Recrystallization of Low Melting Point Metal Alloys in Microgravity

advertisement

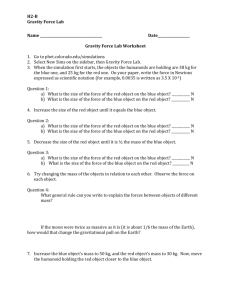

Recrystallization of Low Melting Point Metal Alloys in Microgravity Team Name: 2004-2005 University of Minnesota Microgravity Research Team - Solid Mechanics Institution: University of Minnesota – Twin Cities Aerospace Engineering and Mechanics Department 107 Akerman Hall 117 Union St SE Minneapolis, MN 55455 Team Contact: Jeremy Hanke (hank0072@umn.edu) (920)-819-6127 Faculty Supervisor: Dr. Thomas Shield shield@aem.umn.edu (612)-626-7793 Team Members: Hanke, Jeremy (hank0072@umn.edu). Flyer / Senior / Aerospace Engineering Stephani, Kelly (step0206@umn.edu) Alt. Flyer / Senior / Aerospace Engineering Plumbo, Reid (plum0047@umn.edu) Flyer / Senior / Aerospace Engineering Vue, Fue (vuex0046@umn.edu) Flyer / Senior / Aerospace Engineering Gunderson, Matt (gund0199@umn.edu) Flyer / Senior / Aerospace Engineering Signed: ______________________________ Thomas Shield Faculty Advisor Date: __________ Table of Contents Page No. I. II. Technical Description a. Flight Week Preference b. Abstract c. Test Objectives d. Test Description e. References 2 2 2-3 3-4 5 Experiment Safety Evaluation 6-12 III. Outreach Plan a. Outreach Objectives b. Outreach Phases i. Website ii. School Visits iii. Research Community iv. Media Outreach v. University of Minnesota IV. Administrative Requirements a. Institution’s Letter of Endorsement b. Statement of Supervising Faculty c. Funding/Budget Statement 1 13 13 13 14 14 14 15 16 17 I. Technical Description 1.1 Flight Week Preference: Our team’s top three preferences for flight week are listed below. 1. Flight Group 3 – March 31 - April 9, 2005 2. Flight Group 4 – April 18 – April 22, 2005 3. Flight Group 1 – March 3-12, 2005 1.2 Experiment Abstract: This experiment aims to evaluate the differences in metal alloy crystal structures when the material solidifies in a reduced gravity environment as opposed to typical Earth gravity conditions. As NASA and other space-going organizations push for longer and more demanding space missions, the need to be able to fabricate or manufacture tools and other apparatus during the mission is becoming evident. Little is known about how a reduced gravity environment affects the resulting molecular structure and characteristics of a metal alloy. This experiment will use the metal alloy Cerrobend®, which has a melting point of 158°F, to test this phenomenon. Using an alloy with a low melting point is important to ensure the safety of the experiment. Samples of Cerrobend® will be melted by sending an electric current through the alloy. The sample will then be allowed to solidify within an enclosed environment in reduced gravity. These reduced gravity samples will be analyzed and compared with samples created in a normal gravity environment to determine any difference in crystal structure. A hardness test will also be performed on both sets of samples. 1.3 Test Objectives: Determine an efficient, safe and effective method to melt and solidify a specimen within a short period of reduced gravity. Determine how a reduced gravity environment affects the internal crystal structure of a solidifying metal alloy. Evaluate how material hardness differs in alloys crystallized in microgravity to that of samples made in terrestrial gravity conditions. 2 Study the solidification of an alloy in an environment where the intermolecular attractions are the primary forces involved to learn more about the mechanics of re-crystallization. Determine how the results from this experiment can be used to advance or benefit science and technology and/or society. This experiment is not a follow-up to any previously flown experiments. Hypothesis: Due to a lack of gravitational forces, the dynamics involved in recrystallization will be slightly altered, and thus a change in the resulting crystal structure is expected. Unlike in a terrestrial gravity environment, there will be no convective forces due to gravity. This team hypothesizes that convective flow has an observable effect on the physical and mechanical properties of metal alloys, as shown in previous similar studies (Hayakawa et al. 1). 