Chapter 3 – Multiple Choice

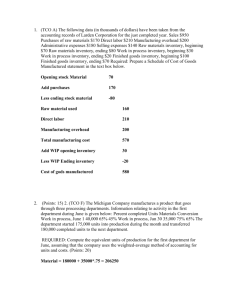

advertisement

CHAPTER 3 PROCESS COSTING CHAPTER INTRODUCTION There are two primary systems for calculating the cost of inventory: a job-order costing system and a process costing system. In a job-order costing system, each unique product is a “job” for which the company needs cost information. Thus, it is necessary to trace manufacturing costs to specific jobs. When jobs are completed, the cost of the jobs is removed from Work in Process Inventory and added to Finished Goods Inventory. When completed jobs are sold, the cost of the jobs is removed from Finished Goods Inventory and added to Cost of Goods Sold. This chapter describes a process costing system, which is essentially a system of averaging. Dividing production costs by the total number of homogeneous items produced results in an average unit cost. When items are completed, multiplying the number of units completed by the average unit cost determines the cost to remove from Work in Process Inventory and add to Finished Goods Inventory. When items are sold, multiplying the number of units sold by the average unit cost determines the cost to remove from Finished Goods Inventory and add to Cost of Goods Sold. Objectives, Terms, and Discussions. LO1 Describe how products flow through departments and how costs flow through accounts. PRODUCT AND COST FLOWS Product Flows through Departments – In the manufacturing operations of a company using process costing, a product typically must pass through two or more departments, and costs are accumulated in each department. Generally, identifying the stage when materials enter the production process is easy. However, determining exactly when labor and overhead are added to the process is more difficult. Labor and overhead are often grouped together and referred to as conversion costs. These costs are often assumed to enter the process evenly throughout the process. Cost Flows through Accounts – The product costs accumulated in a process costing system are essentially the same costs considered in a job-order costing system: direct material, direct labor, and manufacturing overhead. In addition, a processing department may have a cost called transferred-in cost. This is a cost incurred in one processing department that is transferred to the next processing Chapter 3 Process Costing 49 department. For example, the cost transferred into packaging from mixing becomes a material cost added to packaging. However, it is called a “transferred in” cost. Each processing department accumulates product cost in a separate departmental Work in Process account. The following entries illustrate the flow of costs between processing departments: Assume that $142,000 of direct material is used during the month in the Mixing Department: Work in Process, Mixing Raw Materials Inventory (To record use of raw materials) 142,000 142,000 Assume that $62,200 of direct labor cost is incurred during the month in the Mixing Department: Work in Process, Mixing Wages Payable (To record direct labor cost) 62,200 62,200 To assign overhead to products in a process costing system, a company may use either actual overhead cost or a predetermined overhead rate. However, most companies use a predetermined overhead rate to assign overhead to Work in Process. Assume that at the beginning of the year, the Mixing Department estimates it will incur $2,160,000 of overhead cost and $720,000 of direct labor cost. Using direct labor as an allocation base, the department calculates a predetermined overhead rate of $3 for each dollar of direct labor cost. If $62,200 of direct labor costs were incurred during the current month, $186,600 ($62,200 × $3) of overhead would be assigned to Work in Process: Work in Process, Mixing Manufacturing Overhead (To record manufacturing overhead applied to Work in Process) 186,600 186,600 The cost of items transferred from one department to the next is referred to as transferred-in cost. Suppose that during the month, the Mixing Department completes units with a cost of $360,000 and transfers the units to the Packaging Department. The entry to record the transfer is: Work in Process, Packaging Work in Process, Mixing (To record transfer of units from Mixing to Packaging) LO2 360,000 360,000 Discuss the concept of an equivalent unit. CALCULATING UNIT COST Process costing is essentially a system of averaging. An essential concept in process costing is the concept of an equivalent unit. Equivalent Units – In calculating the average unit cost, it is necessary to take into account the number of partially completed units in work in process in terms of an equivalent number of whole 50 Study Guide to accompany Jiambalvo Managerial Accounting