inset chem

advertisement

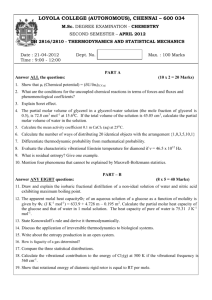

Rheological, thermal and electrical properties of Poly(ethylene oxide) / MMT nanocomposites Martin Reading*, Alun S. Vaughan High Voltage Laboratory Electronics and Computer Science Department, University of Southampton, Southampton, SO17 1BJ *mdr06r@ecs.soton.ac.uk Abstract- Polyethylene oxide (PEO) has been used for several years as an electrolyte solvent in lithium polymer cells. One beneficial quality is its high viscosity, that remains high up to temperatures just short of its solidstate Tm, allowing the production of thin electrolyte layers. PEO batteries are sometimes preferred over lithium ion due to their greater power/weight ratio. PEO is a polar polymer and is water-soluble, which is beneficial for composite dispersion. Its solubility suggests that, with addition of a nanofiller during the solution phase, it could provide easily implemented high levels of dispersion. With the availability of many different average molecular weights it constitutes an ideal model system for studies. This paper details an investigation into the physical, thermal and electrical properties of PEO and PEO-MMT nanocomposites. Three different molecular weight PEO systems were used as the polymer matrix- 100,000 g mol-1, 400,000 g mol-1 and 1,000,000 g mol-1. Properties investigated include- rheological behaviour of solutions; crystallisation and melting; the AC ramp breakdown strength and dielectric response. Dispersion was achieved during initial mixing and the solution stage in the rheometer. After previous investigations, this dispersion method has been seen to be acceptable. I. INTRODUCTION Plastics could be considered to be one of the most important discoveries over the last few hundred years, with society today using variations in almost every part of life. For example, in 2006 the United States generated 14 million tons of plastici. Polymers and plastics have been hugely successful in a multitude of areas for many reasons. As packaging, for example, they are light, strong, easily moulded, cost effective, re-usable and flexible in their application. Despite the excellent physical benefits of using polymers, this should not overshadow the dielectric benefits. Metals have strong electronic conduction, whereas polymers have a significantly lower response, underlying their use as excellent insulators. Although the bulk conductivity of most polymers is low, more subtle effects can be observed, such as space charge, and experimental techniques have been developed to evaluate electrical breakdown strength, dielectric loss, permittivity etcii. However, the dielectrics of polymers are not yet fully understood, such as the cause of electrical breakdown, which has drawn many theories from scientists and engineers. In this investigation, aluminium pillared montmorillonite clay (MMT) was dispersed in a distilled water/PEO solution by use of a cup-bob rheometer, and viscosity data was collected. Samples were melted and crystallised using power compensated differential scanning calorimetry (DSC). Emphasis was placed on any variation seen of the Tc and Tm between the virgin PEO samples and PEO-MMT composites. Samples were also pressed into thin films and tested electrically. For electrical studies, a comparison arbitrary PE sample was also used. Breakdown data was analysed using a Weibull distribution. For comparison of dielectric properties Cole-Cole plots were used. II. EXPERIMENTAL In this investigation, rheometry served two purposes; to characterise the shear rate - shear stress behaviour of the solution and to aid in dispersion of the filler. The rheometer used was a RHEOLAB MC1 Paar Physica. The PEO was supplied by Sigma-Aldrich, as was the MMT (aluminium pillared clay), both in granular form. Samples were mixed in glass flasks and a weight-weight ratio was employed. Solutions contained 20 ml of distilled water and the required amount of PEO/MMT. Initial hand mixing provided basic dispersion. For higher molecular weight solutions a longer mixing time was required before