ELECTROSTATIC CHARGE-DISCHARGE

advertisement

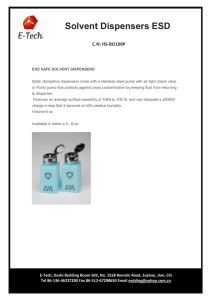

General Application Guide ELECTROSTATIC CHARGE-DISCHARGE Static Electricity To understand electrostatic discharge, let’s start by explaining electrostatic charge or static electricity… Static electricity is a natural phenomenon which, in some cases, can have devastating effects. One of the most impressive manifestations of this phenomenon is lightning but many other far more discrete manifestations can be just as dangerous. Static electricity is most commonly created by friction and separation of two materials (triboelectric charging). For example, if you walk across a nylon carpet, you generate static electricity as your shoe soles contact then separate from the floor. In fact, as contact and separation take place, electrons are transferred from the surface of one material to the surface of the other material. This creates an imbalance of electrons, causing an electrical charge known as static electricity. This imbalance of electrons produces an electrical field, which can influence other objects at a distance. Figure 1: Triboelectric Charge: Materials Make Intimate Contact (Courtesy of the ESD Association) Figure 2: Triboelectric Charge: Materials Separate (Courtesy of the ESD Association) The amount of static electricity generated depends on the materials in presence, on the amount of friction but also on other factors such as the relative humidity of the atmosphere. To give an idea, here are some typical voltage levels encountered in electrostatic charge generation. Examples of Static Generation Typical Voltage Levels Means of Generation 10-25% RH 65-90% RH Walking across carpet 35,000V 1,500V Walking across vinyl tile 12,000V 250V Worker at bench 6,000V 100V Poly bag picked up from bench 20,000V 1,200V 18,000V 1,500V Chair with urethane foam Figure 3: Typical Voltage Levels (Courtesy of the ESD Association) ElectroStatic Discharge (ESD) Electrostatic discharge is defined as the transfer of charge between bodies at different electrical potentials. Sometimes, after walking across a carpet, we feel a shock when touching the elevator button. This corresponds to an electrostatic discharge. Such a shock gives an unpleasant feeling, but is not life threatening. In general, a human being can feel electrostatic discharges of 3,000 Volts or more. Looking at Figure 3, we now understand why we are far more likely to get a shock when closing the car door in winter, when the relative humidity of the air is low, than in summer. In the world of electronics, charges of 1,000 Volts or less can suffice to weaken or permanently damage a component. In sensitive environments like (agro)-chemical factories, gas stations or mines, the slightest spark can lead to a catastrophe. 2. How can I control ESD? It is impossible to avoid completely the generation of static electricity. The whole idea of ESD control is to safely dissipate any electrostatic charge, avoiding excessive accumulation. We must provide paths that lead the charge to earth. For this, conductive materials play a major role. We must also prevent discharges that do occur from reaching sensitive parts. Conductive packaging helps in this field. In today's world, more and more items are made of plastics because they offer many advantages over traditional materials such as metal: no corrosion light weight recyclable ease of creating complex geometries often the most economical solution Unfortunately, virgin polymers are insulative. They can however be made conductive by various means. One very cost effective way of obtaining permanent ESD control is to add conductive carbon black to the polymer. 3. How does carbon black make plastics conductive? The volume resistivity of a polymer is 1014 to 1016 ohm.cm. A virgin polymer is therefore a good insulator. The volume resistivity of dry carbon black is 10-2 to 10-3 ohm.cm. Dry carbon black is therefore a good conductor. When carbon black is compounded in plastics, conductivity is imparted by the carbon black. The level of conductivity obtained is a function of the carbon black loading but the relationship is not linear. Figure 4: Percolation curve The graph presenting resistivity in function of carbon black loading is called percolation curve. At low loadings, the carbon black particles are not close enough to each other to form a path for the passage of electrical charge. Around a certain loading, called percolation threshold, the system passes rapidly from insulative to fully conductive as the particles are now sufficiently numerous to form a network to lead the current. At higher loadings, conductivity will improve further but not dramatically. 