Geelong Manufacturing Council (1) (DOC 156kb)

advertisement

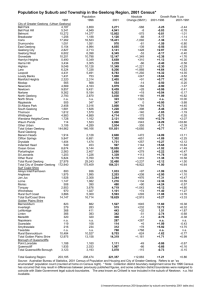

Submission to VCEC INQUIRY INTO A MORE COMPETITIVE VICTORIAN MANUFACTURING INDUSTRY Geelong Manufacturing Council May 2011 Geelong Manufacturing Council P.O. Box 638 GEELONG 3220 Ph 5223 2999 Email: gmc@tpg.com.au Contact: David Peart Executive Officer Geelong Manufacturing Council P.O. Box 638 Geelong Victoria 3220 Tel 03 5223 2999 Email:gmc@tpg.com.au 1. Background to Submission by Geelong Manufacturing Council The Geelong Manufacturing Council welcomes the opportunity to present a response to this Inquiry in relation to ‘A More Competitive Victorian Manufacturing Industry’. In Geelong, manufacturing is by far the largest generator of economic output representing over 40% of the total regional output. The future of manufacturing is closely tied to the economic health of the region and therefore ranks as a very important consideration for the regional economy. When the multiplier effect is taken into account, the manufacturing industry in Geelong accounts for up to half of the region’s economy and employment. It follows that any negative impacts on manufacturing are felt across a large section of the economy and community. Geelong is a major regional population and business centre, as home to over 290,000 people, it is Victoria’s largest regional centre. The City’s existing competitive strengths include a diverse range of manufacturing activities, research and development, education and training, biotechnology, transport, tourism and health. The key manufacturing sectors in the region are automotive and components, textiles, metals, food, cement, timber, engineering and chemicals and petroleum. Currently, by our estimates, the region has around 14,000 people employed in the manufacturing sector across some 500 companies. An example of the diverse range of industry located in Geelong includes the fact that Geelong is home to Victoria’s only cement manufacturer and Australia’s only paper felt manufacturer (a key supplier to the papermaking sector). Manufacturing in Victoria (and Geelong) has recently dealt with a number of complex challenges, which have tested the resilience of the industry. These challenges include those presented by the global financial crisis, on top of the existing challenges such as the emergence of global supply chains with its impact on prices and margins, and the recent proposed implementation of a Carbon Tax. Manufacturing is also a major generator of research and development activity and a number of organisations are working to grow this important work in the Geelong region. This includes the Geelong Technology Precinct at Deakin University and The Gordon (TAFE Institute). The Geelong region has seen the recent loss of industries via closures and downsizing and this has had a significant adverse impact on the regional community when the impacts of the flow on effects are taken into account. Some of these companies have moved operations offshore. The key driver for companies who have moved offshore has historically been the cost of labour compared to lower cost countries, however this is only one of the set of factors which are considered. Issues such as market access are increasingly relevant as the Australian market becomes more accessible to a wider range of competitive countries. Unfortunately, trade opportunities do not flow the other way. Lack of market access is an important factor which could influence industry to consider locating offshore to secure better market access. Geelong Manufacturing Council May 2011 2 2. The Geelong Manufacturing Council The Geelong Manufacturing Council (GMC) was established in 1998 by the Australian Industry Group and the Geelong Development Board to assist and promote the region’s manufacturing industry. The GMC’s vision is “Geelong as an internationally competitive manufacturing centre in the 21st century”, and this will be achieved through facilitation and support for manufacturing by developing and sharing sustainable best practice, encouraging the growth of technologically advanced manufacturing and promoting a favourable environment for manufacturing in Geelong. The Geelong Manufacturing Council facilitates a number of networks and industry groups with similar objectives to the GMC and is a non-political, not for profit group, largely funded by industry. The GMC is also a partner organisation with Enterprise Connect, the flagship Commonwealth Program. The GMC, both directly and through its sub committees has a significant proportion of the largest 100 manufacturers as members, which represents over 10,000 of the 14,000 manufacturing employees across the region. In 2010/11, over 150 manufacturing companies participated in a program or activity conducted by the GMC. 3. Regional Importance of Manufacturing Geelong has traditionally been a manufacturing region. In the 1970’s over 30% of the workforce were employed in this sector. Since this time, increased levels of international competition as a result of tariff reductions has gradually led this to drop to below 20%. Firms have pursued technology and increases in capital intensity, in an effort to compete. Economic analysis indicates that 43% of regional output is derived from the manufacturing sector. It follows from these figures that the health of the manufacturing sector is vital for ongoing stability of the region’s economic and social foundations. The strong recent appreciation