Text for FP and LN

advertisement

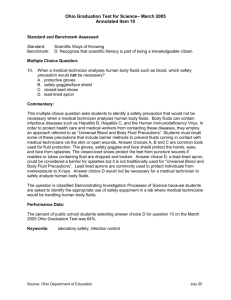

Text for FP and LN. SS04 Going With the Flow 5 10 15 20 THESE days everything seems to be getting smarter. So-called “smart materials” include shapememory alloys, which change shape according to the temperature, and piezoelectric materials that mechanically deform when an electric field is applied. These materials are said to be smart because they can be used to sense and respond to the environment. But smart materials are not limited to solids; liquids, it turns out, can be smart too. Such “smart fluids” are now finding their way into all sorts of devices, from cars to bridges to digital cameras. The term “smart fluid” is generally applied to fluids whose properties can be changed by the application of an electrical or magnetic field. In particular, there are electro-rheological (ER) and magneto-rheological (MR) fluids that can change, in an instant, from free-flowing liquids to become more viscous, or even solid. ER fluids consist of tiny dielectric particles dispersed in an insulating fluid such as silicon oil, while MR fluids use magnetisable particles suspended in a non-magnetisable carrier liquid. Normally, the particles are randomly aligned. But when a field is applied, they line up with it, forming long chains that make the liquid more viscous. The process is reversible: once the field is removed, the fluid flows freely again. And by varying the field, the fluid's viscosity can be carefully controlled. For more than half a century, smart fluids have been little more than a laboratory curiosity. But gradual improvements in their properties—the development, for example, of additives that prevent suspended particles from clumping or settling—and recent advances in the systems used to control them have led to the first commercial applications. Magnetic attraction 25 30 35 40 45 50 MR fluids are the most widely used kind of smart fluid. They can resist large forces more efficiently than ER fluids, since they require less energy to change their properties. The world leader in the commercial development of MR-fluid technology is Lord Corporation, of Cary, North Carolina, a private firm with an interest in vibration and motion control. Its first commercial success came in 1997, using MR fluids to dampen vibration for drivers of 18-wheel trucks. Then Lord, along with Delphi Corporation, of Troy, Michigan, a former subsidiary of General Motors and a big supplier of car parts, applied MR fluids to car suspension. The result, called MagneRide, first appeared on Cadillac's Seville models and is now standard equipment on its XLR convertible roadster, and an option on some other models. Sensors monitor the profile of the road surface and provide a permanent stream of information as to what damping is necessary. An electromagnetic coil inside the piston of the damper creates a magnetic field that adjusts the viscosity of the fluid up to provide continuously variable damping. Unlike traditional suspension, the system has no electromechanical valves or small moving parts that wear out, and provides particularly good control at low frequencies. The industry also claims it offers a smoother ride and improves road-holding. The only problem is its high price. About 100,000 cars with MagneRide suspension have been sold since production started in 2002, says David Hoptry of Delphi. So far only General Motors is using the technology, and only in luxury, high-end sports and specialist vehicles. But as the price of the technology falls it will, he predicts, spread into cheaper cars too. Ford, another carmaker, is researching other applications of MR fluids. It thinks they will be useful one day in automotive suspension, but that they are still too expensive. Instead, Ford is concentrating on their use in automatic clutches. Prototype designs being studied at Ford's Scientific Research Laboratories are extremely quiet compared with mechanical clutches, and can engage gradually by slowly increasing the strength of the magnetic field. This reduces noise and means the car pulls away smoothly. Ford is also examining the use of smart fluids to make quieter air-conditioning compressors. Steady improvements in the technologies used to control smart fluids, such as microprocessors and sensors, are opening up a diverse range of new markets. Lord, for example, has figured out how to use MR fluids to reduce vibration in washing machines. Its system works well; again, the barrier to adoption is cost. MR fluids are also appearing in much larger structures. Japan's National Museum of Emerging Science and Innovation, in Tokyo, has installed seismic-scale MR-fluid dampers developed by Lord. They are integrated with the building's structure and are designed to act as huge shock absorbers in the event of an earthquake, soaking up energy and protecting the building from damage. 