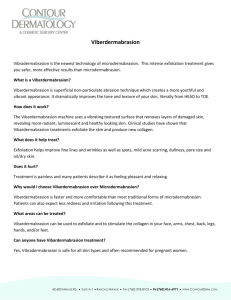

microdermabrasion machines are not the same, nor do they work in

advertisement