units. When partially completed units are converted to a comparable number of completed units, they are referred to as equivalent units. For example, if 100 units in work in process are 50 percent completed, then they are equivalent to 50 whole units (100 × 50%). The number of equivalent units in work in process may be different for material and conversion costs because material and conversion costs enter the production process at different times. LO3 Calculate the cost per equivalent unit. Cost per Equivalent Unit - The average cost in a process costing system is referred to as cost per equivalent unit. The formula for calculating the cost per equivalent unit is: Cost per equivalent unit = Cost in beginning WIP + Costs incurred in current period Units completed + Equivalent units in ending WIP The numerator represents the total cost for which a processing department must account in each period. The cost per equivalent unit is used to spread the total cost over the units completed and the units in process at the end of the period. LO4 Calculate the cost of goods completed and the ending Work in Process balance in a processing department. CALCULATING AND APPLYING COST PER EQUIVALENT UNIT: MIXING DEPARTMENT EXAMPLE An example demonstrates the application of cost per equivalent units for the Mixing Department of Kent Chemical Company. Suppose at the beginning of April, the Mixing Department has on hand beginning work in process inventory consisting of 10,000 gallons of wood preservative that are 80 percent complete. During the month 70,000 gallons are started and 60,000 gallons are completed. At the end of April, 20,000 gallons are on hand that are 50 percent complete. The cost in beginning Work in Process consists of $18,000 of material cost, $7,800 of labor cost, and $23,400 of overhead cost. During April, the Mixing Department incurs $142,000 of material cost and $62,200 of labor cost. The predetermined overhead rate is $3 for each dollar of direct labor cost. Therefore $186,600 ($3 × $62,200) of overhead is applied to production during the month. The cost per equivalent unit for the Mixing Department is as follows: Cost Beginning WIP Cost incurred during April Total Cost Material $ 18,000 142,000 $160,000 Labor $ 7,800 62,200 $70,000 Overhead $ 23,400 186,600 $210,000 Units Units completed Equivalent units, Ending WIP Total units 60,000 20,000 80,000 60,000 10,000 70,000 60,000 10,000 70,000 Cost per equivalent unit (Total cost total units) $2 + $1 + $3 Total $ 49,200 390,800 $440,000 = $6 As shown above, 60,000 gallons were competed by the Mixing Department during April and transferred to the Packaging Department. The unit cost is $6. Therefore, $360,000 ($60,000 gallons x Chapter 3 Process Costing 51 $6) of cost is related to the units completed and transferred out. The entry at the end of April to record the transfer is: Work in Process, Packaging Work in Process, Mixing (To record transfer of units from Mixing to Packaging) 360,000 360,000 The ending balance in Work in Process in the Mixing Department is $80,000 [(20,000 × $2 of material) + (10,000 × $1 of labor) + (10,000 × $3 of overhead)]. LO5 Describe a production cost report. PRODUCTION COST REPORT A production cost report is an end-of-the-month report for a process costing system that provides a reconciliation of units and costs as well as details of the cost per equivalent unit calculations. These reconciliations help ensure that mistakes are not made in calculations. Reconciliation of Units – Assuming no loss of units (e.g., due to evaporation, damage, or theft), the number of units in beginning work in process inventory plus the number of units started during the period will be equal to the number of units completed plus the number of units in ending work in process inventory. In the previous example, the Mixing Department had 10,000 units in beginning work in process Inventory and 70,000 units were started during the period, which means that 80,000 units must be accounted for as completed or remaining in ending work in process inventory. Since 60,000 units were completed and transferred to the Packaging Department and 20,000 units remained in ending work in process inventory, all the units are accounted for. Units in beginning Work in Process 10,000 + Units started 70,000 = Units completed 60,000 + Units in ending Work in Process 20,000 80,000 80,000 Reconciliation of Costs – For each period, the total cost that must be accounted for is the sum of the costs in beginning Work in Process and the costs incurred during the period. As shown in Illustration 3-7 in the textbook, in the Mixing Department this amounts to $440,000. The cost must be either transferred out with the completed units or remain in ending Work in Process