1.4 Test Description In this experiment, the alloy Cerrobend® will be flash melted and solidified in both a terrestrial laboratory environment (where the gravitational force g = 9.8 m/s2 or 32.2 ft/s2), as well as in a microgravity laboratory environment. The goal of this study is to determine how the absence of gravity affects the crystallographic structure and the physical properties of an alloy. A portable laboratory station (PLS) will be utilized for both terrestrial testing (Phase I) and for microgravity testing (Phase II). The execution of this experiment will begin months prior to the flight. The team will establish a means for comparison by performing the experiment in the PLS on the ground. Samples of Cerrobend® will be cast with wires securely set into opposite sides of the samples. Each assembly will be placed into a fully enclosed cubic Lexan® chamber. The four inner chambers will be bolted to a tray that can be slid in and out of an outer safety chamber. The approximate size of the inner chambers and outer chamber is one cubic foot and 37.7 cubic feet, respectively. Both inner and outer chambers are constructed from Lexan® with sealed edges. Note that there will be one sample of Cerrobend® per inner chamber. Wires will be electrically connected and integrated into a circuit consisting of a switch, fuse and constant current source. The entire apparatus will consist of a row of approximately 8 Lexan® chambers, each with its own on/off switch. This entire apparatus will be fully enclosed by a large Lexan® chamber, with switches located on the exterior of the PLS for use by the experimenters. When the set-up and safety check are complete, the large chamber will be closed to begin the flash melting process. The first switch will be turned to the “on” position and approximately 10 Amperes of current will pass through the specimen. Current will be provided until the alloy is melted. To assist in the cooling process, compressed air will be circulated though a single cooling coil. This coil will be immersed in a separately contained ice bath. The cool air will then be circulated throughout the PLS, which will 3 increase the rate of solidification. The alloy will cool, recrystallize inside the chamber, and the sample will be stored for further analysis. This process will repeat until all specimens are flash melted and recrystallized. The same process will be used during the microgravity portion of the experiment. The design of the experiment allows for most of the set-up and preparation to be completed and checked prior to flight, allowing the experimenters to focus on the task at hand. After the samples from both Phases I and II are collected, the specimens will be qualitatively analyzed. Each sphere will be cut in half, and one half of the sphere will be placed under a microscope to observe the crystalline structure formed during solidification. The other half will be polished and will undergo a Brinell hardness test. The results from both of these analyses will be recorded. The team will then compare data gathered from Phase I and II. Results from experiments aboard the United States Microgravity Payload (USMP) mission series support our thesis. Principle Investigator Martin Glicksman of Rensselaer Polytechnic Institute led the Isothermal Dendritic Growth Experiment (IDGE) (UMSP-4 7). The purpose of IDGE was to study the effects of microgravity on the formation of dendrites. Dendrites are “…tree-like crystals with branches and sub-branches emerging from the main stem (UMSP-4 7).” Dendritic formation on earth is unlike dendritic formation under reduced gravity conditions. A dendrite crystal formed on earth has no branches grown off the top end. The same crystal formed in a microgravity environment will experience branch growth throughout the entire structure. This is caused by “…convective flows that cause the top and the bottom of the branch to solidify differently. In microgravity, dendritic growth is symmetrical (UMSP-4 8).” This “…buoyancy-driven convective flow, which is the motion of the molten material caused by gravity acting on the sample, affects the dendrites (UMSP-4 8).” Since convection affects the motion of molten material in general, Cerrobend® will likely be affected by this phenomenon during this experiment in Phase I. The team hypothesizes that convective flow has a qualitatively measurable effect on the physical properties of Cerrobend®. The absence of convection will allow a more freely arranged crystal structure. Because of the less restricted arrangement, atoms will naturally form stronger bonds with other atoms to which they are highly attracted. Convective flow causes atoms to form weaker bonds because they were forced together. The net increase in stronger bonds between atoms suggests that a metal alloy solidified in microgravity conditions will be physically different from the same alloy solidified on earth. The difference in physical properties may be observed by performing a Brinell hardness test on each specimen. It is evident that the essence of this experiment requires a reduced gravity environment. Microgravity is essential in order to determine gravitational influence on the recrystallization of Cerrobend®. After conducting this experiment, this team hopes to have attained three goals: 1) Determine an efficient, safe and effective method to melt and solidify a specimen within a short period of reduced gravity. 