of the Australian dollar has added competitive pressure to manufacturing and led to a severe deterioration in the competitiveness of manufacturing in Victoria. This underlines the importance of the recommendations of this Inquiry being implemented to help redress the loss of competitiveness in the areas it can influence. Geelong is a region where its people and industries contribute to Australia’s GDP more so than any other region of its size in the country. Geelong industry produces a range of very important products including: motor vehicles, engines and other components, automotive and technical textiles; carpet; carpet wool fibre processing; chickens, aluminium, petroleum, polypropylene and a wide range of timber, engineered products, food and consumer goods. Geelong is also pursuing an agenda to build its automotive capabilities and develop a centre of excellence in aspects of automotive design, education, research and manufacturing. Recent major investments have included Australian Future Fibres Research and Innovation Centre (AFFRIC). This Centre is a collaboration between Deakin University, CSIRO and the Victorian Centre for Advanced Materials Geelong Manufacturing Council May 2011 3 Manufacturing (VCAMM). The total project ($102m) which will include an industrial scale carbon fibre plant and create hundreds of jobs and opportunities for the region. Ford Motor Company of Australia, Research and Development Centre ($27m), which now employs over 400 people and ACART (a joint venture between Ford Motor Co and The University of Melbourne) which has seen major investments ($29m) in emissions and testing laboratories at the Ford You Yangs Proving Ground. The Gordon (TAFE) has invested heavily in training facilities to support manufacturing in the Geelong region while Deakin University has been successful in developing major industry partnerships across a number of areas of manufacturing research and product development. The Geelong Innovation and Investment Fund was established in 2007 in response to the then planned Ford engine plant closure. The GIIF has assisted some 22 projects and over 1000 jobs generating over $100m in private investment in the region, with the bulk of projects in the manufacturing sector. The success of the GIIF leads us to strongly support the establishment of an ongoing investment fund for the Geelong region. We propose that this be supported by a combination of local stakeholders as well as state and federal government. Discussions with key bodies in Geelong indicate substantive support for such as fund and a willingness to provide financial and administrative support. 4. Geelong Manufacturing Council programs in partnership with State and Federal Government to support and assist manufacturing In recent years, the Geelong Manufacturing Council has been active in partnering with a range of government programs to assist regional industry. Activities have included being a partner organisation with Enterprise Connect delivering manufacturing reviews. Enterprise Connect, is a $251 million Australian Government initiative designed to boost productivity, improve innovation and increase the competitiveness of Australian small and medium sized enterprises (SMEs). The success of this program and the willingness of industry to undertake the program has been a strong indicator of a renewed desire to improve productivity and sustainability from industry. A major industry based regional cluster program recently established with the support of Local, Victorian and Commonwealth Government is the Engineering Network Geelong (ENG). The Cluster has the objective of bringing further work to Geelong through collaboration and networking activities. ENG currently has 50 members and is achieving results by bringing together the considerable range of engineering expertise and capabilities from across the region. ENG is marketed across the country and allows the regions engineering companies to diversify and develop new markets either individually or as part of a group. A major innovation program is to be commenced by the GMC in conjunction with Deakin University, supported by the Victorian Government will be commenced on 1st July, 2011. The program will assist to increase innovation adoption in the region by increasing the level of innovation in industry through greater university and researcher collaboration with industry. We believe that this program has the potential to significantly increase the level of innovation in the region and have positive impacts on economic growth in the region. Geelong Manufacturing Council May 2011 4 Sustainability initiatives with Sustainability Victoria, aimed at improving productivity and efficiency, reducing waste and energy use have also been implemented in recent years. In 2011, a series of sustainability initiatives will commence with a sustainable industry program supported by the Commonwealth Government through its Enterprise Connect Workshops and Industry Intelligence and Networking (WIIN) Program. Further activities are planned, subject to funding support, to increase the focus on sustainability and carbon reduction activities. Programs to encourage lean manufacturing delivered in partnership with the Victorian and Commonwealth Government’s have also had a positive impact on regional industry. We are committed to keep assisting with offering these programs and where possible seeking to extend the availability of these programs for regional industry. Overall, while