March 1998 - University of Idaho

Analysis of Total PCB Content by Reductive

Dechlorination to Biphenyl

John G. Doyle, TeriAnn Miles, Erik Parker,

I. Francis Cheng

Department of Chemistry

University of Idaho

Moscow, Idaho 83844-2343 ifcheng@uidaho.edu

(208) 885-6387

Outline

1.

Short History of PCBs

2.

Present state of PCB analysis

Multi-component – 209 congeners

Associated problems with GC-ECD

3.

Chemical Reaction to Single Species

Carbon Skeleton

Perchlorination

4.

Complete dechlorination at RTP.

Pd/Mg bimetallic particles

Performance with Arochlor

1221

5.

Elimination of Interferences by other Halocarbons

Mixtures of DDT and Arochlor 1260

PCB history

Clx Cly

10

x + y

Industrial uses 1930 – 1977

Dielectric fluids, capacitors and transformers

Printing inks

Paints

Pesticides

Health and Environmental Risks

Occupational exposure (1936)

Bio-accumulative (low water solubility)

Banned by TSCA 1977

EPA policy

Soils: nonrestricted access areas must 10 ppm or less

PCB analyses

Clx

Cly

209 possible congeners

GC-FID of a PCB mixture

Complicating Features

CG-ECD analysis based on pattern recognition of key congener peaks.

1.

Matrix effects

-DDT/DDE metabolites

-Other Halocarbons

2.

Environmental aging

-Different rates of dechlorination for each congener

-Volatility differences for each congener

3.

ECD response

-Varies with each congener

“

Sources and Magnitude of Bias Associated with Determination of

Polychlorinated Biphenyls in Environmental Samples”

Analytical Chemistry ,

1991 , 63 , 2130-2137.

Chemical Reaction of PCBs

To one predominate species

1. Reductive Dechlorination:

Clx

+ 2(x+y) e -

+ (x+y) Cl -

Cly

2. Perchlorination:

Clx

Cly

+ 2 (10-x+y) Cl -

Cl

Cl

Cl

Cl

Cl

Cl

Cl

Cl

Cl

+ (10-x+y) H + + (10-x+y) e -

Cl

Requirements for Chemical Reaction to Single

Species

1.

Reproducible and Quantitative

100% Yield

2.

Rapid

R oom Temperature and Pressure

3.Simple minimal work-up

Literature methods

Reductive Dechlorination:

Procedure Analysis Detection

Limit

150 ng H

2

reduction on Pd catalyst @ 305 0 C

GC-FID

Heated Pd catalysts GC-FID

Na reduction Cl ISE

10 ng

10 mg

LiAlH

4

HPLC UV@248 nm 100 ng

Perchlorination

SbCl

5

@ 205 0 C GC-ECD ?

Most of the above involve extensive procedures.

Rapid reductive dechlorination under mild conditions

1. Standard Reduction Potential of PCBs

Clx

+ 2(x+y) e -

+ (x+y) Cl -

Cly

E 0 red

= 0.5 to 1.0 volts

2. Reducing Agents (aqueous)

Fe

Fe 2+ + 2e -0.44 V

Cr

Cr 3+ + 3e -0.74 V

Mn

Mn 2+ + 2e -1.182 V

Mg

Mg 2+ + 2e -2.36 V

E 0 red

Complete dechlorination of PCB by zero-valent metals is slow.

1.

Most congeners are completely stable in presence of metal reducing agents at RTP.

2.

Requires catalyst.

Pd/Fe bimetallic system*.

2 g, 10

m, 99.9% Fe particles

0.05 % Pd w/w

5 ml 20 ppm Arochlor 1260

(30% MeOH , 20% acetone, 50% water)

Complete dechlorination in 10 minutes

Majority product, biphenyl

*C. Grittini, M. Malcomson, Q. Fernando, N. Korte

Environ. Sci. & Tech., 1995 , 29 , 2898-2900.

Analysis of total PCB by reductive dechlorination with Pd/Mg bimetal.

1.

Mg vs. Fe

Fe surface requires extensive pretreatment

Anaerobic acid washing

Air sensitive

Mg requires no special treatment

2.