inventory. Since $360,000 was transferred out to Packaging and $80,000 remained in ending Work in Process inventory, the total cost of $440,000 has been accounted for. Costs in beginning Work in Process $ 49,200 + Costs incurred During the period 390,800 $440,000 Cost transferred out = + Cost in ending Work in Process $360,000 80,000 $440,000 52 Study Guide to accompany Jiambalvo Managerial Accounting BASIC STEPS IN PROCESS COSTING: A SUMMARY There are four basic steps in process costing. Step 1. Account for the number of physical units. This is the number of physical units in work in process at the beginning of the period plus the number of units started during the period. This should equal the number of units completed and transferred to the next department or to Finished Goods Inventory plus the units remaining in ending Work in Process Inventory. Step 2. Calculate the cost per equivalent unit for material, labor and overhead. The numerator includes the cost in beginning Work in Process plus the cost incurred during the month for material, labor and overhead. The denominator includes the number of units completed plus the number of equivalent units in ending Work in Process Inventory. Step 3. Assign cost to items completed and items remaining in ending Work in Process Inventory. The cost of completed items is the product of the total cost per equivalent unit and the number of units completed. The cost remaining in ending Work in Process is the sum of the products of equivalent units in process and cost per equivalent unit for material, labor, and overhead. Step 4. Account for the amount of product cost. The cost of beginning Work in Process Inventory plus the cost incurred during the period should equal the amount of cost assigned to completed items plus the amount of cost assigned to ending Work in Process Inventory. This chapter illustrated the use of process costing in the Mixing Department of Kent Chemical Company. The units were transferred from Mixing to Packaging. In addition to using the same procedures already used to calculate product cost in the Mixing Department, Packaging must also account for the transferred-in costs. In steps one and four of the Production Cost Report, Packaging will account for its units and amounts in the same manner as did Mixing. However, in step two, the calculation of cost per equivalent unit must account for the transferred-in costs. The sum of transferred in cost in beginning Work in Process plus the cost transferred-in during the month is the numerator of the calculation. The denominator is the sum of the units completed plus the equivalent units in ending Work in Process. The result is a cost per equivalent unit for transferred-in cost. In step three, once the units are completed in the Packaging Department, they include the cost of both the mixing operation and the packaging operation and they are ready to be transferred to Finished Goods. The cost of ending Work in Process is composed of material, labor, overhead, and transferred-in cost. For each cost category, the equivalent units in ending Work in Process is multiplied by the cost per equivalent unit. Illustration 3-8 in the textbook provides an example of the Production Cost Report for the Packaging Department. PROCESS COSTING AND INCREMENTAL ANALYSIS Recall from Chapter 1 that whenever we make a decision, we need to perform incremental analysis. We need to determine the change in revenue and the change in cost assuming a particular decision alternative is selected. If the change is positive, the decision alternative is “good” since it will have a positive impact on firm profit. If the net change is negative, the decision alternative is “bad” in that it will have a negative impact on firm profit. When using process costing information to make a decision, we have to be careful to recognize that the cost per unit is typically the average of fixed and variable costs. Thus, it does not measure the change in cost associated from producing an additional unit. Chapter 3 Process Costing 53 ‘YOU GET WHAT YOU MEASURE!” AND MANUFACTURING PROCESS Cost information for a manufacturing firm can be quite useful. Additionally, nonmonetary performance measures can help a manufacturing company create value. If a performance measure is viewed as important, then employees will pay more attention to the measure. The important point to remember is that manufacturing companies can create value by measuring performance related to important company goals. Just as with job-order costing, process costing systems provide information on the full cost of units produced rather than their incremental cost. Since decision making relies on incremental analysis, care must be taken not to treat full cost as if it were incremental