the solution was visually dispersed. To counter any water lost through evaporation, the flask’s total weight was recorded and checked, with addition of distilled water where necessary. In addition to providing rheological data, the rheometer helped to break up any agglomeration within the solution and provide good dispersion of the final system. The rheological behaviour and experiment details are discussed elsewhere iii. For DSC the previously mixed and dried samples were cut into samples weighing around 5-6 mg and placed into a Perkin Elmer DSC can. The can was heated to melt the sample to the base of the can, a lid was added and the can sealed. The DSC used was a power compensated Perkin-Elmer DSC 7 with a nitrogen feed using Perkin-Elmer Pyris software. The DSC was calibrated using melt traces from an Indium sample, a method commonly used for calibrationiv. For calculation of Tc values an isothermal scan was taken from 80-20 0C and from 20-80 0C for Tm. To avoid detection of thermal history effects on the samples, all isothermal scans were performed after a 5 minute ‘hold’ command at a high temperature. leaving a ring of uncoated sample at the edge to avoid pure conduction across the electrodes. The data obtained from dielectric spectroscopy was used to generate five graphs for each sample. The natural log of impedance was plotted against frequency to ensure collected data was acceptable, and should show a straight line decreasing with frequency. The natural log of real relative permittivity and natural log of imaginary relative permittivity were plotted as a function of frequency. In both cases, a background scan was subtracted from the raw data to remove any contributions to the measured impedance resulting from the cables or the measurement cell itself. Also graphs were generated for tan delta against frequency and ColeCole plots with real relative permittivity against imaginary relative permittivity. For AC breakdown strength tests, thin air-free discs were required, therefore all samples were de-gassed in a vacuum oven held at 80 0C. This process worked well for the 1,000,000 g mol-1 and 400,000 g mol-1 PEO systems, the 100,000 g mol-1 samples appeared to undergo a thermal aging process before the air was successfully removed. The behaviour of this aged PEO will be reported elsewhere. A Grazeby Spec-ac press was then used to press samples to a thickness of around 100 m. For most polymers this process simply involves melting the sample within a press, pressing the sample to the desired thickness, followed by quenching the sample in cold water. However the solubility of PEO meant that this quenching method could not be used. Instead, quenching was achieved using a separate chilled press that the sample was placed into straight from the hot press. After initial tests this proved quite effective. To analyse the data, three Weibull equations were considered, allowing for one, two or three parameters.v In general, the one parameter Weibull fails to accurately fit the data and the three parameter is considered to “over-parameterise”. This is the belief of many researchers, such as Chunsheng et. al.vi. To evaluate uncertainty, two types of confidence bounds were considered – Fisher matrix and Maximum Likelihood. Fisher matrix confidence bounds are sometimes considered to be too optimistic, an opinion expressed by Greenvii, therefore Likelihood bounds will be used.viii For dielectric spectroscopy tests thicker discs were produced, using the same method as above, of around 400 m. These samples were gold coated to provide a better contact for the electrodes using a gold sputter coater. Initial tests provided an estimate of the required time/current to use to generate a coating with reasonably low resistance. Both sides of the samples were coated, RESULTS Initial results strongly suggested shear re-dispersion within the solutions, followed by repeatable data. As expected, with increasing PEO content came more shear thinning, starting from near-Newtonian characteristics at 1% to a large shear thinning curve at 10%. Generated