Deposition of Pd onto Mg

Untreated 0.5 grams 20 mesh Mg

(98%, Aldrich)

20 mg K

2

PdCl

6

PdCl

6

2 + 2Mg = Pd + 6Cl + 2Mg 2+

Pd

Mg

PCB dechlorination

Analyte solution

3-5 ml of 50/50 v/v 2-propanol/water

1 – 60

M Arochlor 1221

0.5 grams 20 mesh Mg particles

20 mg K

2

PdCl

6

powder

reaction complete in 5 minutes

Preparation for HPLC

syringe filter 0.2 ml of above

Role of Pd in the catalysis of zero-valent metal reduction of halocarbons.

R-H + H + + Cl -

Mg 2+ 2H +

Pd

.

H

Pd island

H

H

R-Cl

Metal surface

2e -

Pd is a catalytic surface for hydrogen evolution

Increases Mg dissolution (galvanic corrosion)

Hydrogen intercalates in bulk Pd

May result in excellent surface for hydrodehalogenation

Pt fails as hydrodehalogenation catalyst

I.F. Cheng, Q. Fernando, N. Korte, Environmental

Science and Technology, 1997, 31 (4) 1074-1078.

Analytical performance of Mg/Pd reductive dechlorination system

HPLC analysis

50 uL sampling loop

UV absorbance detector 200 nm (HP 79853C)

Isocratic 65/35 v/v acetonitrile/water

C-8 Zorbax column

Arochlor 1221 biphenyl content, 3.3%

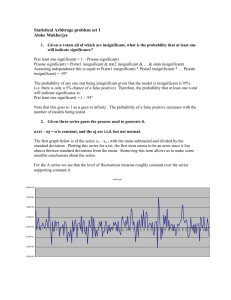

Biphenyl Calibration Curve

Biphenyl

4.50E+07

4.00E+07

3.50E+07

3.00E+07

2.50E+07

2.00E+07

1.50E+07

1.00E+07 y = 7.95E+11x + 3.59E+05

R

2

= 9.99E-01

5.00E+06

0.00E+00

0.00E+00 1.00E-05 2.00E-05 3.00E-05 4.00E-05 5.00E-05 6.00E-05

Concentration (M)

Biphenyl from Arochlor 1221 dechlorination

Biphenyl From Arochlor 1221 with Mg/Pd

4.50E+07

4.00E+07

3.50E+07

3.00E+07

2.50E+07

2.00E+07

1.50E+07

1.00E+07

5.00E+06 y = 7.76E+11x - 1.53E+06

R

2

= 9.97E-01

0.00E+00

0.00E+00 1.00E-05 2.00E-05 3.00E-05 4.00E-05 5.00E-05 6.00E-05

Concentration (M)

Biphenyl yield = 98% (from slopes)

Chemical Interferences

DDT and major impurities and metabolites

10 major GC-FID peaks

Co-elute with PCBs

DDT

Cl Cl

CCl

3

DDE

Cl Cl

CCl

2

DDO

Cl Cl

CH

3

DDNS

CCl

3

Cl

Reductive dechlorination of DDT/metabolites by

Pd/Mg.

RTP reaction completed in 10 minutes

Only demonstrated method for the complete and rapid dechlorination of DDT at RTP

Procedure as with PCB dechlorination

Cl

Pd/Mg

+ 5 Cl -

CCl

3

CH

3

Major product of DDT/metabolite reductive dechlorination

GC-FID of PCB & DDT mixtures

Illustrates DDT interference

Top 50 ppm PCB (Arochlor 1260) and 50 ppm DDT

Bottom 50 ppm DDT

Pd/Mg Treatment of DDT/PCB mixtures

GC-FID

Conclusions and Future Work

Advantages

PCB reductive dechlorination by Pd/Mg to biphenyl

Rapid (< 5mins)

Reproducible (98% yield)

Detection Limit (no sample preconcentration)

5 x 10 -6 M

100 ppb

5 ng

Disadvantages

Loss of congener specific information

Requires analysis for biphenyl background

Future

Elimination of halocarbon interferences (DDT)

Acknowledgements

Co-authors

John G. Doyle

TeriAnn Miles

Erik Parker

Other Contributors

Mark Engelmann

Kristy Henscheid

Keri Colvin

Roshan Koshravi

Josh Linard

University of Idaho Research start-up funds

Contact Information:

Frank Cheng

Department of Chemistry

University of Idaho

Moscow, Idaho 83844-2343 ifcheng@uidaho.edu

(208) 885-6387