cost. Review of Key Terms Conversion costs: The total cost of labor and overhead. (90) Cost per equivalent unit: The sum of the cost in beginning work in process and the cost incurred in the current period divided by the sum of the units completed and the equivalent units in ending work in process. (94) Equivalent units: Partially completed units expressed as a comparable number of whole units. (93) Production cost report: A report in a process costing system that provides a reconciliation of units and a reconciliation of costs as well as the details of the cost per equivalent unit calculations. (96) Transferred-in cost: The cost a prior processing department incurs and transfers to the next processing department. (91) 54 Study Guide to accompany Jiambalvo Managerial Accounting Chapter 3 – True/False ________ 1. The two primary systems for calculating the cost of inventory are process and joborder. ________ 2. Process costing is essentially a system of averaging. ________ 3. An example of a firm using a process costing system is Exxon Mobil. ________ 4. In a process costing system, dividing production costs by the total number of homogeneous items produced results in equivalent units of production. ________ 5. The product costs accumulated in a process costing system are not the same as those costs considered in a job-order costing system. ________ 6. When a processing department completes items, they are transferred to the next department along with the related costs. This cost is called sunk cost. ________ 7. The journal entry to record the use of direct material in the Mixing Department would include a credit to Work in Process, Mixing. ________ 8. In the formula for determining cost per equivalent unit, the costs in beginning Work in Process plus the costs incurred in the current period is divided by the units completed plus equivalent units in beginning inventory. ________ 9. A production cost report provides a reconciliation of only units. ________ 10. In a production cost report, for each period the total costs to be accounted for is the sum of the beginning Work in Process and the costs incurred during the period. ________ 11. The cost of beginning Work in Process Inventory plus the costs incurred during the period should equal the amount of costs assigned to completed items plus the amount of costs assigned to items in ending Work in Process Inventory. ________ 12. Step 2 in process costing is to account for the number of physical units. Chapter 3 Process Costing 55 Chapter 3 - Key Terms Matching Match the terms, found in Chapter 3, with the following definitions: a. Conversion costs b. Cost per equivalent unit c. Equivalent units d. Production cost report e. Transferred-in cost ________ 1. Partially completed units converted to a comparable number of completed units. ________ 2. A cost incurred in one processing department that is transferred to the next processing department. ________ 3. An end-of-the-month report for a process costing system that provides a reconciliation of units and a reconciliation of costs as well as the details of the cost per equivalent unit calculations. ________ 4. The average unit cost in a process costing system. ________ 5. Labor and overhead. 56 Study Guide to accompany Jiambalvo Managerial Accounting Chapter 3 – Multiple Choice 1. Process costing is a method for accumulating cost in a manufacturing environment that is: a. the only generally accepted method. b. essentially a process of averaging. c. a method where manufacturing costs are traced to specific jobs. d. an appropriate method of assigning costs to inventory for a custom home manufacturer. 2. Conversion costs consist of: a. direct labor and indirect labor only. b. direct labor and manufacturing overhead. c. direct materials and direct labor only. d. direct materials and indirect materials only. 3. In the manufacturing operations of a company using process costing, a product typically must a. pass through two or more departments and costs are accumulated in each department. b. pass through two or more processes and costs are accumulated by job. c. pass through the entire manufacturing process before costs are assigned to products. d. be assigned costs based on estimated cost of materials, labor and overhead. 4. Generally, identifying the stage in which an item is added to the production process is easy for which of the following? a. Material, labor and overhead. b. Material and labor only. c. Labor only. d. Material only. 5. In a process costing system, each processing department accumulates product cost in which of the following departmental account? a. Finished goods. b. Manufacturing Overhead. c. Work in Process. d. Raw materials. 