2) Compare the similarities and differences of the Cerrobend® crystalline structure when solidified in a terrestrial environment and a reduced gravity environment. 3) Determine how the results from this experiment can be used to advance or benefit science and technology and/or society. 4 References: Hayakawa, Yasuhiro, et al. “Study on the Crystallization of InGaSb under Different Gravity Conditions.” Shizouka University. <http://www.space.gc.ca/asc/pdf/2000_Hayakawa.pdf >. “UMSP-4: The Final Round of a Great Series.” Microgravity News 4.3 (Fall 1997). <http://microgravity.msfc.nasa.gov/mgnews/fall97/lead.html>. United States. National Aeronautics and Space Administration. Educational Brief: A NASA Recipe for Protein Crystallography. <http://spacelink.nasa.gov/Instructional.Materials/NASA.Educational.Products/R ecipe.for.Protein.Crystallography/Protein.Crystallography.pdf>. 5 II. Experiment Safety Evaluation 2.1 Flight Manifest Proposed Fliers: Matt Gunderson Jeremy Hanke Reid Plumbo Fue Vue Alternate Flyer/Ground Crew: Kelly Stephani There is currently no journalist working with this team. None of the team members have any previous NASA flight experience. 2.2 Experiment Description/Background The objective of this team is to research the effects of reduced gravity on the crystal structure growth of metal alloys. When a metal is in its liquid state, no crystal structure exists. Only when the sample cools and solidifies does a crystal structure form. Each element of this crystal structure has mass and is therefore influenced by the effects of gravity. This research will examine the crystal structure of an alloy formed under the absence of these gravitational forces. This will be accomplished by melting and cooling a small sample of Cerrobend® alloy with electric current while under microgravity conditions. This is the first year this research has been offered from the University of Minnesota @ Minneapolis; this is not a re-flight. 2.3 Equipment Description To successfully melt and harden a sample of Cerrobend® in microgravity, it must be quickly heated and cooled. The alloy selected for this experiment has a low melting point of 160°F. In order to sidestep the problems associated with the heating and containment of a reservoir of molten Cerrobend®, this team intends to use electricity. Current will flow from a constant current source at a level of approximately 10 Amperes through a prefabricated plug of the alloy. The wires passing this current to the sample will be pre-molded into the metal before arrival at Ellington Field. The resistance intrinsic to the metal will cause heating and the sample will melt. This technique of flash melting negates the need to contain excess liquid metal and allows the experiment to be performed on a “by-sample” basis. This method also contains a unique safety feature; when the solid sphere turns to liquid and detaches from the wires, the electrical circuit is automatically broken. This is similar to most fuse technologies. Alternative fuses will be be installed to prevent sudden large current discharges. When the sample has fully 6 melted, a manually operated switch will open the circuit carrying the current and the metal will begin to cool. The cooling process, and possibly the melting process, will take place in microgravity. All of this will happen within a small Lexan® box completely isolated from the rest of the airplane. The cooling process will be helped by the circulation of compressed air through a single cooling coil. This coil will be immersed in a separately contained ice bath. When the air moves through the coils, it will cool below ambient temperature and help speed the solidification process. This is important as the sample must fully solidify in microgravity in order to obtain meaningful results. Switches Individual Containment Box Alloy Sample Constant Current Source Ice Bath and Cooling System Figure 1: Portable Lab Station and Test Setup Schematic 2.4 Structural Design The main structure of this test apparatus is composed of Unistrut® tubing that forms a box measuring 62” x 21” x 50”. This primary structure will be recycled from the 2004 University of Minnesota @ Minneapolis team. This framework will be strapped to 7 the C-9 floor taking advantage of the onboard cargo straps. Inside the steel frame resides a Lexan® box that fills the entire volume of the outer steel structure. This is the primary test chamber. The primary test chamber is bolted to the primary structure and a siliconebased glue will seal