there are currently a range of positive program responses by State and Federal Government to encouraging innovation, particularly among the small to medium sized sector and programs for several targeted sectors, more can be done to encourage innovation. For example, there is an opportunity to promote aluminium recycling in our region. The CO2 benefits of recycling aluminium are very significant, because it uses 95% less energy to recycle the metal than producing virgin aluminium. It is imperative the Victorian government supports and promotes the value of diverting aluminium waste from landfill. There is significant opportunity to leverage life cycle capabilities in carbon constrained economy and the GMC supports Alcoa’s belief that recycling and recovery of embodied energy should be strongly encouraged. 5. Response to the Terms of Reference GMC members were consulted with respect to the terms of reference for this inquiry. The following is an aggregated response obtained from a range of discussions. The changing nature of Victorian manufacturing. A wide proportion of Geelong region industries are linked to global supply chains. As protection and tariffs are now low for Australia, industries operate already in a very competitive environment. Any increases in cost bases in excess of the CPI will threaten the industrial base of the region and therefore the regional economy. To ensure that industry is not burdened with costs which make them uncompetitive, The Essential Services Commission (which is charged with regulating costs of services) should continue to monitor these costs and ensure that costs increases do not exceed the consumer price index. The impending introduction of a Carbon Tax will also bring additional costs to our region’s manufacturers. Under carbon pricing, coal-fired power station operators will experience significantly increased costs which they will pass onto power purchasers. For the largest users of electricity (aluminium smelters are by far the largest) this represents a very significant additional cost that could prematurely close some Australian smelters. Smelters in Victoria are particularly at risk due to the Electricity Allocation Factor (EAF). Alcoa of Australia operates a smelter at Point Henry, Geelong. Geelong Manufacturing Council May 2011 5 As part of the Freight Futures Strategy, it has been announced that a Freight Infrastructure Charge would be introduced at the Port of Melbourne. The charge, expected to be around $180 per truck, will apply to trucks accessing the two main international container terminals at Swanson Dock to pick up and deliver containers. This will hurt our international competitiveness The costs to the Victorian economy of the manufacturing sector continuing to decline relative to the growth of other sectors, including services. As manufacturing in the region accounts for 43% of output (source REMPLAN) any reduction in manufacturing activity and employment will be acutely felt across the regional community. For every one manufacturing job lost the multiplier impact points to another 3-5 jobs which will be eventually lost across the regional economy in the supply chain, support and ancillary services. We believe that this high multiplier impact justifies strong support for the retention of manufacturing activities, in general but especially at this time where the high dollar is undermining manufacturing competitiveness. The key drivers of future growth in Victorian manufacturing. While the high Australian dollar relative the US dollar is currently threatening the growth prospects for the industry, costs such as infrastructure provision, services, and taxation of all forms are also relevant. An up to date analysis of these costs for industry in Victoria compared with our major trading partners and other low cost locations would assist to identify areas of uncompetitivenes and indicate possible pressure for companies considering locating offshore. This benchmarking information may already be available to identify these issues. For this reason we are urging the Victorian Government to do what it can to identify cost impediments and barriers to investment in Victoria (including information obtained in this current review) with a view to examining ways to reduce any areas of disadvantage with respect to any new or existing investment proposals. If manufacturing is to grow and prosper the following will be required: Access to: -competitively priced services -skills development, retention and training in relevant areas -innovation services and expertise priced at competitive rates -best practice exemplars and case studies -investment capital confident in the future of manufacturing in Victoria and a clear state strategy and strong policy response for industry development Infrastructure projects such as improvements to rail access to the Port of Geelong are sought to maximise the potential of the port. This has been the subject of previous submissions to government but has not been able to be fully completed, leading to lost opportunities for the Port. To cater for future investment, significant improvement in services infrastructure is vital and this specifically relates to the Heales Rd Industrial Area on Geelong’s northern Geelong Manufacturing Council May 2011 6 edge, (Geelong Ring Road Employment Precinct) this has also been the subject of other submissions to government. The challenges and opportunities for building a competitive manufacturing