6. The Body Care, Inc. produces body lotion that goes through three departments – A, B, and C. Department B has 80,000 liters in the beginning Work in Process. An additional 350,000 liters are added into production during the current period. The ending Work in Process inventory totaled 60,000 liters. How many liters were transferred to Department C? a. 330,000. b. 370,000. c. 410,000. d. 430,000. 7. In a process costing system, costs are accumulated: a. By job. b. By processing department. a. By jobs and processing departments. b. By accounting cycle. Chapter 3 Process Costing 57 8. The number of equivalent units in Work in Process may be different for material and conversion costs because: c. conversion costs cannot be assigned to Work in Process until the manufacturing process is complete while material costs can be assigned at any time. d. material cost is assigned for each equivalent unit while conversion cost is assigned for each actual unit. c. material and conversion costs enter the production process at different times. d. conversion cost can be assigned to Work in Process at any time while all material costs are added at the beginning of the manufacturing process. 9. The formula for determining the cost per equivalent unit is: a. Cost of beginning WIP + Cost incurred in current period Units completed + Equivalent units in ending WIP b. Cost incurred in current period + Cost of ending WIP Units completed + Equivalent units in ending WIP c. Cost incurred in current period Units completed d. Cost in ending WIP Equivalent units in ending WIP The following data are to be used in answering 10 and 11. The Dudes Diaper Company uses a process costing system to account for the cost of manufacturing cloth diapers. The diapers go through two departments, Cutting and Assembly. Assembly started the month with 8,000 diapers in beginning Work in Process Inventory that were 70 percent complete with respect to conversion costs. An additional 40,000 diapers were transferred from Cutting to Assembly. At the end of the month there were 6,000 diapers in the ending Work in Process Inventory of the Assembly Department that were 75 percent with respect to conversion costs. 10. How many diapers were transferred to finished goods during the month? a. 600. b. 2,000. c. 38,000. d. 42,000. 11. What were the equivalent units of production for conversion costs in the Assembly Department for the month? a. 38,000. b. 38,900. c. 41,100. d. 46,500. 12. Which of the following is not one of the steps in solving a process costing problem?: a. Account for the number of physical units. b. Calculate the cost per equivalent unit. c. Assign cost to items completed and items in ending Work in Process d. Assign cost in ending Work in Process to specific jobs. 58 Study Guide to accompany Jiambalvo Managerial Accounting Exercise 3 –1 The Cabelle Corporation uses a process costing system. Materials are added at the beginning of the process and conversion costs are incurred uniformly throughout the manufacturing process. On December 1, 2013, the Assembly Department had 12,000 units that were 60 percent complete. During December the department added 78,000 units into production. On December 31, the Assembly Department had 16,000 units in ending work in process that were 40 percent complete with respect to labor and overhead. 1. 2. Prepare a Unit Reconciliation schedule of a Production Cost Report for the Assembly department. Units in Beginning WIP _____________ Units started during December _____________ Units to account for _____________ Units completed and transferred to Sewing _____________ Units in Ending WIP _____________ Units accounted for _____________ Compute total equivalent units for materials and for conversion costs for the Assembly Department for December. Units Materials Labor Overhead Units completed __________ __________ __________ EU, ending WIP __________ __________ __________ Total Units __________ __________ __________ Chapter 3 Process Costing 59 Exercise 3 – 2 Berry, Inc. produces an array of organic spice mixes that goes through two processes – blending and packaging. Material and conversion costs are incurred uniformly throughout the manufacturing process. Complete the Cost Reconciliation section of the May, 2014 Production Cost Report for the Blending Department of Berry, Inc. Production Cost Report Blending Department May 2014 Unit Reconciliation Units in Beginning WIP (80% complete) Units started during May Units to account for Units completed and transferred Units in Ending WIP (60% complete) Units accounted for 4,000 68,000 72,000 70,000 2,000 72,000 Cost per Equivalent Unit Calculation Material Labor Overhead Total 5,440 80,000 $85,440 $ 600 35,000 $35,600 $ 16,040 236,720 $252,760 Cost Beginning WIP Cost incurred – May Total $ 10,000 121,720 $131,720 