Stress-Free Temperature Test Record Sheet

advertisement

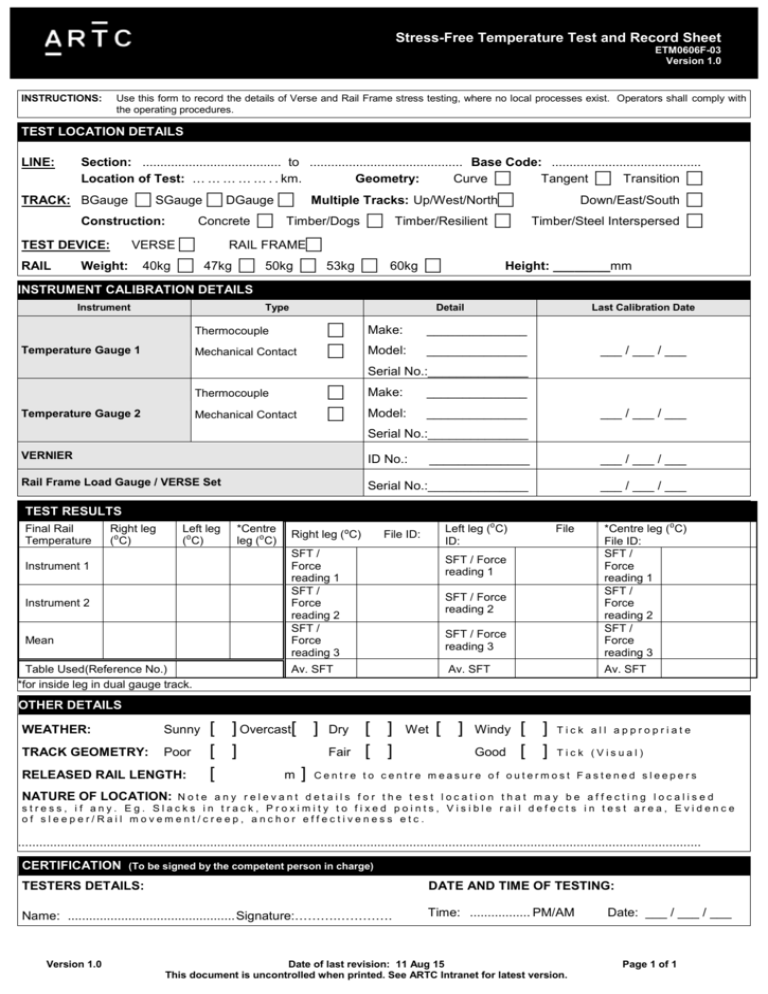

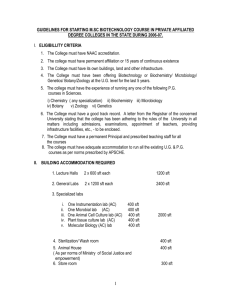

Stress-Free Temperature Test and Record Sheet ETM0606F-03 Version 1.0 INSTRUCTIONS: Use this form to record the details of Verse and Rail Frame stress testing, where no local processes exist. Operators shall comply with the operating procedures. TEST LOCATION DETAILS LINE: Section: ....................................... to ........................................... Base Code: .......................................... Location of Test: … … … … … . . km. Geometry: Curve Tangent Transition SGauge DGauge Multiple Tracks: Up/West/North Construction: Concrete Timber/Dogs Timber/Resilient TRACK: BGauge VERSE TEST DEVICE: RAIL Weight: 40kg Timber/Steel Interspersed Down/East/South RAIL FRAME 47kg 50kg 53kg 60kg Height: ________mm INSTRUMENT CALIBRATION DETAILS Instrument Type Detail Thermocouple Temperature Gauge 1 Mechanical Contact Make: ______________ Model: ______________ Last Calibration Date ___ / ___ / ___ Serial No.:______________ Thermocouple Temperature Gauge 2 Mechanical Contact Make: ______________ Model: ______________ ___ / ___ / ___ Serial No.:______________ VERNIER ID No.: ______________ ___ / ___ / ___ Rail Frame Load Gauge / VERSE Set Serial No.:______________ ___ / ___ / ___ TEST RESULTS Final Rail Temperature Right leg (⁰C) Left leg (⁰C) *Centre leg (⁰C) Right leg (⁰C) File ID: SFT / Force reading 1 SFT / Force reading 2 SFT / Force reading 3 Instrument 1 Instrument 2 Mean Table Used(Reference No.) *for inside leg in dual gauge track. Av. SFT Left leg (⁰C) ID: File SFT / Force reading 1 SFT / Force reading 2 SFT / Force reading 3 Av. SFT *Centre leg (⁰C) File ID: SFT / Force reading 1 SFT / Force reading 2 SFT / Force reading 3 Av. SFT OTHER DETAILS WEATHER: Sunny TRACK GEOMETRY: Poor RELEASED RAIL LENGTH: [ ] Overcast[ ] Dry [ ] Wet [ ] Windy [ ] T i c k a l l a p p r o p r i a t e [ ] Fair [ ] Good [ ] T i c k ( V i s u a l ) [ m ] Centre to centre measure of outermost Fastened sleepers NATURE OF LOCATION: N o t e a n y r e l e v a n t d e t a i l s f o r t h e t e s t l o c a t i o n t h a t m a y b e a f f e c t i n g l o c a l i s e d stress, if any. Eg. Slacks in track, Proximity to fixed points, Visible rail defects in test area, Evidence of sleeper/Rail movement/creep, anchor effectiveness etc. ................................................................................................................................................................................................ CERTIFICATION (To be signed by the competent person in charge) TESTERS DETAILS: DATE AND TIME OF TESTING: Name: ............................................... Signature:……….…………. Time: ................. PM/AM Version 1.0 Date of last revision: 11 Aug 15 This document is uncontrolled when printed. See ARTC Intranet for latest version. Date: ___ / ___ / ___ Page 1 of 1

![[110]](http://s2.studylib.net/store/data/012980371_1-1bdb3065fac587a0d101a2657c00c950-300x300.png)