sector in rural and regional Victoria, and whether a differential approach to supporting manufacturing is warranted in rural and regional locations. We firmly believe that a differentiated approach works best for the Geelong region. An example of this is contained in some of the clusters which have been developed in the Geelong region. We have found a strong response from clusters which focus on industry sectors such as Engineering, and general areas such as Innovation and Lean. Industry has shown a strong response to these initiatives being pursued on a regional level, measured by attendance, networking and collaborative activities. Before the ENG was established, many engineering companies based in the Geelong region had never actively collaborated with other companies, presumably because of the level of competition and a lack of awareness of other firms capabilities. In its first year of operation ENG has exceeded expectations in respect of the number of companies involved and contracts tendered for and successfully won by regional companies. The challenges of growing in a regional area have never been greater. Access to capital for small companies remains an issue and can impede business growth and may be a reason for a lack of succession planning among SME’s to be now stifling growth. Access to a skilled and professional quality workforce has emerged as a constraining factor in some sectors of manufacturing. The talent drain for head office locations may further exacerbate this in a regional location. We are concerned that the mining boom is already impacting on the manufacturing sector. The skills bases of manufacturing and engineering sectors are highly sought after. Mining companies are already undertaking or planning fly in fly out (FIFO) operations from the region. This has the real potential to further drain the skills pool of the region. This problem will adversely impact across Victoria and it would be helpful if retention strategies were developed and actively implemented. Principles to support the development of policy for manufacturing sector and the Government’s ongoing review of current programs of financial assistance to industry. Industries operate in global marketplaces and the best companies have well defined strategies for growth across regions. This will be best achieved when they clearly know and understand government’s strategic intent for that particular industry and industry in general. Government policy sends a signal to industry domestically and worldwide and is critical to growth opportunities being identified. A strong plan and vision for manufacturing development and appropriate policies and commitment to achieve the vision are key requirements for government policy. This includes an understanding of the strategic nature of certain industries such as the automotive and aerospace sectors. Once many of these sectors decide to move offshore they will be unlikely to ever return. We also argue that existing industries have Geelong Manufacturing Council May 2011 7 proven their resilience and competitive ability and should be given every encouragement. Defending current industry should be a central policy position. Actions to improve competitiveness, productivity, investment, jobs and export growth in the manufacturing sector that the Victorian Government can take consistent with these principles. Manufacturing is a critical economic driver for the state and needs to be given strong direction and security to allow for the long term investment decisions, which dominate expensive capital intensive industry. Promotion and implementation of relevant strategies to support manufacturing is always important. Recent efforts to promote programs such as the Competitive Business Fund is commendable and an excellent way to promote supportive programs. Industry seeks to gain support to continue to invest to improve their competitiveness and sustainability. In this funds’ case we would argue that the total amount of the fund is insufficient to allow for the strongest response from industry. If the current round of the fund is found to be oversubscribed we would encourage the consideration of additional resources to be put into such a fund to fully capitalise on opportunities for investment and employment creation. The establishment of an ongoing Investment Fund for Geelong In 2007, the Geelong Investment and Innovation Fund was established by the Australian and Victorian Governments, together with Ford Australia following Ford's proposed restructure of its manufacturing operations in Geelong. The Fund has assisted industry development in the Geelong region by providing grants to support new investment that will create sustainable jobs. These projects have the potential to significantly stimulate the regional economy and create employment. The experience to date is that while restructuring of manufacturing will continue, it will be necessary to provide assistance to promote new investment in manufacturing and encourage advanced manufacturing. An ongoing investment fund focusing on attracting new investment into manufacturing and advanced manufacturing would, on a regional basis, assist to support jobs and investment. Other measures will be required to assist existing companies that do not qualify for investment fund assistance. We believe that an ongoing regional fund will deliver a strong response and support from industry based on recent history. Industry has called for a fund which