the edges. This is necessary to keep gaps and orifices to a minimum to reduce the risk of molten metal at 160°F from escaping into the cabin should one of the secondary test chambers fail. The secondary test chambers are also made from Lexan® with sealed edges. These inner chambers, where the actual melting will occur, will measure 12” x 12” x 12”. The team currently plans to encapsulate approximately 8 test chambers inside the primary test chamber. Each of these chambers will be identical in construction, but may vary in either testing methods or materials. The test chambers will all have a toggle switch accessible from the outside that controls the current flow to the sample. In line with this switch will be a fuse that shall prevent sudden, excessive current spikes. Component Unistrut® frame with Lexan® walls Secondary Lexan® test chambers (including switches, fuses etc.) Constant Current Source Laptop computer Data logging equipment Cerro Alloy spheres to be melted Estimated Weight 120 lbs. 25 lbs. 25 lbs. 10 lbs 10 lbs 1 lb. Total Weight Estimate: 194 lbs. 2.5 Electrical System The electrical requirements for this research are minimal. The major sink of power will be the constant current source. This piece is essential to the experiment as it allows the melting of a sample without the use of flame or other hot materials. The team estimates that 10 Amperes will be required to melt the samples quickly. This is an estimate attained through basic power and resistivity calculations. We will experimentally determine the exact current requirements prior to flying the experiment. The team also plans to bring aboard a laptop computer for data logging purposes. A standard laptop computer requires 110VAC power at 60Hz if available. The laptop battery may also be used if the required power is unavailable. Component Constant current supply Laptop computer Use Provide current to melt sample Data logging Voltage, Frequency 110VAC, 60Hz Current Required 10A 110VAC, 60Hz 1.2A The electrical requirements remain the same for ground testing. A schematic of the electric circuit for the experiment is shown in Figure 2. 8 Constant Current Source Fuse Switch Test Box Alloy Sample Figure 2: Electrical Circuit Schematic 2.6 Pressure/Vacuum System The only pressure mechanism used in this experiment involves the compressed air system used for cooling. The team would like to use pressurized air from the C-9 if it is available. The cooling system will exhaust freely into the PLS. The box itself is vented to the atmosphere and the air jet system will not result in any appreciable pressure increase in the box. 2.7 Laser System There are no lasers used in this experiment. 2.8 Crew Assistance Requirements No assistance from the crew is anticipated to complete this experiment successfully. 2.9 Institutional Review Board This experiment contains to biological substances or human test subjects. This experiment will not require an IRB review. 9 2.10 Hazard Analysis Event Molten metal at 160°F escapes test chamber Cause -Failure of test chamber structure -Failure of seals on test chamber Electrocution -Contact with bare wires Repercussions -Burns (after 1 second of contact) -Temporary blindness (if eye contact) -Damage of nonmetal aircraft interior -Death -Incapacitation Fracture of Lexan® containers -Impact of free floating object -Excessive stresses from flight conditions -Injury to experimenters/flight crew -Damage to cabin Impact with sharp edge/corner Stowage Restraint Failure -Sharp edges or corners -Bodily harm -Failure of tie-down straps -Bodily harm -Damage to cabin -Damage to PLS Inhalation of alloy fumes -Overheating of alloy -Overexposure to AND concurrent failure harmful alloy of test chamber elements 10 Precautions Taken -Molten samples will be within secondary test chambers inside the primary test chamber -All interaction with electricity is done through toggle switches; wires are insulated and contained within primary and secondary test chambers -Gloves will be worn for any interaction with electrical components -High safety factor of structure makes this possibility highly unlikely -All sharp edges and corners will be covered in padding -Load analysis will be performed to ensure adequate straps are used -Electric circuit will be broken once alloy is melted -Primary and secondary test chambers for containment 2.11 Tool Requirements Tools brought aboard the airplane 1 Straight and Phillips screwdriver 1 Leatherman or equivalent multi-purpose pliers 1 pair of leather gloves per experimenter Tools that remain on ground 1 Ratchet and Socket set 1 Set of box end wrenches 1 Extra cargo strap Extra cable ties Each tool will be marked with our team and school name. Each tool will have a team member responsible for its control and safekeeping. 