemical must be conducted in a fume hood. Additional engineering/ventilation controls for the handling of this chemical include: Adequate exhaust ventilation. Keep away from sources of ignition. Keep it in a well-ventilated place. Use components with workplace control parameters 0.01 mg/m3 TWA PERSONAL PROTECTIVE EQUIPMENT Include specific personal protective equipment required for the handling of this chemical. See the following references: 1. The USF Hazardous Inventory Tracking System (HITS) provides access to MSDS. 2. A glove compatibility chart provides specific information on the type of safety gloves that should be used based on the hazards of specific chemicals. 3. The following EH&S webpage provides links to glove manufacturers as well as other PPE selection resources, http://usfweb2.usf.edu/eh&s/labsafety/links.html. At minimum, safety glasses, lab coat, and gloves are to be worn when using this hazardous chemical. Additional PPE Requirements for the handling of this chemical include: appropriate clothing (long pants, close-toed shoes) gloves; indicate type:______________________________ safety goggles □ face shield □ flame-resistant lab coats □ other:__________________________ If the use of an N95, half mask, or full face respirator is requested, the individual and/or their supervisor must first contact Environmental Health & Safety for a consultation to determine if respirator use is necessary. If EH&S determines the use of a respirator is necessary, the individual must participate in the University’s respirator program. This includes a medical evaluation; respirator fit test, and training. At minimum, safety glasses, lab coat, long pants, and closed toed shoes are to be worn when entering lab having dangerous chemicals. Respiratory protection: where risk assessment shows air-purifying respirators are appropriate use a fullface particle respirator type N100 (US) or type P3 (EN 143) respirator cartridges as a backup to engineering controls. If the respirator is the sole means of protection, use a full-face supplied air respirator. Hand protection: handle with gloves. Gloves must be inspected before use. Remove the gloves without touching the glove’s outer surface to avoid skin contact with this product. Dispose of contaminated gloves after use as per applicable laws and good lab practices. Wash and dry hands. Eye protection: face shield and safety goggles Skin and body protection: complete suit protecting against chemicals. Hygiene measures: handle in accordance with good industrial hygiene and safety practice. Wash Page 3 of 6 hands before breaks and at the end of workday. EMERGENCY PROCEDURES If a there is a spill involving an extremely hazardous chemical, emergency responders should be contacted immediately. Dial 911 during and after normal business hours to contact the local emergency responders for your area and provide detail information to the emergency responders including chemical name, volume, hazards, spill location, and any injuries incurred. Building occupants can be notified of a building evacuation through the activation of a fire alarm pull station. Personnel: If lab personnel are exposed to an extremely hazardous chemical, call 911 immediately. Remove any contaminated clothing, and IMMEDIATELY flush contaminated skin with water for at least 15 minutes following any skin contact. For eye exposures, IMMEDIATELY flush eyes with water for at least 15 minutes. Consult MSDS for guidance on appropriate first aid. Where medical attention is required, ensure to bring along MSDS(s) of chemical(s) to aid medical staff in proper diagnosis and treatment. Fire and Emergency Evacuation Procedures: In case of fire or emergency situation, call 911 and or use emergency blue phone immediately to notify the fire emergency services and campus police. Immediately evacuate the building via the nearest exit when the fire alarm is activated. If unable to evacuate due to a disability, shelter in the area of rescue / refuge, typically a stairwell landing, and wait for assistance from drill volunteers or emergency responders. Instruct visitors and students to evacuate and assist them in locating the nearest exit. Do not use elevators to exit the building during an evacuation as they may become inoperable. Carry only those personal belongings that are within the immediate vicinity. Close doors to limit the potential spread of smoke and fire. Terminate all hazardous operations and power off equipment. Close all hazardous materials containers. Remain outside of the building until the building is released for reentry. Do not restrict or impede the evacuation. Convene in the designated grassy gathering area and await instruction from emergency responders or drill volunteers. Avoid parking lots. Report fire alarm deficiencies, (e.g., trouble hearing the alarm) to facilities personnel for repair. Notify evacuation drill volunteers or emergency responders of persons sheltering in the areas of rescue/ refuge. Never assume that an alarm is a “false alarm”. Treat all fire alarm activations as emergencies. Get out of the building! Use personal protection equipment. Avoid dust formation. Avoid breathing vapors, mist or gas. Ensure adequate ventilation. Evacuate personnel to safe areas. Avoid breathing dust. Prevent further leakage or spillage if safe to do so. Do not let product enter drains. Avoid discharging into the environment. For containment and cleaning up, sweep up and shovel. Contain spillage and then collect with an electrically protected brushing and place in container for disposal according to local regulations. Keep in suitable, closed containers for disp General advice: consult a physician. Show this MSDS to the doctor. Move out of dangerous area. If breathed in, move person into fresh air. If not breathing, give artificial respiration and consult a physician. In case of skin contact, take off contaminated clothing and shoes immediately. Wash off with soap and plenty of water. Consult a physician. Page 4 of 6 In case of eye contact, rinse thoroughly with plenty of water for at least 15 min and consult a physician. Continue rinsing eyes during transport to hospital. If swallowed, do not induce vomiting. Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician. The Laboratory/Studio and Field Incident Report form is to be completed by the Lab Manager/Teaching Assistant/Instructor for any incident that occurs in any University of South Florida affiliated teaching or research laboratory/studio or field research project. An incident means any unplanned event within the scope of a procedure that causes, or has the potential to cause, an injury or illness and/or damage to equipment, buildings, or the natural environment. Please fill out the online Laboratory/Studio and Field Incident Report form below and submit to Environmental Health & Safety within 24 hours of the incident. Due to medical privacy concerns, no personal identifying information of the person involved in the incident shall be entered or submitted with the form. http://usfweb2.usf.edu/eh&s/labsafety/LabIncident.html WASTE DISPOSAL All chemical waste generated within USF System laboratories are considered hazardous waste and must be disposed of as hazardous waste in accordance with USF Hazardous Waste Management Procedure, the EPA, and the DEP. The USF Hazardous Waste Management Procedure can be found using the following link, http://compass.custhelp.com/app/answers/detail/a_id/1118/kw/hazardous%20waste. Product: burn in a chemical incinerator equipped with an afterburner and scrubber but exert extra care in igniting, as this material is highly flammable. Offer surplus and non-recyclable solutions to a licensed disposal company. Contact a professional waste disposal service to dispose of the material. Dissolve or mix with a combustible solvent and burn in a chemical incinerator equipped with an afterburner and scrubber. Contaminated packaging: dispose of as unused product. TRAINING REQUIREMENTS All individuals working with chemicals in USF laboratories must take EH&S’s Laboratory & Research Safety Training. To register for Laboratory & Research Training, please use the following link, http://usfweb2.usf.edu/eh&s/labsafety/tmaterials.html. However, the use of this chemical may warrant additional safety training per the PI, EH&S, or an authorizing unit such as the Biosafety or Radiation Safety programs. Additional training requirements are listed below. Training Requirements: Laboratory & Research Safety Training (EH&S) Research-specific Training (PI) □ Other _____________________________________________________________ Page 5 of 6 PRIOR APPROVALS □ The handling of this chemical requires prior approval from the PI/designee. The handling of this chemical does not require prior approval from the PI/designee. Approval Signature (if required by PI) _________________________________________________________ Page 6 of 6