Electronic supplementary information (ESI)

advertisement

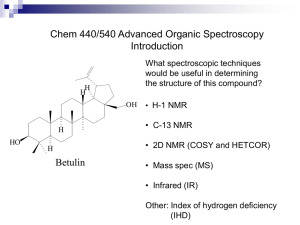

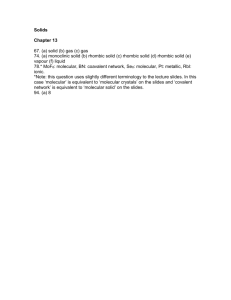

Electronic supplementary information (ESI) for A Novel Method for Preparing Silver/Poly(siloxane-b-methyl methacrylate) Nanocomposites with Multiple Properties in the DMF-Toluene Mixture Solvent Hua Chengb, Yin-Ning Zhoua, Zheng-Hong Luoa, b* a Department of Chemical Engineering, School of Chemistry and Chemical Engineering, Shanghai Jiao Tong University, Shanghai 200240, P R China b Department of Chemical and Biochemical Engineering, College of Chemistry and Chemical Engineering, Xiamen University, Xiamen 361005, P R China * Correspondence to: Z.H. Luo; e-mail: luozh@sjtu.edu.cn Tel.: +86-21-54745602 Fax: +86-21-54745602 1 Experimental Materials Monocarbinol-terminated polydimethylsiloxane (PDMS-OH, 5000 g/mol) and Ethyl 2-bromoisobutyrate (Eib-Br, 98%) and 2-bromo-2-methyl-propionylbromide (98%) were obtained from A Better Choice for Research Chemicals GmbH & Co. KG (ABCR, Germany). Triethylamine(99%) was supplied by Sinopharm Chemical Reagent Co, Ltd. (SCRC,China) and stored over 4-Å molecular sieves. Methyl methacrylate (MMA, CP) was purchased from SCRC and was washed with 5 wt. % aqueous NaOH solution to remove the inhibitor. 1,1,4,7,7-pentamethyl diethylenetriamine (PMDETA, 98%), tryptone, yeast powder as well as agar were of analytical grade and used without further purification which were obtained from Sigma-Aldrich, USA. Cu (I) Br (98%) was supplied by SCRC and was purified by glacial acetic acid and methanol. Dimethyl formamide (DMF, 99%), silver nitrate (AgNO3, AR) and all other reagents and solvents were of analytical grades which were obtained from SCRC and used without further purification. Measurement methods Proton nuclear magnetic resonance (1H NMR) of PDMS-b-PMMA was recorded on a Bruker AV400 instrument with deuterated chloroform as the solvent. The molecular weight (Mn) and molecular weight distribution (Mw/Mn, PDI) of the cleaved polymers of PDMS-Br and PDMS-b-PMMA were determined at 40 °C by gel permeation chromatography (GPC) equipped with a waters 1515 isocratic HPLC pump, three Styragel columns (Waters HT4, HT5E, and HT6) and a waters 2414 2 refractive index detector (set at 30 °C), using THF as the eluent at the flow rate of 1.0mL min-1. A series of polystyrene narrow standards were employed to generate a universal calibration curve. X-ray photoelectron spectroscopy (XPS) spectra were recorded in order to determine the surface composition of Ag/PDMS-b-PMMA nanoparticles using a PHI quantum 2000 scanning ESCA microprobe (physical electronic, USA), equipped with an Al Kα1, 2 monochromatic source of 1486.60 eV. The formation of AgNPs was monitored by observing the surface plasmon resonance of the AgNPs using a UV-visible spectrophotometer (UV-2550). Transmission electron micrographs (TEM) were obtained on a transmission electron microscope (JEM-2100) operated at an accelerating voltage at 200 kV. SEM images were obtained from a field emission scanning electron microscope (LEO1530), equipped with a setup for element analysis by X-ray energy dispersion(EDX). Sample preparation for SEM was performed by dropping the reaction solution on clean silicon wafer. After air-drying for 3 h at room temperature, the samples were treated by gold sputtering. The thermol property was recorded on SDTQ600 thermo gravimetric analyzer and set the measurable temperature range from room temperature to 800 ℃ in nitrogen atmosphere while fixing the heating rate at 10 ℃/min. Static water contact angles of the nanocomposites films were measured by casting the 2 wt% THF nanocomposite solutions on glass slides and were recorded on a telescopic goniometer (DSA30) contact angle measurements. The reduction rate of 3 the silver ions was characterized on Atomic Absorption Spectrophotometer (TAS-986), while keep the acetylene flow rate at 1.3-1.4 L/min and set the wavelength at 328.1 nm. Preparation of PDMS-b-PMMA with different block lengths PMMA was synthesized by atom transfer radical polymerization (ATRP) in this work. The typical molar ratio of [CuBr]/[PMDETA]/[Eib-Br]/[MMA] was 1:1:1:100, (yield: 65%). The 1H NMR and GPC were shown in Figure S1-2. PDMS-b-PMMA block copolymers were prepared by ATRP as our contemporaneous work showed in Scheme S1-2.1 Different lengths of PMMA block were synthesized with [MMA]/[I]=20/1, 50/1, 80/1, and 100/1. The four kinds of copolymer were obtained and their chemical structures are shown in the 1H NMR spectrum. As shown in Figure S3, a distinct peak at 3.70 ppm belongs to -OCH3, which indicated the copolymerization of MMA with PDMS. Herein, the PDMS block has distinctive peak centered at 0.15 ppm, corresponding to the dimethylsiloxane repeat units. Integal ratios of the dimethylsiloxane repeat units at 0.15 ppm to the region at 3.70 ppm could be used to calculate the absolute number-average molecular weight value. In addition, Figure S4 describes the number-average molecular weight (Mn,GPC) and molecular weight distribution (PDI) of the resulting macroinitiator and copolymers. The elution peaks are symmetric and exhibits few tailing at the lower molecular weight side with narrow molecular weight distribution of the resulting copolymers. For comparison, the number of monomer units agreed quite well with the NMR results. The ultimately 4 chemical compositions of the resultant products are composed of PDMS65-b-PMMA8, PDMS65-b-PMMA18, PDMS65-b-PMMA30 and PDMS65-b-PMMA67, respectively. Figure S1. 1H NMR spectrum of the PMMA polymer in CDCl3. Figure S2. GPC traces of the PMMA polymer. 5 Scheme S1. Synthetic Scheme of the PDMS-Br Macroinitiator. Scheme S2. Synthetic Scheme of the PDMS-b-PMMA Diblock Copolymers. 6 Figure S3. 1H NMR spectrum of the PDMS-b-MMA diblock copolymers in CDCl3. (A) PDMS65-b-PMMA8; (B) PDMS65-b-PMMA18; (C) PDMS65-b-PMMA30; (D) PDMS65-b-PMMA67. 7 Figure S4. GPC traces of the PDMS-Br and PDMS-b-MMA diblock copolymers. (from right to left) PDMS-Br, PDMS65-b-PMMA8, PDMS65-b-PMMA18, PDMS65-b-PMMA30, PDMS65-b-PMMA67. Literature Cited 1. Yu L, Qiu JJ, Cheng H, Luo ZH. Facile preparation of gold nanoparticles using the self-assembled ABC non-amphiphilic fluorosilicone triblock copolymer template. Mater Chem Phys. 2013;138:780-786. 8