PSE 487 PULP AND PAPER CAPSTONE DESIGN

advertisement

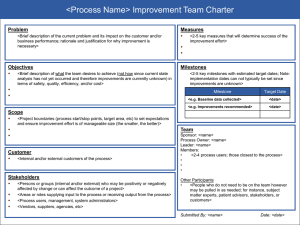

1 BSE 480 BIORESOURCE CAPSTONE DESIGN First Report Requirements Literature Review and Critical Issues The first task in the project is reviewing the literature on the subject, acquiring whatever data are necessary for the design and laying out a design plan. For your first progress report (due January 19th) you are to provide a report on what information is available in the literature (or from other sources) for your design, and a list of critical issues that you think will need to be addressed to complete this design exercise. We will discuss the literature review and the critical issues when we meet on the 19th. In addition, we will discuss how each of these issues may be resolved. A thorough understanding of what data are available will be needed to discuss resolution of the questions. It is imperative that your literature review be complete. Finally, as a group, we will come up with an overall problem statement and a list of critical issues that apply to the entire design exercise. For this 1st review you should be focusing on the following questions: 1. What technologies are used to produce ethanol/glycols from sugars? 2. What are the advantages and disadvantages of these technologies? 3. What are the raw material (e.g. purity) requirements for these technologies? a. Fermentation inhibitors, catalyst poison 4. What are the product purity requirements? 5. How are the raw materials and product streams cleaned up (fractionated) to meet purity requirements? 6. What are the potential impacts of removing sugars from the red liquor stream (issue for “ethanol” group)? 7. What are the markets for ethanol and glycols? a. How much is sold and for how much $$. Planning Report In addition to defining the problem, you will need to begin mapping out how you will do the project. In this first report, you should outline what you will be doing over the quarter, and how you will be doing it. The following expands into more details the kind of information that is expected in the planning report. General Information: There are two parts to the planning report. The first part of the report deals with group goals (milestones) through the balance of the project. A time line should identify when goals or milestones are to be completed. Milestones and goals can be considered significant steps toward completion of the project. As an example, you might indicate at what point your group will have determined all the process or product alternatives to be considered. Another goal might be when the first flow sheet is to be completed. A third goal might be when the preliminary capitol cost estimates will be complete and conveyed to the others in the class. A fourth goal might be when your group finishes with the first draft of the final report. Page 1 of 5 2 The second part of the planning report will focus on the group assignments for the project. The group time line will provide more detail on the work to be done. Here group assignments are made indicating at what point group projects will be completed throughout the balance of the project. This part of the report needs to be especially detailed. It is unsatisfactory to indicate over the next two weeks that some group is going to work on the reactor system. Instead, that two-week period should be broken into segments with specific goals. For example, the conversion processing conditions will be established and a report written to the group giving the possible process conditions. A second goal would then to develop flow diagrams of various process configurations. Each task should have a clear objective, who is responsible, and when it will get done. In preparing this group planning report, keep in mind the overall picture provided by the design goals. Always strive to provide as much detail as possible. By doing so you not only provide yourself and your other group members with an idea of what will be done when, you will also give yourself an idea of the scope of the project and be better able to assign it an appropriate amount of time in the project planning. By providing details of what is expected, you should not have misunderstandings about missing information or using incorrect assumptions. While we expect that these planning reports be made as accurate as possible, we also expect that they will change and deadlines may turn out to be unrealistic. That does not mean, however, that repeated missing of deadlines is satisfactory. The planning report should be laid out in the form of a table with the columns representing time, the rows should be major tasks and milestones within your part of the project. Examples below show how the time line can be presented. Page 2 of 5 3 Objective 7/2008 1/ 2009 7/2009 1/2010 7/2010 Task 1. Development of the versatile and robust pretreatment process for mixed feedstock a) Source necessary biomass b) Optimize steam pretreatment conditions c) Complete in-depth comparison of SSF and SHF processes Task 2. Hydrogenation of pentose sugars and separation of mixed glycols a) Complete equipment set-up and start-up trials b) Decontamination of pentose rich, post fermentation stream c) Establish best catalysis and process conditions for pentose sugar streams containing hexoses and other potential contaminants d) Develop optimized separation train for glycols and alcohols Task 3. Aspen model and technoeconomic evaluation a) Develop Aspen models for primary unit operations and support utilities b) Assemble complete process simulaitons from unit operations models c) Update and revise process models based on experimental data from tasks 1 and 2. d) Optimize process based on final data from tasks 1 and 2. Assess technial and economic feasiblity Figure 6. Project schedule broken down by tasks and major milestones. Page 3 of 5 1/2011 7/2011 4 Table 1. Project milestones with quantifiable measure of performance and deliverables. Milestone Task I: Biomass decomposition and ethanol production a) Source necessary biomass b) Optimize steam pretreatment conditions c) Complete in-depth comparison of SSF and SHF processes Task II: Hydrogenation of C5 sugars and separation of mixed glycols a) Complete equipment setup and start-up trials b) Decontamination of pentose rich, post fermentation stream c) Establish best catalysis and process conditions for pentose sugar streams containing hexoses and other potential contaminants d) Develop optimized separation train for glycols and alcohols from actual process streams Task III: Aspen model and techno-economic evaluation a) Develop Aspen models for primary unit operations and support utilities b) Assemble complete process simulaitons from unit operations models c) Update and revise process models based on experimental data from tasks 1 and 2. d) Optimize process based on final data from tasks 1 and 2. Assess technial and economic feasiblity Quantifiable performance measures Adequate (~60kg) wheat straw and poplar are obtained for the project Process conditions that result in 90% recovery of hexoses and pentoses, 90% of the theoretical maximum ethanol yield from hexoses, have less than 10% non-sugar organics in pentose streams Operational data and product yields from both processes to be used in modeling analysis Deliverables Definition of technology to generate process with 90% recovery of hexoses and pentoses, 90% of the theoretical maximum ethanol yield from hexoses, have less than 10% non-sugar organics in pentose streams Recommendation of which process technology to adopt and associated optimal processing conditions All equipment will be functional. Thorough safety audit will be complete Pentose stream will be clean enough to process without significant catalytic degradation Sufficiently clean pentose stream for catalytic conversion to glycols Catalysts and conditions that result in good glycol yields will be determined 85% conversion of pentoses to glycols. Over 40% of glycols produced will be propylene glycol Appropriate catalyst and process and reaction conditions to achieve 85% conversion of sugars to glycols and product mix that is over 40% glycol. Separation methodology that yields glycols with sufficient purity for commercial use; 98.6% Separation process design that results in 98.6% purity for major final products. Aspen plus models of all major process unit operations Working simulations of major biorefinery unit operations Complete biorefinery simulations Complete simulation that is internally consistent and matches results published in the literature Identification of key variables for economic and environmental performance. Quantification of acceptable range of these variables for profitable operation An optimized process that approaches 100% energy self sufficient and has an ROI in the range of 20% Complete assessment of sensitivity to key economic and environmental factors Optimized process configuration. Final technical and economic assessment of proposed process. Desired process needs to produce 100% of its energy needs internally and has a return on investment in the range of 20 % Page 4 of 5 5 Specific items needed for Report #1: A written report that reviews the pertinent literature and provides a project time line. The report should also specifically say what will be accomplished in the next two weeks and who is responsible for what. I also want to see a list critical issues you think need to be addressed. Each group will also be responsible for making a PowerPoint presentation on the 19th. Page 5 of 5