Units Units completed EU ending WIP Total 70,000 1,200 71,200 70,000 1,200 71,200 70,000 1,200 71,200 Cost per EU $1.85 $1.20 $.50 $ $3.55 Cost Reconciliation Total cost to account for _______________ Cost of completed units (__________@_____) _______________ Cost of Ending WIP: Materials (__________@_____) _______________ Labor (__________@_____) _______________ Overhead (__________@_____) _______________ Total cost accounted for _______________ 60 Study Guide to accompany Jiambalvo Managerial Accounting Exercise 3 – 3 Sand Toys, Inc. buys plastic that is used as a direct material in the production of toy pails. After work is completed in the Shaping Department, pails are transferred to the Finishing Department where a handle is added. Direct materials are added at the beginning of the process while conversion costs are incurred uniformly throughout the process. During the month of June the following cost were incurred in the Shaping Department: Direct Materials Labor Overhead $16,200 7,900 11,850 During June, the first month of operation, the Shaping Department started a total of 20,000 pails, of which a total of 17,500 were completed during the month. The remaining 2,500, which were in work in process on June 30, were 90 percent complete with respect to conversion costs. 1. 2. Prepare a Unit Reconciliation schedule for Sand Toys. Units in Beginning WIP ____________________ Units started during June ____________________ Units to account for ____________________ Units completed and transferred to Finishing ____________________ Units in Ending WIP ____________________ Units accounted for ____________________ Compute total equivalent units for materials and for conversion costs for the Shaping Department for June. Units Materials Labor Overhead Units completed __________ __________ __________ EU, ending WIP __________ __________ __________ Total Units __________ __________ __________ Chapter 3 Process Costing 61 Exercise 3 – 3 Continued 3. Compute the cost per unit for materials and conversion. Material Labor Overhead Total Cost Costs: Beginning WIP __________ __________ __________ __________ Cost incurred – June __________ __________ __________ __________ Total __________ __________ __________ __________ Units completed __________ __________ __________ EU, Ending WIP __________ __________ __________ Total __________ __________ __________ Cost per equivalent unit __________ __________ __________ Units 4. __________ Complete a cost reconciliation schedule. Total cost to account for _______________ Cost of completed units (__________@_____) _______________ Cost of Ending WIP: Materials (__________@_____) _______________ Labor (__________@_____) _______________ Overhead (__________@_____) _______________ Total cost accounted for _______________ 62 Study Guide to accompany Jiambalvo Managerial Accounting Problem 3 – 4 The Mathis Company manufacturers a product that goes through two departments: Mixing and Finishing. During the month of May the following data were recorded for the Mixing Department: Units in Beginning WIP Units started during May Units transferred Units in Ending WIP Costs added during May Units 16,000 50,000 40,000 26,000 Materials $ 79,730 Labor $ 33,680 Overhead $ 16,760 $220,000 $400,000 $100,000 The ending work in process was 70 percent complete with respect to materials and 60 percent complete with respect to labor and overhead. Prepare a Production Cost Report for May. Production Cost Report Mixing Department May Unit Reconciliation Units in Beginning WIP Units started during May Units to account for Units completed and transferred to Finishing Units in Ending WIP Units accounted for ____________________ ____________________ ____________________ ____________________ ____________________ ____________________ Cost per Equivalent Unit Calculation Material Labor Costs: Beginning WIP __________ __________ Cost incurred – May __________ __________ Total __________ __________ Units Units completed __________ __________ EU, Ending WIP __________ __________ Total __________ __________ Cost per equivalent unit __________ __________ Overhead __________ __________ __________ __________ __________ __________ __________ __________ __________ __________ Cost Reconciliation Total cost to account for Cost of completed units (__________@_____) Cost of Ending WIP: Materials (__________@_____) Labor (__________@_____) Overhead (__________@_____) Total cost accounted for Total Cost __________ _______________ _______________ _______________ _______________ _______________ _______________ Chapter 3 Process Costing Problem 3 – 5 Fill in the missing information in Mitchell’s Production Cost Report. Unit Reconciliation Units in Beginning WIP (100% material, 10% conversion costs) Units started Units to account for Units completed Units in Ending WIP (80% material, 60% conversion costs) Units accounted for Cost per Equivalent Unit Calculation Material Labor Costs: Beginning WIP $6,680 $16,915 Cost incurred – May ? ? Total ? ? Units completed EU, Ending WIP Total Cost per equivalent unit ? ? ? $3.00 Cost of completed units Cost of Ending WIP: Materials Labor Overhead Total cost accounted for Overhead ? ? ? $8.00 Cost Reconciliation Total cost to account for 5,000 ? ? ? 