viscosity values for the samples were plotted on ln-ln graphs to ascertain any effect the MMT may have on the molecular mobility within the system. The addition of MMT to any of the varying molecular weight PEO solutions showed no noticeable effect. Further discussion of these results can be found here ix. 1000 1000 C105 100 100 10 Viscosity / Pa.s 10 Viscosity / Pa.s 8-12 discs were produced for each sample, with 5 breakdown sites designated for each, providing a healthy population for analysis. In the test cell silicone oil was used to cover the sample and lower electrode. The two electrodes were 6.3 mm steel ball bearings and were changed after every other sample. To check the linearity of the AC ramp rate a thick plastic plate was inserted in between the ball bearings and the voltage was measured as a function of time. Once calibrated for a linear AC ramp rate all sites on samples were broken down and data collected. III. C55 1 C25 0.1 0.001 0.001 0.01 0.1 1 10 . Shear rate / s-1 C210 0.1 C15 0.01 C510 1 100 C110 0.01 1000 10000 0.001 0.01 0.1 1 10 100 1000 . Shear rate / s-1 Fig. 2. Comparing samples with 0%, 5% and 10% MMT loading showed little effect on the viscosity Having made no effect physically within the solution, it was expected that Tc and Tm curves should also show no effect, due to the proposal that the MMT has not affected the mobility within the system. As seen in figures 2 and 3, the Tc and Tm respectively showed no noticeable variation with 5 or 10% MMT. However it was observed that the 400,000 g mol-1 had the highest Tc and Tm values, followed closely by 1,000,000 g mol-1 and finally 100,000 g mol-1. Future research using Avrami analysis may hopefully confirm this unchanged mobility. 10000 30 99.0 99.0 95.0 95.0 70.0 70.0 50 Weibull Breakdown Probability (%) 20 15 Virgin PEO 10 48 5 0 Approx. Tc 30 40 50 60 70 46 44 Weibull Breakdown Probability (%) 25 50.0 20.0 10.0 5.0 1.0 0.5 50.0 20.0 10.0 5.0 1.0 Arbitrary PE sample 0.5 42 1,000,000 g mol-1 PEO -1 1,000,000 g mol PEO -1 400,000 g mol PEO 0.1 40 0.0 0.2 0.4 0.6 0.8 1.0 0.1 30 1.2 50 60 70 80 30 Breakdown Strength (kV/mm) Molecular weight /106 g mol-1 40 50 60 70 80 100 120140 Breakdown Strength (kV/mm) Fig. 5. A small but distinct difference was observed with varying molecular weight (Left). PEO is seen to have a breakdown strength around half that of a comparison PE sample (Right) 30 25 50 40 20 15 MMT-PEO Composites 10 48 99.0 99.0 95.0 95.0 70.0 70.0 5 40 50 60 70 44 42 40 0.0 0.2 0.4 0.6 0.8 1.0 1.2 Weibull Breakdown Probability (%) Approx. Tc 30 Weibull Breakdown Probability (%) 0 46 50.0 20.0 10.0 5.0 1.0 0.5 Molecular Weight / 106 g mol-1 + 50.0 20.0 10.0 5.0 1.0 0.5 1,000,000 g mol-1 PEO With 5% MMT With 10% MMT + 0.1 Fig. 3. Little change was seen between the Tc values for virgin PEO and PEO-MMT samples 400,000 g mol-1 PEO With 5% MMT With 10% MMT 0.1 30 40 50 60 70 80 30 Breakdown Strength (kV/mm) 40 50 60 70 80 Breakdown Strength (kV/mm) Fig. 6. Little change was observed with addition of 5% or even 10% MMT to either 1,000,000 g mol-1(Left) or 400,000 g mol-1 (Right) 70 Approx. Tc or Tm 65 Despite observing no MMT effect in the breakdown data, it was hopeful that the MMT would perhaps affect the disc electrically as a whole, more than at specific points. For virgin PEO samples the permittivity and tan delta were almost identical, and independent of molecular weight, Fig 7. 60 Virgin PEO Tm 55 Virgin PEO Tc 50 30 45 Real Relative Permittivity 20 40 0.0 0.2 0.4 0.6 0.8 1.0 1.2 10 Molecular Weight /106 g mol-1 Fig. 4. Similar distributions of Tm and Tc values were observed for molecular weight, with 400,000 g mol-1 having the highest. 5 3 1 2 1e-2 1e-1 1e+0 1e+1 1e+2 1e+3 1e+4 1e+5 1e+6 1e+7 Frequency (Hz) Tan delta With no apparent effect on thermal and physical properties, addition of MMT may still affect the electrical properties of the composite. A quick test for reliability of the data was to check that the beta value generated by the Reliasoft Weibull program for each data set was higher than 10, which it was for all samples. Comparison of varying PEO molecular weights showed that the higher molecular weights exhibited a decrease in breakdown strength. Comparison of the MMT-PEO composites to their virgin counter-parts, again showed little to no change. 