55 60 65 70 75 80 Large MR-fluid dampers are also being put into bridges, such as the Dong Ting Lake Bridge in China's Hunan province, to steady it in high winds. Meanwhile, CSA Engineering of Albuquerque, New Mexico, has developed a damping system based on MR fluids to suppress vibration during rocket launches, which can damage satellites. MR fluids have also been suggested as a way to reduce vibration in surveillance satellites. Another military use is being explored at the Massachusetts Institute of Technology: the idea is to create a fluid-filled uniform that is flexible and comfortable to wear in normal conditions, but that can instantly be made much more resistant—and ultimately bullet-proof. The development of ER fluids has been much slower, since they require large amounts of energy to keep them in a viscous or solid state. But there have been some recent and significant scientific developments in this area, so it may only be a matter of time before ER fluids begin appearing in commercial products too. For if the energy-consumption problem can be overcome, they have advantages over MR fluids. They do not need bulky magnets to be activated and can, instead, rely on only a couple of electrodes. In particular, they might find applications in “haptic” (touch-based) systems. One idea is to use ER fluids to develop Braille readers and writers. Another is to use them as dampers in prosthetic devices. Existing haptic devices rely on MR fluids. More than a dozen prototype artificial knees, based on MR fluids, are already in use. MR fluids are also used in one type of drive-by-wire forklift truck to impart a sense of rigidity and stiffness to the steering. And carmakers are looking into the use of MR fluids to impart the sensation of road resistance to drive-by-wire vehicles, where the steering wheel has no mechanical connection to the wheels of the car. (The physical sensation of the road is an important component of driving, but is missing in drive-by-wire systems.) Smart fluids could thus be used in haptic devices ranging from joysticks for gaming to instruments for remote surgery. The benefits of smart fluids are also becoming apparent to the makers of digital cameras. Although the technology is different, the benefit is similar: using a fluid in place of mechanical parts enhances control and reduces the number of bits that can break. Camera designers are finding that, as cameras become ever smaller, and are integrated into mobile phones and portable computers, the friction between the moving parts of the lens is increasingly problematic. So lenses based on smart fluids could have widespread appeal. They would also be more resilient than traditional lenses, which could be particularly useful in portable devices. 85 Look smart 90 95 100 105 Varioptic, a firm based in Lyon, France, and Philips Electronics, a consumer-electronics giant based in the Netherlands, have both developed tiny lenses based on smart fluids. (The two firms are currently involved in a patent dispute over the technology.) Both firms' designs rely on an effect called “electrowetting” where the application of an electrical field alters the surface tension of a liquid. As with other kinds of smart fluids, the effect is not new, but was seen as a curiosity until recently. Two non-mixing fluids are placed in a short tube with transparent end caps. One is an aqueous (waterbased) fluid, the other a transparent oil. The internal surfaces of the tube wall, and one of its end caps, are coated with a water-repellent coating that causes the water-based fluid to form itself into a hemispherical mass at the opposite end of the tube, where it acts as a spherically curved lens. The shape of the lens is adjusted by applying an electric field across the hydrophobic coating, reducing the surface tension and making the coating less hydrophobic. The water-based fluid is then less repelled by the walls of the tube, which makes the lens change shape. By increasing the applied electric field, the normally convex surface of the lens can be made completely flat or even concave. This allows the lens to adjust its focus. Using two smart-fluid lenses in combination, it is possible to make a zoom lens. Varioptic recently announced that it has licensed its technology to Samsung of South Korea, for use in camera-phones, handheld computers and other devices. With tens of millions of camera-phones sold each year, that could carry smart fluids into the consumer mainstream. But however they end up being used—whether in cars, buildings or mobile phones—it appears that smart fluids have a solid future ahead of them.