directly supports existing jobs in addition encouraging to new jobs. We believe that industry will strongly reinvest, if given a degree of encouragement of the nature proposed in this submission. We strongly support the recommendation that the Victorian Government in collaboration with regional stakeholders support the establishment of a Regional Innovation and Investment Fund for the Geelong Region. Activities to improve the perception of industry are critical for the continued sustainability and growth of the manufacturing sector. Programs in the past, such as Geelong Manufacturing Council May 2011 8 Careers in Manufacturing, have proved to be valuable contributors to this effort. Getting the message to schools in regional areas remains important and may have lost focus in recent years. Alcoa, in conjunction with the Geelong Regional Vocational Education Council and the Geelong Manufacturing Council, has run the Future Leaders of Industry scholarships program since 2006 which annually engages 20 secondary school students to promote careers in the manufacturing sector through a structured 6 month program. The basis of this program could be used in other regional areas - government funding could enhance and grow the reach of this program, Potential strategies to strengthen Victorian manufacturing. A strong Victorian manufacturing strategy will provide industry with the required certainty to allow it to consider further investment in the State. It will also positively influence a range of other responses from government when the policy settings are fully supportive of manufacturing. If the strategy framework is well developed, so that it provides existing industry with strong encouragement to invest this can also be expected to have a positive impact on investment from outside the region. Unnecessary regulatory burdens imposed on manufacturing activity and investment beyond those under review by the Council of Australian Governments or those already identified in past VCEC reviews. The State Government of Victorian is encouraged to review the many regulatory burdens imposed on industry by government. An example is the reporting of environmental indicators which has become more onerous in recent years with a range of State and Federal measurements. This is an area where regulatory burdens could be reduced, and allowing industry an opportunity to focus on implementation rather than reporting. This area could be further explored as this inquiry continues. The impact of the Victorian Government’s procurement policy on the development of the manufacturing sector, and the extent to which local content requirements can stimulate growth and innovation. Government procurement to the extent it is focused on locally made goods can benefit industry. Purchasing policies across a range of areas can be of significant positive to Victorian industry. We believe that Victorian Government purchasing policy should recognise and actively support the purchase of Victorian made products. Local content is fundamental but regularly overlooked. We are alarmed and concerned at the amount of overseas components being imported to supply the Macarthur Wind Farm, which is presently under construction in South Western Victoria. If our understanding is correct then much more must clearly be done to increase local content in these large infrastructure projects. 6. Concluding comments Industry can be mobile domestically and internationally. Information with respect to services costs, incentives and other assistance provided by governments can regularly be well known within the industry. This information is continually taken into account by Geelong Manufacturing Council May 2011 9 industry when considering locational decisions. Indeed, there is strong evidence that lower cost countries actively seek investment from Australian companies. Other important factors considered by industry include: Cost and supply of labour Cost of infrastructure, services and taxation Access to export markets Government incentives/assistance compared to other locations Strength of government industry policy. A strong understanding of our relative position in respect to these criteria is an important step in ensuring Victoria remains a competitive location for manufacturing investment. This will also highlight areas where improvement needs to be focused. During the past four years we estimate that some 1000 jobs have been lost from manufacturing in Geelong, resulting in a direct impact of between $50m and $100m lost from the economy, largely made up of wages and contractor payments. This serves to illustrate the competitive nature of industry and need to develop a strong strategic and policy response as outlined in this submission. The comments provided in this submission are done so in a constructive manner and on the basis of the scope of the inquiry. We look forward to further responding to the draft report in due course. In summary, we strongly support the Government’s rationale for developing a new approach to manufacturing based on getting the basics right, backing local innovation and creating more local jobs. The GMC is keen to contribute to the further development of manufacturing and is prepared to be part of ongoing dialogue and activities. Please advise if you require clarification or elaboration of any of the issues raised above. Yours Sincerely David Sykes Chairman Geelong Manufacturing Council 5 May 2011 Geelong Manufacturing Council May 2011 10