10 0.1 0.01 400,000 g mol-1 Tan delta 1,000,000 g mol-1 Tan delta 0.001 1e-2 1e-1 1e+0 1e+1 1e+2 1e+3 1e+4 1e+5 1e+6 Frequency (HZ) Fig. 7. Little change in Tan delta or relative real permittivity (inset) was observed with varying molecular weigh 400 1e+5 100 100 1e+4 50 20 10 5 10 3 1e-2 1e-1 1e+0 1e+1 1e+2 1e+3 1e+4 1e+5 1e+6 1e+7 Frequency (Hz) Tan delta 1 0.1 Relative Imaginary Permittivity Real Relative Permittivity 200 1e+3 1e+2 1e+1 400,000 g mol-1 with 10% MMT 1,000,000 g mol-1 with 10% MMT 1,000,000 g mol-1 with 5% MMT 1e+0 1e-1 0.01 0.001 1e-2 400,000 g mol-1 PEO 400,000 g mol-1 with 10% MMT 1e-2 5 1e-1 1e+0 1e+1 1e+2 1e+3 1e+4 1e+5 1e+6 400 Real Relative Permittivity 200 100 100 50 20 100 200 500 Figures 8-9 outline the increased tan delta and real permittivity with addition of MMT. The Cole-Cole plot figure 10 shows the resultant two PEO-MMT samples containing 10% MMT behaved almost identically dielectrically. It was also observed that the amount of MMT added was irrelevant, figure 11 showing very close correlation between 5% and 10% weightings. 10 10 5 3 1e-2 Tan delta 50 Fig. 11. Cole-Cole plots for samples with MMT. Real and imaginary permittivity appears independent to amount of MMT added 1e+7 Fig. 8. Addition of MMT to 400,000 g mol-1 causes a large increase to real permittivity at low frequencies (inset) as well as a flatter tan delta curve compared to virgin PEO 1e-1 1e+0 1e+1 1e+2 1e+3 1e+4 1e+5 1e+6 IV. 1e+7 Conclusions Frequency (Hz) 1 0.1 0.01 1,000,000 g mol-1 PEO 1,000,000 g mol-1 with 10% MMT 1e-1 1e+0 1e+1 1e+2 1e+3 1e+4 1e+5 1e+6 1e+7 Frequency (HZ) Fig. 9. Addition of MMT to 1,000,000 g mol-1 again causes an increase to real permittivity at low frequencies (inset) as well as a flatter tan delta curve 1000 1e+5 1,000,000 g mol-1 PEO 400,000 g mol-1 PEO 100 10 1 0.1 With the observation that the viscosity of the PEOMMT composite was the same as virgin PEO, this suggests that the molecular mobility was not affected. This belief was confirmed by thermal melting and crystallization data by DSC. The addition of MMT was deemed to cause no change in the electrical breakdown strength, however an increase in molecular weight exhibited a decrease in breakdown strength. The dielectric data however, showed a large increase in tan delta and real permittivity with addition of MMT. This shows an increase in conduction when viewed as a Cole-Cole plot. Further investigations into a new ColeCole method will determine whether another relaxation process is present.x -1 1,000,000 g mol with 10% MMT -1 400,000 g mol with 10% MMT 1e+4 Relative Imaginary Permittivity Relative Imaginary Permittivity 20 Relative Real Permittivity Frequency (HZ) 0.001 1e-2 10 1e+3 REFERENCES i Municipal Solid Waste (MSW), U.S. Environmental Protection Agency 1e+2 1e+1 www.epa.gov/msw/plastic.htm ii “Electrical properties of polymers” iii ME! 1e+0 Tony Blythe, David Bloor 1e-1 “An evaluation of the transition temperature range of super-elastic orthodontic NiTi springs using differential scanning calorimetry” iv 0.01 1e-2 2 5 10 20 30 Relative Real Permittivity 2 5 10 20 50 100 250 600 Relative Real Permittivity Fig. 10. Cole-Cole plots for virgin PEO samples (Left) displaying a single relaxation with conduction, and PEO-MMT samples (Right) displaying possibly two relaxations and conduction. Otto Barwart, Judith M Rollinger, Artur Burger 1999 European Journal of Orthodontics, Volume 21, pp. 497-502 v “Life Data Analysis Reference” Reliasoft 2005 “Influence of Threshold Stress on the Estimation of the Weibull Statistics” vi Chunsheng Lu, Robert Danzer, Franz Dieter Fischer 2002 Journal of the American Ceramic Society, Vol 85, issue 6, pp 1640-1642 vii CHRIS viii “Life Data Analysis Reference” Reliasoft 2005 ME x “A new graphical representation for dielectric data” Yan-Zhen Wei, S Sridhar J. Chem. Phys. 99 (4) 1993 ix