15_SWP_Gel extraction_CM

advertisement

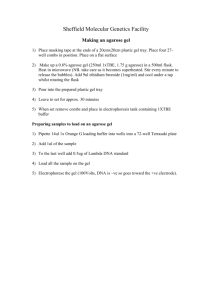

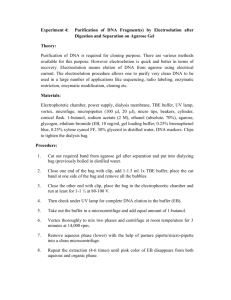

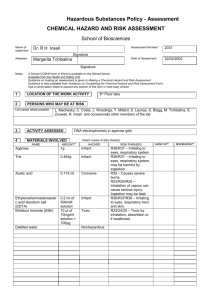

OHS026 Safe Work Procedure Faculty/Division Medicine Document number SOMS.CGM SWP015 Initial Issue date 30/06/09 School/ Divisional Unit SoMS / Oncology Research Unit/MDU Current version Current Version Next review date 1.0 30/06/09 Issue date 30/06/09 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Extraction of DNA Fragments from Agarose Gel Description: To safely and correctly extract DNA fragments from agarose gels using Promega Wizard SV Gel Clean-Up system Associated risk assessment title and location:15_RA_Gel extraction_CM Describe the activity or process Take ethidium-bromide-stained agarose gel with electrophoresed DNA, and over a UV transilluminator carefully cut out DNA fragment of interest using a scalpel. Place agarose fragment in an eppendorf tube and add an equal volume of binding buffer (1μL per mg agarose) Heat in 50-65°C heat block until agarose is entirely melted (approx. 10 minutes) Transfer melted agarose solution to SV minicolumn, placed inside collection tube. Incubate for 1 min. Spin in microcentrifuge for 1 min at top speed Discard spin-through, and wash by adding 800μL wash buffer Spin in microcentrifuge for 1 min at top speed Discard spin-through, and wash by adding 500μL wash buffer Spin in microcentrifuge for 1 min at top speed Discard spin-through, and Spin in microcentrifuge for 1 min at top speed Place SV minicolumn into clean eppendorf tube and add 50 μL H2O or TE buffer. Incubate for 1 min. Spin in microcentrifuge for 1 min at top speed to collect DNA List all resources required including plant, chemicals, personal protective clothing and equipment, etc Agarose gel with electrophoresed DNA UV transilluminator Scalpel Eppendorf tubes Personel protective clothing: gloves, labcoat, face shield Promega Wizard Gel Extraction kit Heat block Microcentrifuge List potential hazards and risk controls including specific precautions required Exposure to UV light from transilluminator Minimise exposure to UV light by turning the UV lamp on for a minimal amount of time, don PPE including labcoat and gloves, and protect the face and eyes with a plastic face-shield. [See 62_SWP_UVEquipment_JH.doc] Exposure to Ethidium Bromide Ethidium bromide may be harmful Wear PPE. Minimise direct contact with gel. Cutting hazard when using scalpel Be careful when using scalpel not to cut self. Always cut away from self. Wear closed-shoes in case of dropped scalpel. Take care when exchanging scalpel blades. Electrical shock hazard from electrical equipment (heat block, centrifuge) Ensure electrical devices are correctly plugged in. Microcentrifuge Ensure microcentrifuge is correctly balanced. Always tighten lid before turning on. ___________________________________________________________________________________________________________ ___________ Page 1 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List emergency shutdown instructions Emergency electrical shutdown button is located in laboratory near entrance List clean up and waste disposal requirements Dispose of agarose gel in biohazard bin Dispose of all buffers and supernatents in biological liquid waste Dispose of scalpel blades in sharps bin Dispose of Ethidium bromide waste in toxic waste bin. Clean ethidium bromide contaminated equipment with ethanol (dissolves EtBr), or by exposure to UV light List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000, NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006. Safety in laboratories. Part 2: Chemical aspects AS/NZS 2243.3:2002 Safety in laboratories, Part 3:Microbiological aspects and containment facilities) AS/NZS 2243.3:2002/Amdt 1:2003 Safety in laboratories, Part 3:Microbiological aspects and containment facilities) AS/NZS 2243.7-1991. Safety in laboratories. Part 7: Electrical Aspects. AS/NZS 2243.6-1990. Safety in laboratories. Part 6: Mechanical Aspects. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection AS/NZS 2211.9:2002 Safety of laser products - Compilation of maximum permissible exposure to incoherent optical radiation AS/NZS 1338.2:1992 Filters for eye protectors - Filters for protection against ultraviolet radiation Safe Work Procedure Form (OHS026 Supervisory approval, training, and review Supervisor: Peter Gunning Signature: Plant custodian: Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training as per Training Needs Analysis, Induction to Lab, Training in this SWP ___________________________________________________________________________________________________________ ___________ Page 2 of 2 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007