2.12 Ground Support Requirements No ground support services are required for this experiment. 2.13 Hazardous Materials There are no toxic, corrosive, explosive or flammable materials used in this experiment. 2.14 Procedures Ground Operation: We will verify the proper working of all experiment components upon arrival in Houston. This may include some assembly of the PLS and test boxes after transport. Once the PLS and all apparatus are properly assembled, we will ensure that the experiment functions as planned prior to flight date. Pre Flight: The team will install the test package on the airplane using the cargo straps already on the C-9 aircraft. All necessary electrical connections will be made at this time. The laptop and constant current sources will be plugged in. The constant current source will be switched to the “off” position and will not be turned on until the moments before the first period of weightlessness. Each of the inner test chambers will be loaded with its metal alloy and the main test chamber will then be shut and locked into place. It is the 11 hope of the team that this lock will be accessible in flight to retrieve spent samples and swap in new samples from the inner test chambers. In Flight: Just prior to the period of weightlessness, the constant current source will be turned on and shall be ready to deliver the requisite 10 Amperes. When the C-9 enters the flight path that simulates weightlessness, the first switch on the first test chamber will be turned to the “on” position. The provided compressed air will be circulated through the cooling system and into the PLS. The sample will cool and when the C-9 begins to climb again, the sample will fall to the bottom of the chamber where it will remain until all the other samples have been processed. When all 8 samples have been used, the box will be opened during either the climb phase, or a period of weightlessness. The used samples will be collected and replaced with fresh ones. These samples will be placed in a sealed box attached to the test package. This procedure will then be repeated. Post Flight: When the flight is completed and the airplane has safely landed, the constant current source will be switched off and unplugged. The laptop will also be switched off and unplugged. The samples will be collected from the previously mentioned container and preserved for further study. When the team returns home to Minnesota, the samples will be cut apart and their crystal structure will be analyzed. The team also hopes to characterize the physical properties and compare them to that of a sample recrystallized under the influence of gravity. This experiment is different in that most of the meaningful science will take place away from Ellington Field. Preparation for the second flight will include a full debrief by the first team of flyers. Successes and failures will be shared in hopes that the second team of flyers can expand on the triumphs of the first. Adjustments to the test package will be made based on the suggestions of the first team. One of the goals of this year’s research is to develop the techniques that future teams can use to obtain consistently good results. 12 III. Outreach Plan 3.1 Outreach Objectives Being involved in this exciting research project is not only a great experience for the members of the team, but will provide our team with a great opportunity to showcase the possibilities in science to younger students and the general public. The team hopes to get students excited about the opportunities in science and engineering fields by presenting our research to schools. We also hope to reach out to the local media in order to expand our outreach audience to a wide variety of people. 3.2 Outreach Phases Website: The team has already created and uploaded a website for our project, which can be found at http://www.aem.umn.edu/proj-prog/sfo/materials-2005/. The team will soon purchase the domain name http://www.floatinggophers.org in order to make our site more accessible. The site will be updated to reflect the progress of the team as we move from initial experiment design to testing and finally to our trip to Houston. Information about the team members is available, and links to other sites for more information will be added throughout the year. We hope to use the website to advertise our outreach program and to provide an easy spot to locate information that we collect. School Visits: The team plans to make visits to several schools in the spring to showcase our findings and experiment. Several schools around the Twin Cities will be contacted, as well as some of the team members’ alma