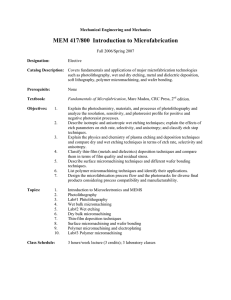

Thermal Oxidation Lab Activity

advertisement

En.wikepidia.org FIU /RET Lesson Plan Microfabrication Techniques Thermal Oxidation Lab Carlos Hernandez Summer 2014 Openrotterdam.nl Carlos Hernandez RET Summer program 2014 School: Miami Sunset Senior High Subject Area: Chemistry Associated Unit: Engineering Lesson Title: Thermal Oxidation Lab Activity wiki.org Grade Level: 9-12 Lesson # 3 of 4 This lab activity is used to reinforce topics covered in a prior lesson on elements and their uses in society. This Lesson is the third component of a four lessons activity. Lesson 1 involves uses of elements and the periodic table. Lesson 2 involves a power point presentation involving the manufacturing of a MicroElecrical Mechanical Systems (MEMS) pressure sensor created by Dr. Pala. The PowerPoint is used to show the relationship between computer science math and chemistry. The fourth component is the assessment portion of the salient. Time Required: 60 minutes total time. (Time can be altered depending on the student population) 45 minutes suggested time for lab activity leaving 15 minutes for attendance, instruction and closure. Lesson Summary The student will be asked to design a furnace and collect water vapor on a paper wafer in an allotted time frame. The purpose of this lesson is to imitate thermal oxidation techniques using everyday household materials. Thermal oxidation is the first step in many microfabrication building processes this activity provides the student with an insight into microfabrication. Engineering Connections: The students will be using the same concepts of evaporation and absorption techniques engineers employ in today’s microfabrication processes. They will also be using engineering concepts in constructing the makeshift furnace as well. The student will be exposed to the concepts of combining engineering concepts to chemistry. 1. Engineering Category: Engineering design process, Chemical Engineering Key words: Diffusion: a scientific law that describes the flow of a substance from high to low concentrations. Furnace: An appliance used to heat. Microfabrication: the design of devices in the micro meter range. Thermal oxidation: The process of creating thin layers of oxide onto a silicon wafer. This application is done be diffusing an oxidizing agent onto the wafer. Phase change: the ability of a substance to go from one form to another. Evaporation Rate: The rate at which a solution boils and forms a gas Phase change: A change of state Boiling point: The temperature which a liquid boils. Educational Standards STEM: SC.912.N Nature of Science / SC9.12.P Physical Science ITEEA: Nature of Science NGSS: HS-ETS1-2, HS-PS1-3 Pre requisite Knowledge. Teacher: How micro sensors are engineered using MEMS applications. The use of silicon in the microfabrication field. Types of furnace used in the microfabrication field. Student: Boiling point, phase change and the process of thermal oxidation in microfabrication building processes. Learning Objectives: The learning objective is for the student to understand how thermal oxidation is used in coating silicon wafers for microfabrication processes. . 2. Introduction Motivation. The lab activity should be used to engage the students with hands on activity and provide a visual reference into microfabricaiton techniques by imitating thermal oxidation. The teacher should start the lesson with a recap of the two types of furnaces applications (vertical and horizontal) and the purpose of the activity. The following lab will be performed by small student groups. General Lab activity procedures 1. Recap the furnace design (vertical and horizontal directions ) and purpose of lab (prompt) 2. Introduce the materials / Lab safety 5 minutes Aluminum paper, 250 ml Beaker, water, paper clips 2, empty napkin roll any size, hot plate, ring stand, clamps 2, 3 construction paper wafer, scissors, ruler and a two decimal place scale. 3. Gathering of materials 4. Ask students to build a furnace that evaporates water vapor onto a paper wafer. The student is allowed to choose a horizontal design or a vertical design. The wafer is to be placed onto the roll by making incisions on its side. 5. Run lab: Have each group complete three trials of increasing absorption time of 1 to 3 minute intervals. 6. Data: have students weight the wafer before and after they place it in the furnace. 7. Clean up 10 minutes. 8. Closure: Quick wrap up of the lesson, how did the experiment fair. Engage students in how did the placing of the napkin roll affect the amount of water vapor collected. (5 minutes) The general lab procedure is an outline to help the teacher design their own set of guidelines to better fit the needs of the class. During Lab Teacher activity during lab: Walk around and assist students as needed in their design. Provide assistance when needed based on grade level or ability of student. The images below are two examples of makeshift furnaces. 3. Vertical Setup Horizontal design Lesson Background: The lesson is based on techniques used in real world engineering process of microfabrication. Thermal oxidation is a process of diffusing elements onto a silicon wafer to create a foundation for later techniques such as photolithography which can be used to create patterns in the micro meter range. The following are resources recommended for the teachers prior to the lab activity. www.Wikipedia.com : Thermal oxidation/ Furnaces used in thermal oxidation / Microfabricaiton / photolithography. www.Google.com : minibrute image MEMS Pressure Sensor PowerPoints presentation by Dr. Pala Associated Activities : Photolithography 4. Suggested Assessment Writing Component The assessment will be the lab write up for the lab activity. This will involve the student summarizing the purpose of thermal oxidation in the micro fabrication of silicon and describing and drawing their design. This will be done the next day in class following the lab activity. The assessment portion is the 4th part of the lesson. The design drawing can be done as a homework assignment and the actual lab write up as an in class assessment. The report is written per student as an in class assignment and assigned three separate grades. The teacher can decide what rubric to use to grade each component of the lab report based on grade level and individual student level. Math Engineering Component Have students create a graph of absorption of water vapor mass vs time. Students will be asked to plot three points based on the data collected and draw the shape of the graph. Students must also show algebraically the calculation of the vapor mass. The student should be given one class period, 60 minute, to write the lab report and graph. Based on student population and grade level teacher can alter the time frame here as well. 5.