12,000 ? $1,159,800 $969,000 ? ? ? $1,159,80 Total Cost $30,405 ? ? $54,000 ? ? ? ? ? $14.50 ? 63 64 Study Guide to accompany Jiambalvo Managerial Accounting Solutions – True/False 1. T 2. T 3. T 4. F In a process costing system, dividing production costs by the total number of equivalent items produced results in an average unit cost. 5. F The product costs accumulated in a process costing system are essentially the same costs considered in a job-order costing system. 6. F When one processing department completes its work, the items are transferred to the next department along with the related costs. This cost is referred to as transferred-in costs. 7. F The journal entry to record the use of direct material in the Mixing Department would include a debit to Work in Process, Mixing. 8. F In the formula for determining cost per equivalent unit, the costs in beginning Work in Process plus the costs incurred in the current period is divided by the units completed plus equivalent units in ending inventory. 9. F A production cost report provides a reconciliation of units and costs. 10. T 11. T 12. F Step 1 in process costing is to account for the number of physical units. Solutions – Key Terms Matching 1. 2. 3. c. Equivalent units e. Transferred-in cost d Production cost report 4. 5. b. Cost per equivalent unit a. Conversion costs Solutions – Multiple Choice 1. 2. 3. 4. 5. 6. b b a d c b 7. 8. 9. 10. 11. 12. b c a d d d Chapter 3 Process Costing 65 Solution – Exercise 3 – 1 The Cabelle Corporation uses a process costing system. Materials are added at the beginning of the process and conversion costs are incurred uniformly throughout the manufacturing process. On December 1, 2013, the Assembly Department had 12,000 units that were 60 percent complete. During December the department added 78,000 units into production. On December 31, the Assembly Department had 16,000 units in ending work in process that were 40 percent complete with respect to labor and overhead. 1. Prepare a Unit Reconciliation schedule of a Production Cost Report for the Assembly department. 2. Units in Beginning WIP 12,000 Units started during December 78,000 Units to account for 90,000 Units completed and transferred to Sewing 74,000 Units in Ending WIP 16,000 Units accounted for 90,000 Compute total equivalent units for materials and for conversion costs for the Assembly Department for January. Units Materials Labor Overhead Units completed 74,000 74,000 74,000 EU, ending WIP 16,000 6,400 6,400 Total Units 90,000 80,400 80,400 66 Study Guide to accompany Jiambalvo Managerial Accounting Solution – Exercise 3 – 2 Berry, Inc. produces an array of organic spice mixes that goes through two processes – blending and packaging. Material and conversion costs are incurred uniformly throughout the manufacturing process. Complete the Cost Reconciliation section of the May, 2014 Production Cost Report for the Blending Department of Berry, Inc. Production Cost Report Blending Department May 2014 Unit Reconciliation Units in Beginning WIP (80% complete) Units started during May Units to account for Units completed and transferred Units in Ending WIP (60% complete) Units accounted for 4,000 68,000 72,000 70,000 2,000 72,000 Cost per Equivalent Unit Calculation Material Labor Overhead Total 5,440 80,000 $85,440 $ 600 35,000 $35,600 $ 16,040 236,720 $252,760 Cost Beginning WIP Cost incurred – May Total $ 10,000 121,720 $131,720 Units Units completed EU ending WIP Total 70,000 1,200 71,200 70,000 1,200 71,200 70,000 1,200 71,200 Cost per EU $1.85 $1.20 $.50 $ Cost Reconciliation: Total cost to account for $252,760 Cost of completed units (70,000 @ $3.55) $248,500 Cost of ending WIP Materials (1,200 units @ $1.85) Labor (1,200 units @ $1.20) Overhead (1,200 units @ $0.50) $2,220 1,440 600 4,260 $252,760 $3.55 Chapter 3 Process Costing 67 Solution – Exercise 3 – 3 Sand Toys, Inc. buys plastic that is used as a direct material in the production of toy pails. After work is completed in the Shaping Department, pails are transferred to the Finishing Department where a handle is added. Direct materials are added at the beginning of the process while conversion costs are incurred uniformly throughout the process. During the month of June the following cost were incurred in the Shaping Department: Direct Materials Labor Overhead $16,200 7,900 11,850 During June, the first month of operation, the Shaping Department started a total of 20,000 pails, of which a total of 17,500 were completed during the month. The remaining 2,500, which were in work in process on June 30, were 90 percent complete with respect to conversion costs. 