4. What are the different types of potential ESD damage in electronics? In the world of electronics, there are different types of ESD damage, such as: Catastrophic failure: If an electronic component is submitted to an ESD event, permanent and immediate damage such as junction breakdown, oxide failure or metal melt can occur. In this case, the component no longer functions. If the part is tested in the factory after the ESD event, the defect will be easily detected. If not, the final customer will be disappointed when he tries to turn on his new acquisition. Latent defect: In this case, the electronic component exposed to an ESD event is partially degraded but continues to operate. However, its lifetime can be seriously reduced, leading to breakdown of the part shortly after the beginning of use. And we all know how annoying it is to have to take our almost new television or computer back to the shop for repair. ESD Damage—Facts and Figures: It has been estimated that average product losses in the electronic industry due to static electricity can be as high as 33%! Per year, the cost of ESD to the industry can be figured in billions of dollars. As the world of electronics progresses, parts are becoming smaller and smaller. This means that distances between insulators and circuits are decreasing, thereby increasing the sensitivity of the device to ESD. ESD control is, therefore, a flourishing area of activity, with a promising future. 5. ESD Solutions - Conductive Packaging Electronic components are submitted to handling and transport all along the chain from their production to their incorporation in a finished article. To avoid accumulation of electrostatic charge which would be dangerous to the ESD sensitive device, it is advisable to use conductive packaging at all stages. This way, the sensitive devices are shielded from charge and the generation of charge caused by the movement of the item within its packaging is reduced. Thermoplastic based compounds containing conductive carbon black can be transformed by a variety of techniques to best suit the application. Let’s take a closer look at some examples of conductive packaging for the electronics industry. IC Carrier Tapes: The compound used is based on a styrenic polymer or on polycarbonate. It is extruded into a flat sheet, typically 300 to 500 µm thick. Pockets are then made by thermoforming. The shapes and sizes of the pockets are variable, in function of the part to package. When the pockets have been filled with the electronic component, a transparent cover tape is applied to close the pocket and the carrier tape is wound on a reel. The parts are now ready to be transported to the end user (eg a producer of computers or mobile phones). When needed, the transparent cover tape will be peeled off and the parts will then be available for assembly. IC Thermoformed Trays: The compound used is also based on styrenic resin. It is extruded into flat sheet, typically 300 to 1000 µm thick. By thermoforming, pockets will be produced to house ESD sensitive devices. IC Rigid Trays: IC rigid trays are prepared by injection molding. The base polymer is variable, depending on whether the tray needs to withstand baking or not. ESD Boxes: The compound used is often based on polypropylene. It is transformed by injection molding to produce crates or boxes, with or without lids. These are used for the transport of ESD sensitive devices. ESD Corrugated Board: Compound based on polypropylene is transformed into corrugated sheet by extrusion. The template of the box we want to produce is then cut out of the flat sheet. By folding, we obtain a container of the chosen geometry. ESD Film: In this case, polyethylene is the preferred base resin. The compound is transformed by blown film extrusion. The bubble is subsequently cut and welded to form conductive pouches for the packaging of ESD sensitive elements. 6. ESD Protected Areas For optimal ESD control, all electronic components must be produced and assembled in ESD protected areas (EPA). The idea is to lead all charge safely to ground to avoid discharge into a sensitive part. Conductive materials are present in a wide variety of applications in EPAs, as we can see from the following list of examples: surfaces: flooring, work benches equipment for workers: wrist straps, shoe soles tools: screwdriver handles furniture: chair wheels 7. Safety-Related Applications Material in powder form is potentially explosive. We have all heard of dust explosions in chemical factories or grain silos. Many liquids also present a risk of explosion. Just imagine what a devastating effect an ESD event would have in a gasoline station. Confined areas such as mines are also high risk zones where the slightest spark can lead to a catastrophe. In all these areas and situations where an electrostatic discharge represents a big danger, conductive plastics play a major role. Blow molded containers: HDPE based compounds can be processed by blow moulding to produce jerricans or drums for the transport and storage of dangerous goods, generally flammable liquids or materials in powder form. Blown film: blown film is also used for the packaging of liquids or powders, for example in the form of conductive liners for non-conductive drums. Fibers/slit tape: conductive fibers can be woven into the structure of big bags to form conductive paths, thereby dissipating safely any eletrostatic charge. Pipes and profiles: Conductive compounds are used to produce pipes for mines, chemical or agrochemical factories, gasoline stations or any other sensitive areas which need ESD protection. 8. Reference Web site of the ESD Association: http://www.esda.org/