maters in Wisconsin and Minnesota. Schools that we plan to contact include: Wausau West High School - Wausau, Wisconsin Trinity Lutheran School – Wausau, Wisconsin Bethany Academy – Bloomington, Minnesota St. Mary’s Springs – Fond du Lac, Wisconsin Apple Valley High School – Apple Valley, Minnesota Echo Park Elementary School – Burnsville, Minnesota The main target audience will be middle school and early high school students because we feel that making an impression at that age has a greater impact. These visits will show students the exciting aspects of the field of science. By sharing our experiences in testing aboard the C-9 aircraft in zero gravity, we hope to show that engineering and research are much more than sitting around a lab staring at test tubes. Additionally, we hope to impress upon the students that many of the best experiences to 13 be had in college and in life require student initiative, like this microgravity project. Getting students to motivate themselves is perhaps the most important lesson that can be learned to prepare them for life after high school. Technical Journals: Although a major motivation for our team in pursuing this project is for the experience itself, we hope to provide results that are of real value to the academic community at large. As such, we hope to pursue journals and technical publications to publish our findings, such as International Journal of Solids and Structures, Journal of the Mechanics and Physics of Solids, and Scripta Materialia. Sharing our research with others in the field is an important facet of the research process. Media Outlets: The team plans to involve the local media with our project to spread the word about the program and the University of Minnesota’s Aerospace Engineering Department. We will seek to use various media outlets to distribute our story, including the University’s own Minnesota Daily, the Minneapolis Star-Tribune, local television stations such as KARE 11, KSTP and KMSP, as well as the local National Public Radio affiliate, KNOW. It is important to share that students can have valuable experiences with running their own research project and the creative processes that are involved in that. Through these media outlets, we will be able to reach a large audience who we hope will then visit our website to learn more about the project. At the University of Minnesota: We will outreach to others within our own department at the University of Minnesota. We hope to speak to students in some of the freshman and sophomore level courses to pique their interest in both the NASA Reduced Gravity Flight Opportunities Program offered here and the Aerospace Engineering Department as a whole. We also may make presentations to the University’s chapter of AIAA and other professional societies. By making sure that students are informed about the opportunities available to them, we hope to ensure that the microgravity program here at the University of Minnesota remains an exciting and rewarding experience for students. 14 IV. Administrative Requirements 15 4.2 Statement of Supervising Faculty As the faculty advisor for an experiment titled “Recrystallization of Low Melting Point Metal Alloys in Microgravity” proposed by a team of undergraduate students from the University of Minnesota – Twin Cities campus, I concur with the concepts and methods by which the experiment will by conducted. I will ensure that all reports and deadlines are completed by the student team members in a timely manner. I understand that any default by this team concerning any Program requirements (including submission of final report materials) could adversely affect selection opportunities of future teams from the University of Minnesota – Twin Cities. Signed, Date: Dr. Thomas Shield 16 4.3 Budget and Funding The costs of travel and equipment will be provided by a combination of the Aerospace Engineering and Mechanics Department of the University of Minnesota and the Undergraduate Research Opportunity Program (UROP) at the University of Minnesota. Equipment itself will either be provided or purchased. Equipment Expenses Constant Current Supply $500 Plexiglass for test boxes and test stand $100 Cerro Alloys for test material $65 Bolts, Fasteners, Misc. $40 Shop Labor $250 Electrical Switches and Wires $50 Miscellaneous Structural and Electronic Components $600 Total Estimated Equipment Cost = $1605 Travel Expenses Hotel Accommodations: 5 people, 14 nights, $140 per night $1960 Food: 5 people, 14 days, $25 per person per day $1750 Transportation: 5 people, roundtrip airfare, Car Rental, $500 per person $2500 Shipping: Experiment both ways $800 Proposal Copies (Publications) $100 Total Estimated Travel Cost = 17 $7110