1. Prepare a Unit Reconciliation schedule for the Sand Toys. Units in Beginning WIP -0Units started during June 20,000 Units to account for 20,000 Units completed and transferred to Finishing 17,500 Units in Ending WIP 2500 Units accounted for 20,000 2. Compute total equivalent units for materials and conversion costs for June. Units Materials Labor Units completed 17,500 17,500 EU, ending WIP 2,500 2,250 Total Units 20,000 19,750 3. Compute the cost per unit for materials and conversion. Material Labor Costs: Beginning WIP -0-0Cost incurred – June $16,200 $7,900 Total $16,200 $7,900 Units Units completed EU, Ending WIP Total Cost per equivalent unit 17,500 2,500 20,000 $.81 4. Complete a cost reconciliation schedule. Reconciliation Total cost to account for Cost of completed units (17,500 @ $1.81) Cost of Ending WIP: Materials (2,500 @ $.81) Labor ( 2,250 @ $.40) Overhead ( 2,250 @ $ .60) Total cost accounted for 17,500 2,250 19,750 $.40 Overhead Overhead 17,500 2,250 19,750 Total Cost -0$11,850 $11,850 -0$35,950 $35,950 17,500 2,250 19,750 $ .60 $1.81 $35,950 $31,675 2,025 900 1,350 4,275 $35,950 68 Study Guide to accompany Jiambalvo Managerial Accounting Solution – Problem 3 – 4 The Mathis Company manufacturers a product that goes through two departments: Mixing and Finishing. During the month of May the following data were recorded for the Mixing Department: Units in Beginning WIP Units started during May Units transferred Units in Ending WIP Costs added during May Units 16,000 50,000 40,000 26,000 Materials $ 79,730 Labor $ 33,680 Overhead $ 16,760 $220,000 $400,000 $100,000 The ending work in process was 70 percent complete with respect to materials and 60 percent complete with respect to labor and overhead. Prepare a Production Cost Report for May. Production Cost Report Mixing Department May Unit Reconciliation Units in Beginning WIP Units started during May Units to account for 16,000 50,000 66,000 Units completed and transferred to Finishing Units in Ending WIP Units accounted for 40,000 26,000 66,000 Cost per Equivalent Unit Calculation Cost Material Beginning WIP $ 79,730 Cost incurred - May 220,000 Total $299,730 Units Units completed 40,000 EU, Ending WIP 18,200 Total 58,200 Cost per EU $5.15 Labor $ 33,680 400,000 $433,680 Overhead $ 16,760 100,000 $116,760 40,000 15,600 55,600 40,000 15,600 55,600 $7.80 $2.10 Cost Reconciliation Total costs to account for $850,170 Cost of completed units (40,000 @ $15.05) Cost of Ending WIP: Materials (18,200 @ $5.15) Labor (15,600 @ $7.80) Overhead (15,600 @ $2.10) Total cost accounted for $602,000 $93,730 121,680 32,760 248,170 $850,170 Total $130,170 720,000 $850,170 $15.05 Chapter 3 Process Costing Solution – Problem 3 – 5 Fill in the missing information in Mitchell’s Production Cost Report. Unit Reconciliation Units in Beginning WIP (100% material, 10% conversion costs) Units started Units to account for Units completed Units in Ending WIP (80% material, 60% conversion costs) Units accounted for Cost per Equivalent Unit Calculation Material Labor Costs: Beginning WIP $6,680 $16,915 Cost incurred – May 136,120 344,685 Total 142,800 361,600 Units completed EU, Ending WIP Total Cost per equivalent unit Cost Reconciliation Total cost to account for Cost of completed units Cost of Ending WIP: Materials Labor Overhead Total cost accounted for 69 38,000 9,600 47,600 $3.00 Overhead 38,000 7,200 45,200 $8.00 $1,159,800 $969,000 $28,800 57,600 104,400 Cost per EU: $3.00 + $8.00 + $14.50 = $25.50 Units complete: $969,000/$25.50 = 38,000 Units accounted for: 38,000 + 12,000 = 50,000 Units to account for: 50,000 Units Started: 50,000 – 5,000 = 45,000 EU, Ending WIP material: 12,000 x .80 = 9,600 EU, Ending WIP labor and overhead: 12,000 x .60 = 7,200 Cost of Ending WIP Material: $3 x 9,600 = $28,800 Cost of Ending WIP Labor: $8.00 x 7,200 = $57,600 Cost of Ending WIP Overhead: $14.50 x 7,200 = $104,400 Cost incurred in May: $1,159,800 = $54,000 = $1,105,800 Total cost, material: 47,600 x $3.00 = $142,800 Cost incurred May: $142,800 - $6,680 = $136,120 Total cost, labor: 45,200 x $8 = $361,600 Cost incurred May: $361,600 - $16,913 = $344,685 Total cost, overhead: 45,200 x $14.50 = $655,400 Cost incurred, May: $655,400 = $30,405 = $624,995 5,000 45,000 50,000 38,000 12,000 50,000 190,800 $1,159,800 Total Cost $30,405 624,995 655,400 $54,000 1,105,800 1,159,800 38,000 7,200 45,200 $14.50 $25.50