ISEM SOP TEMPLATE - UCI Environmental Health & Safety

advertisement

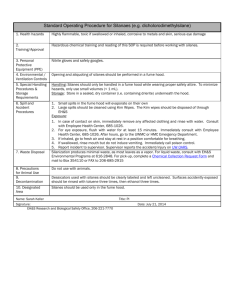

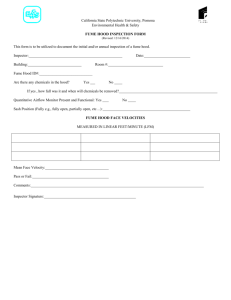

READ AND REVIEW ANY APPLICABLE MANUFACTURER/VENDOR SAFETY INFORMATION BEFORE DEVELOPING STANDARD OPERATING PROCEDURE AND PERFORMING WORK. Name of Work Unit: Standard Operating Procedures for 2-Chloroethyl Ethyl Sulfide (CEES, Half Mustard Gas) (CAS# 693-07-2) Please write improvement ideas in space below. #1 Scope of Work/Activity: State the process/operation/equipment that the SOP concerns. Topical application of CEES to tissue culture cells or oral surfaces in animals #2 Specific Safety and Environmental Hazards: State the specific hazard and consequences if procedure not followed to person, environment, or property. Harmful by inhalation, skin contact or swallowing. Possible mutagen. Toxic. Causes blisters on contact with skin. #3 Engineering Controls: Describe any specific engineering controls which are required to prevent employee injury to hazards such mechanical lifts, automatic sensors, machine guards. Perform all work inside an approved fume hood. Work 6” back from fume hood mouth. Flow at hood mouth should be at least 100 linear feet per minute. Designated Area: Indicate the designated area for performing this process. #4 Fume hoods in ______________. #5 #6 Personal Protective Equipment (PPE): State the personal protective equipment selected and required. Examples: safety spectacles, work gloves, steel toe shoes. Lab coats; safety goggles; double glove with nitrile gloves over latex-band latex at wrist over lab coat sleeve. Gloves should be changed hourly if work takes longer than 60 minutes. Important Steps to Follow: List the specific sequence staff should follow to avoid hazard. 1. The fume hood should be checked for flow rate within 24 hours of expected use. 2. Gloves should be inspected for holes or tears. 3. The double layered container with the stock CEES should be opened only inside the fume hood. Once the desired amount of stock material has been removed, the container should be resealed and returned to the refrigerator where stored. 4. All containers with CEES solutions should be kept capped any time not being actively manipulated. 5. If tissue culture dishes/flasks are used they should be placed on an impermeable tray for secondary containment. 6. If animals are used they should be fully anesthetized before being placed in the hood for exposure and inside a secondary containment apparatus lined with absorbent material backed with plastic. 7. After use all contaminated materials should be immediately placed in the appropriate waste receptacles placed inside the hood and kept inside the hood until picked up by EH&S. Liquid waste should not be placed in glass containers. All waste should be double bagged. UC Irvine Environmental Health & Safety, SOP Library, 2/16/2016 #7 Accident Procedures: Describe any special procedures staff should follow in case of accident. Spill: Small—wipe up with absorbent material, wash area with water, place contaminated materials in appropriate waste containers Spill: Large—Cover area with absorbent material, close hood sash, contact EH&S immediately Outer Glove contact: Remove outer gloves, place in disposal container inside hood, replace with new gloves. Clothing: Remove immediately, follow directions for skin contact Skin contact: Wash with soap and water, rinse for at least 15 minutes, seek medical advice if reaction seen Eye contact: Flush with water for at least 15 minutes, seek medical advice immediately Mouth contact: Rinse mouth with water (if conscious), seek medical advice immediately Inhalation: Remove to fresh air. Give oxygen if breathing is difficult, if not breathing give artificial respiration. Seek immediate medical treatment. #8 Training & Competency Requirements: Describe necessary training and demonstration of competency for performing the hazardous operation. To be handled only by permanent, supervisory research staff with documented laboratory safety training. #9 Approval Required: Indicate if and when an approval form the Supervisor is required. #10 Not required since only supervisors will be handling the materials. SOP Review Frequency: Specify how often the SOP is reviewed for effectiveness. Before each experiment. Training Acknowledgement: I have read, asked questions, and understand the hazards of and safe working procedures for the activity/materials described herein. NAME DATE These safety training resources, prepared solely for the use of the Regents of the University of California, were provided by a variety of sources. It is your responsibility to customize the information to match your specific operations. Neither the University of California nor any of its employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the University of California. The views and opinions of authors expressed herein do not necessarily state or reflect those of the University of California, and shall not be used for advertising or product endorsement purposes. UC Irvine Environmental Health & Safety, SOP Library, 2/16/2016